Professional Documents

Culture Documents

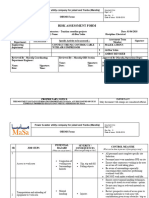

Chemical Cleaning Risk Assessment

Uploaded by

Syed Ahmed manzoorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chemical Cleaning Risk Assessment

Uploaded by

Syed Ahmed manzoorCopyright:

Available Formats

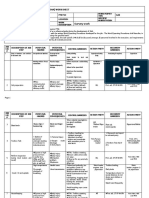

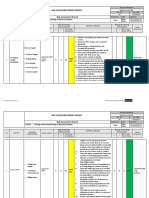

OPERATIONS MANAGEMENT SYSTEM OMS No. SHEM02.

02

Rev. #( 1 ) Date Jan-22

SAFER - Health and Safety Risk Assessment Attachment 5.1: JSA Format

Next review Date Dec-25

JOB SAFETY ANALYSIS (to be filled out by Operations/Maintenance Staff or Group Leader together with JSA Team Members)

Area: PKN Job Description: . Chemical Cleaning of 11TK30 (TANK) JSA number : TIS-PK-N-03 Requester name: TAMIMI INDUSTRIAL SERVICES

Mention Applicable Procedures: SMP - OS - 005,SMP-PS-01, SHEM 8.10,SHEM-08.09, SHEM-08.07,SHEM-

Job Location: 11TK30

08.08

Team Leader: Dept: Olefin IV Use additional sheets if necessary.

Attachments: Yes / No If Yes state number of pages:

Name & ID: Date:

No. Job Steps Potential Hazards Risk Level Steps to Reduce Hazard Remaining Risk Level

Obtain a work permit before the start of the job. Tool

box meeting with working crews shall be done by job

C3,L4 / MINOR supervisor. C3,L5 INSIGNIFICANT

Supervisor or WP Receiver shall be discussing the work to

Incompetencey of Crew be done including the steps of the job happens & their

C3,L4 / MINOR C3,L5 INSIGNIFICANT

mitigation plan JSA & with the crew

Competency check for the crane/forklift operator, rigger,

flagman, and other personnel involved (Personnel must

C3,L4 / MINOR be certified ) TUV certificate for each operator. C3,L5 INSIGNIFICANT

Improper planning C3,L4 / MINOR Maintain access way a free from the obstructions. C3,L5 INSIGNIFICANT

Ensure proper housekeeping during and after the job

Bad housekeeping C3,L4 / MINOR completion. C3,L5 INSIGNIFICANT

Employee selection in work assignments should be

matched to the job in terms of knowledge and physical

C3,L4 / MINOR abilities. C3,L5 INSIGNIFICANT

Improper supervision

Proper Supervision from the Immediate Supervisor

C3,L4 / MINOR communicate and know the procedures to be done. C3,L5 INSIGNIFICANT

Ensure to maintain a comfortable body posture, do not

Face and Hand injuries C3,L4 / MINOR bend your body for a long period of time to prevent back C3,L5 INSIGNIFICANT

pain.

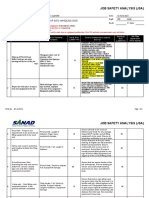

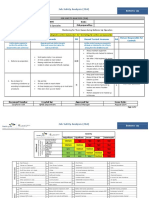

Site Preparation, Loading & unloading

1

Materials

Ensure the lifting of materials has been planned before

C3,L4 / MINOR work execution with roles and responsibilities being C3,L5 INSIGNIFICANT

coordinated.

All existing hazards like loose soil, electrical & other

Equipment failure energized lines are to be identified before the start of

C3,L4 / MINOR each job. C3,L5 INSIGNIFICANT

Ensure all equipment to be used at the site is inspected &

C3,L4 / MINOR approved by a competent person for its use. Take the C3,L5 INSIGNIFICANT

client’s approval as applicable.

Physical injury C3,L4 / MINOR All required PPE must use and wear properly. C3,L5 INSIGNIFICANT

Ensure all the tools/hoses and cleaning machines are

properly tested and inspected by the third-party

C3,L4 / MINOR inspector and provide all the certificates and TUV stickers. C3,L5 INSIGNIFICANT

damaged tools and materials

Ensure all the tools/hoses and cleaning machines are

inspected by the client and provide plant stickers or color

C3,L4 / MINOR codes. C3,L5 INSIGNIFICANT

Ensure to provide guard rail system on top of around the

C3,L4 / MINOR tank and manhole to prevent fall of personnel.

Tripping and falling C3,L5 INSIGNIFICANT

Ensure to use full body safety harness during working at

C3,L4 / MINOR height.

C3,L4 / MINOR Never move open edges without guardrails C3,L5 INSIGNIFICANT

Always maintain 3-point contact on the fix ladder and

C3,L4 / MINOR scaffold ladder C3,L5 INSIGNIFICANT

Fall Hazard Verify scaffolding inspection tag. Access one at a time.

C3,L4 / MINOR Provide adequate illumination. C3,L5 INSIGNIFICANT

Ensure adequate housekeeping on-site before and after

C3,L4 / MINOR the job. C3,L5 INSIGNIFICANT

C3,L4 / MINOR Remove unnecessary materials on the site. C3,L5 INSIGNIFICANT

Ensure people are trained in manual lifting techniques.

C3,L4 / MINOR C3,L5 INSIGNIFICANT

2 Prepare and Installation of blinds, equipment,

hoses, and fittings

back Injury C3,L4 / MINOR Wear heavy-duty hand gloves with proper grip. C3,L5 INSIGNIFICANT

Don’t lift or lower loads that cannot be handled safely.

C3,L4 / MINOR C3,L5 INSIGNIFICANT

physical Injury Required PPE must be worn at all times (safety harness,

C3,L4 / MINOR Goggles) C3,L5 INSIGNIFICANT

C3,L4 / MINOR Remove the unwanted materials C3,L5 INSIGNIFICANT

Ensure existing effective supervision to monitor and

Tripping Hazard C3,L4 / MINOR remind the hazards C3,L5 INSIGNIFICANT

C3,L4 / MINOR Housekeeping at the work area. C3,L5 INSIGNIFICANT

C3,L4 / MINOR Personnel must have the necessary training, skills, and C3,L5 INSIGNIFICANT

C3,L4 / MINOR experience in the

Communicate thejob.

SDS to the involved workers. C3,L5 INSIGNIFICANT

Proper Supervision from Immediate Supervisor and

Untrained worker C3,L4 / MINOR standby operator during starting the pump. C3,L5 INSIGNIFICANT

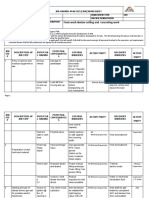

3 Leak Test (body injury)

Equipment Failure Ensure not to over pressurized the hose and piping than

its operating design pressure (Confirm the limitation

C3,L4 / MINOR from EDC Operation) C3,L5 INSIGNIFICANT

C3,L4 / MINOR Use adequate PPE ear plug /ear muff C3,L5 INSIGNIFICANT

C3,L4 / MINOR Only a competent person shall handle the activity. C3,L5 INSIGNIFICANT

C3,L4 / MINOR Use the required PPE C3,L5 INSIGNIFICANT

C3,L4 / MINOR Follow the manual handling techniques. C3,L5 INSIGNIFICANT

C3,L4 / MINOR Proper supervision during the execution of the job. C3,L5 INSIGNIFICANT

Ensure a safe distance of the heat source away from the

C3,L4 / MINOR personnel involved. C3,L5 INSIGNIFICANT

C3,L4 / MINOR Double-check the integrity of the equipment C3,L5 INSIGNIFICANT

C3,L4 / MINOR Monitoring the pressure and Temperature C3,L5 INSIGNIFICANT

C3,L4 / MINOR Provision of containment such as drip trays C3,L5 INSIGNIFICANT

C3,L4 / MINOR Communicate the MSDS of Sodium Hydroxide C3,L5 INSIGNIFICANT

Hearing Damage Chemical Precautionary measures must be in place in handling

splash burns C3,L4 / MINOR chemical substances. C3,L5 INSIGNIFICANT

4 Hot Alkaline Degreasing hose leaks and

damage chemical spills C3,L4 / MINOR STOP the pump C3,L5 INSIGNIFICANT

C3,L4 / MINOR Isolate the valve C3,L5 INSIGNIFICANT

C3,L4 / MINOR Replace the damage hose/pipe C3,L5 INSIGNIFICANT

C3,L4 / MINOR Isolate the area through barricades C3,L5 INSIGNIFICANT

Ensure to install chemical splash guard at all flange joint

C3,L4 / MINOR C3,L5 INSIGNIFICANT

Supervisor must always be present on-site to monitor the

C3,L4 / MINOR job execution. C3,L5 INSIGNIFICANT

Wear Proper PPE (Chemical suit, chemical gloves,

C3,L4 / MINOR goggles, Cartridge Respirator Mask) C3,L5 INSIGNIFICANT

Ensure to no to over pressurized the hose and piping

C3,L4 / MINOR than its operating design pressure (Confirm the limitation C3,L5 INSIGNIFICANT

from EDC Operation)

Ensure water drainage and removal system to keep

C3,L4 / MINOR water levels to a minimum C3,L5 INSIGNIFICANT

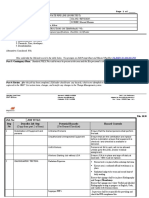

5 Water Flushing Spills

C3,L4 / MINOR Provision of drip tray if necessary C3,L5 INSIGNIFICANT

Communicate and know the procedures to be done.

C3,L4 / MINOR C3,L5 INSIGNIFICANT

Ensure the safe distance of the involved personnel from

6 Passivation Process Over Pressure C3,L4 / MINOR the heat source. C3,L5 INSIGNIFICANT

Communicate the MSDS of the Rodine, Citric acid,

C3,L4 / MINOR ammonia solution, sodium nitrite C3,L5 INSIGNIFICANT

C3,L4 / MINOR Provide Drip Tray C3,L5 INSIGNIFICANT

Control the air pressure in the high vent point while

C3,L4 / MINOR draining C3,L5 INSIGNIFICANT

7 Draining Drain valve must be opened condition to the waste skip.

Damage to Environment C3,L4 / MINOR C3,L5 INSIGNIFICANT

Monitor the waste storage skip level to prevent overflow.

C3,L4 / MINOR C3,L5 INSIGNIFICANT

Wear Proper PPE (hand gloves and safety goggles) C3,L5 INSIGNIFICANT

8 Inspection Hand & Eye Injury Slips C3,L4 / MINOR Proper housekeeping to be done before and after the

cleaning activity. C3,L5 INSIGNIFICANT

Communicate the MSDS of the chemicals to all involved

9 Waste Water Neutralization Damage to Environment C3,L4 / MINOR personnel C3,L5 INSIGNIFICANT

Hazardous chemical details must be specified correctly in

C3,L4 / MINOR the waste manifest C3,L5 INSIGNIFICANT

Liquid waste must be disposed of at the designated

10 Waste disposible outside Damage to Environment C3,L4 / MINOR location as approved by the RC and environmental C3,L5 INSIGNIFICANT

engineer.

Communicate the MSDS to involved personnel in waste

C3,L4 / MINOR disposal. C3,L5 INSIGNIFICANT

Slip Trips and Fall C3,L4 / MINOR Egress/ingress free of obstruction C3,L5 INSIGNIFICANT

11 Housekeeping C3,L4 / MINOR Cords/hoses and materials properly arranged. C3,L5 INSIGNIFICANT

C3,L4 / MINOR Good Housekeeping must be maintained. C3,L5 INSIGNIFICANT

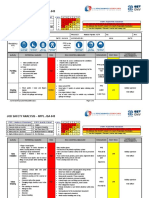

Section A :JSA Preparation /review Section B: JSA Approval

1- Team Leader (PK maintenance / execution Supervisor): I have led the JSA team during the

preparation phase and I have agreed to the highlighted risks, mitigation actions and listed steps of 5-Approved by Maintenance \Technical Manager

this JSA

NAME & ID : DEPT: NAME & ID : DEPT:

SIGN : DATE SIGN : DATE

2-Contractor/Operator/Subject Matter Expert (as applicable): I have reviewed and agreed with all

steps of this JSA 6-Acknowledged by Area Operation \ Owner Manager

NAME & ID : WAHID AZIZ DEPT: TAMIMI NAME & ID : DEPT:

SIGN : DATE SIGN : DATE

NAME & ID : DEPT:

7-Approved by Department Sr. Manager: (Only required if any of the remaining risks is higher than Insignificant )

SIGN : DATE

NAME & ID : DEPT: NAME & ID : DEPT:

SIGN : DATE SIGN : DATE

3-Operation Supervisor: I have reviewed and agreed with all steps of this JSA 8- Acknowledged by Director (Only required if any of the remaining risks is either Significant or Major).

NAME & ID : DEPT: NAME & ID : DEPT:

SIGN : DATE SIGN : DATE

4-EHSS representative: I have reviewed and agreed with all steps of this JSA 9- Approved by President: (Only required if any of the remaining risks is either Significant or Major).

NAME & ID : DEPT: NAME & ID : DEPT:

SIGN : DATE SIGN : DATE

You might also like

- 5.19 JSP Electrical Power InstallationDocument4 pages5.19 JSP Electrical Power InstallationDarius DsouzaNo ratings yet

- 5.19 JSP ScaffoldDocument4 pages5.19 JSP Scaffoldpoorm879No ratings yet

- Hydroseeding WorkDocument26 pagesHydroseeding WorkSamsiah TolaNo ratings yet

- Job Hazard Analysis (Jha) WorksheetDocument4 pagesJob Hazard Analysis (Jha) WorksheetSamer AlsumaryNo ratings yet

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyDocument9 pagesJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- Erection of ScaffoldingDocument3 pagesErection of ScaffoldingAbdul Hakam Mohamed Yusof100% (3)

- ELEC/RA-001 Risk Assessment CCPP, MBPL: Pipe Rack and Bottom Ash AreaDocument12 pagesELEC/RA-001 Risk Assessment CCPP, MBPL: Pipe Rack and Bottom Ash AreaYuva samaj sewa TrustNo ratings yet

- Installation Risk AssessmentDocument4 pagesInstallation Risk AssessmentMuhammad Umar GondalNo ratings yet

- RA For MPI TestDocument3 pagesRA For MPI TestLu Min Han100% (1)

- MSSB-JHA-Hot WorkDocument3 pagesMSSB-JHA-Hot WorkELDIABLO 24KNo ratings yet

- Dismantle of ScaffoldingDocument3 pagesDismantle of ScaffoldingAbdul Hakam Mohamed YusofNo ratings yet

- Construction Risk AssessmentDocument21 pagesConstruction Risk AssessmentMuhammad Shahid Iqbal0% (1)

- JHA - Civil Work - Excavation (Manual & Mechanical), Form Work & Concreting For Marlin ProjectDocument9 pagesJHA - Civil Work - Excavation (Manual & Mechanical), Form Work & Concreting For Marlin ProjectKelvin TanNo ratings yet

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument8 pagesRisk Assessment For Testing and Commissioning of Electrical SystemAnandu Ashokan100% (8)

- Job Safety Analysis PSA-MailDocument50 pagesJob Safety Analysis PSA-MailechaNo ratings yet

- JOB SAFETY ANALYSIS FORMDocument7 pagesJOB SAFETY ANALYSIS FORMIulian Costin IonNo ratings yet

- Task Risk Assessment for Excavation, Backfilling, Leveling and CompactionDocument7 pagesTask Risk Assessment for Excavation, Backfilling, Leveling and CompactionBilal50% (2)

- Survy WorkDocument4 pagesSurvy Workاسامه محمد راضي جعفرNo ratings yet

- JOB SAFETY ANALYSIS (JSA) AND HAZARD IDENTIFICATION PLAN (HIP) FOR MECHANICAL WORKSDocument25 pagesJOB SAFETY ANALYSIS (JSA) AND HAZARD IDENTIFICATION PLAN (HIP) FOR MECHANICAL WORKSrishibarathiNo ratings yet

- Rare GusterDocument16 pagesRare Gusterreemy sarkNo ratings yet

- Pipe Nitrogen Testing in Non Confined SpaceDocument4 pagesPipe Nitrogen Testing in Non Confined SpaceKannan KamalNo ratings yet

- DEL - 064 Jsa For Load Test of Davit ArmsDocument4 pagesDEL - 064 Jsa For Load Test of Davit ArmsMohammed Minhaj100% (1)

- Jsa Breaking Down Bop Into Handling SkidDocument4 pagesJsa Breaking Down Bop Into Handling SkidPaulNo ratings yet

- JSA For Hydrotesting PDFDocument6 pagesJSA For Hydrotesting PDFMohammed Minhaj100% (1)

- Pa Hsec 02 040 002 F03Document4 pagesPa Hsec 02 040 002 F03Abdul KhaliqNo ratings yet

- JSA Appendix Cutting, Grinding ConcreteDocument8 pagesJSA Appendix Cutting, Grinding ConcreteĐặng Quang Huy100% (1)

- JSA For NDTDocument4 pagesJSA For NDTMohammed Minhaj50% (2)

- 03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressDocument16 pages03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressSavio SunnyNo ratings yet

- Safe Work ProcedureDocument5 pagesSafe Work ProcedureSurya Narayan MahapatraNo ratings yet

- JSA Installation of PumpsDocument6 pagesJSA Installation of Pumpsyc safety100% (2)

- JRA-CDA-PL-033-REV-0 - Top Sheave Driving System Sensor AdjustmentDocument4 pagesJRA-CDA-PL-033-REV-0 - Top Sheave Driving System Sensor AdjustmentMiller DutraNo ratings yet

- 1 SurveyDocument5 pages1 Survey王志伟0% (1)

- JSA-Scaffolding Erection & Dismantling Works RV-00Document2 pagesJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNo ratings yet

- Risk Assessment LoaderDocument3 pagesRisk Assessment Loadermohamed ghalyNo ratings yet

- Risk Assessment For Flushing of Chilled Water PipingDocument9 pagesRisk Assessment For Flushing of Chilled Water PipingAnandu AshokanNo ratings yet

- Proposed 2 Torre Lorenzo: Taft Avenue, ManilaDocument45 pagesProposed 2 Torre Lorenzo: Taft Avenue, ManilaMariel ColladoNo ratings yet

- Connect The PLC Control Cable With Air CompressorDocument5 pagesConnect The PLC Control Cable With Air CompressorAmrou Ben RjebNo ratings yet

- JSA For Pipe Installation TS 3Document8 pagesJSA For Pipe Installation TS 3Shilpiengg SafetyNo ratings yet

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument7 pagesRisk Assessment For Testing and Commissioning of Electrical Systemvo100% (2)

- Bottoms-Up: Job Safety Analysis (JSA)Document2 pagesBottoms-Up: Job Safety Analysis (JSA)Nishad MuhammedNo ratings yet

- JSA Appendix Backfilling Soil, Welding HDPEDocument8 pagesJSA Appendix Backfilling Soil, Welding HDPEĐặng Quang HuyNo ratings yet

- JSA For Battar ProtectionDocument4 pagesJSA For Battar ProtectionMohammed MinhajNo ratings yet

- Gate Entrance Traffic Plan Proposal JSADocument10 pagesGate Entrance Traffic Plan Proposal JSArahul tkNo ratings yet

- BMS Risk AssessmentDocument8 pagesBMS Risk Assessmentanish7785100% (3)

- JHA Manual HandlingDocument5 pagesJHA Manual HandlingFatin Zulkifli100% (1)

- JSP-SPARK-SS-ELEC-032 Installation of 115 KV Cable Terminations and EHV - HV - MV Cables Rev00Document10 pagesJSP-SPARK-SS-ELEC-032 Installation of 115 KV Cable Terminations and EHV - HV - MV Cables Rev00Barkat UllahNo ratings yet

- RISK ASSESSMENTDocument8 pagesRISK ASSESSMENTEm Niax100% (1)

- DOCUMENT Job Hazard AnalysisDocument11 pagesDOCUMENT Job Hazard AnalysisFrancis Enriquez Tan0% (1)

- Jsa For Intallation of Sub Pipe RackDocument7 pagesJsa For Intallation of Sub Pipe RackMohammed Minhaj100% (2)

- JRA-CDA-PL-032-REV-0 - Removal, Modification and Reinstallation of Snatch PostsDocument6 pagesJRA-CDA-PL-032-REV-0 - Removal, Modification and Reinstallation of Snatch PostsMiller DutraNo ratings yet

- 09.2014-Install Formwork, Re-Bar Setting and HousekeepingDocument8 pages09.2014-Install Formwork, Re-Bar Setting and Housekeepingاسامه محمد راضي جعفرNo ratings yet

- 32job Observation ChecklistDocument3 pages32job Observation Checklistsanjeev kumarNo ratings yet

- JSA-049 Valves & Support Installation and DismantlingDocument4 pagesJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri75% (4)

- Hot Work Safety MeasuresDocument6 pagesHot Work Safety Measurestamoor sarwarNo ratings yet

- JSA Penetrant RDMPDocument3 pagesJSA Penetrant RDMPRizal Raudia AbadaNo ratings yet

- JHA For Manual Excavation Near On Control RoomDocument9 pagesJHA For Manual Excavation Near On Control RoomFrancis Enriquez Tan100% (1)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 pagesRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- JSA FOR CONCREATE AND CIVILWORKSDocument7 pagesJSA FOR CONCREATE AND CIVILWORKSAnna JisabaNo ratings yet

- Tis-Hse FRM-31 Crane-Checklist-WeeklyDocument2 pagesTis-Hse FRM-31 Crane-Checklist-WeeklySyed Ahmed manzoorNo ratings yet

- Fsn-Olf Iv-2023-Mmd-01Document16 pagesFsn-Olf Iv-2023-Mmd-01Syed Ahmed manzoorNo ratings yet

- JSA Confined Space To Carry Out Repair Anticipated For TANK Bottom Floor Plate and Annular Plate, Repair by Hot Work Rev-00Document39 pagesJSA Confined Space To Carry Out Repair Anticipated For TANK Bottom Floor Plate and Annular Plate, Repair by Hot Work Rev-00Syed Ahmed manzoorNo ratings yet

- TIS-HSE FRM-26 HSE Award Nomination FormDocument1 pageTIS-HSE FRM-26 HSE Award Nomination FormSyed Ahmed manzoor100% (1)

- JSA Confined Space To Carryout Manual Cleaning, Inspection, Grit Blasting and Painting Rev-00Document42 pagesJSA Confined Space To Carryout Manual Cleaning, Inspection, Grit Blasting and Painting Rev-00Syed Ahmed manzoor100% (1)

- 4 Safety Community - EnglishDocument28 pages4 Safety Community - EnglishRaqUiibul IsSlam ShaWanNo ratings yet

- HSE Interview Question 1680466590Document43 pagesHSE Interview Question 1680466590Syed Ahmed manzoorNo ratings yet

- Trench Safety 1681549656Document30 pagesTrench Safety 1681549656Syed Ahmed manzoorNo ratings yet

- PTW Test QuestionsA - All Q&ADocument8 pagesPTW Test QuestionsA - All Q&ASyed Ahmed manzoorNo ratings yet

- Sabic ExamDocument9 pagesSabic ExamSyed Ahmed manzoor100% (3)

- Data tables and charts comparisonDocument14 pagesData tables and charts comparisonSyed Ahmed manzoorNo ratings yet

- HSE Report Format 1681346710Document10 pagesHSE Report Format 1681346710Syed Ahmed manzoorNo ratings yet

- Planning and Analysis of Monthly Sales by ManagersDocument25 pagesPlanning and Analysis of Monthly Sales by ManagersSyed Ahmed manzoorNo ratings yet

- HSE Power Tools Audit Check ListDocument1 pageHSE Power Tools Audit Check ListSyed Ahmed manzoorNo ratings yet

- Banks Man TrainingDocument20 pagesBanks Man TrainingSyed Ahmed manzoorNo ratings yet

- QHSE Roadmap 2023Document1 pageQHSE Roadmap 2023Syed Ahmed manzoorNo ratings yet

- RM255 Fast Track R1 PDFDocument8 pagesRM255 Fast Track R1 PDFarjr51No ratings yet

- API 571 Damage MechanismsDocument29 pagesAPI 571 Damage Mechanismsahmadlie100% (4)

- The Inca: From Village To EmpireDocument14 pagesThe Inca: From Village To EmpireNEOINFORMATION50% (2)

- Plumbing Terminologies With Illustrations (From An American Plumbing Code)Document52 pagesPlumbing Terminologies With Illustrations (From An American Plumbing Code)Denzel NgNo ratings yet

- IB HL Biology Notes Cell MembranesDocument12 pagesIB HL Biology Notes Cell MembranesayushfmNo ratings yet

- Irrigation and Drainage Engineering: Printed BookDocument1 pageIrrigation and Drainage Engineering: Printed BookOsama HussainNo ratings yet

- Grundfos PDFDocument8 pagesGrundfos PDFDan PetricNo ratings yet

- Abn Amro Bank, Ahmedabad: Submitted By: Sadiha Almas Sejal MengajiDocument7 pagesAbn Amro Bank, Ahmedabad: Submitted By: Sadiha Almas Sejal Mengajisadiya almasNo ratings yet

- Diatom Assemblage in The Lake of Gaberoun, Southern LibyaDocument6 pagesDiatom Assemblage in The Lake of Gaberoun, Southern LibyaKanhiya MahourNo ratings yet

- Difference Between Industrial Wastewater and Municipal WastewaterDocument11 pagesDifference Between Industrial Wastewater and Municipal Wastewatertawsifamin19896% (25)

- Abu Dhabi Sew, SWD Irr Specsc Design CriteriaDocument30 pagesAbu Dhabi Sew, SWD Irr Specsc Design Criteriamalgendy0No ratings yet

- Katherine Museum New Building Concept DesignDocument22 pagesKatherine Museum New Building Concept DesignDivya Nair50% (2)

- Clean Brick Safely with Everbuild BrickcleanerDocument10 pagesClean Brick Safely with Everbuild BrickcleanerMhd ThrNo ratings yet

- Pureit UTS CatalougeDocument10 pagesPureit UTS CatalougeArvinder VirdiNo ratings yet

- Chlortetracycline Hydrochloride BP 20% in BMP Microgranulate FormDocument6 pagesChlortetracycline Hydrochloride BP 20% in BMP Microgranulate FormvtpsNo ratings yet

- Table 1. Roughness Coefficients, N, For The Manning Equation. Type and Description of Channel N ValuesDocument1 pageTable 1. Roughness Coefficients, N, For The Manning Equation. Type and Description of Channel N Valuesshalaka dhokneNo ratings yet

- Water ManagementDocument13 pagesWater Managementshinexixi100% (1)

- Ecosystems Adaptation To Global WarmingDocument6 pagesEcosystems Adaptation To Global WarmingEditor IJTSRDNo ratings yet

- MHM School ExperiencesDocument35 pagesMHM School ExperiencesAshutosh SinghNo ratings yet

- Dll-Science-Q4-Week 1Document7 pagesDll-Science-Q4-Week 1Janelle Grecia NepomucenoNo ratings yet

- Hydropower Development Policy of NepalDocument26 pagesHydropower Development Policy of NepalManoj BishtNo ratings yet

- Making Climatograms Homework GarciaDocument2 pagesMaking Climatograms Homework Garciaapi-261192636No ratings yet

- Training Manual: Prepared byDocument29 pagesTraining Manual: Prepared byjpsingh75No ratings yet

- Origin and Structure of Earth and OceansDocument96 pagesOrigin and Structure of Earth and OceansJashayla GillespieNo ratings yet

- Solar Energy - 2023Document25 pagesSolar Energy - 2023sheila louiseNo ratings yet

- Efficient absorption of runoff water through ground methodsDocument11 pagesEfficient absorption of runoff water through ground methodsRohan SharmaNo ratings yet

- ConodontsDocument10 pagesConodontsFrancisco JavierNo ratings yet

- STS EDAC WELD REPAIR PROCEDUREDocument51 pagesSTS EDAC WELD REPAIR PROCEDUREmohd as shahiddin jafriNo ratings yet

- Feng Shui and Modern Sustainable BuildingsDocument17 pagesFeng Shui and Modern Sustainable BuildingsjparanotiNo ratings yet

- The Floor of The Ocean-New Light On Old Mysteries - Daly - 1942Document230 pagesThe Floor of The Ocean-New Light On Old Mysteries - Daly - 1942geoecologistNo ratings yet