Professional Documents

Culture Documents

Job Safety Practices Backfilling and Compaction

Uploaded by

Barkat Ullah0 ratings0% found this document useful (0 votes)

21 views3 pagesThe document outlines the job safety practices for backfilling and compaction work during the construction of a power line project. It identifies three key job tasks - positioning equipment, soil backfilling, and soil compaction. Hazards associated with each task include traffic accidents, equipment failures, collisions, and noise exposure. Controls to minimize risks include inspections, permits, training, PPE, and emergency response procedures. The job safety practices were prepared by an equipment operator, accepted by management, and approved by health and safety officers.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines the job safety practices for backfilling and compaction work during the construction of a power line project. It identifies three key job tasks - positioning equipment, soil backfilling, and soil compaction. Hazards associated with each task include traffic accidents, equipment failures, collisions, and noise exposure. Controls to minimize risks include inspections, permits, training, PPE, and emergency response procedures. The job safety practices were prepared by an equipment operator, accepted by management, and approved by health and safety officers.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views3 pagesJob Safety Practices Backfilling and Compaction

Uploaded by

Barkat UllahThe document outlines the job safety practices for backfilling and compaction work during the construction of a power line project. It identifies three key job tasks - positioning equipment, soil backfilling, and soil compaction. Hazards associated with each task include traffic accidents, equipment failures, collisions, and noise exposure. Controls to minimize risks include inspections, permits, training, PPE, and emergency response procedures. The job safety practices were prepared by an equipment operator, accepted by management, and approved by health and safety officers.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

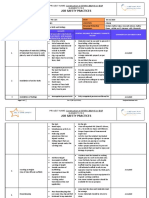

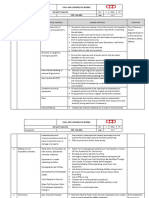

PROJECT NAME: Construction of SPARK 380/115 kV BSP

ELEMENT 5.19.3

JOB SAFETY PRACTICES

DEPARTMENT/DIVISION PE-199 Civil DATE 24/09/2019

EMPLOYEE JOB TITLE Equipment Operator LOCATION Abqaiq

Personal Protective Helmet, Safety Glass, Coverall, Gloves, Safety

JOB/ TASK TITLE Backfilling and compaction

Equipment Shoes, visible vest, Ear Plug

STEPS HAZARDS

IN EACH STEP, WHAT COULD CONTROL REQUIRED TO MINIMIZE/ ELIMINATE

LIST ALL STEPS IN PERFORMING THIS COMMENTS OF JOB OBSERVATION

STEPS # CAUSE INJURY, LOSS DAMAGE, HAZARD

TASK

INTRRUPTION, OR POLUTION?

Traffic hazard Ensure necessary permits from

Collision on other vehicle authorities are secured prior start of

Serious personal injury activity

Struck of moving Early warning sign (plastic barrier & and

Equipment’s Positioning and equipment of personnel had barricade) must be installed

1.

maneuvering at site properly with a safe distance before the

banks man and equipment

Accepted

Only experienced and trained banks

man will assigned to assist and manage

traffic

2. Soil backfilling using dump truck Failure of equipment may Operator and driver shall carry out daily

and skid loader lead to accident and equipment inspection prior to work

injuries Ensure the competency of the operator

Collision by sudden and driver

operation of equipment Operator must carry SAG driving license

may cause serious injury and third party certificates.

or damage to property Reverse alarm of the equipment must

Struck by or hit by moving be working properly

vehicle All equipment must be provided with Accepted

Positioning of equipment trained and competent flagman to

near to the edge of control the movement of equipment to

excavation prevent any incident that may cause

physical injury, damage to property or

even fatality.

Page 1 of 3 Rev.2 [08-April-2019] Projects Business Unit

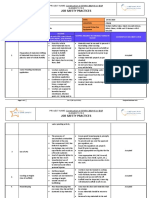

PROJECT NAME: Construction of SPARK 380/115 kV BSP

ELEMENT 5.19.3

JOB SAFETY PRACTICES

Equipment shall position more than 1.5

meter away from the edge of

excavation. Accepted

Incompetent equipment Only competent and certified operator

operator shall operate the roller compactor

Expose to continuous Operator and equipment must be third

vibration and sound party certified

Struck by the moving Equipment checklist must be done prior

equipment to start activity

Property damage during Flagman must be present at all times

Soil Compactor using roller

the operation when activity commence. Accepted

3. compactor, jumper compactor

Mechanical failure of the Ear plug for operator mandatory to

and plate compacter

equipment that leads to prevent any damage to hearing.

accident Ensure that seat springs is in good

Continues operation that condition to reduce vibration.

leads to over fatigue and Implement duty rotation to avoid over

stress fatigue and stress.

Exposed to high noise that

can lead to loss of hearing

Emergency Response and Arrangements

The injured person should be given first aid immediately.

First aid box shall be made available with required medicines in adequate quantity.

Emergency response team should be available at site.

All personnel on site should be aware on site evacuation procedure, location of muster point.

Emergency Numbers shall be posted at different locations.

One vehicle shall be made available for meeting emergency needs.

All employees shall be explained about the provisions of first aid, assembly point and contact number, etc.

JSP Prepared By: Mr. Haitham Abouelella Signature: Date: 24/09/2019

JSP Accepted By: Mr. Mohamed Abdellatif Signature: Date: 24/09/2019

JSP Approved By (SEC / Site): Mr. Ronald Marteja Signature: Date: 24/09/2019

Page 2 of 3 Rev.2 [08-April-2019] Projects Business Unit

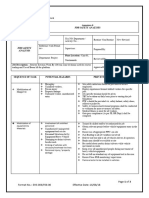

PROJECT NAME: Construction of SPARK 380/115 kV BSP

ELEMENT 5.19.3

JOB SAFETY PRACTICES

JSP Approved By (SEC- PD): Mr. Abdul Majeed Signature: Date: 24/09/2019

Page 3 of 3 Rev.2 [08-April-2019] Projects Business Unit

You might also like

- JSA InsulationDocument8 pagesJSA InsulationOlavilam Prakash100% (3)

- JSA For Pipe Line DemolitionDocument7 pagesJSA For Pipe Line DemolitionSiraj Mohamed Ikbal80% (5)

- Nekisha Taneil - Bikini Body at HomeDocument18 pagesNekisha Taneil - Bikini Body at HomeMegan86% (7)

- Risk Assessment For Kerb Stones, Wheel Stopper and Paving InterlocksDocument4 pagesRisk Assessment For Kerb Stones, Wheel Stopper and Paving Interlockspete chiz91% (22)

- Jsa For Lifting Crane 016Document6 pagesJsa For Lifting Crane 016kiran kumar100% (1)

- Job Safety Analysis Sheet: Operation Concrete Batching PlantDocument2 pagesJob Safety Analysis Sheet: Operation Concrete Batching Plantzabiulla100% (7)

- Yanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of PipelineDocument3 pagesYanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of Pipelinesam mathewNo ratings yet

- 5.19 JSP Electrical Power InstallationDocument4 pages5.19 JSP Electrical Power InstallationDarius DsouzaNo ratings yet

- Fabrication Work Risk AssessmentDocument11 pagesFabrication Work Risk Assessmentstansilous100% (1)

- Excavation Job Safety AnalysisDocument1 pageExcavation Job Safety AnalysisVishal Upadhyay100% (3)

- SS JSP - 063 Testing and Pre-Commissioning WorksDocument9 pagesSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahNo ratings yet

- RA-for Glass Installation 30-04-2022Document6 pagesRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- Jsa For HydrotestDocument10 pagesJsa For HydrotestAnonymous CcGYhZb080% (5)

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyDocument9 pagesJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- AIR CRASH INVESTIGATIONS - THE BOEING 737 MAX DISASTER PART 1 - The Crash of Lion Air Flight 610From EverandAIR CRASH INVESTIGATIONS - THE BOEING 737 MAX DISASTER PART 1 - The Crash of Lion Air Flight 610No ratings yet

- JSA of CentrifugeDocument8 pagesJSA of CentrifugeGajanan NalegaonkarNo ratings yet

- JSP-SPARK-SS-ELEC-032 Installation of 115 KV Cable Terminations and EHV - HV - MV Cables Rev00Document10 pagesJSP-SPARK-SS-ELEC-032 Installation of 115 KV Cable Terminations and EHV - HV - MV Cables Rev00Barkat UllahNo ratings yet

- JSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware HouseDocument9 pagesJSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware Houseradeep100% (1)

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- Job Safety Practices FirefightingDocument16 pagesJob Safety Practices Firefightingmohammed tofiqNo ratings yet

- Jsa D. G. INSTALLATIONDocument5 pagesJsa D. G. INSTALLATIONRavi thokalNo ratings yet

- Risk Assessment For Earth Works (Excavation Back Filling) Require...Document13 pagesRisk Assessment For Earth Works (Excavation Back Filling) Require...khalid khan100% (1)

- Flower Pop Up Card Template ColorDocument0 pagesFlower Pop Up Card Template ColorNguyễn Xuân ThuNo ratings yet

- 1st Aid Training Siemens ContractorDocument11 pages1st Aid Training Siemens ContractorTigor GurningNo ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- Letter: Flight of An Aeroplane With Solid-State PropulsionDocument8 pagesLetter: Flight of An Aeroplane With Solid-State PropulsionMuhammad Faiz BaihaqiNo ratings yet

- Metering Skid ErectionDocument4 pagesMetering Skid ErectionNature BeautiesNo ratings yet

- Jsa For Lifting Activities With Mechanical EquipmentDocument4 pagesJsa For Lifting Activities With Mechanical EquipmentMuhammad Umar GondalNo ratings yet

- SS JSP - 017 Backfilling and CompactionDocument6 pagesSS JSP - 017 Backfilling and CompactionSn Ahsan100% (1)

- JSA Erection StructureDocument11 pagesJSA Erection StructureJAYESH JOSHINo ratings yet

- JSA 03 Gate Entrance Traffic ProposalDocument10 pagesJSA 03 Gate Entrance Traffic Proposalrahul tkNo ratings yet

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- 5.19.3 Job Safety Practices Finishing WorksDocument3 pages5.19.3 Job Safety Practices Finishing WorksBarkat UllahNo ratings yet

- 5.19.3 Job Safety Practices Installation of Anchor Bolts and RailingsDocument3 pages5.19.3 Job Safety Practices Installation of Anchor Bolts and RailingsBarkat UllahNo ratings yet

- 5.19.3 Job Safety Practices Installation of Cable TrayDocument3 pages5.19.3 Job Safety Practices Installation of Cable TrayBarkat UllahNo ratings yet

- 5.19.3 Job Safety Practices Grouting WorksDocument3 pages5.19.3 Job Safety Practices Grouting WorksBarkat UllahNo ratings yet

- Job Safety Practices Block and Plastering WorksDocument3 pagesJob Safety Practices Block and Plastering WorksBarkat UllahNo ratings yet

- Job Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsDocument4 pagesJob Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsBarkat UllahNo ratings yet

- 5.19.3 Job Safety Practices Water Proofing WorksDocument3 pages5.19.3 Job Safety Practices Water Proofing WorksBarkat UllahNo ratings yet

- 5.19.3 Job Safety Practices Installation of Fire Alarm Detection and ProtectionDocument3 pages5.19.3 Job Safety Practices Installation of Fire Alarm Detection and ProtectionBarkat UllahNo ratings yet

- Equipment/reactor Erection Work JsaDocument3 pagesEquipment/reactor Erection Work JsaAKBAR ALINo ratings yet

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- 5.JOB SAFETY ANALYSIS Scaffolding Project Title Installation of Wet Sprinkler System at Main WarehouseDocument6 pages5.JOB SAFETY ANALYSIS Scaffolding Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar GondalNo ratings yet

- Jsa 14Document6 pagesJsa 14Abhi SandiNo ratings yet

- 5.19 JSP ScaffoldDocument4 pages5.19 JSP Scaffoldpoorm879No ratings yet

- JCB - Breaking WorksDocument2 pagesJCB - Breaking WorksKoneti JanardhanaraoNo ratings yet

- Ra ChsDocument12 pagesRa ChsResearcherNo ratings yet

- New JuneDocument6 pagesNew JuneShovon khanNo ratings yet

- Leveling Dressing of Access Way ISOM Tank AreaDocument3 pagesLeveling Dressing of Access Way ISOM Tank AreaMohammed MinhajNo ratings yet

- 5.19 JSP Self Levelling Epoxy Painting ActivityDocument8 pages5.19 JSP Self Levelling Epoxy Painting Activitymuhammad.younisNo ratings yet

- 07 SWMS - Material Loading and UnloadingDocument6 pages07 SWMS - Material Loading and UnloadingPRIYESH . K. PRIYANNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisMuhammad KaleemNo ratings yet

- RA-Containment WorksDocument17 pagesRA-Containment WorkshseNo ratings yet

- Job Step Description of Job Step Potential Hazard Potential Consequences Control Barriers Action Party Recovery BarriersDocument4 pagesJob Step Description of Job Step Potential Hazard Potential Consequences Control Barriers Action Party Recovery Barriers王志伟No ratings yet

- JHSA Water Supply and Sewer InstallationDocument4 pagesJHSA Water Supply and Sewer InstallationAnna JisabaNo ratings yet

- Soft Cut Saw Operations (Generic) : Job Safety AnalysisDocument1 pageSoft Cut Saw Operations (Generic) : Job Safety AnalysisBorislav VulićNo ratings yet

- Hazard Identification, Risk Assessment & Control Measures: NCC/BMRCL/PH-2B/P2/69 (B) /MS-012Document1 pageHazard Identification, Risk Assessment & Control Measures: NCC/BMRCL/PH-2B/P2/69 (B) /MS-012somashekhar. ncclNo ratings yet

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaNo ratings yet

- Risk Assessment - Installation of Back Painted GlassDocument7 pagesRisk Assessment - Installation of Back Painted GlassMuhammad NadeemNo ratings yet

- JSA Additional Lamp Paiton 3Document10 pagesJSA Additional Lamp Paiton 3MarhendraNo ratings yet

- Jsa For Cable LayingDocument2 pagesJsa For Cable LayingSabari VtNo ratings yet

- CLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityDocument4 pagesCLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityshafieNo ratings yet

- IntroDocument3 pagesIntroBarkat UllahNo ratings yet

- PrefDocument1 pagePrefBarkat UllahNo ratings yet

- R10-H10-KEO-MOM-SU-0026 - TRSP H10 LEED MoM 230509Document18 pagesR10-H10-KEO-MOM-SU-0026 - TRSP H10 LEED MoM 230509Barkat UllahNo ratings yet

- Job Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsDocument4 pagesJob Safety Practices Erection of Precast Columns, Beams, TT Slab, Hollow Core Slab, Insulated Wall Panels & Cladding and StairsBarkat UllahNo ratings yet

- Document DISCH & LOADDocument54 pagesDocument DISCH & LOADNur AminudinNo ratings yet

- JTlecture 01 PrintDocument17 pagesJTlecture 01 PrintJae-Soo ChangNo ratings yet

- Distributed Information Systems: Lecture9 - Networkingbasics: Osi Model Basedon Agrawalandsharma, ProspectpressDocument172 pagesDistributed Information Systems: Lecture9 - Networkingbasics: Osi Model Basedon Agrawalandsharma, ProspectpressSaitejNo ratings yet

- Tree of LifeDocument909 pagesTree of LifeMariza D. KabamaruNo ratings yet

- Academic PressureDocument7 pagesAcademic PressureJohn Mark MontillaNo ratings yet

- Kti Word Di Ubah Ke KtiDocument52 pagesKti Word Di Ubah Ke KtiRhaihan Eka SNo ratings yet

- The Story of KeeshDocument4 pagesThe Story of KeeshEmman SanoNo ratings yet

- OkDocument24 pagesOkresp-ectNo ratings yet

- Cod1410 3110Document11 pagesCod1410 3110Tj TalhaNo ratings yet

- Your Electronic Ticket ReceiptDocument2 pagesYour Electronic Ticket ReceiptTuty Alawiyah LubisNo ratings yet

- Armitage, 2015. American Academy of Periodontology Task Force Report On The Update To The 1999 Classification of Periodontal Diseases and ConditionsDocument4 pagesArmitage, 2015. American Academy of Periodontology Task Force Report On The Update To The 1999 Classification of Periodontal Diseases and ConditionsClaudia Antonia Ortiz PeraltaNo ratings yet

- Corona Treatment: Why Is It Necessary?Document6 pagesCorona Treatment: Why Is It Necessary?Taufiq RidhoNo ratings yet

- Dkg-329 User ManualDocument43 pagesDkg-329 User ManualKỹ Sư TđhNo ratings yet

- Benefits of Aviation Brazil 2011 IATADocument28 pagesBenefits of Aviation Brazil 2011 IATAKatia Mantovani MirandaNo ratings yet

- TroxerutinDocument3 pagesTroxerutincarlosNo ratings yet

- KBOB Empfehlung BACnet e 2017 v1.1Document91 pagesKBOB Empfehlung BACnet e 2017 v1.1testNo ratings yet

- FPJ Indore Edition 15 January 2023Document22 pagesFPJ Indore Edition 15 January 2023Abhishekh GuptaNo ratings yet

- Acid Base TestDocument8 pagesAcid Base TestDoris GrimaldiNo ratings yet

- FluidDocument4 pagesFluidt5qhpc2ck9No ratings yet

- Torrico ReinforcedConcrete 01 PDFDocument8 pagesTorrico ReinforcedConcrete 01 PDFNajib A. CasanNo ratings yet

- User's Guide: Modeling Guitar ProcessorDocument28 pagesUser's Guide: Modeling Guitar ProcessorGabriel AlencarNo ratings yet

- Intel® Core™ I3-9100f Processor (6M Cache, Up To 4.20 GHZ) Specificatii Tehnice CompatibilitatiDocument3 pagesIntel® Core™ I3-9100f Processor (6M Cache, Up To 4.20 GHZ) Specificatii Tehnice CompatibilitatiNicu MuțNo ratings yet

- ZF Vector Drive ConceptsDocument48 pagesZF Vector Drive ConceptsConcept of ReasoningNo ratings yet

- Disaster ManagementDocument1 pageDisaster ManagementNISHANT YADAVNo ratings yet

- PEM Self Clinching Nuts CL SeriesDocument12 pagesPEM Self Clinching Nuts CL SeriesAce Industrial SuppliesNo ratings yet

- Liebherr LTM 1035 899617708 Service ManualDocument22 pagesLiebherr LTM 1035 899617708 Service Manualevanthomas080893ofc100% (122)

- Is 3965 PDFDocument13 pagesIs 3965 PDFYuvaraj SathishNo ratings yet