Professional Documents

Culture Documents

Eye Wash Inspection Checklist

Eye Wash Inspection Checklist

Uploaded by

kenneth.bOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eye Wash Inspection Checklist

Eye Wash Inspection Checklist

Uploaded by

kenneth.bCopyright:

Available Formats

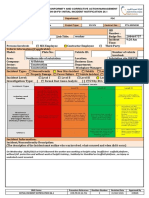

UNCONVENTIONAL RESOURCES MAINTAIN POTENTIAL PROJET (URMPP)

CONTRACT NO. 660005091

NA Gas Production 2 Wells

EYE WASH INSPECTION CHECKLIST

An eyewash station can be a life-saving device, especially in the manufacturing industry, if a

worker is exposed to harmful chemicals or other substances. By quickly flushing the eyes

with water, it can help to remove the substance and prevent serious injury.

Month & Year Facility/Site Name Location: Eye Wash No.:

O

No. Item No Comments

k

1 Tank handle on the top to allow for easy handling is in good condition

2 Is there any hole that allows water to leak

3 A wide fill opening with threaded cap permits easy inspection, cleaning, and filling

4 The fold-down eyewash arm has a positive upper limit stop that also covers and

protects the spray outlets when not in use.

5 Are the jets or spray outlet working properly

6 Water is clean and tank replenish as per schedule

7 Is the area around the station clear of obstruction

DAILY & WEEKLY INSPECTION

W# S M T W T F S Date Refill Name/Signature

1 1 2 3 4 5 6 7

Ok

No

W# S M T W T F S Date Refill Name/Signature

2 8 9 10 11 12 13 14

Ok

No

W# S M T W T F S Date Refill Name/Signature

3 15 16 17 18 19 20 21

Ok

No

W# S M T W T F S Date Refill Name/Signature

4 22 23 24 25 26 27 28

Ok

No

W# S M T W T F S Date Refill Name/Signature

5 29 30 31

Ok

No

Note: Water contents shall be replaced immediately after use or when the water level is less than the

required capacity of the tank.

You might also like

- VE ST HE LM ET SH OE S GO GG LES: Violation DateDocument1 pageVE ST HE LM ET SH OE S GO GG LES: Violation DateSubzone ThreeNo ratings yet

- F 016 Accommodation Inspection ChecklistDocument4 pagesF 016 Accommodation Inspection Checklistngomsia parfaitNo ratings yet

- Work Permit-Form PDFDocument1 pageWork Permit-Form PDFNijo JosephNo ratings yet

- Annexure 9 - Declaration by The Subcontractor For HSE ComplianceDocument1 pageAnnexure 9 - Declaration by The Subcontractor For HSE ComplianceShamim Mahmudur RahmanNo ratings yet

- Chemical Cleaning of 11TK30 (TANK) Rev-00Document2 pagesChemical Cleaning of 11TK30 (TANK) Rev-00Syed Ahmed manzoorNo ratings yet

- Contractor's EHSS Evaluation by PMT EHSS PK CLC Project FMO Jan 2020Document5 pagesContractor's EHSS Evaluation by PMT EHSS PK CLC Project FMO Jan 2020ManPower RecruitingNo ratings yet

- Hse ObservationDocument23 pagesHse ObservationAnees CalicutNo ratings yet

- Acf-Mra-063 - UaDocument1 pageAcf-Mra-063 - UaFateh AliyaNo ratings yet

- Weekly Safety Management Walkthrough Report: Gas Compression Project DepartmentDocument12 pagesWeekly Safety Management Walkthrough Report: Gas Compression Project DepartmentSheri DiĺlNo ratings yet

- Monsoon Safety AdvisoryDocument16 pagesMonsoon Safety AdvisoryRajneesh KumarNo ratings yet

- Site Environmental Control ReportDocument5 pagesSite Environmental Control ReportJasonTeeNo ratings yet

- Safety Observation ReportDocument12 pagesSafety Observation Reportmohammed minhaj0% (1)

- Daily SOC Report RIG Name: Hilong 05 S# Date Name Position Company DescriptionDocument6 pagesDaily SOC Report RIG Name: Hilong 05 S# Date Name Position Company DescriptionYaqoob IbrahimNo ratings yet

- Office Safety PosterDocument2 pagesOffice Safety PosterAndrei MargaritNo ratings yet

- HSE Plan SubconDocument27 pagesHSE Plan SubconTaufan Arif Zulkarnain100% (1)

- 2018 06.02.2018 Bin Omran GC14113100 HSE WalkthroughDocument9 pages2018 06.02.2018 Bin Omran GC14113100 HSE WalkthroughBishop Ojonuguwa AmehNo ratings yet

- Observation Report 3b 2Document4 pagesObservation Report 3b 2Amobi EvidenceNo ratings yet

- Nearmiss Trending AnalysisDocument40 pagesNearmiss Trending AnalysisTayyab MayoNo ratings yet

- Igc3-The Health and Safety Practical ApplicationDocument21 pagesIgc3-The Health and Safety Practical ApplicationSamuel P SNo ratings yet

- GC3 Candidates Observation Sheet7112013121151Document23 pagesGC3 Candidates Observation Sheet7112013121151Tom KuriakoseNo ratings yet

- Daily Weekly Safety Observation Register-Corrective Action Form (Individual) - Wk-12Document96 pagesDaily Weekly Safety Observation Register-Corrective Action Form (Individual) - Wk-12anisaanNo ratings yet

- EHS Observation & Corrective Action Report (Template)Document13 pagesEHS Observation & Corrective Action Report (Template)Tolentino Frias JezreelNo ratings yet

- DOR-HSE Observations-Zone 01-04nov19Document27 pagesDOR-HSE Observations-Zone 01-04nov19Aravindhan Ganesan100% (1)

- Appendix-AC, Guide For Working at HeightsDocument23 pagesAppendix-AC, Guide For Working at HeightsApm FoumilNo ratings yet

- RB - HSE Daily Observation Report Dated 04.11.2021Document3 pagesRB - HSE Daily Observation Report Dated 04.11.2021Idris AdeniranNo ratings yet

- Safety Observation Report FoDocument5 pagesSafety Observation Report FoKaran SinghNo ratings yet

- Weekly Safety Management Walkthrough Report: Gas Compression Project DepartmentDocument6 pagesWeekly Safety Management Walkthrough Report: Gas Compression Project DepartmentMuhammad TariqNo ratings yet

- JSA-Confined Space Activity - 05Document4 pagesJSA-Confined Space Activity - 05babjihanumanthuNo ratings yet

- Wael GC3 Observation SheetDocument11 pagesWael GC3 Observation SheetSivaNo ratings yet

- Site Emergency Evacuationl Plan JEC Aramco Phase-01Document4 pagesSite Emergency Evacuationl Plan JEC Aramco Phase-01Shah MuzzamilNo ratings yet

- Environmental Emergency Response Plan TemplateDocument5 pagesEnvironmental Emergency Response Plan TemplateGlenda SibongaNo ratings yet

- Environmental Weekly Checklist PDFDocument2 pagesEnvironmental Weekly Checklist PDFsathakathullaNo ratings yet

- Emergency Response Drill Scenario - Collision & Damage Control (MBTC - Abaja)Document3 pagesEmergency Response Drill Scenario - Collision & Damage Control (MBTC - Abaja)Alok SinghNo ratings yet

- TBT Attendance Format - NRP WorkersDocument2 pagesTBT Attendance Format - NRP WorkersIsrael Raja AbhilashNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- Evaluation of Camp OHS Risks AssessmentDocument3 pagesEvaluation of Camp OHS Risks Assessmenthasanhse640100% (1)

- Ms For Tele Tower ErectionDocument12 pagesMs For Tele Tower ErectionSahabzada AamirNo ratings yet

- OHS-PR-09-26-F01 INITIAL INCIDENT NOTIFICATION SS8358 Misk City ABC, January 26, 2022Document2 pagesOHS-PR-09-26-F01 INITIAL INCIDENT NOTIFICATION SS8358 Misk City ABC, January 26, 2022Shafie ZubierNo ratings yet

- Msds Diesel PDFDocument11 pagesMsds Diesel PDFSooraj PoochaliNo ratings yet

- Construction Assessment Checklist: Green TagDocument2 pagesConstruction Assessment Checklist: Green TagRyan GillespieNo ratings yet

- Water Tanker Inspection ChecklistDocument2 pagesWater Tanker Inspection ChecklistVepxvia NadiradzeNo ratings yet

- Acf-Mra-064 - SCDocument1 pageAcf-Mra-064 - SCFateh AliyaNo ratings yet

- HSE Weekly Report-On 5 April-2018Document4 pagesHSE Weekly Report-On 5 April-2018emmy100% (1)

- Ohs-Pr-09-03-F11 (A) Ra & JSP Daily Briefing - TBT RecordDocument1 pageOhs-Pr-09-03-F11 (A) Ra & JSP Daily Briefing - TBT RecordShafie ZubierNo ratings yet

- JAPL-F-HE-001-Weekly Grader Inspection ChecklistDocument2 pagesJAPL-F-HE-001-Weekly Grader Inspection ChecklistAli HassanNo ratings yet

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- Lessons Learnt - Trench CollapseDocument2 pagesLessons Learnt - Trench CollapseEhab SaadNo ratings yet

- PROJECT: Construction of The New Link Road Between Shah Gas Field & Mezairaa Area Phase-1 (Packages 1 & 2)Document7 pagesPROJECT: Construction of The New Link Road Between Shah Gas Field & Mezairaa Area Phase-1 (Packages 1 & 2)saqibNo ratings yet

- Contractor Environmental Monthly Returns: Monthly Air Quality Sampling Data AttachedDocument3 pagesContractor Environmental Monthly Returns: Monthly Air Quality Sampling Data AttachedJayvee Baradas ValdezNo ratings yet

- PMSS Building Walkthrough HSE Observations CloseoutDocument11 pagesPMSS Building Walkthrough HSE Observations Closeoutbalasubramaniam ranjuNo ratings yet

- Compressed Gas CylinderDocument4 pagesCompressed Gas CylinderjeyesbelmenNo ratings yet

- Risk Assessment - 1106Document2 pagesRisk Assessment - 1106Francis Enriquez TanNo ratings yet

- Conmix W1: Material Safety Data SheetDocument4 pagesConmix W1: Material Safety Data Sheetalbarajeel forwarding001No ratings yet

- 07-2011 Concrete PumpDocument2 pages07-2011 Concrete PumpBlake Charles Diniz MarquesNo ratings yet

- Safety Observation Formate - 01Document3 pagesSafety Observation Formate - 01Peter LuvisNo ratings yet

- 3.3.4 Monthly Suction Septic Tank LogDocument2 pages3.3.4 Monthly Suction Septic Tank LogSubzone ThreeNo ratings yet

- TSA 005 Rev 0 General LiftingDocument5 pagesTSA 005 Rev 0 General LiftingMusadiq HussainNo ratings yet

- Daily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryDocument5 pagesDaily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryYaqoob IbrahimNo ratings yet

- Excavation Safety Dos and DontsDocument4 pagesExcavation Safety Dos and DontsVidya SagarNo ratings yet