Professional Documents

Culture Documents

Oil and Gas Piping Components

Uploaded by

Padmakumar Bhaskaran0 ratings0% found this document useful (0 votes)

3 views42 pagesOriginal Title

Oil and gas piping components

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views42 pagesOil and Gas Piping Components

Uploaded by

Padmakumar BhaskaranCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 42

Oil and Gas Pipeline Design,

Maintenance and Repair

Dr. Abdel-Alim Hashem

Professor of Petroleum Engineering

Mining, Petroleum & Metallurgical Eng.

Dept.

Faculty of Engineering – Cairo University

aelsayed@mail.eng.cu.edu.eg

ahshem2000@yahoo.com

Part 4: Pipeline Components

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 1

Contents

• Metallic Pipes Rubber and Elastomer

Ordinary Steel Pipe Piping

Corrugated Steel Pipe Glass Pipe

Cast-Iron Pipe • Tubing & Pipe

Ductile-Iron Pipe Designation

Stainless Steel Pipe Connections (joints)

Aluminum Pipe Fittings

Copper Pipe Valves

Other Metal Pipes Pressure Relief Valves

• Nonmetallic Pipe Pressure Regulating

Valves, Problems

Plastic Pipe

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 2

METALLIC PIPES

• Most metallic pipes are stronger and harder to break

• They are more conductive to heat and electricity and

less corrosive-resistant than nonmetallic pipes.

• Commercially available metallic pipes are discussed in

the following

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 3

Ordinary Steel Pipe

• Made of wrought (carbon) steel

• Seamless or seamed (welded)

• Seamed made of steel sheets or steel plates rolled or

press formed into circular shape, with the edge (scam)

of each pipe closed by welding

• Four types of welding

A. Butt weld,

B. Lap weld,

C. Electric arc weld (single-welded joint)

D. Electric arc weld (double welded joint)

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 4

Different Types of Welding For Seamed

Steel Pipe

Spiral welded pipe

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 5

Seamless Pipe

Formation seamless pipe

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 6

Corrugated Steel Pipe

• Thin-wall, large-diameter pipes made of galvanized steel

sheets having either helical or annular corrugations

• Used extensively in sewer and drainage systems where

both the internal pressure (water pressure) and the

external pressure (soil pressure) are low and where

leakage will not cause serious problems.

• Some come with perforations to allow drainage into them

• The water in a large diameter corrugated pipe is often

gravity flow (open channel flow) rather than pressure flow

(pipe flow).

• Come in a great range of sizes, and have a large variety of

fittings.

• Some are fabricated to have a pecan-shaped (arched)

instead of circular cross section

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 7

Cast-Iron Pipe

• Two types: the ordinary or gray cast-iron pipe, and the

ductile-iron pipe.

• The ordinary cast-iron pipe made of iron containing 3 to

4% of carbon in the form of graphite flakes

• Gray cast-iron pipe has relatively strong corrosion-

resistance ability and long life

• Two strength designations for cast-iron pipes: 18/40 and

21/45. In the first designation

• The number 18 means that the minimum bursting tensile

strength is 18,000 psi, and the number 40 means that

the minimum modules of rupture (i.e., the tensile stress

that causes failure due to bending) is 40,000 psi

• The meaning of the 21/45 designation is similar.

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 8

Ductile-Iron Pipe

• Made of iron containing approximately 3.5% of carbon

in spheroidal or nodular form, and a magnesium alloy

• Have the advantages of gray cast-iron pipe (corrosion-

resistance and long life) and steel pipe (ductility).

• Often lined and/or coated with cement mortar, Like the

gray cast-iron pipe

• Strength designation is 60/42/10.

– 60 means a minimum tensile strength of 60,000 psi

– 42 means a minimum yield strength of 42,000 psi

– 10 means 10% minimum elongation.

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 9

Stainless Steel Pipe

• 300 series such as SS304 or SS316, the most

used stainless steel pipes

• Steel contains chrome-nickel alloys, and

corrosion resistant

• High price, used only in special applications

such as:

– when the fluid, or environment is rather

corrosive,

– when no rusting of pipe can be tolerated such

as in pharmaceutical or food industries.

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 10

Aluminum Pipe

• Corrosion resistant

• Used in certain food plants and chemical plants

• 1100 and 6000 series of aluminum are used for

making pipes,.

• Aluminum 1100 is low in strength but easy to

weld.

• 3000 or 6000 series is High-number aluminums

are stronger mechanically and more corrosion-

resistant, and hard to weld.

• Pipes formed by a drawing or extrusion process;

they are seamless.

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 11

Copper Pipe

• Corrosion-resistant but expensive

• Used only for small pipes such as those

used in plumbing.

• Pipes can be formed by cold drawing

• Note that many of the stainless steel,

aluminum and copper pipes are actually

tubing rather than pipes.

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 12

Other Metal Pipes

• Many other metal pipes are available.

• Made from different alloys and are used

for different purposes, such as corrosion

resistance to a particular fluid, high-

temperature, low-temperature resistance,

etc.

• Some examples are listed in table

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 13

Some Metal Pipes for Special Applications

Type Applications

Admiralty metal Resistant to corrosive water, including saltwater

Aluminum 1100 Most weldable type of aluminum, low strength, and resistant to

formaldehyde, ammonia, phenol, and hydrogen sulfide; used in

food plants

Aluminum 3003 Superior mechanical properties; contains manganese; used in

chemical plants

Aluminum 6061 Contains silicon and magnesium; highly corrosion resistant

or 6063

Brass and Resistant to corrosive waters, including brines. sugar water

silicon and organic acids

Copper Resistant to corrosive water

Cast iron Corrosion resistant; used for water and gas distribution. and

sewage systems

Ductile iron Similar corrosion-resistant properties as cast iron. but is more

ductile

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 14

Some Metal Pipes for Special Applications

Type Applications

Ductile iron Similar corrosion-resistant properties as cast iron. but is more

ductile

Monel Nickel-based alloy; high strength; corrosion resistant to alkaline

solutions and air free acids; used only when copper

contamination is not a problem

Nickel Highly corrosion resistant

Stainless steel Corrosion resistant; commonly used in processing food and

(type 304) medicine; extra low carbon (ELC) grade provides good

weldability

Stainless steel Also available in ELC grades; good corrosion resistance at

(types 316.321. elevated temperatures and pressures; available in ELC grade

or 347) for good weldability

Tantalum Resistant to nitric and other acids

Titanium Highly resistant to corrosion in oxidizing media: resistant to

sulfuric acid and perchlorites: resistant to abrasion and

cavitation

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 15

NONMETALLIC PIPES

IPS SDR-11 PE2406 CEC ASTM D2513 PLEXCO GAS PIPE 2”

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 16

NONMETALLIC PIPES

• Not be as strong as metallic pipes

• Lighter in weight.

• More economical

• Have certain other advantages such as

being more corrosion resistant.

• There different types of nonmetallic pipes

• The one which used in oil and gas industry

is plastic pipes

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 17

Plastic Pipes

• Three types of plastic pipes commonly used.

– PVC (polyvinyl chloride)

– PE (polyethylene)

– PP (polypropylene)

• Used for

– Water,

– Waste water

– Natural gas

– Other fluids that do not dissolve or chemically interact

with plastics

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 18

Plastic Pipes

• Users must know that

– Plastic pipes are usually not strong as metal

pipes,

– Deform easily

– Expand five times as mush as steel pipe as a

result of temperature,

– Become brittle in very cold weather.

• Besides, not enough data have been

accumulated about plastic pipes to know their

long term performance

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 19

PVC

• Currently very popular for answers of relatively small

diameter- up to 24 inches (610 mm)

• Used for water supply and indoor plumbing.

• Relatively hard (as compared to PE pipes)

• Highly abrasive (wear resistance)

• Corrosion resistant to a number of chemicals

• Will not deteriorate under the attack of bacteria and other

microorganisms, macrooragnisms, or fungi.

• Suited for use as-sewers.

• Soluble solids such as calcium carbonate cannot

accumulate and attach to the interior surface (smooth &

hard)

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 20

PVC

• Free from the tuberculation problem that often exists in

water works using steel or other metal pipes.

• Weakness: deteriorate when exposed to ultraviolent light.

• Not to be exposed to direct sunlight (used or stored over

extended time.

• Suited for underground pipelines.

• Come in segments 40 ft (12.2 m) each, often 20 ft (11.1 m)

or less.

• Joined together by using solvent-cement, or gaskets.

• Solvent-cement for flat ends of pipes such as those due to

cuts

• Gaskets for full lengths of pipes with bell and spigot ends.

• Gasketed joints allow for thermal expansion.

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 21

PE

• Very flexible, coiled for compactness in storage and

transportation.

• Hundreds of feet, up to 6-inch (152 mm), can be rolled

around a single spool.

• This reduces the number of joints, and facilitates

transportation and laying of pipe.

• Can be easily laid on surface or underground without

having joints over a long distance - several hundred feet

or meters.

• Flexibility allows the pipe to follow the curvature of

topography easily.

• Joining is usually done by thermal fusing - heating and

melting the pipe ends while holding them together.

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 22

PE

• Widely used for natural gas distribution lines up to 10-

inch (254 mm) diameter

• Used for water lines and other applications.

• Classified according to their density (or specific gravity)

• Low density (LDPE), Sp. Gr. (0.910 to 0.925

• Medium density (MDPE), Sp. Gr. (0.926 to 0.940)

• High density (HDPE), Sp. Gr. ( 0.941 to 0.965)

• All PE pipes are highly corrosion resistant and abrasion

resistant.

• Weakness: material deteriorates under exposure to

sunlight.

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 23

PIPE DESIGNATION

• A common designation of pipe size in the U.S. is the

nominal pipe size (NPS)

• Nominal diameter of pipes is given in inches.

• The weight (or thickness) of the pipe is given in

– schedule number (steel, stainless steel, and PVC),

– or class number (for cast iron or ductile iron pipes )

• Table 4.2 gives the designations for steel pipe

– Class numbers:

– STD (standard),

– XS (extra strong)

– XXS (double extra strong).

• Schedule number (from 10 to 160)

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 24

PIPE DESIGNATION

• An exception to the foregoing designation system for

steel pipes is light-gauge piping such as the spiral-

welded pipe.

• Sizes from 1 inch to 12 inches, the wall thickness of

spiral-welded pipes is the same as schedule 10S (S

stands for stainless steel), and for sizes from 14 to 24

inches, it is the same as schedule 10.

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 25

Table 4.2 Dimensions and weights of

welded wrought steel pipe

NPS OD Pipe Thickness Schedule Number

in in STD XS XXS 10 20 30

W all W t. W all W t. W all W t. W all W t. W all W t. W all W t.

1/8 0.405 0.068 0.24 0.095 0.31

1/4 0.540 0.088 0.42 0.119 0.54

3/8 0.675 0.091 0.57 0.126 0.74

1/2 0.840 0.109 0.85 0.147 1.09 0.297 1.71

3/4 1.050 0.113 1.13 0.154 1.47 0.308 2.44

1 1.315 0.133 1.68 0.179 2.17 0.358 3.66

1-1/4 1.660 0.140 2.27 0.191 3.00 0.382 5.21

1-/2 1.900 0.145 2.72 0.200 3.63 0.400 6.41

2 2.375 0.154 3.65 0.218 5.02 0.436 9.03

2-1/2 2.875 0.203 5.79 0.276 7.66 0.552 13.70

3 3.500 0.216 7.58 0.300 10.25 0.600 18.58

3-1/2 4.000 0.226 9.11 0.318 12.51

4 4.500 0.237 10.79 0.337 14.98 0.674 27.54

4 5.863 0.258 14.62 0.375 20.78 0.750 38.55

6 6.625 0.280 18.97 0.432 28.57 0.864 53.16

8 8.625 0.322 28.55 0.500 43.39 0.875 72.42 0.250 22.36 0.277 24.70

10 10.750 0.365 40.48 0.500 54.74 1.000 104.13 0.250 28.04 0.307 34..24

12 12.750 0.375 49.56 0.500 65.42 1.000 125.49 0.250 33.38 0.330 43.77

14 14.000 0.375 54.57 0.500 72.09 0.250 36.71 0.312 45.61 0.375 54.57

16 16.000 0.375 62.58 0.500 82.77 0.250 42.05 0.312 52.27 0.375 62.58

18 18.000 0.375 70.59 0.500 93.45 0.250 47.39 0.312 58.94 0.438 82.15

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 26

CONNECTIONS (JOINTS)

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 27

CONNECTIONS (JOINTS)

• Bonded (welded) joints - Include welding for steel pipe,

brazing or soldering for brass, copper and lead pipes,

and fusing of plastic pipes.

• Threaded joints - Connecting threaded pipe sections

together, or connecting a threaded pipe to a threaded

coupling or fitting.

• Flanges - Flanges most common way to provide a

strong joint without permanently joining the pipe sections

together as done in welding. used for steel pipes at both

the inlet and the outlet of pumps, valves, flow meters,

and other fittings. Allows easily installation and

disconnection from the pipe.

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 28

CONNECTIONS (JOINTS)

• Mechanical joints - Various mechanical

connectors exist for ease in

assembly/disassembly.

• Bell-and-spigot joints - See Figure 4.4 for

those used in pressure concrete pipes. Other

pipes, including glass pipes and plastic pipes,

also use bell-and-spigot joints.

• Push-on joints - can be connected together

simply by pushing two pipe sections (segments)

against each other. Likewise, the sections can

be disconnected simply by pulling them apart.

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 29

FITTINGS

Fittings Type Purpose

Bushing connect a threaded small pipe to a large one

Cap seal the end of a pipe

Coupling connect two threaded pipes of the same size

together

Half coupling one end threaded, and the other plain. The

plain end can be welded to, for example, a

tank to from a pipe entrance

Cross connect a pipe to three others

Elbow change flow direction

Nipples tap a pipe (small tap)

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 30

FITTINGS

Fittings Type Purpose

Plug seal the end of a threaded pipe

Reducer change (reduce or enlarge) pipe diameter

Saddle tap a pipe

Sleeve connect two pipes together

Tee connect a 90° branch

Union connect two threaded pipes of the same

size together without having to turn the

pipes-just turn the union

Y connect two pipes to one pipe in the shape

of a Y

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 31

VALVES

• Gate valve –

– Closed and opened by turning the handle connected to it, which

raises or lowers a stem (shaft) connected to the gate.

– Takes many turns to completely open or close a gate valve.

– Headloss of the valve is small when the gate is fully open.

– May be a wedge or a disk (for nonslurry), or a knife (for slurry).

– Used in oil or natural gas pipelines has a conduit with a full round

bore for smooth passage of pigs or scrapers.

– called conduit gate, valves or full-bore gate valves.

• Globe valve –

– Outside is globe shaped.

– Flow changes direction as it goes through the valve.

– Large head loss is generated even when the valve is fully open.

– Gives better control of flow than gate valves - good for flow

throttling.

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 32

Gate Valves

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 33

Globe Valve

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 34

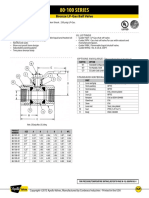

VALVES

• Angle valve

– Except that the flow direction is changed by 90° as

the flow leaves the valve.

– Used in locations of 90° bends and is good for flow

throttling.

• Ball valve

– A large bead (i.e., a large sphere having a central

piercing).

– Turned from a completely closed to a fully open

position in 90°.

– When fully open, it causes little blockage to the flow

and hence has little headloss.

– Used mainly for on-off operations.

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 35

Butterfly Valves

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 36

VALVES

• Check valve

– Flow cannot reverse through a check valve; the valve

produces unidirectional flow

– Three types of check valves are swing check valves

(horizontal or vertical lift types), tilt disk check valve

(does not slam), and ball check valve.

• Foot valve

– A special vertical-lift type check valve embedded in

the vertical end of a pipe connected to a reservoir

below.

– Used there to prevent the pump from losing priming

when the flow is stopped

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 37

Lift or Piston Check Valves

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 38

Swing Check Valves

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 39

PRESSURE RELIEF VALVES AND

PRESSURE REGULATING VALVES

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 40

PRESSURE RELIEF VALVES

There are two major groups

of pressure relief valve:

1. Direct-acting pressure relief

valves which are actuated

directly by the pressure at

the valve inlet

2. Pilot pressure relief valves

in which a pilot mechanism

opens and closes a main

valve in response to the

pressure in the pressure

system

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 41

Pressure Safety Valves

PE 607: Oil & Gas Pipeline Design, Maintenance & Repair 42

You might also like

- Tuberias y TubosDocument31 pagesTuberias y TubosJosé Ismael Castillo BernalNo ratings yet

- Pipe PresentationDocument68 pagesPipe PresentationOk OhNo ratings yet

- Lecture Note 4 (Metallic & Non-Metallic Pipes) PDFDocument20 pagesLecture Note 4 (Metallic & Non-Metallic Pipes) PDFhkaqlqNo ratings yet

- Pipe SpecificationDocument11 pagesPipe SpecificationSajib Chandra RoyNo ratings yet

- Pipline EngineerDocument19 pagesPipline Engineermohammed9k9albhadlyNo ratings yet

- Material Selection For PipingDocument16 pagesMaterial Selection For PipingYousuf MemonNo ratings yet

- Specifications of Ductile Iron Pipes and Carbon Steel Pipes - en - 01Document3 pagesSpecifications of Ductile Iron Pipes and Carbon Steel Pipes - en - 01djrote4No ratings yet

- Specifications of Ductile Iron Pipes and Carbon Steel Pipes - en - 01Document3 pagesSpecifications of Ductile Iron Pipes and Carbon Steel Pipes - en - 01djrote4No ratings yet

- Stainless Steel Pipe SpecificationsDocument11 pagesStainless Steel Pipe SpecificationsGonzalo MazaNo ratings yet

- Lecture 8 Plumbing MaterialsDocument49 pagesLecture 8 Plumbing Materialspepito manalotoNo ratings yet

- Types of Pipes, Classification of PipesDocument4 pagesTypes of Pipes, Classification of PipeschkibiNo ratings yet

- AstmDocument25 pagesAstmcasperxxxNo ratings yet

- Stainless steel pipe specs for corrosion resistanceDocument3 pagesStainless steel pipe specs for corrosion resistance1trungson1No ratings yet

- م13 صحيةDocument61 pagesم13 صحيةabdelrahman moubarakNo ratings yet

- Pipe Is A Long Hollow Cylinder Used Chiefly To Convey FluidDocument1 pagePipe Is A Long Hollow Cylinder Used Chiefly To Convey FluidG-one PaisonesNo ratings yet

- Stainless steel pipe specifications guideDocument3 pagesStainless steel pipe specifications guideBhairu BaniNo ratings yet

- Datasheet For Carbon Steel A333 Grade 6Document10 pagesDatasheet For Carbon Steel A333 Grade 6Aneesh JoseNo ratings yet

- Technical Catalouge PDFDocument41 pagesTechnical Catalouge PDFDhanish KumarNo ratings yet

- Piping and Plumbing FittingDocument25 pagesPiping and Plumbing Fittingignatus lupapuloNo ratings yet

- Valve Material TypesDocument3 pagesValve Material TypesimanadbNo ratings yet

- أنواع المواسير المختلفه وخواص كل نوع وإستخداماته والمميزات والعيوبDocument60 pagesأنواع المواسير المختلفه وخواص كل نوع وإستخداماته والمميزات والعيوبMuhammad MedhatNo ratings yet

- Classification of Materials in Plumbing 1Document5 pagesClassification of Materials in Plumbing 1SHANE MATUGASNo ratings yet

- ASTM Steel Pipe StandardsDocument10 pagesASTM Steel Pipe StandardsNoushad P HamsaNo ratings yet

- Piping Material - GuidanceDocument17 pagesPiping Material - GuidanceAlfon50% (2)

- Intro PipingDocument64 pagesIntro PipingAjay Kumar92% (12)

- Cast Iron PipesDocument10 pagesCast Iron Pipesmanoj amNo ratings yet

- PipingDocument13 pagesPipingrudiwoworNo ratings yet

- Stainless Steel Tube SpecificationsDocument7 pagesStainless Steel Tube Specificationsgkamesh84No ratings yet

- Piping TechniquesDocument8 pagesPiping TechniquespiglitNo ratings yet

- COnveyance of Water and ValveDocument25 pagesCOnveyance of Water and ValveMadan GorathokiNo ratings yet

- SteelPipe Versus DIPDocument10 pagesSteelPipe Versus DIPHichem BenniaNo ratings yet

- Steel Pipe Thickness Tolerance of API 5L, ASTM A53 and EN10219 - HYSP - Steel Pipe SupplierDocument4 pagesSteel Pipe Thickness Tolerance of API 5L, ASTM A53 and EN10219 - HYSP - Steel Pipe SupplierShoaib NazirNo ratings yet

- Lesson 2 - Plumbing Pipes and FittingsDocument39 pagesLesson 2 - Plumbing Pipes and FittingsNicholas Bonn SingNo ratings yet

- Piping Technology and Design OverviewDocument19 pagesPiping Technology and Design OverviewRahestya Kusuma AuraNo ratings yet

- Module 3 Lesson 1 Plumbing MaterialssDocument13 pagesModule 3 Lesson 1 Plumbing MaterialssCherry MuycoNo ratings yet

- Copper Tube Federal and Astm SpecificationsDocument4 pagesCopper Tube Federal and Astm SpecificationsSai PrasathNo ratings yet

- Asme Sa 210 Grade C TubesDocument1 pageAsme Sa 210 Grade C TubesFerroPipENo ratings yet

- Study of Carbon Steel Pipes 2013Document26 pagesStudy of Carbon Steel Pipes 2013Deepak Ramchandani100% (1)

- ASTM International - Volume 01.01 Steel - Piping, Tubing, FittingsDocument3 pagesASTM International - Volume 01.01 Steel - Piping, Tubing, Fittingsamitkumar8946No ratings yet

- Asme Sa 209 Grade T1a TubesDocument1 pageAsme Sa 209 Grade T1a TubesFerroPipENo ratings yet

- Tuberias de CobreDocument9 pagesTuberias de CobreSarahMurilloNo ratings yet

- Lecture 4Document30 pagesLecture 4officialhemed41No ratings yet

- Stainless Steel Technical InformationDocument10 pagesStainless Steel Technical InformationGonzalo MazaNo ratings yet

- Asme Sa 199 Grade t11 TubesDocument1 pageAsme Sa 199 Grade t11 TubesFerroPipENo ratings yet

- Asme Sa 333 Grade 6 PipesDocument1 pageAsme Sa 333 Grade 6 PipesFerroPipENo ratings yet

- Fema 484 Part 2Document75 pagesFema 484 Part 2וויסאם חטארNo ratings yet

- Uni 7945 Grade Fe360 Tubes PDFDocument1 pageUni 7945 Grade Fe360 Tubes PDFMitul Mehta0% (1)

- Plumbing Materials: Reporter: Altar, Charles Ysrael TDocument25 pagesPlumbing Materials: Reporter: Altar, Charles Ysrael TYsrael AltarNo ratings yet

- Petropipe Brochure (English)Document16 pagesPetropipe Brochure (English)Nuaym KhalidNo ratings yet

- Everything About Pipes in 38 CharactersDocument8 pagesEverything About Pipes in 38 CharactersMohit BauskarNo ratings yet

- Pipe FittingsDocument40 pagesPipe FittingsLucky Jaswal100% (1)

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicFrom EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithFrom EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithNo ratings yet

- 2013lean PDFDocument53 pages2013lean PDFmuralikrish25No ratings yet

- EnglishDocument2 pagesEnglishPadmakumar BhaskaranNo ratings yet

- WC Claim FormDocument3 pagesWC Claim FormPadmakumar BhaskaranNo ratings yet

- Health and Safety at Work Etc Act 1974 - HSEDocument129 pagesHealth and Safety at Work Etc Act 1974 - HSELaetitia CassignacNo ratings yet

- Steering Hydraulics - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . 2Document16 pagesSteering Hydraulics - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . - . 2Sales AydinkayaNo ratings yet

- 580L 580 Super L 590 Super L Series Service Manual PDFDocument1,468 pages580L 580 Super L 590 Super L Series Service Manual PDFNever 2Lo91% (11)

- GF Signet 2580 Flowtramag Meter: The Performance You Ve Been Waiting For Is HereDocument8 pagesGF Signet 2580 Flowtramag Meter: The Performance You Ve Been Waiting For Is HereOmar GuillenNo ratings yet

- Convair Traveler Vol. X 1958-59Document180 pagesConvair Traveler Vol. X 1958-59TateNo ratings yet

- 160993728-Steam-Turbine-Stop-Valve-Testing NewDocument22 pages160993728-Steam-Turbine-Stop-Valve-Testing NewAmit shringiNo ratings yet

- ManualDocument62 pagesManualMelissa CastañedaNo ratings yet

- Final ReportDocument30 pagesFinal ReportSatish HSNo ratings yet

- F4ael 04 WDocument4 pagesF4ael 04 Wkejart100% (1)

- Automatic TransaxleDocument25 pagesAutomatic Transaxlethanhchuongtp100% (1)

- Instruction Manual QUINCY QGV 66000-1a El CafeDocument184 pagesInstruction Manual QUINCY QGV 66000-1a El Cafedanielarteaga100% (1)

- Kinetrol - QTR Turn Valve Spring ReturnDocument3 pagesKinetrol - QTR Turn Valve Spring ReturnLeoNo ratings yet

- 200 Series: Insert Style Flow Sensors by Data Industrial Owner's ManualDocument16 pages200 Series: Insert Style Flow Sensors by Data Industrial Owner's Manualaries26marchNo ratings yet

- 094135-PE-SPC-001 Piping Material Specification-REV 4Document76 pages094135-PE-SPC-001 Piping Material Specification-REV 4thongpvgas100% (1)

- Re29014 2006-05 PDFDocument322 pagesRe29014 2006-05 PDFIsmail CivgazNo ratings yet

- Common Uses For Load SensingDocument7 pagesCommon Uses For Load SensingVinod YbNo ratings yet

- 028320Document116 pages028320Хелфор УкраинаNo ratings yet

- SAIDI Butterfly Valves PDFDocument218 pagesSAIDI Butterfly Valves PDFHARSHANo ratings yet

- Rapid Pressure Rise Relay Response CurvesDocument4 pagesRapid Pressure Rise Relay Response CurvesTarun Bhateja0% (1)

- Operation Manual: Saike Fuel DispenserDocument21 pagesOperation Manual: Saike Fuel DispenserUpenyu MutsumbaNo ratings yet

- Oid71784 Ib WW5000C-MD en 230915Document68 pagesOid71784 Ib WW5000C-MD en 230915Vicky DiamondNo ratings yet

- Actuator Controls Ac 01.2/acexc 01.2: Operation and Setting ManualDocument160 pagesActuator Controls Ac 01.2/acexc 01.2: Operation and Setting ManualJorge Antonio Lovera CastroNo ratings yet

- Pilot Valve (Command Control Steering) 966Document16 pagesPilot Valve (Command Control Steering) 966Ahmed RezkNo ratings yet

- Hydraulic Motors - Overall Instructions M5AF / M5B : Denison Vane Technology, Fixed DisplacementDocument36 pagesHydraulic Motors - Overall Instructions M5AF / M5B : Denison Vane Technology, Fixed DisplacementSitecsaNo ratings yet

- Recommended Practice - Davey PumpDocument32 pagesRecommended Practice - Davey PumpAlghazee Abo-jlalNo ratings yet

- Overhaul of PSVDocument5 pagesOverhaul of PSVmeeraksam42100% (2)

- Valvulas Apollo GLPDocument4 pagesValvulas Apollo GLPJuan Carlos Pardo RimachiNo ratings yet

- Badger M1000 ManualDocument36 pagesBadger M1000 ManualMahbub HemalNo ratings yet

- Matchless 1939 1955 Manual de Reparatie WWW - Manualedereparatie.info NoRestrictionDocument60 pagesMatchless 1939 1955 Manual de Reparatie WWW - Manualedereparatie.info NoRestrictionBhavesh Hathiwala67% (3)

- VXD Old SMC 0900766b8094a5b0Document32 pagesVXD Old SMC 0900766b8094a5b0FranzKafkaNo ratings yet

- UG Lever Type GovernorDocument56 pagesUG Lever Type Governorr100% (1)