Professional Documents

Culture Documents

02-Firecel 100 9 Sr-114e

Uploaded by

Brendan Stack0 ratings0% found this document useful (0 votes)

5 views1 pagefgfdgf fdgdgfdg fhh dgff

Original Title

02-FIRECEL_100_9__SR-114E (2)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentfgfdgf fdgdgfdg fhh dgff

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views1 page02-Firecel 100 9 Sr-114e

Uploaded by

Brendan Stackfgfdgf fdgdgfdg fhh dgff

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

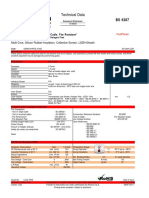

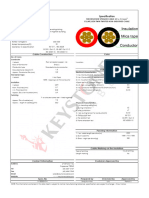

Fire Resistant Cables

FIRECEL SR 114E Enhanced Cable 300/500 V

BS 5839-1:2017 Clause 26.2e

Mica/Silicone Insulation / Overall Screen BS EN 50200:2015 (PH 120)

Solid & Stranded conductor 830°C fire and mechanical shocks

BS 8434-2:2003 +A2:2009 930°C - 120 min. (60 min.

fire and mechanical shocks + 60 min. fire mechanical

shocks and water spray)

BS 6387:2013

Cat. C fire @ 950°C - 180 min

Cat. W fire 15 min. + fire and water spray 15 min.

Cat. Z fire and mechanical shocks

@ 950°C - 15 min.fire

APPLICATIONS OPERATING TEMPERATURE

FIRECEL SR 114E are primarily intended for -40°C to +90°C

use in fire detection and fire alarm systems,

emergency lighting circuits or if cables need to MINIMUM BENDING RADIUS

LPCB ref. 217g properly operate when fire resistance improve-

(cables up to 4 cores) ment is required. 6 times the outer diameter.

For the scope of the LPCB Typical applications are:

Approval see BS 5839-1 for enhanced fire resistant cables in

www.redbooklive.com fire detection and fire alarm systems for building

BS 5839-8 for voice alarm systems

BS 5839-9 for emergency voice communication

systems.

BS 5266-1 for emergency lighting of premises

BS 8519 for fire-resistant control cable systems

For the scope of the BASEC for life safety and fire-fighting application - Cat-

Approval see www.basec.org.uk egory 2

CABLE CONSTRUCTION COLOUR CODE UP TO 4 CORES N° of cond. Outer diameter Weight

TO HD 308 x cross section (mm2) (mm) (kg/km)

Conductors

Plain annealed copper wire, solid class 1 1 mm2 solid SR 114H

2 cores: 2x1.0 7.9 85

or stranded class 2 according to

3 cores: 3x1.0* 8.4 105

EN 60228.

4 cores: 4x1.0* 9.3 125

Insulation 7 cores: centre 7x1.0 10.9 175

Mica/Glass fire resistant tape covered by 1st layer - 4 cores 12x1.0 14.5 300

high performance fire resistant silicone 12 cores: centre 19x1.0 17.0 470

rubber type EI2 to BS EN 50363-1.

1st layer - 7 cores 1.5 mm2 solid SR 114H

Cabling 19 cores: centre 2x1.5 8.8 105

Insulated cores are cabled together. 1st layer - 4 cores 3x1.5 9.3 130

Overall screen 2nd layer - 10 cores 4x1.5 10.3 165

Aluminium/polyester tape. 7x1.5 12.1 230

(on request the cores can be one colour

12x1.5 16.0 380

Circuit protective conductor or drain wire only, identified by printed numbers)

19x1.5 19.0 590

Uninsulated tinned copper conductor 1.5 mm2 stranded SR 114H-R

of the same section and class as the APPLICABLE STANDARDS

2x1.5 9.2 110

insulated conductors in the 2-, 3- and

Basic design 3x1.5 9.7 135

4-core cables. Drain wire of 0.5 mm2

BS 7629-1 4x1.5 10.5 170

tinned copper conductor is provided in

Fire resistant 2.5 mm2 solid SR 114H

cables with more than 4 conductors.

BS 6387 (cat. C-W-Z) 2x2.5 10.2 150

Outer sheath BS EN 50200 (PH120) 3x2.5 10.8 190

LSZH thermoplastic material type LTS3 BS EN 50200 annex E (fire, mechanical 4x2.5 12.0 240

to BS 7655-6.1. shock and water spray) 2.5 mm2 stranded SR 114H-R

Colour red or white (other colours on BS 8434-2 (120 min) 2x2.5 10.6 155

request). IEC 60331 3x2.5 11.3 190

Flame retardant

4x2.5 12.5 250

BS EN 60332-1-2

Fire retardant 4 mm2 stranded SR 114H-R

BS EN 60332-3-24 (cat. C) 2x4 12.2 220

Acid gas emission 3x4 13.0 280

BS EN 60754-1 4x4 14.4 350

Smoke density approximate values

*

not included in BS 7629-1:2015 and in LPCB/BASEC

BS EN 61034-2 approval.

You might also like

- 01-Firecel 100 9 - SR-114HDocument1 page01-Firecel 100 9 - SR-114HMohammed MustafaNo ratings yet

- FIRECEL-SR104 110 1b 2021-2Document1 pageFIRECEL-SR104 110 1b 2021-2Nuwan JayaweeraNo ratings yet

- Firecel SR 104: Fire Resistant CableDocument2 pagesFirecel SR 104: Fire Resistant CableDenis BuonoNo ratings yet

- N2xy-Frc KmiDocument8 pagesN2xy-Frc Kmirnd.ptcwiNo ratings yet

- Nexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHDocument2 pagesNexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHRijo RajanNo ratings yet

- Ramfireco CableDocument1 pageRamfireco CableahsanNo ratings yet

- Description: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhDocument4 pagesDescription: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhTarek FawzyNo ratings yet

- DS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstDocument3 pagesDS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstAppzNo ratings yet

- N1P-1.5 Mgt-Xosswah-LDocument2 pagesN1P-1.5 Mgt-Xosswah-LRijo RajanNo ratings yet

- SR 114HDocument1 pageSR 114HMosin Bin MahammedNo ratings yet

- Fire Alarm-Fir (Shield) : 2 Core (Cu/Mica Tape/PVC-FR/CAM+ATC Drain wire/PVC-FRLS)Document1 pageFire Alarm-Fir (Shield) : 2 Core (Cu/Mica Tape/PVC-FR/CAM+ATC Drain wire/PVC-FRLS)Cost RootsNo ratings yet

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocument1 pageSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaNo ratings yet

- Solar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Document1 pageSolar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Koushik KarmakarNo ratings yet

- Lifeline® Specialty: Fire Resistant QFCI Cable: Fire Resistant, Flame Retardant Halogen-Free Loose Tube - QFCI/O/RM-JMDocument2 pagesLifeline® Specialty: Fire Resistant QFCI Cable: Fire Resistant, Flame Retardant Halogen-Free Loose Tube - QFCI/O/RM-JMkevinwz1989No ratings yet

- Cable Nac 81602Document1 pageCable Nac 81602Andres Varea RomoNo ratings yet

- Datos CableDocument3 pagesDatos CablePablo Briceño NavarroNo ratings yet

- Fire Resistant QFCI F101: Draka - MogDocument3 pagesFire Resistant QFCI F101: Draka - Mogkevinwz1989No ratings yet

- Mgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedDocument2 pagesMgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedJason Secret100% (1)

- Color Cable Construction: SpecificationDocument1 pageColor Cable Construction: SpecificationsedexxNo ratings yet

- 10X4 A2xfy (FRLS) Alum ArmdDocument2 pages10X4 A2xfy (FRLS) Alum ArmdParth DhobiNo ratings yet

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetAgustina De Winne100% (1)

- Fsis09cxswyl004c006sa (FR LSH)Document1 pageFsis09cxswyl004c006sa (FR LSH)pkNo ratings yet

- Keystone Fire Alarm Cables (Twisted Pair Non Sheathed)Document3 pagesKeystone Fire Alarm Cables (Twisted Pair Non Sheathed)Edwin LoquinaNo ratings yet

- Kil FlamDocument2 pagesKil Flamjonnyh85No ratings yet

- NFC 1kv ABC 2&4c16 Ees CableDocument5 pagesNFC 1kv ABC 2&4c16 Ees CableazzouzimedNo ratings yet

- 1.93.3KV 3Cx 35 SQMM Cable GTPDocument1 page1.93.3KV 3Cx 35 SQMM Cable GTPDarshit VyasNo ratings yet

- Data Sheet Fire Rated Cable Shield LPCBDocument2 pagesData Sheet Fire Rated Cable Shield LPCBMd. Asrafujjaman (Livon)No ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.rajesh1200100% (1)

- 10X4 A2xfy Alum - ArmdDocument2 pages10X4 A2xfy Alum - ArmdParth DhobiNo ratings yet

- ATNL 1000 1kV - Armoured Tunnel Cable - Ventilation: Standards ApplicationDocument2 pagesATNL 1000 1kV - Armoured Tunnel Cable - Ventilation: Standards ApplicationSioneNo ratings yet

- Power and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVDocument3 pagesPower and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVShashank SaxenaNo ratings yet

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetEdwin Bustamante Cabrera100% (1)

- Technology Department Technical Data Sheet Low Voltage Power CableDocument2 pagesTechnology Department Technical Data Sheet Low Voltage Power CableMuhammad ShahidNo ratings yet

- Brosur LV Cable - NewDocument24 pagesBrosur LV Cable - NewDuta Jaya SentosaNo ratings yet

- LT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02Document2 pagesLT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02y8jkfz98m9No ratings yet

- Extensible RMU - GIS BushingDocument1 pageExtensible RMU - GIS BushingvikrantNo ratings yet

- Medium Voltage Cable-File PDFDocument66 pagesMedium Voltage Cable-File PDFPrasetiyo HanantoNo ratings yet

- KEC - Instrumentation-Cables PDFDocument8 pagesKEC - Instrumentation-Cables PDFbharatsehgal00No ratings yet

- Opgw: Optical Cables Optical Ground WireDocument3 pagesOpgw: Optical Cables Optical Ground WireMilagros Mercedes Olmos CervantesNo ratings yet

- Datasheet Armoured Cable PVC SheathedDocument9 pagesDatasheet Armoured Cable PVC SheathedDave KousudhanNo ratings yet

- Technical SPecifications 1Cx35 SQMM CableDocument1 pageTechnical SPecifications 1Cx35 SQMM CableAbhinav TewariNo ratings yet

- EU Data Sheet Chainflex CF890Document8 pagesEU Data Sheet Chainflex CF890gaconlonton410No ratings yet

- 0.6 - 1 KV XLPE - LSHF (4 CORES)Document1 page0.6 - 1 KV XLPE - LSHF (4 CORES)suttichaiteamNo ratings yet

- Draka - Xlpe CableDocument2 pagesDraka - Xlpe Cablewe202No ratings yet

- General PropertiesDocument2 pagesGeneral PropertiesIsrael ExporterNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.rajesh1200No ratings yet

- Datasheet BF Solar 125 RV Flex 1500V DC 0000461 V02Document2 pagesDatasheet BF Solar 125 RV Flex 1500V DC 0000461 V02Fábio PereiraNo ratings yet

- RE 2X (ST) YSWAY FLDocument3 pagesRE 2X (ST) YSWAY FLandy175No ratings yet

- RE 2X (ST) YSWAY FL PDFDocument3 pagesRE 2X (ST) YSWAY FL PDFAnas AzzedineNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.JayagurunathanNo ratings yet

- Fiber Optic Cable Outdoor,: Bellcomms BellcommsDocument1 pageFiber Optic Cable Outdoor,: Bellcomms BellcommsChawengsak ChoomuangNo ratings yet

- B-09 HT Power CablesDocument8 pagesB-09 HT Power Cablesrahul patraNo ratings yet

- DC Cable CatalogueDocument3 pagesDC Cable Cataloguenursyazwani johariNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C006SA002S Date: Rev No.maharia_22No ratings yet

- 3 M Fire Barrier Duct Wrap 15 ADocument20 pages3 M Fire Barrier Duct Wrap 15 ArasheedillikkalNo ratings yet

- Li# 1 - 3c X 70 + 35mm2 Swa Fr-3 BahraDocument2 pagesLi# 1 - 3c X 70 + 35mm2 Swa Fr-3 BahraMuhammad ShahidNo ratings yet

- RE2YKRY KMI VendorDocument2 pagesRE2YKRY KMI VendorArthurNo ratings yet

- 2 - 7714-U0gy8-HaDocument1 page2 - 7714-U0gy8-HaMohd Sami UddinNo ratings yet

- Electroarc - Heat Shrink TapeDocument1 pageElectroarc - Heat Shrink TapeVenkata Reddy100% (1)

- Icon Accounting Brochure 2023 - Welcome To ContractingDocument19 pagesIcon Accounting Brochure 2023 - Welcome To ContractingBrendan StackNo ratings yet

- MTR - 830208 - Cui L 20 GR 3.5M - 10047403 - 000 - 00Document6 pagesMTR - 830208 - Cui L 20 GR 3.5M - 10047403 - 000 - 00Brendan StackNo ratings yet

- Lecturer: Dr. O.U. Dairo Synopsis:: AGE 401: Design of Agric. and Food Processing Machines I (3 Units)Document11 pagesLecturer: Dr. O.U. Dairo Synopsis:: AGE 401: Design of Agric. and Food Processing Machines I (3 Units)Brendan StackNo ratings yet

- 2 Pole: 1 Phase IP21 or IP23Document2 pages2 Pole: 1 Phase IP21 or IP23Brendan StackNo ratings yet

- Beton Translucid 2Document6 pagesBeton Translucid 2Nicoleta Diana DuiculeteNo ratings yet

- Convective Boiling and Condensation Heat Transfer With A Twisted-Tape Insert For R12, R22, R152a, R134a, 8290, R32/R134a, R32/R152a, R290/R134a, R134a/R600aDocument15 pagesConvective Boiling and Condensation Heat Transfer With A Twisted-Tape Insert For R12, R22, R152a, R134a, 8290, R32/R134a, R32/R152a, R290/R134a, R134a/R600aQuirti AmarNo ratings yet

- Floating Tablet MetronidazoleDocument3 pagesFloating Tablet MetronidazoleBang GhalibNo ratings yet

- Liver Metabolism: Liver Is The Chief Metabolic Organ of Our BodyDocument123 pagesLiver Metabolism: Liver Is The Chief Metabolic Organ of Our Bodymex Gbrekorkos100% (1)

- Review of The Applications of MicroreactorsDocument21 pagesReview of The Applications of MicroreactorsGodofredoNo ratings yet

- Norton Lubricating OilDocument5 pagesNorton Lubricating OilRajesh BNo ratings yet

- Role of ATP in Energy Coupling and TransferDocument1 pageRole of ATP in Energy Coupling and TransferOmbrog JustinNo ratings yet

- Aci 318-02Document3 pagesAci 318-02Fiorella CondorNo ratings yet

- Chemistry - Copy of Lesson 6.6 - Theories of The AtomDocument19 pagesChemistry - Copy of Lesson 6.6 - Theories of The AtomarielNo ratings yet

- CarcinogensDocument85 pagesCarcinogensNidyaletchmy ReddyNo ratings yet

- Ess Topic 1.3Document8 pagesEss Topic 1.3areenaNo ratings yet

- Ger 4217 ADocument30 pagesGer 4217 Atehranqom100% (2)

- Elemental Parts CatalogueDocument112 pagesElemental Parts CatalogueLuis LagunaNo ratings yet

- Lithosphere and Soil PollutionDocument102 pagesLithosphere and Soil PollutionPranav MittalNo ratings yet

- Arcelor-Mittal Granite PVDFDocument1 pageArcelor-Mittal Granite PVDFZlatko KrsicNo ratings yet

- Painting Inspection - SlidesDocument66 pagesPainting Inspection - SlidesVinoth Kumar SubramaniNo ratings yet

- What Is Lithium CarbonateDocument8 pagesWhat Is Lithium CarbonateNurAneesaNo ratings yet

- Effluent ToxicityDocument7 pagesEffluent ToxicityKrishnakumar P KadinjappalliNo ratings yet

- Restriction Digestion and Analertysis of Lambda DNA Student ManualDocument24 pagesRestriction Digestion and Analertysis of Lambda DNA Student ManualSaswat DasNo ratings yet

- A270 PDFDocument5 pagesA270 PDFrobertoNo ratings yet

- 2 Uptake of Crystal Violet From WaterDocument15 pages2 Uptake of Crystal Violet From WaterMervatNo ratings yet

- Gas Laws ProblemsDocument46 pagesGas Laws ProblemsIris LeuterioNo ratings yet

- V.1. MAT Chart BrochureDocument4 pagesV.1. MAT Chart BrochurekhaledallouchNo ratings yet

- New Brochure 20pagesDocument20 pagesNew Brochure 20pagesSikander0% (1)

- Group 14 Elements - C, Si, Ge,..Document58 pagesGroup 14 Elements - C, Si, Ge,..Looi Chui YeanNo ratings yet

- Gupta, R.B., Kompella U.B., Nanoparticle Technology For Drug DeliveryDocument42 pagesGupta, R.B., Kompella U.B., Nanoparticle Technology For Drug DeliverytaufikNo ratings yet

- Design of Distillation Column Control SystemsDocument540 pagesDesign of Distillation Column Control SystemsAlessio Scarabelli100% (2)

- PSV Process Data Sheet Zubair ADocument2 pagesPSV Process Data Sheet Zubair ASIVANo ratings yet

- Tuboblanc RubDocument3 pagesTuboblanc Rubasebaei95No ratings yet

- Hydrogen Generator: Low Capacities To 300cc/minDocument2 pagesHydrogen Generator: Low Capacities To 300cc/minNheanvatnak AukNo ratings yet