Professional Documents

Culture Documents

5.JOB SAFETY ANALYSIS Scaffolding Project Title Installation of Wet Sprinkler System at Main Warehouse

Uploaded by

Muhammad Umar Gondal0 ratings0% found this document useful (0 votes)

24 views6 pagesThe document provides a job safety analysis for scaffolding erection, modification, and dismantling activities. It lists required personal protective equipment and potential hazards at each step, including improper work area preparation, unauthorized personnel, falling materials, falls from heights, and scaffolding collapse. Recommendations are given to obtain necessary permits, inspect equipment, use flaggers for material transport, wear harnesses, and check scaffolding for safety.

Original Description:

Original Title

5.JOB SAFETY ANALYSIS Scaffolding Project Title Installation of Wet Sprinkler System at Main Warehouse

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a job safety analysis for scaffolding erection, modification, and dismantling activities. It lists required personal protective equipment and potential hazards at each step, including improper work area preparation, unauthorized personnel, falling materials, falls from heights, and scaffolding collapse. Recommendations are given to obtain necessary permits, inspect equipment, use flaggers for material transport, wear harnesses, and check scaffolding for safety.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views6 pages5.JOB SAFETY ANALYSIS Scaffolding Project Title Installation of Wet Sprinkler System at Main Warehouse

Uploaded by

Muhammad Umar GondalThe document provides a job safety analysis for scaffolding erection, modification, and dismantling activities. It lists required personal protective equipment and potential hazards at each step, including improper work area preparation, unauthorized personnel, falling materials, falls from heights, and scaffolding collapse. Recommendations are given to obtain necessary permits, inspect equipment, use flaggers for material transport, wear harnesses, and check scaffolding for safety.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

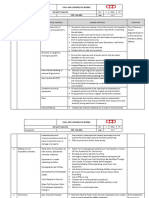

MA’ADEN PHOSPHATE COMPANY

JOB SAFETY ANALYSIS

Location Main Warehouse JSA# RD-03 Page of 1-6

Department (Prepared by) PIU

JSA Title or Job Scaffolding Erection, Modification and Dismantling Activity

Description

Personal Protective Equipment Required Full body harness, Hardhat, Safety Goggles, Hand Gloves, Safety boot, dust

mask, Ear muffs

Project Title : Installation of Wet Sprinkler System at Main Warehouse

Revised JSA Review

Check One New JSA

Revision# Date

BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDATIONS

Area should be clear from any debris

Material must be segregate

Good housekeeping

Adequate access

Ensure area is properly prepared for job

Area must be leveled properly

Provide proper barricades

Improper access Provide Signage

Material scattered All Heavy Equipment must be inspected

Work area preparation Bad housekeeping Plant Equipment and Hand Tools must

Uneven ground be inspected prior to start the work

Oil spillage Follow the color coding system

Damaged & Defective Equipment's Safety induction should be done for new

and Tool person and specific training (fire

watcher, permit receiver)

Approved control measure and

prevention measures and JSA are

discussed with all persons involved of

the work

PTW Obtain Valid Work Permit Obtain Hot Work Permit

All personals must be inducted by MPC

Injury/ damage as a result of Gas test must be done if it is required/

incorrect information for work permit instruction

Unauthorized personal Permit Must Be Obtain from MPC

Miscommunication Permit Issuer and received by

Subcontractor's MPC approved permit

receivers.

Permit must be closed at the end of the

shift

Shifting of scaffolding materials at Incompetent Worker/Operator Pre-inspection of equipment’s prior to

required location by fork lift and truck Struck by reversing truck start the job and obtain MPC sticker

Falling of materials PPE must be provided to all workers

Person could be struck during (Safety Helmet, Safety Glass, Safety

Loading and Unloading of Shoe, Reflective Vest)

scaffolding materials All Heavy Equipment Operator must

Person hit or crushed by have valid SAG license and 3rd party

equipment certificates

Property damage Trained flag man (from MPC) with flag

Traffic inconvenience and reflective vest. Use light batons in

Tip over darkness

Mechanical failure Flagman must be provided at all times

especially while the truck/forklift is

reversing.

Reverse alarm must be function

properly

Vision must be clear

Keep the forks as low as possible

Materials to be secured during

transportation.

Transportation of materials for long

distance and long materials are not

allowed with forklift.

Only authorized personnel are allowed

to this activity.

Never sit, stand and work between two

objects and lifted objects.

Never sit, stand and work under lifted or

suspended loads.

Wedge block must be provided

Signage must be provided in the work

area

Provide revolving danger light in all

transporting vehicle

Equipment third party certified and must

be valid.

Falling hazards Personnel injuries, All platforms shall have complete

fatality guardrails system and toe boards.

Scaffolding collapse Wear full body harness and secure at

Un authorized entry 100 % tie off at all times.

Damaged scaffolding planks Over Do not allow to keep any loose material

load and Tools must be tie off

Working at height Check the scaffolding tag before using

Slipping, Tripping the Scaffolding

Ensure that the person who performing

the job attend working at height training.

Follow the scaffolding tags system

Inspect the permanent platform

Make sure the guard rail and maid rail,

gratings in place on permanent platform

Hard Hat must be secured by Chin

Strap

Provide direct supervision

Personal injury Comply with MAADEN/ scaffolding

Scaffolding Erection, Modification and Falling from height standard.

Dismantling Slip, trip, crush/stuck mandatory PPE must be use

Falling of objects ensure 100% tie off safety harness

Property damage ensure that all the tools tied

Down time Comply with safe work method and

Scaffold collapse practices.

Heat stress Obtain safe manual materials

Miss communication handling/lifting techniques.

Damage material All crews should be trained for work at

height and scaffolding.

Use pulley with manila rope, canvas

buckets in lowering and lifting of small

materials.

No throwing the materials.

Platform free from cluttered materials

and debris

Use only approved tools

Install guardrails and toe board as per

standard

Inspect the erected scaffolding in every

7 days

Check the weather condition (rain,

heavy wind, sand storm, slippery

condition)

Certified scaffold inspector can inspect

the erected scaffold

Maintain scaffold tag system. Scaffold

more than 12 meter height or any

special scaffold need prior submittal of

Engineering drawing and approval.

Scaffolding platform should be erected

without any gap

While scaffolding erection at least put 2

planks and tie off to stand scaffolder

Install life line when there is no any

suitable anchorage point.

Stop work during high wind more than

32 km/h.

Use buddy system.

Inspect scaffold component and before

erection. Comply with scaffold tagging

and inspection system.

Nobody allowed to do any kind of

modification on existing scaffolding

except scaffolders

Certified scaffolders only allowed to

perform the job and should be

monitored by 3rd party certified scaffold

supervisor.

Scaffolder can use leather belt to tie the

tools

Open Holes/Gap must be hard

barricaded with

warning signage and to be inspected by

authorized and competent person.

House Keeping Tripping Hazards Arrange/ stage all the material in neat

Fire orderly manner.

Slip, Trip, Injury Remove damage, banding, crate

Environmental impacts material, nails etc. and dispose of

properly Provide trash receptacles for

work areas means for maintaining.

Keep the working area always clean

Maintain regular housekeeping

throughout the job

Waste must be disposed

Keep the working area always clean

Maintain regular housekeeping

throughout the job

Prepared By:- Date: Jaseem Shadab Alam

Employees

Mohammed Younes.

Participating

Approved By:- Date:

in the

Development

Reviewed By:- Date: Of JSA

HSE Department

SHEM-P-08.10.09-A

You might also like

- JSA For Diesel Filling at Del CampDocument6 pagesJSA For Diesel Filling at Del CampMohammed Minhaj60% (5)

- Jsa For HydrotestDocument10 pagesJsa For HydrotestAnonymous CcGYhZb080% (5)

- Jsa For Work at HeightDocument8 pagesJsa For Work at HeightMuhammad Umar Gondal50% (2)

- Jsa For Lifting Activities With Mechanical EquipmentDocument4 pagesJsa For Lifting Activities With Mechanical EquipmentMuhammad Umar GondalNo ratings yet

- JSA For Scaffolding and Shed ErectionDocument1 pageJSA For Scaffolding and Shed ErectionAnonymous voA5Tb0No ratings yet

- 2.JSA-Electrical Work Installation of Fire Alarm SystemDocument5 pages2.JSA-Electrical Work Installation of Fire Alarm SystemMuhammad Umar Gondal83% (6)

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- Knee Strengthening and Stability Exercises - tcm28-180797Document16 pagesKnee Strengthening and Stability Exercises - tcm28-180797jpgutierrez11100% (1)

- Jsa For Civil WorkDocument6 pagesJsa For Civil WorkMuhammad Umar GondalNo ratings yet

- Jsa For Civil WorkDocument6 pagesJsa For Civil WorkMuhammad Umar GondalNo ratings yet

- 5.19 JSP Electrical Power InstallationDocument4 pages5.19 JSP Electrical Power InstallationDarius DsouzaNo ratings yet

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- Job Safety Analysis Work SheetDocument5 pagesJob Safety Analysis Work SheetMuhammad UsmanNo ratings yet

- Jsa For Choke Valve InstallationDocument9 pagesJsa For Choke Valve InstallationjavithNo ratings yet

- 3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseDocument5 pages3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar Gondal100% (1)

- Risk Assesment Excavation & BackfillingDocument5 pagesRisk Assesment Excavation & BackfillingMuhammad Jamshid100% (3)

- SS JSP - 063 Testing and Pre-Commissioning WorksDocument9 pagesSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahNo ratings yet

- Scaffold Inspection ChecklistDocument2 pagesScaffold Inspection ChecklistMuhammad Umar Gondal100% (3)

- JSA - Foam RefillingDocument13 pagesJSA - Foam RefillingMuhammad Umar GondalNo ratings yet

- JSA For Diesel Filling at Del CampDocument6 pagesJSA For Diesel Filling at Del CampMohammed Ali QaziNo ratings yet

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyDocument9 pagesJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- 1.JSA-Mechanical Work Hydrant InstallationDocument9 pages1.JSA-Mechanical Work Hydrant InstallationMuhammad Umar GondalNo ratings yet

- Jsa-Rp-002 General Excavation & TrenchingDocument16 pagesJsa-Rp-002 General Excavation & Trenchingibaig1970100% (1)

- ARK-JSA - Installation of Form Works, Rebars & Concrete PouringDocument7 pagesARK-JSA - Installation of Form Works, Rebars & Concrete PouringREMYA100% (3)

- Daily JSA - Excavation and Soil CollectionDocument4 pagesDaily JSA - Excavation and Soil Collectionshoaib akhtarNo ratings yet

- Job Safety AnalysisDocument6 pagesJob Safety AnalysisMuhammad TariqNo ratings yet

- Al-Nafay Engeenering Solution Co. BSPM Kasur: Description: Risk Assessment of General Maintenance Work On Bio MassDocument11 pagesAl-Nafay Engeenering Solution Co. BSPM Kasur: Description: Risk Assessment of General Maintenance Work On Bio MassMuhammad Muneeb Naeem NaeemNo ratings yet

- Jsa For Lifting Crane 016Document6 pagesJsa For Lifting Crane 016kiran kumar100% (1)

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970No ratings yet

- Petrofac: Job Safety AnalysisDocument3 pagesPetrofac: Job Safety AnalysisMon Trang Nguyễn100% (5)

- Safety Observation Form: Date: Job: Work Site: Employee You're Observing: Your NameDocument1 pageSafety Observation Form: Date: Job: Work Site: Employee You're Observing: Your NameMuhammad Umar GondalNo ratings yet

- ZATHA Manual (English)Document12 pagesZATHA Manual (English)Rocio Martinez SsandovalNo ratings yet

- Jsa-Rp-004 Form WorksDocument13 pagesJsa-Rp-004 Form Worksibaig1970No ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- Project: Install Generator For Back Up Power Supply For Building 3056 For ShedgumDocument11 pagesProject: Install Generator For Back Up Power Supply For Building 3056 For ShedgumAnonymous voA5Tb0No ratings yet

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- AST JSA Excavations.Document3 pagesAST JSA Excavations.md_rehan_2No ratings yet

- Anatomical Landmarks: Bds Final Professional ExaminationDocument10 pagesAnatomical Landmarks: Bds Final Professional ExaminationmisdduaaNo ratings yet

- JSP-SPARK-SS-ELEC-032 Installation of 115 KV Cable Terminations and EHV - HV - MV Cables Rev00Document10 pagesJSP-SPARK-SS-ELEC-032 Installation of 115 KV Cable Terminations and EHV - HV - MV Cables Rev00Barkat UllahNo ratings yet

- Jsa - ExcavationDocument7 pagesJsa - ExcavationNOOR AISYA AMIRA ZUKAFLI100% (1)

- Job Safety Analysis: Touch Up PaintDocument3 pagesJob Safety Analysis: Touch Up PaintMuhammad Umar GondalNo ratings yet

- JSA - FOR Confined Space-2Document4 pagesJSA - FOR Confined Space-2Muhammad Umar GondalNo ratings yet

- Neha SharmaDocument1 pageNeha SharmaNeha SharmaNo ratings yet

- Code Pink PPT1Document15 pagesCode Pink PPT1PRADIP100% (2)

- 4.JOB SAFETY ANALYSIS Lifting Project Title Installation of Wet Sprinkler System at Main WarehouseDocument8 pages4.JOB SAFETY ANALYSIS Lifting Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar GondalNo ratings yet

- Jsa For Plaster WorkDocument4 pagesJsa For Plaster Workumar KhitabNo ratings yet

- Job Safety Analysis FLOORING AND DADO WORKDocument4 pagesJob Safety Analysis FLOORING AND DADO WORKumar KhitabNo ratings yet

- ISLA JHA Wall ProtectionDocument4 pagesISLA JHA Wall Protectionaasafety06No ratings yet

- ISLA JHA Grouted RiprapDocument3 pagesISLA JHA Grouted Riprapaasafety06No ratings yet

- JSA For Joinery WorkDocument4 pagesJSA For Joinery Workumar KhitabNo ratings yet

- ISLA JHA LiftingDocument1 pageISLA JHA Liftingaasafety06No ratings yet

- Jsa 14Document6 pagesJsa 14Abhi SandiNo ratings yet

- ISLA JHA Site DevelopmentDocument3 pagesISLA JHA Site Developmentaasafety06No ratings yet

- ISLA JHA Removal of BarricadeDocument3 pagesISLA JHA Removal of Barricadeaasafety06No ratings yet

- ISLA JHA For Terminal FenceDocument4 pagesISLA JHA For Terminal Fenceaasafety06No ratings yet

- 2.JOB SAFETY ANALYSIS Preparation of Temporary Yard Facility Project Title Installation of Wet Sprinkler System at Main WarehouseDocument4 pages2.JOB SAFETY ANALYSIS Preparation of Temporary Yard Facility Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar GondalNo ratings yet

- Job Safety Practices Backfilling and CompactionDocument3 pagesJob Safety Practices Backfilling and CompactionBarkat UllahNo ratings yet

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisMuhammad KaleemNo ratings yet

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaNo ratings yet

- JSA For SURGE VESSEL WorkDocument6 pagesJSA For SURGE VESSEL Workathul subashNo ratings yet

- New JuneDocument6 pagesNew JuneShovon khanNo ratings yet

- Jha JOHN DEERE Engine PumpDocument4 pagesJha JOHN DEERE Engine Pumpperquino oasanNo ratings yet

- Jsa-Rp-004 Form WorksDocument13 pagesJsa-Rp-004 Form Worksibaig1970No ratings yet

- Jha Clarke Engine PumpDocument4 pagesJha Clarke Engine Pumpperquino oasanNo ratings yet

- Jha John Deere Fire Engine PumpDocument4 pagesJha John Deere Fire Engine Pumpperquino oasanNo ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970No ratings yet

- Jha Miura Z-Steam Boilers Intallation2Document8 pagesJha Miura Z-Steam Boilers Intallation2perquino oasanNo ratings yet

- ISLA JHA Delivery of Container VanDocument1 pageISLA JHA Delivery of Container Vanaasafety06No ratings yet

- 5.19 JSP Self Levelling Epoxy Painting ActivityDocument8 pages5.19 JSP Self Levelling Epoxy Painting Activitymuhammad.younisNo ratings yet

- JSA - Cast in Place Reinforced Concrete ChamberDocument8 pagesJSA - Cast in Place Reinforced Concrete ChamberSkinhead TvNo ratings yet

- Jsa-Rp-005 Concrete WorksDocument19 pagesJsa-Rp-005 Concrete Worksibaig1970No ratings yet

- SR - No Name Position Signature: Manpower ListDocument2 pagesSR - No Name Position Signature: Manpower ListMuhammad Umar GondalNo ratings yet

- 000.653.F0147 Health, Safety, and Environmental Responsibilities AcknowledgementDocument1 page000.653.F0147 Health, Safety, and Environmental Responsibilities AcknowledgementMuhammad Umar GondalNo ratings yet

- Halliburton Multi Chem Batch Plant Project Safety Inspection Checklist - Angle GrinderDocument1 pageHalliburton Multi Chem Batch Plant Project Safety Inspection Checklist - Angle GrinderMuhammad Umar GondalNo ratings yet

- Instructions For Completing This Form: Form 000.653.F0100 Job Safety AnalysisDocument7 pagesInstructions For Completing This Form: Form 000.653.F0100 Job Safety AnalysisMuhammad Umar Gondal100% (1)

- 000.653.F0100 JSA - Hydrotesting of Fire Water LinesDocument8 pages000.653.F0100 JSA - Hydrotesting of Fire Water LinesMuhammad Umar GondalNo ratings yet

- 2.JOB SAFETY ANALYSIS Preparation of Temporary Yard Facility Project Title Installation of Wet Sprinkler System at Main WarehouseDocument4 pages2.JOB SAFETY ANALYSIS Preparation of Temporary Yard Facility Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar GondalNo ratings yet

- JSA-Replacement of GD, FD & MCP - Rev.00Document7 pagesJSA-Replacement of GD, FD & MCP - Rev.00Muhammad Umar GondalNo ratings yet

- JSA-Burn Pit Automation Project-Rev 02Document9 pagesJSA-Burn Pit Automation Project-Rev 02Muhammad Umar Gondal100% (1)

- JSA Gate Installation - 1 ProjectDocument4 pagesJSA Gate Installation - 1 ProjectMuhammad Umar GondalNo ratings yet

- Daily Toolbox Talk Attendance: Conducted By: Name: Muhammad Umar-HSE Lead SignatureDocument1 pageDaily Toolbox Talk Attendance: Conducted By: Name: Muhammad Umar-HSE Lead SignatureMuhammad Umar GondalNo ratings yet

- LivAgeWell - Integrative Health & Wellness SolutionsDocument1 pageLivAgeWell - Integrative Health & Wellness SolutionsDigital Wellness DirectoryNo ratings yet

- Iec AnpDocument16 pagesIec AnpValarmathiNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument5 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresFaisal RazaNo ratings yet

- (123doc) - De-Thi-Chon-Hsg-Lop-9-Cap-Huyen-Van-Giang-Hung-YenDocument6 pages(123doc) - De-Thi-Chon-Hsg-Lop-9-Cap-Huyen-Van-Giang-Hung-YenKhiêm Trần ThịNo ratings yet

- Barley Water PresentationDocument16 pagesBarley Water Presentationhirenvyas20001137No ratings yet

- Solved Problems: Problem 1Document48 pagesSolved Problems: Problem 1Iwaiz KhanNo ratings yet

- Vere Labs: VL-Delta 8 THC Cartridge 1Document1 pageVere Labs: VL-Delta 8 THC Cartridge 1Michael WalkerNo ratings yet

- Hydrogen Peroxide Ear DropsDocument1 pageHydrogen Peroxide Ear Dropsmr.k.revanth8493No ratings yet

- Self Health Declaration Form: TRV VNSDocument2 pagesSelf Health Declaration Form: TRV VNSVeena ThankachanNo ratings yet

- It Is Easy To Stay Healthy. Please Listen To This Message and Follow My Ideas For Being HealthyDocument2 pagesIt Is Easy To Stay Healthy. Please Listen To This Message and Follow My Ideas For Being HealthyBREINER DAVID GARCA RODRGUEZNo ratings yet

- Agenda Packet 4-12-21 Work SessionDocument23 pagesAgenda Packet 4-12-21 Work SessionSinclair Broadcast Group - EugeneNo ratings yet

- Resume Fall 2022 PDFDocument2 pagesResume Fall 2022 PDFapi-663012445No ratings yet

- Operating and Delivery Room Cases: Data SheetDocument9 pagesOperating and Delivery Room Cases: Data SheetQuijano GpokskieNo ratings yet

- GratitudeDocument4 pagesGratitudeJosue TorresNo ratings yet

- Potential Hazards For Workers in Construction IncludeDocument2 pagesPotential Hazards For Workers in Construction IncluderickyNo ratings yet

- 11 Form Lesson 2 Date: Theme: The Aim: TasksDocument46 pages11 Form Lesson 2 Date: Theme: The Aim: TasksAntonina UzunNo ratings yet

- 1.part 1 3 Option Multiple ChoiceDocument6 pages1.part 1 3 Option Multiple ChoiceStayMarcusNo ratings yet

- COVID 19 Positive Test Report Form: 24 HoursDocument2 pagesCOVID 19 Positive Test Report Form: 24 HoursRaju SambheNo ratings yet

- DoctorsDocument5 pagesDoctorsavNo ratings yet

- Geneva Consensus Declaration EnglishDocument2 pagesGeneva Consensus Declaration EnglishTim BrownNo ratings yet

- Untuk ArtikelDocument25 pagesUntuk ArtikelMuhammad HaritsNo ratings yet

- Prodi Manajemen: e - Jurnal Riset Manajemen Fakultas Ekonomi Dan Bisnis Unisma WebsiteDocument10 pagesProdi Manajemen: e - Jurnal Riset Manajemen Fakultas Ekonomi Dan Bisnis Unisma WebsiteputrifaNo ratings yet

- Eng - OUT SOURCE & Recognised PVT Hosp - To EDPDocument8 pagesEng - OUT SOURCE & Recognised PVT Hosp - To EDPMinerva Medical Treatment Pvt LtdNo ratings yet

- Red Lobster 6272 - PrintInspectionDocument2 pagesRed Lobster 6272 - PrintInspectionBryce AirgoodNo ratings yet

- Resume 2021Document4 pagesResume 2021api-555218722No ratings yet