Professional Documents

Culture Documents

The Dangers of Uncontrolled Gases in Steam Systems: Pecial

Uploaded by

Osamah AlzubadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Dangers of Uncontrolled Gases in Steam Systems: Pecial

Uploaded by

Osamah AlzubadiCopyright:

Available Formats

Reprinted from CHEMICAL PROCESSING February, 1990

SPECIAL REPORT

The Dangers

of Uncontrolled Gases

in Steam Systems

WALTER T. DEACON

Sr. Application Engineer

Armstrong Machine Works

B

Walter Deacon is senior application en uild-up of air and other non-condensible gases such as

gineer for Armstrong Machine Works am

carbon dioxide and oxygen in a steam system can be a

L has been employed by the company fol

eight years. Although his main responsi serious, costly hazard. Left unattended, such

bility is sales representative training, hc accumulations accelerate corrosion and block flow, resulting in

also works closely with customers, pro- leaks, steam or water hammer, reduced heat transfer and,

viding technical advice and counsel or

complex steam energy management ap-

eventually, expensive repairs.

plications. He has a B.S. in Mechanicar The real danger is in the corrosion potential of these gases

Technology from Purdue University. when combined with condensate. Carbon dioxide combines with

condensate below steam temperature to form carbonic acid,

which can cause leaks at heat exchanger walls or tubes. It’s also

strong enough to eat away drain lines, leading to leaks in steam

fittings and condensate return lines. Oxygen in the system

speeds corrosion (oxidation) of piping through pitting action.

Corrosion is often so severe that condensate discharged from

a steam trap may be bright red or dark brown from iron content.

Under such conditions, components within the heat transfer

equipment may not withstand the pressure of the system.

The root of many problems

Corrosive condensate is only one of several hazards caused by

air and non-condensibles in steam systems. Other potential

problems include:

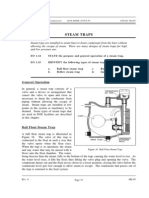

System binding. Even though they are compressed, air and

non-condensible gases still occupy volume and can displace

steam and condensate. When system binding occurs, flow of

steam and condensate can be blocked. Since the condensate

All boiler feedwaters contain

elements that can produce non-

condensible gases when the

water is boiled. KEY 0 Condensate n Steam

cannot drain, it cools down. When it

comes into contact with the hotter

steam, it causes instantaneous conden-

sation which unleashes severe velocity

and pressure fluctuations within the sys- Steam Chamber 100% Steam

tem. Water is accelerated and impacts Total Pressure 100 psia

Steam Pressure 100 psia

piping, elbows, fittings and valves in Steam Temperature 327.8”F

potentially destructive water or steam

hammer. This may result in leaks, float

collapse and other component failures.

Energy costs. Most systems use steam

to transfer heat. Any reduction in the

capability of the steam to transfer heat

is a potential inefficiency. When steam

is distributed and flowing through the

system, its pressure actually drops. Steam Chamber 90% Steam 10% Air

Mains and branch lines are sized to Total Pressure 100 psia

distribute the steam without excessive Steam Pressure 90 psla

pressure drop. To avoid the energy loss Steam Temperature 320.3”F.

associated with steam pressure drop,

these lines must be sized carefully, As Steam mixed with air delivers only the heat of the Condensing steam moves air to the heat transfer

steam pressure drops, so does the tem- partial pressure of the steam, not the total pressure surface where it collects to form an insulatingfilm

perature. This could slow heat transfer,

demanding more steam, increasing the gases and can be pushed along by the to the gases in solution, feedwaters usu-

pressure drop and wasting more total flowing steam within the tube. The gen- ally contain carbonates and/or bicarbon-

energy. eral steam flow is toward the walls of ates that are converted in the boiler

Air and non-condensible accumula- the heat exchanger, where the air and drum to CO,.

tions reduce heat transfer similarly to non-condensible gases can accumulate

steam pressure drop: By 1) reducing at the walls and form an insulating film. Removal and control

effective steam temperature and 2) in- Most industrial and institutional steam

sulating heat transfer surfaces. Sources of gases systems are designed to reduce intake

Temperature drop. Dalton’s law of Steam systems are full of air at start-up. and accumulation of non-condensible

partial pressures states that “the pres- As the steam enters the system, it con- gases. Understanding the operating

sure of a mixture of gases is equal to the denses and will form high condensate principles of this equipment and how to

sum of the partial pressures.” In the case loads. This liquid and steam mixture manage the system can eliminate recur-

of air and non-condensibles with steam, moving through the piping will force the ring hazards.

the gases will exert part of the pressure air ahead of it into the far reaches of the Deaeration. Deaerators are designed

and the pressure exerted by the steam system. Since the end of the system is to do exactly what the name implies-

will be reduced. As we have seen, there the heat exchange equipment and the remove gases from incoming boiler feed-

is a direct relationship between the tem- steam trap, the ability of these compo- water. As we saw earlier, CO? goes into

perature and pressure of steam. As the nents to deal with high volumes of air solution when the temperature is de-

pressure of steam decreases so does the at low pressures determines the effect- creased. Deaerators give the CO? and

temperature, along with heat transfer iveness of air removal. Pockets within oxygen an opportunity to come out of

efficiency (Figure 1). heat exchangers will normally form at solution, where they are under very low

Insulating effect. Air and non-con- the last place the steam and condensate pressure and can be easily vented.

densible accumulations can also reduce flow reach. These air pockets are free The equipment is designed to spread

heat transfer by insulating the heat ex- to remain in the system unless steam or the feedwater out over an extended

changer. As steam flows within a heat condensate flow sweeps them away. surface area and, at the same time, heat

exchanger tube, as shown in Figure 2, All boiler feedwaters contain ele- it up, encouraging the gas to come out

it moves from the center of the tube ments that can produce non-condensi- of solution and vent to atmosphere.

toward the wall. ble gases when the water is boiled. Returned condensate, often laden with

Since air and non-condensibles do not These gases are transported into the C02, is also typically deaerated.

condense, they behave as relatively lazy system along with the steam. In addition Thermostatic vents. Thermostatic

Condensate should be

maintained as hot as possible

L in the return system to

minimize the carbonic acid Shell and tube heat exchanger

formation. (Typical piping diagram)

steam traps (particularly bellows type) I Steam main

can be used as automatic air vents on I

I \/

f==Y

heat exchange equipment. Air and non-

condensibles in the system do not con-

dense so they get pushed to quiet zones

by the flowing steam. At these locations

the thermostatic device senses the tem-

perature reduction caused by gas accu-

mulation and vents it. Batch process

autoclaves, large shell-and-tube heat ex-

changers and large steam coils should

incorporate automatic air vents to elim-

inate gas accumulations.

Steam traps. Steam traps should dis-

charge condensate from a process appli-

cation at or near saturation temperature. To drain To low pressure return

Selection of traps that back up or sub-

cool condensate will accelerate carbonic Traps should be located close to and below drip points whenever possible

acid corrosion, cause steam leaks, re-

duce heat transfer and possibly increase non-subcooling traps, such as inverted- of amines can be helpful by neutralizing

maintenance. Subcooling traps are typ- bucket and float-and-thermostatic carbonic acid and thus controlling cor-

~ ically thermostatic traps that are de- types, will help maximize heat energy rosion.

signed to back up condensate. These transfer in the system.

traps may be of thermal expansion de- CO, and oxygen corrosion can also Taking action

sign, balanced pressure bellows, bi- be a major cause of problems in steam Uncontrolled air and non-condensible

metal, wafer or diaphragm type. How traps with small orifices. If copper or gases in steam systems can cause cor-

much these traps will subcool depends iron products of corrosion are in the rosion, water hammer, heat transfer and

mainly on the mechanical characteris- condensate flowing to the steam trap (as drainage problems in steam systems and

tics of the trap. The degree of subcooling they are in many older systems), they go steam heat exchange equipment. There-

also depends on the steam pressure and into solution in the carbonic acid. When fore a program to minimize gas intro-

condensate load. they pass through an orifice of small size duction rates, to vent gases where they

It’s important to locate steam traps to a lower pressure, the condensate accumulate, to drain condensate before

properly because one of their functions flashes and these corrosion products can it subcools, to prevent cooling of con-

is to vent the air and non-condensible be deposited as oxides that may plug densate return systems and to minimize

gases as in Figure 3. When installing small orifices. Even when larger orifices the corrosive effects of carbonic acid

steam traps, follow the ABCs of trap are used, plugging can occur in the should be implemented.

location: outlet piping of the steam trap. A complete action plan would entail:

A-ACCESSIBLE for inspection and Insulated condensate returns. When l Studying deaerator piping design and

repair, condensate is at a higher temperature, existing piping practices,

B-BELOW drip points whenever pos- corrosion is slowed because CO, goes l Analysis of major heat exchange

sible, and into solution best in cooler condensate. equipment for air vent inclusion and

C-CLOSE to the drip point. Condensate should be maintained as piping practices,

Steam traps are like thermostatic air hot as possible in the return system to l Analysis of steam trap selection and

vents in that they do not reach into the minimize the carbonic acid formation. piping practices,

system to draw out air and non-conden- Chemical treatment. The proper l Analysis of maintenance records on

sibles for venting. They will vent only makeup treatment is essential to remove heat exchanger tube bundles and

whatever reaches them; unless they are as much CO, as possible from the boiler steam coil repairs and replacement

located so they see air and non-conden- feedwater. However, even with proper for persistent corrosion or water ham-

sibles, they will not vent them. A prop- deaeration and alkalinity control of mer problems,

- erly located non-subcooling steam trap makeup water and condensate return, l Surveying condensate return lines for

can usually take care of the lower quiet it’s impossible to eliminate all CO, from adequate insulation, and

zones within a heat exchanger since the the system. At some point the conden- l Analysis of chemical treatment prac-

trap will vent air also. Properly sized sate will become corrosive. The addition tices and problems. n

You might also like

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- Air Cooled CondenserDocument20 pagesAir Cooled CondenserVivek SinghNo ratings yet

- Chapter 15 Condensate SystemDocument11 pagesChapter 15 Condensate SystemsambhuNo ratings yet

- Steam and Condensate SystemsDocument5 pagesSteam and Condensate SystemsAayush AgrawalNo ratings yet

- Chemistry For PDFDocument15 pagesChemistry For PDFvenka07No ratings yet

- Gases in Steam: Material Btu/hr-Ft2 - °f/inDocument5 pagesGases in Steam: Material Btu/hr-Ft2 - °f/inaliNo ratings yet

- Steam: Fig. 10.1.1 A Typical Basic Steam CircuitDocument47 pagesSteam: Fig. 10.1.1 A Typical Basic Steam Circuitkris_2k3No ratings yet

- Air Venting Heat Loss and SummaryDocument9 pagesAir Venting Heat Loss and Summarysandeep kumarNo ratings yet

- Condenser Vacuum MarEDocument4 pagesCondenser Vacuum MarEMayeiaElenorNo ratings yet

- Boiler Feedwater DeaerationDocument5 pagesBoiler Feedwater DeaerationFA AyNo ratings yet

- Air Venting, Heat Losses and A Summary of Various Pipe Related StandardsDocument7 pagesAir Venting, Heat Losses and A Summary of Various Pipe Related StandardsAam Phobia MusisiNo ratings yet

- Steam Condensor Gas RemovalDocument7 pagesSteam Condensor Gas Removales9857No ratings yet

- Deaerating Boiler FeedwaterDocument4 pagesDeaerating Boiler Feedwaterritesh sharmaNo ratings yet

- Engineering Letter: IndustrialsteamheatingsystemsDocument8 pagesEngineering Letter: Industrialsteamheatingsystemsmontie3No ratings yet

- Condenser CondenserDocument36 pagesCondenser Condenserobisonandlaw100% (1)

- Energy Efficiency in Steam Systems Through Improved Condensate RemovalDocument1 pageEnergy Efficiency in Steam Systems Through Improved Condensate Removalonizuka-t2263No ratings yet

- Steam Basic Concepts: Condensate Drainage Why It's NecessaryDocument4 pagesSteam Basic Concepts: Condensate Drainage Why It's NecessarylopezmedgarNo ratings yet

- Basic Application Principles: 1. Aspect Ratio of Duct. The Ratio of Duct Height To Width Is ADocument4 pagesBasic Application Principles: 1. Aspect Ratio of Duct. The Ratio of Duct Height To Width Is AAkbar Khan 7118016No ratings yet

- Introduction To Steam DistributionDocument26 pagesIntroduction To Steam DistributionEmeka Nkwocha100% (1)

- PTQ Q2 - Spirax PT 1Document6 pagesPTQ Q2 - Spirax PT 1Pop-Coman Simion100% (1)

- Boiler Feedwater Deaeration and Economizers ExplainedDocument11 pagesBoiler Feedwater Deaeration and Economizers ExplainedRaja TNo ratings yet

- B10 Steam-Distribution SpiraxSarcoDocument56 pagesB10 Steam-Distribution SpiraxSarcomello_dubNo ratings yet

- Layout of Condensate Return LinesDocument8 pagesLayout of Condensate Return Linessimran_99No ratings yet

- DeaerationDocument5 pagesDeaerationEffy SaifulNo ratings yet

- Technical Reference Guide On Steam DistributionDocument66 pagesTechnical Reference Guide On Steam DistributionDainycious KibiwottNo ratings yet

- Steam Distribution Piping ManualDocument66 pagesSteam Distribution Piping ManualPanagiotis Giannakopoulos100% (1)

- Understanding EjectorDocument6 pagesUnderstanding EjectormrazamudinishakNo ratings yet

- Steam EjectorsDocument6 pagesSteam EjectorsmayurjannuNo ratings yet

- Improved Steam Condenser Gas Removal SystemDocument7 pagesImproved Steam Condenser Gas Removal Systemtfernandes.x18No ratings yet

- wpd - steamcondensate (Hơi sấy)Document28 pageswpd - steamcondensate (Hơi sấy)Hoang TranNo ratings yet

- Presentation On Steam TrapsDocument88 pagesPresentation On Steam TrapsSalman ShafiqueNo ratings yet

- Mine ClimateDocument16 pagesMine ClimateRehal JandialNo ratings yet

- WPD SteamcondensateDocument28 pagesWPD SteamcondensateJhoan Fernando Acevedo EspinosaNo ratings yet

- Introduction To Steam DistributionDocument6 pagesIntroduction To Steam DistributionKagira Drawing SoltuionNo ratings yet

- SpiraxSarco-B10-Steam DistributionDocument56 pagesSpiraxSarco-B10-Steam Distributiondanenic100% (3)

- Performance Analysis of Separating and Throttling Calorimeter To Determine PDFDocument5 pagesPerformance Analysis of Separating and Throttling Calorimeter To Determine PDFCarolin megitaNo ratings yet

- Heating With Coils and Jackets - CompressDocument14 pagesHeating With Coils and Jackets - CompressIonut StavaracheNo ratings yet

- Automatic Purgers in Refrigeration Systems PDFDocument7 pagesAutomatic Purgers in Refrigeration Systems PDFrofasiNo ratings yet

- Condenser: Function of A CondenserDocument6 pagesCondenser: Function of A CondenserShirr SagerNo ratings yet

- Deaerator Principle & ApplicationDocument3 pagesDeaerator Principle & Applicationarvidkumar87060100% (1)

- Ensure Proper Air Venting for Efficient Steam SystemsDocument2 pagesEnsure Proper Air Venting for Efficient Steam SystemsmasilamaniNo ratings yet

- Surface Condenser Design and OperationDocument7 pagesSurface Condenser Design and OperationJesús Santiago QuijadaNo ratings yet

- STEAM SavingDocument30 pagesSTEAM SavingShariq AliNo ratings yet

- Troubleshooting Steam EjectorsDocument6 pagesTroubleshooting Steam EjectorsGabriel Eduardo Contreras PerozoNo ratings yet

- The Process Piping: Introduction To Steam TrapsDocument17 pagesThe Process Piping: Introduction To Steam TrapsMohamed AdelNo ratings yet

- Prevention of Water HammerDocument6 pagesPrevention of Water HammerHabshanaNo ratings yet

- Steam Trap Manuals ExplainedDocument61 pagesSteam Trap Manuals Explainedbarrysmith77No ratings yet

- How it Works: Dealing in simple language with steam, electricity, light, heat, sound, hydraulics, optics, etc., and with their applications to apparatus in common useFrom EverandHow it Works: Dealing in simple language with steam, electricity, light, heat, sound, hydraulics, optics, etc., and with their applications to apparatus in common useNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Chimneys & Fireplaces: They Contribute to the Health Comfort and Happiness of the Farm Family - How to Build ThemFrom EverandChimneys & Fireplaces: They Contribute to the Health Comfort and Happiness of the Farm Family - How to Build ThemNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)

- Warm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationFrom EverandWarm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationNo ratings yet

- 02 03 Design For Commisioning and Cleaning PDFDocument19 pages02 03 Design For Commisioning and Cleaning PDFwylie010% (1)

- Causes of Over PressurizationDocument2 pagesCauses of Over PressurizationrkubalNo ratings yet

- 3 FullDocument9 pages3 FullVijay KumarNo ratings yet

- Arvind ReportDocument44 pagesArvind ReportArpit PangariaNo ratings yet

- Mac LS 0 002 0Document4 pagesMac LS 0 002 0arifayee-1No ratings yet

- AalborgDocument61 pagesAalborgChristopher King50% (2)

- Finned Tube Heat ExchangerDocument6 pagesFinned Tube Heat ExchangerShailesh DeshmukhNo ratings yet

- Thermodynamics II - LectureDocument82 pagesThermodynamics II - LectureJohn Panopio100% (1)

- Switchyard Protection Study at NTPC Ramagundam Power PlantDocument74 pagesSwitchyard Protection Study at NTPC Ramagundam Power Plantniha patha100% (1)

- PT-104 Pumping Trap Installation and MaintenanceDocument12 pagesPT-104 Pumping Trap Installation and MaintenancevkumaranNo ratings yet

- SteamInjectionHeating SteamSparge SpargingEfficiencyvsSteamInjectionHeating TB 6 20101210Document4 pagesSteamInjectionHeating SteamSparge SpargingEfficiencyvsSteamInjectionHeating TB 6 20101210Herlina ChandraNo ratings yet

- BATTERY lIMITDocument33 pagesBATTERY lIMITHussain KhanNo ratings yet

- Indonesia Medan Industrial Park 2 ×: November 2015, ChengduDocument5 pagesIndonesia Medan Industrial Park 2 ×: November 2015, ChengduNashruNo ratings yet

- Statim 5.1 Field Troubleshooting Guide PDFDocument59 pagesStatim 5.1 Field Troubleshooting Guide PDFLeandro Neves de Oliveira100% (1)

- Gas Turbine Aux. MachineriesDocument2 pagesGas Turbine Aux. Machineriesshin deiruNo ratings yet

- Bulk Carrierl (Solina) PDFDocument156 pagesBulk Carrierl (Solina) PDFAlex TănaseNo ratings yet

- Boiler EfficiencyDocument32 pagesBoiler Efficiencyइंजी. महेन्द्र प्रताप सिंह100% (2)

- EPCM Stress Analysis SpecificationDocument30 pagesEPCM Stress Analysis SpecificationsajadranjbaranNo ratings yet

- 8.4 Reactions of Metals With WaterDocument18 pages8.4 Reactions of Metals With Waterdua ahmadNo ratings yet

- LNGC LUSAIL - IMO 9285952 - Machinery Operating ManualDocument229 pagesLNGC LUSAIL - IMO 9285952 - Machinery Operating Manualseawolf50No ratings yet

- M-00-d07 Urs Hot Water Generator (10 m3) - r0Document13 pagesM-00-d07 Urs Hot Water Generator (10 m3) - r0dhanu_lagwankarNo ratings yet

- Synloop Waste Heat Boiler in Ammonia Plants: Borsig Process Heat Exchanger GMBHDocument20 pagesSynloop Waste Heat Boiler in Ammonia Plants: Borsig Process Heat Exchanger GMBHArif AhmedNo ratings yet

- Special Report Make The Most Heat Transfer ParathermDocument12 pagesSpecial Report Make The Most Heat Transfer ParathermFabioSalaNo ratings yet

- Electrical Installation Course ChaptersDocument69 pagesElectrical Installation Course Chapterseugeni madaNo ratings yet

- Steam Trap ScienceDocument5 pagesSteam Trap ScienceSandi AslanNo ratings yet

- 38 Thermal Power PlantDocument26 pages38 Thermal Power PlantSwaraj TodankarNo ratings yet

- Heat Recovery Steam Generator (HRSG) - Chemical EngineeringDocument3 pagesHeat Recovery Steam Generator (HRSG) - Chemical EngineeringMahmoud RagabNo ratings yet

- Steam Turbine Generator Fundamental PDFDocument202 pagesSteam Turbine Generator Fundamental PDFAlex Seguida100% (1)

- A Parabolic Trough Solar Power Plant Simulation ModelDocument12 pagesA Parabolic Trough Solar Power Plant Simulation ModelOrn-uma PimpochaNo ratings yet

- Coal Fired Boiler Water Cycle OverviewDocument16 pagesCoal Fired Boiler Water Cycle OverviewFahrul FauziNo ratings yet