Professional Documents

Culture Documents

JSP-SPARK-SS-ELEC-032 Installation of 115 KV Cable Terminations and EHV - HV - MV Cables Rev00

Uploaded by

Barkat UllahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSP-SPARK-SS-ELEC-032 Installation of 115 KV Cable Terminations and EHV - HV - MV Cables Rev00

Uploaded by

Barkat UllahCopyright:

Available Formats

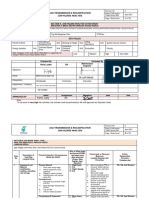

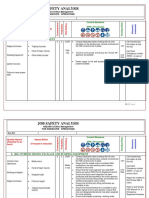

CONSTRUCTION OF SPARK 380/115 kV BSP

PROJECT NAME:……………………………………………………………………………

ELEMENT 5.19.3

JOB SAFETY PRACTICES

DEPARTMENT/DIVISION Power Transmission and Distribution DATE 02 February 2020

EMPLOYEE JOB TITLE Rigger, Operator, Helpers, Engineers, Supervisor LOCATION Control Building, 115 Building & 380 Building

JSP ID JSP-SPARK-SS-ELEC-038 Uniform, Safety Helmet, Safety Shoes, Safety

Personal Protective

Installation of 115 KV Cable Terminations of Goggle, Rubber Coated Gloves, Dust Mask,

JOB / TASK TITLE Equipment

Cables Florescent Vest, Safety Harness,FBH

STEPS HAZARDS

IN EACH STEP, WHAT COULD COMMENTS OF JOB

LIST ALL STEPS IN CONTROL REQUIRED TO MINIMIZE/ ELIMINATE HAZARD

STEPS # CAUSE INJURY, LOSS DAMAGE, OBSERVATION

PERFORMING THIS TASK

INTRRUPTION, OR POLUTION?

Permit to Work shall be obtained as a pre-requisite to perform work

Unathorized work to be Work shall not be started until duly approved Permit to Work is available at site

performed within a defined and that Safety Toolbox meeting was conducted

location and boundary Permit to Work shall be displayed at the worksite

Work shall not proceed without the presence of approved Permit to Work with the

Permit Receiver overseeing the activity

Permit Receiver shall account all workers under his Permit to Work before the

1 Obtain Permit to Work Uncontrolled personnel

start of work

entering a restricted location

Permit Receiver shall not leave the area for the whole duration of work

Unidentified hazards with A safe work practice shall be implemented to reduce the possibilities of accident /

unplanned safety mitigating incident

measures Inadequate Permit Receiver and Permit Issuer shall visit together at the site to ensure that

coordination and area workplace hazards are adequately identified and mitigating measure shall be

control protocol established

2 Site mobilization / selection All workers / personnel and visitors must attend the required safety induction

of equipment, operator and before allowing to work on the site

driver All workers / personnel and visitors must sign the attendance records and

acceptance for new employee on the job orientation

Unfamiliar to the Workers shall be issued with appropriate PPE’s such as safety shoes (BS 1970

construction site or ANSI Z 41.1), safety helmet (BS EN 397 or ANSI Z 89.1), safety glasses (BS

2092 or ANSI Z 87.1), ear plugs (ANSI S3.19), protective clothing or equivalent

for all, etc.

Provision of pedestrian access, signage and building / structure identification

Awareness / training for all operator and driver

Poor housekeeping in the Housekeeping shall be done before, during and after the job

workplace Designate location for unloading of personnel and materials be stored only on a

designated storage area signage

Page 1 of 10 Rev.2 [08-April-2019] Projects Business Unit

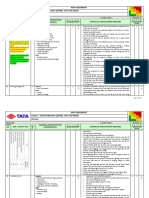

CONSTRUCTION OF SPARK 380/115 kV BSP

PROJECT NAME:……………………………………………………………………………

ELEMENT 5.19.3

JOB SAFETY PRACTICES

Struck with sharp and hard

Designated access shall be free from any obstruction

object

Unorganized materials and Designate material disposal area

access Area congested All material location and storage shall be barricaded and provided with adequate

Establish equipment access and shall be free from any obstruction

Struck by moving equipment Designate parking area

and vehicle Designate location for unloading of materials

Designate spotter and flagman to guide all equipment and personnel movement

Equipment operator and assist worker shall be provided with earplugs

Exposure to excessive

Earplugs or earmuff shall be worn properly to effectively reduce the noise to

noise

permissible level

All heavy equipment shall be inspected by the authorized operator on a daily

basis to ensure that equipment is in good working condition before using to the

site

Dilapidated equipment Repair of heavy equipment shall not be done on the site. It must be brought to the

designated work shop and only certified mechanic shall make repair of the

equipment

Select and mobilize only good condition equipment

Heavy equipment shall not be used if found any defects or damage that might

Damage or defective affect its safe operation

condition of equipment Ensure that there are no leaking hydraulic oil system or signs of leaks and oil

contamination

All heavy equipment and its driver/operator shall hold a valid third party

Incompetent equipment certification authorizing them on the specified equipment to operate

operator or driver Equipment certification and registration must be secured and available

Operator and driver must have certification and license

Informing the contractor about arrival time of Crane to work site so that he may

Toolbox Talk / Pre job safety Poor/unsafe routing of arrange in advance.

3 briefing & getting the task Crane Unsafe parking of Arrival of Crane to site should be through proper and safe route only.

instruction from supervisor. Crane Crane arriving the site should be parked at specific location where its boom can

reach easily to the required location for Operation.

Pre start checking of Equipment e.g. Crane must be physically fit and safe to be used at site.

Poor or damaged

4 equipment and filling the Should be stopped if found any fault, damage or noise to avoid any unseen

equipment

daily vehicle checklist circumstances.

5 Preparation of tools, lifting Obtain valid permit to work.

gears and necessary Ensure that all workers are given a HSE induction prior to deployment on site.

accessories to start heavy Lack of safety awareness

Conduct safety toolbox meeting and discussed the work procedures prior to start

equipment lifting and knowledge for the job

of work.

Use of damage or defective Proper tools should be selected for the material loading activity.

Page 2 of 10 Rev.2 [08-April-2019] Projects Business Unit

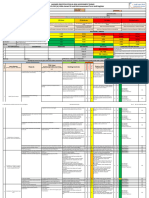

CONSTRUCTION OF SPARK 380/115 kV BSP

PROJECT NAME:……………………………………………………………………………

ELEMENT 5.19.3

JOB SAFETY PRACTICES

No handmade/damaged tools to be used. Supervisor should check tools before

tools

going to be used at site.

Only 20 kg allowed lifting by an individual. Use bobcat or other equipment to shift

Incorrect manual handling

required lifting gears to site.

of lifting gears

Ensure correct body positioning and manual lifting procedures.

Ensure that all workers are provided with all the required Personal protective

Use of damaged personal

equipment’s for minimum and general requirements.

protective equipment

Use hand gloves, safety glass, protective clothing, hard hat, safety shoe.

Poor Access/ Egress Access pathways to be kept clear from any obstruction.

Poor heavy inside store Maintain proper housekeeping inside store to avoid any injury

Provide sufficient drinking water and scheduled breaks.

High ambient temperature

Drinking containers shall be protected from direct exposure from the sun

during walking towards

Provision of rest shelter area if outside the building.

store

Provide shuttle vehicle to drop and pick from store

Work Supervisor obtaining Work Permit and SWP before the start of material

Congestion due to other

delivery and crane positioning.

ground activity

Safety signage shall be posted to communicate the hazards and activity

Struck by maneuvering Provide flagman and spotter to guide the trailer operator when maneuvering for

heavy equipment its position

Trailer blind spot Trained Flagman/spotter guiding the crane/trailer when going into work location

Positioning of crane and Inexperienced or untrained Verification of Crane Operator’s 3rd party certification and Trailer Drivers driving

6 trailer in preparation for operator license before allowing them to enter the site.

lifting activity

Supervisor/Foreman with the Crane/Trailer operator making walkthrough of the

Site access limitation

access and work area before entering site.

Responsible Engineer and his Supervisor/ Foreman inspection of exclusion

Soft ground /Uncompact fill

zone/staging area for compaction and level of the ground.

Overhead/Nearby Barricading the exclusion zone/ working radius once crane and trailer are in

obstructions position

Struck into adjacent Barricade the working area around the trailer and crane to prevent unnecessary

structures or worker workers to enter the area

7 Installation / Lifting of Unavailability of approved Lifting plan shall be prepare and approved prior to erection of transformer, etc.

Capacitor Banks lifting plan for critical lifting Appropriate size / capacity of the equipment should be mobilized as per the lifting

works (erection of plan

transformer, etc.) Site engineer and the rigging supervisor should discuss the approve lifting plan to

the operator and rigger prior to lifting works

Safety personnel should check and verify the approve lifting plan

Lifting plan shall be made and prepare by the competent and certified rigging

Page 3 of 10 Rev.2 [08-April-2019] Projects Business Unit

CONSTRUCTION OF SPARK 380/115 kV BSP

PROJECT NAME:……………………………………………………………………………

ELEMENT 5.19.3

JOB SAFETY PRACTICES

supervisor.

Closed supervision is required from the engineers, supervisor / foreman and

safety personnel during the erection

Closed coordination with SEC / NG site engineers during preparation and

erection

Approved lifting plan must be readily available at site for immediate reference

Refer to equipment manual for correct operation

Continuous safety training and awareness related to lifting operation

To provide proper and sufficient anchorage point / lifeline

Only use approve materials for anchorage point / lifeline

Approve design and calculation for anchorage point must be secured

In-charge supervisor and foreman shall check and verify the availability of the

The workers in elevated anchorage point / lifeline.

areas have no anchorage

Anchorage point / lifeline must be install by the competent person

point or lifeline during the

To comply with 100% tie-off

installation capacitor bank

shade. Provision of retractable lifeline

Continuous safety training and awareness related to working at heights

Civil engineer should conduct pre-inspection in the area before the lifting works

Anchorage point lifeline shall cater the suspended load, minimum strength of 22

KN for free fall

Periodical inspection or color coding for all lifting gears

Rigger performing the regular inspection for all lifting gears

Lifting gears (shackles, sling Tagging system or marking for faulty lifting gears

belt, leg chain, chain blocks,

Only certified rigging inspector are allowed for the inspection

___, etc.) used for the

All lifting gears must be inspected by the third parties

erection of transformer, etc.

has no inspection All lifting gears rated capacity / SWL must be available or clearly visible

All lifting gears must be properly stored, handled and labelled in the storage area

Quarantine box for all damage / defective lifting gears

Ground must be stable, leveled, firm and compacted

Out rigger must be fully extended on a stable and flat even ground

Poor set-up of lifting Appropriate and sufficient size of outrigger pads must be provided

equipment (mobile crane, Site engineer should make an assessment and conform the stability of the ground

___, etc.) on an uneven and Consider to provide spare pads or steel plates

lose ground surface. Crane operator shall evaluate the ground if capable to withstand the equipment

and the load

Conduct pre-planning on which crane will be positioned

The heavy equipment Heavy equipment used on the site shall have a valid third party certification

(mobile crane, boom truck, Operator conduct pre-inspection of the equipment and checking of documents

____, etc.) used for the Supervisor check and verify the certification

erection of transformer, etc. Ensure to lease heavy equipment with valid certification must be from establish

has no valid certification. company

Page 4 of 10 Rev.2 [08-April-2019] Projects Business Unit

CONSTRUCTION OF SPARK 380/115 kV BSP

PROJECT NAME:……………………………………………………………………………

ELEMENT 5.19.3

JOB SAFETY PRACTICES

Third party certification must be from the accredited and approve company

Daily verification of equipment documents from the safety personnel

Administration personnel should process the renewal before the expiration date

Heavy equipment must have valid registration and insurance

Operator on the site shall have a valid third party certification

Operator conduct daily checking of documents

The operator of heavy Supervisor should check and verify the certification

equipment (mobile crane, Supplied heavy equipment operator must be from establish and approve

boom truck____, etc.) used company

for lifting works has no valid Third party certification must be from the accredited and approve company

certification. All heavy equipment operator must have valid Saudi Driving license

Daily verification of equipment documents from the safety personnel

Administration personnel should process the renewal before the expiration date

Periodical maintenance for all heavy equipment

Operator conduct pre-inspection of the equipment and complete the checklist

Used of defective heavy

Ensure that only heavy equipment with good and satisfactory condition used at

equipment (mobile crane,

site

boom truck,____, etc.) for

All heavy equipment should send to workshop for proper maintenance

the erection of transformer,

etc. Immediate repair / replacement for any comments / issues in the equipment

checklist

Ensure sufficient stocks of equipment spare parts

Provide rigger with proper identification (different color of helmet, reflective vest,

etc.)

Ensure the competency level of operator and rigger regarding the international

communication- hand signal

No assigned certified rigger Supervisor and equipment operator should not allow any lifting works without the

for the lifting works and rigger

erection of transformer, etc. Ensure that the rigger has valid certification

Consider the rigger level (I, II, III) when obtaining the rigger certification

Rigger certification must be from the accredited and recognized company

Mobilized supplemental certified rigger if there’s a blind spot during lifting works

Continuous safety training and awareness related to the lifting operation

The worker / rigger in To provide proper and sufficient anchorage point / lifeline

elevated areas has no Only use approve materials for anchorage point / lifeline

anchorage point or lifeline Approve design and calculation for anchorage point must be secured

during the installation of In-charge supervisor and foreman shall check and verify the availability of the

transformer accessories anchorage point / lifeline.

To provide good and inspected scaffolding platform.

Civil engineer should conduct pre-inspection in the area before the lifting works

Anchorage point lifeline shall cater the suspended load, minimum strength of 22

KN for free fall

Page 5 of 10 Rev.2 [08-April-2019] Projects Business Unit

CONSTRUCTION OF SPARK 380/115 kV BSP

PROJECT NAME:……………………………………………………………………………

ELEMENT 5.19.3

JOB SAFETY PRACTICES

Anchorage point / lifeline must be install by the competent person

To comply with 100% tie-off

Provision of retractable lifeline

Continuous safety training and awareness related to working at heights

Consider to use other mobile elevated working platform with valid certification

Operator's cabin shall be free from any obstruction on its view.

The operator's cabin was Instruct and remind the operator to keep cabin free from any obstruction.

obstructed by some

Issuance of dark safety glass to restrain the sunlight glare.

materials (curtain, papers,

Ensure to remove all unwanted materials inside the operator's

magazine, posters, etc.)

Cabin.

during the lifting and

installation of Transformer Continuous monitoring and supervision from the supervisor,

body Foreman and safety personnel.

Issuance of disciplinary action for those who violates the rules.

Above 32 km/h wind speed, all the lifting works are suspended

Records the wind speed periodically using anemometer

Load shall be lowered, placed on the ground and suspend the lifting activity

Equipment boom shall be retracted and facing opposite the wind direction

Supervision from supervisor / foreman and safety personnel is required during the

Lifting works is exposed to

lifting works

extreme bad weather

Provision of calibrated anemometer

condition (high wind speed -

Ensure that the equipment has incorporated wind speed monitoring

32 kph, sand storm, etc.)

Refer to the equipment manual for the correct equipment operation

Continuous supervision from civil engineer / supervisor is required for this activity

Operator and rigger must be competent for any critical works

Approve lifting procedures must be available and accessible for immediate

reference

All items to be lifted will be inspected prior to the lift to ensure that there is no

Loose equipment or items that may fall off during the lift.

No personnel will be permitted to stand under or close to a suspended item.

Items falling from piece Barrier flags or tape will be used to form an exclusion zone around the cranes

being lifted. And equipment being lifted.

Avoid working or passing beneath suspended loads.

Lifting radius area shall be barricaded and signage posted "Keep

Away on - going lifting activity"

Suspended load over No personnel shall be under a suspended load unless absolutely necessary

equipment with personnel And where machinery connections are required limited personnel will conduct

working in close proximity. these duties.

All loads lifted will be slung by competent operatives and by means of certified

Lifting accessories only.

Tag lines shall be used where practicable to control loads being lifted. All non-

Essential personnel will be restricted from the rigging area.

Page 6 of 10 Rev.2 [08-April-2019] Projects Business Unit

CONSTRUCTION OF SPARK 380/115 kV BSP

PROJECT NAME:……………………………………………………………………………

ELEMENT 5.19.3

JOB SAFETY PRACTICES

Avoid working or passing beneath suspended loads.

Lifting radius area shall be barricaded and signage posted

"Keep Away on - going lifting activity"

Do not store / stacked empty containers at the site

Shift all empty containers to temporary storage area

Separate the empty and full containers with proper identification / labels

Refer to chemical MSDS for proper handling and storing

Empty drums should be completely drained and properly bunged

Improper storing / stacking Coordinate and promptly shipped to the supplier or a drum reconditioned

of empty transformer oil Periodical disposal and collection of all emptied containers

drum / containers at the site Use and store this material in cool, dry, well-ventilated areas away from heat and

all sources of ignition

Provide sufficient and appropriate fire extinguisher in the area

All containers should be disposed of in an environmentally safe manner and in

accordance with governmental regulations.

Keep away from any incompatible material

Scaffolding platform must have complete components (railings, bracing, boards,

access, etc.)

Scaffolding platform inspection perform by the scaffolding supervisor

Tagging system of the scaffolding platform

• The workers working on an Scaffolding inspector must have valid certification

incomplete scaffolding

Scaffolding platform shall only erect, modified and dismantled by the certified

platform for Capacitor Bank

scaffold erectors.

installation

All access ladder must have appropriate tag

All involve personnel’s must undergo and passed the working at height training

Only use approve and in good physical state of scaffolding materials.

Ensure sufficient stocks of approved scaffolding materials

Scaffolding supervisor conduct inspection to the complete scaffolding platform

Inspection tag (Red or Green) must be provided to all access ladder of the

inspected platform

The scaffolding platform has

Periodical inspection and update of inspection tag for all scaffolding platform.

no inspection tag or not

Scaffolding inspector must have valid certification

updated

Ensure sufficient stocks of inspection tags and marker.

Details in the inspection tag must be completed, including the loading the

capacity

Workers step outside on the Supervisor / foreman must instruct all workers only to work inside the working

scaffolding platform platform

All workers must follow all the instructions from the supervisor

Scaffolding platform should modify by the certified erectors as per the activity

wise

Continuous monitoring from the safety personnel and supervisor

Page 7 of 10 Rev.2 [08-April-2019] Projects Business Unit

CONSTRUCTION OF SPARK 380/115 kV BSP

PROJECT NAME:……………………………………………………………………………

ELEMENT 5.19.3

JOB SAFETY PRACTICES

Continuous safety training and awareness related to working at heights

Issuance of personal fall arrest system for workers working in elevated areas

Workers working in elevated Supervisor / foreman must ensure that all workers are wearing their respective

area (above 1.8m) has no personal fall arrest system

personal fall arrest system - Compliance with the tagging system of the inspected scaffolding platform

full body harness with Close monitoring from the safety personnel, supervisor and foreman.

double lanyard with shock Ensure sufficient stocks of personal fall arrest system.

absorber Periodical replacement for all defective personal fall arrest system

Only procure and use the approve personal fall arrest system

All floor / manhole opening shall be provided with appropriate size and materials

of covers

Ensure that the covers are stable

Covers shall be provided with appropriate signage / warning signs

The presence of unprotected

Discuss the importance of covering the opening in the daily toolbox meeting

/ unsecured floor opening in

Supervisor must ensure that the permanent grating are already installed prior to

the workplace

the installation works

Supervisor / foreman in-charge should conduct pre-inspection prior the activity

Ensure sufficient stocks of materials for covering of opening

Consider in painting the cover with appropriate color

All protruding object should be provided by rebar cap, scaffolding cap, etc.

All excess / unwanted steel rebar / object should be remove from site

The presence of Provision of warning signs / tapes for protruding object

uncontrolled / unprotected

Provision of designated wooden boxes for protruding object

protruding object (steel

Ensure sufficient stock of rebar cap, scaffolding, caps, etc.

rebar, scaffolding pipes,

etc.) in the workplace Consider to bend the other end as other company's practice

Continuous monitoring from the supervisor and safety personnel

Consider to provide wooden caps in replacement for plastic rebar cap

The compressed gas To provide and use only the approved gas regulators, etc.

cylinders (oxygen - Ensure that the regulators are properly fit/fix prior to opening.

acetylene) for cutting works Conduct pre-inspection prior to use the gas cylinders, regulators and hose

used defective regulators Worker must be competent to perform the job

All compressed gas cylinders must be properly stored and handled, keep in

upright position

Provide appropriate and sufficient standby fire extinguisher

Secure the availability of spare parts for immediate replacement

Supplier of compressed gas regulators should be from the recognized and

accredited company

The slugs and ejected The workplace shall be provided with sufficient barriers (steel)

particles during cutting, Appropriate PPE signage shall be posted in the area

grinding, etc. is not isolated / Portable / movable barrier shall be provided

controlled Supplemental barrier like fire blanket shall be provided and considered

Page 8 of 10 Rev.2 [08-April-2019] Projects Business Unit

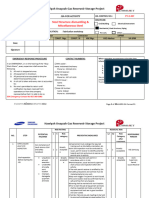

CONSTRUCTION OF SPARK 380/115 kV BSP

PROJECT NAME:……………………………………………………………………………

ELEMENT 5.19.3

JOB SAFETY PRACTICES

All rotating parts must be guarded

All workers shall comply and use the issued appropriate PPE's

The galvanized steel Steel structure and web sling belt must be provided by softener in between

structure has no softener Proper slinging of materials shall be done only by the certified rigger

(padding) during the lifting Ensure sufficient stock of softener

works To improve the safety monitoring for all lifting works

Continuous safety training and awareness related to lifting operation

All lifting operation and scaffolding erection must be properly isolated

Appropriate warning signs shall be installed

Rigger / supervisor should not allow any unauthorized entry to the on-going

activities

Lifting works and running

Initiate closed coordination in between the other group

equipment are not isolated

Continuous monitoring and supervision from the assign supervisor and safety

from the other personnel

personnel

Continuous safety training and awareness related to the lifting operation and

scaffolding works

Ensure sufficient stocks safety materials for warning sign

Issuance and replacement of personal protective equipment (PPE)

Safety personnel, supervisor and store keeper should not allow to issue or use

the substandard PPE

Only issued the appropriate and approve PPE's to all workers and staff

Used of substandard

PPE's should conform to the following specification such as safety shoes (EN

personal protective

345, ANSI Z 41), high-visibility vest (ANSI 107:2004 and EN471:2003), safety

equipment (PPE)

helmet (ANSI Z89.1-2014 CLASS E), safety glass (EN166, ANSI Z87.1-2010/ EN

166:2001), work gloves (EN 420: 2003), etc.

Refer to PPE SPECIFCATIONS 2018 - 2019 OHS-SP-002-01 for more details

and information

Facilitate training for manual handling.

Manual handling

Observe proper posture during manual lifting, pushing, pulling, etc.

Housekeeping, clearing the

Materials lying on the

area with all used materials, Provide storage box for cables/materials.

ground

8 tools and equipment and

brought to the designated Protruding object / materials

Remove all unwanted / protruding materials / object at the site

storage and disposal area at the site

Uncollected / scattered Provision of waste skip in the strategic location at the site with marking

rubbish Provision of color coded waste bins at the site

9 Closing of Permit to Work Permit Receiver shall ensure that housekeeping in done before, during and after

the work

Poor housekeeping

All materials used at the site such as chemicals, flammable and combustible

materials shall be stored at the designated storage at the end of each day

Undisposed waste materials All waste materials generated from the work shall be disposed properly and shall

not be left unattended at the worksite.

Page 9 of 10 Rev.2 [08-April-2019] Projects Business Unit

CONSTRUCTION OF SPARK 380/115 kV BSP

PROJECT NAME:……………………………………………………………………………

ELEMENT 5.19.3

JOB SAFETY PRACTICES

Unattended unsafe parking Mobile equipment shall properly parked on a designated equipment laydown

Unsecured electrical

equipment, energized

Electrical equipment shall be properly secured, distribution board closed and

padlocked

equipment

JSP Prepared By: Ralph Liddasan Signature: Date:

JSP Reviewed By: Haitham Abouelella Signature: Date:

JSP Approved By: Mohamed Abdellatif Signature: Date:

Page 10 of 10 Rev.2 [08-April-2019] Projects Business Unit

You might also like

- Safe Usage of PPE Toolbox Talk Global EHS TBT 006Document4 pagesSafe Usage of PPE Toolbox Talk Global EHS TBT 006Global EHSNo ratings yet

- Managing mobile plant risksDocument2 pagesManaging mobile plant risksPravin GowardunNo ratings yet

- 5.19 JSP Electrical Power InstallationDocument4 pages5.19 JSP Electrical Power InstallationDarius DsouzaNo ratings yet

- Risk Assessment Asphalt WorksDocument7 pagesRisk Assessment Asphalt Workskannanjaduzz100% (1)

- Jsa-Rp-002 General Excavation & TrenchingDocument16 pagesJsa-Rp-002 General Excavation & Trenchingibaig1970100% (1)

- Supervisor's Guide to Fall PreventionDocument16 pagesSupervisor's Guide to Fall Preventionlwin_oo2435No ratings yet

- Hira PDFDocument69 pagesHira PDFvinod100% (1)

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- SOP - Burisch 100Ltr Air CompressorDocument1 pageSOP - Burisch 100Ltr Air CompressorDaniel DerzaNo ratings yet

- JSA - Baby Rollar and CompectorDocument5 pagesJSA - Baby Rollar and CompectorRaju100% (1)

- 2 Hand and Power ToolsDocument34 pages2 Hand and Power ToolsEthyl Jean Gallarte100% (1)

- Ceiling WorkDocument10 pagesCeiling WorkNisanth ThulasidasNo ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- Job Safety Analysis (Jsa) ProcedureDocument7 pagesJob Safety Analysis (Jsa) ProcedurerinkusahuNo ratings yet

- 01 JSA - Material ShiftingDocument5 pages01 JSA - Material Shiftingsyed khaja misbhuddinNo ratings yet

- 1.tech Pneumatic Tool Safety 20180207Document2 pages1.tech Pneumatic Tool Safety 20180207Ku RatheeshNo ratings yet

- Concrete Work Formingand PouringDocument3 pagesConcrete Work Formingand PouringKimberly Juarez100% (1)

- Information Sheet: Crystalline Silica DustDocument2 pagesInformation Sheet: Crystalline Silica DustIoana UrsanNo ratings yet

- URC Insulation For Ducting (SWMS)Document9 pagesURC Insulation For Ducting (SWMS)syed khaja misbhuddinNo ratings yet

- OHS-PR-09-03-F02 HIRA - 001 Mobilization and Preparation of Site Offices Rev. 2021Document21 pagesOHS-PR-09-03-F02 HIRA - 001 Mobilization and Preparation of Site Offices Rev. 2021Jaafar LagayanNo ratings yet

- Job Safety Analysis (JSA) SheetDocument26 pagesJob Safety Analysis (JSA) SheetGMANo ratings yet

- Rare GusterDocument16 pagesRare Gusterreemy sarkNo ratings yet

- Master Hira - 01Document4 pagesMaster Hira - 01Angw BasumataryNo ratings yet

- Sop Changing A Toner CartridgeDocument2 pagesSop Changing A Toner CartridgezaheerNo ratings yet

- RA For HydrotestDocument26 pagesRA For HydrotestSandeep kumarNo ratings yet

- Form E26-Inspection of Earthing Electrodes-SignDocument16 pagesForm E26-Inspection of Earthing Electrodes-SignFinanceAdmin FKSIENo ratings yet

- Lawn Scarifier PDFDocument1 pageLawn Scarifier PDFcityofdarwingisNo ratings yet

- SWP Automotive Parts Washer - AS502Document2 pagesSWP Automotive Parts Washer - AS502Gowtham KishoreNo ratings yet

- Jsa-007 PaintingDocument14 pagesJsa-007 PaintingDamien Monize100% (1)

- JHA - 162 Cutting Breaking Demolition of Existing Asphalt Road Mechanical Excavation For Trench and Removal of Excavated Materials For 10Document11 pagesJHA - 162 Cutting Breaking Demolition of Existing Asphalt Road Mechanical Excavation For Trench and Removal of Excavated Materials For 10M.k.BurhanNo ratings yet

- Hand Tools & Safety PracticesDocument4 pagesHand Tools & Safety PracticesRecel Ann RiveraNo ratings yet

- 2 ConectionDocument2 pages2 ConectionMohammed AdnanNo ratings yet

- HSE-RA-052 Repairs of Concrete Imperfections - Rev 0Document11 pagesHSE-RA-052 Repairs of Concrete Imperfections - Rev 0عمروNo ratings yet

- Work at HeightDocument36 pagesWork at HeightSantosh KolhatkarNo ratings yet

- HSE-RA-029 Straight and Cut Operation - Rev 0Document8 pagesHSE-RA-029 Straight and Cut Operation - Rev 0عمروNo ratings yet

- RAMS MAnual LiftingDocument12 pagesRAMS MAnual LiftingCarlos Immanuel100% (1)

- JSP For SS No. 1 Battery Charging and TestingDocument11 pagesJSP For SS No. 1 Battery Charging and TestingmohammedtofiqahmedNo ratings yet

- 3.gypsum CeilingDocument5 pages3.gypsum Ceilingmohammed sohailNo ratings yet

- R F (H W C) :: Crushing & Screening Operations BDocument5 pagesR F (H W C) :: Crushing & Screening Operations Bkmohamedkeita906No ratings yet

- Intelliview - Baseline Safety Hazard Identification & Risk Assessment - RA001 - Rev 2Document221 pagesIntelliview - Baseline Safety Hazard Identification & Risk Assessment - RA001 - Rev 2raymundwat11No ratings yet

- Shailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentDocument21 pagesShailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentNandini RajNo ratings yet

- Hot Work PermitDocument17 pagesHot Work PermitJunaid KhanNo ratings yet

- Steel YardDocument6 pagesSteel YardAtiq ShaikhNo ratings yet

- Obtain Authorisation Before Overriding or Disabling Safety ControlsDocument9 pagesObtain Authorisation Before Overriding or Disabling Safety ControlsKathleen Faith C. BrionesNo ratings yet

- Heat Stress Awareness Poster (Ezza Team)Document1 pageHeat Stress Awareness Poster (Ezza Team)Mohammad Bin Othman100% (1)

- JHA For BreakingDocument18 pagesJHA For BreakingRaheenNo ratings yet

- Overhead RAMS2Document5 pagesOverhead RAMS2Asad RazaNo ratings yet

- Prevention of Falls Portable LaddersDocument5 pagesPrevention of Falls Portable LaddersRaziolOjiNo ratings yet

- HIRA - MS Staircase ErectionDocument7 pagesHIRA - MS Staircase ErectionRamNo ratings yet

- Fencing and HordingDocument2 pagesFencing and HordingAsad RazaNo ratings yet

- Night WorkDocument3 pagesNight Workkessery koivoguiNo ratings yet

- 30-Hour Construction Safetey - Updated (2017 - 09 - 04 12 - 51 - 06 UTC)Document393 pages30-Hour Construction Safetey - Updated (2017 - 09 - 04 12 - 51 - 06 UTC)nuhNo ratings yet

- Safety Management: Scaffolds and BarricadesDocument25 pagesSafety Management: Scaffolds and BarricadesIrene Pudiquet SilvaniaNo ratings yet

- OHS-PR-09-03-F02 HIRA - 003 Temporary Perimeter Fencing Rev. 2021Document7 pagesOHS-PR-09-03-F02 HIRA - 003 Temporary Perimeter Fencing Rev. 2021MuhammadAsimMuneerNo ratings yet

- SWP Grinder Bench AS520Document1 pageSWP Grinder Bench AS520Tosif AliNo ratings yet

- Risk assessment and register for electrical pole installationDocument8 pagesRisk assessment and register for electrical pole installationshaibaz chafekarNo ratings yet

- Toolbox Talk 12 Banks Men Lifting GearDocument2 pagesToolbox Talk 12 Banks Men Lifting GearSajid HussainNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- Welder SpotDocument1 pageWelder SpotShubham NayakNo ratings yet

- 5.19 JSP ScaffoldDocument4 pages5.19 JSP Scaffoldpoorm879No ratings yet

- CLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityDocument4 pagesCLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityshafieNo ratings yet

- IntroDocument3 pagesIntroBarkat UllahNo ratings yet

- PrefDocument1 pagePrefBarkat UllahNo ratings yet

- 5.19.3 Job Safety Practices Finishing WorksDocument3 pages5.19.3 Job Safety Practices Finishing WorksBarkat UllahNo ratings yet

- R10-H10-KEO-MOM-SU-0026 - TRSP H10 LEED MoM 230509Document18 pagesR10-H10-KEO-MOM-SU-0026 - TRSP H10 LEED MoM 230509Barkat UllahNo ratings yet

- Job Safety Practices Block and Plastering WorksDocument3 pagesJob Safety Practices Block and Plastering WorksBarkat UllahNo ratings yet

- Job Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsDocument4 pagesJob Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsBarkat UllahNo ratings yet

- Design Calculation Sheet: General AssumptionsDocument8 pagesDesign Calculation Sheet: General Assumptionszerohot890% (1)

- Job Safety Practices Backfilling and CompactionDocument3 pagesJob Safety Practices Backfilling and CompactionBarkat UllahNo ratings yet

- Johonson Control Quiz Hand - Protection - QuizDocument1 pageJohonson Control Quiz Hand - Protection - QuizBarkat UllahNo ratings yet

- DPPR-26-01-2020, Removal and Installation of Light Luminaires On External Grid Facade of YAS W Hotel PDFDocument1 pageDPPR-26-01-2020, Removal and Installation of Light Luminaires On External Grid Facade of YAS W Hotel PDFBarkat UllahNo ratings yet

- PPE Safety EssentialsDocument2 pagesPPE Safety EssentialsMas AgusNo ratings yet

- Curriculum Vitae KEVINDocument4 pagesCurriculum Vitae KEVINPT. THE WELDING INDONESIANo ratings yet

- Incident Analysis FormDocument6 pagesIncident Analysis FormMike FranksNo ratings yet

- TR - Motorcycle Small Engine Servicing NC IIDocument162 pagesTR - Motorcycle Small Engine Servicing NC IIClint50% (2)

- Product Name: Ferric Chloride: Material Safety Data SheetDocument4 pagesProduct Name: Ferric Chloride: Material Safety Data SheetocalensNo ratings yet

- Risk assessment for laboratory equipmentDocument7 pagesRisk assessment for laboratory equipmentgullipalli srinivasa raoNo ratings yet

- Personal Protective Equipment (PPE) - AirportsDocument12 pagesPersonal Protective Equipment (PPE) - AirportsThamilaarasan SonOf NathanNo ratings yet

- Manual de Soldadora Chicago ElectricDocument34 pagesManual de Soldadora Chicago ElectricjgpazdNo ratings yet

- Jsa-Hot Oil FlushingDocument2 pagesJsa-Hot Oil Flushingyelsa otrebla100% (5)

- Remove Epoxy & Polyurethane CoatingsDocument2 pagesRemove Epoxy & Polyurethane CoatingsbennetmirkinNo ratings yet

- JHEA Loading and Offloading FENCEDocument13 pagesJHEA Loading and Offloading FENCEStansilous Tatenda NyagomoNo ratings yet

- EX1800-3 TMDocument384 pagesEX1800-3 TMazry_alqadry100% (1)

- 093 Potassium ChlorideDocument6 pages093 Potassium Chlorideeng20072007No ratings yet

- Msds Hardtop XP B JotunDocument13 pagesMsds Hardtop XP B JotuncrysNo ratings yet

- Iosh Ws Sample MaterialDocument6 pagesIosh Ws Sample MaterialElçin ElçinNo ratings yet

- JSA HEMP Well Services Pg11-15Document5 pagesJSA HEMP Well Services Pg11-15Ashok SureshNo ratings yet

- USPL Hydrogen Sulfide Safety ManualDocument5 pagesUSPL Hydrogen Sulfide Safety ManualmuralisunNo ratings yet

- Project Information: Hazard Risk Control MeasureDocument7 pagesProject Information: Hazard Risk Control MeasureAlejandro CampomarNo ratings yet

- Thyssenkrupp Elevator (India) Pvt. LTD.: Safety Inspection Check List New Installation/Modernisation/Quoted RepairsDocument2 pagesThyssenkrupp Elevator (India) Pvt. LTD.: Safety Inspection Check List New Installation/Modernisation/Quoted Repairsgajendrabanshiwal8905No ratings yet

- FDS Clinker CEMEX Rev7 InglesDocument16 pagesFDS Clinker CEMEX Rev7 InglesJackson VuNo ratings yet

- Ammonia Based Refrigeration SystemsDocument19 pagesAmmonia Based Refrigeration SystemsHoainam NguyenNo ratings yet

- SKS System - B - Q4 LSQ5 UNI5 PF5 - V1.0 - ENDocument149 pagesSKS System - B - Q4 LSQ5 UNI5 PF5 - V1.0 - ENJuan ZaragozaNo ratings yet

- OP's & Serv Manual May 13 PDFDocument130 pagesOP's & Serv Manual May 13 PDFYacob Pangihutan100% (1)

- Foam Proportioning - Diesel Tank-Data Book-1 PDFDocument207 pagesFoam Proportioning - Diesel Tank-Data Book-1 PDFMaycol SanchezNo ratings yet

- Front Office Services CompendiumDocument41 pagesFront Office Services CompendiumMari PagxNo ratings yet

- Hoja de SeguridadDocument243 pagesHoja de SeguridadJanny BareiroNo ratings yet

- Tnemec (MSDS) Series 46h-413Document15 pagesTnemec (MSDS) Series 46h-413PubcrawlNo ratings yet

- Safe Use of Power Tools Rev0Document92 pagesSafe Use of Power Tools Rev0Vaibhav Vithoba NaikNo ratings yet

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument8 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationUkesh Wangpa NegiNo ratings yet