Professional Documents

Culture Documents

RA-65-R0-T&C of Working in Cradle

Uploaded by

Abrar AhmedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RA-65-R0-T&C of Working in Cradle

Uploaded by

Abrar AhmedCopyright:

Available Formats

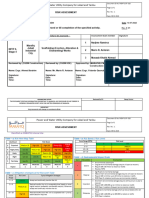

Document No : MSAR-MEP-GEN-

Revision No : 0

Date : 18 March 2018

Page No : Page 1 of 12

Date: 18/03/2018

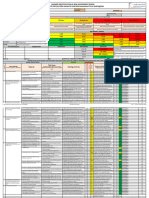

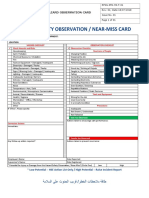

HAZARD IDENDIFICATION AND RISK ASSESSMENT Ref. No: ASEMECO-J1657-RA065-R0

ACTIVITY BY : Al Shirawi Electrical & Mechanical Engineering Co. L.L.C

PROJECT : TIARA UNITED TOWERS

JOB DESCRIPTION: WORKING IN CRADLE

EMERGENCY ACTION: Gathered at Assembling point mention on job.

Whether trained Fire Fighters & trained First-Aid professional Personnel affected

YES NO

available on site? Al Shirawi staff & workers/ Suppliers/ Visitors/ Other company workers.

Points where an injured person may receive treatment: MINOR INJURY: First aid at site SERIOUS INJURY: Hospital

RISK ASSESSMENT DEVELOPED BY: REVIEWED BY THE FOLLOWING PERSONNEL:

No Name Signature Position No Name Signature Position

1 Mohammed Ahmed Ali HSE Officer 1 Wasim Akram Construction Manager

2 Yusuf Raghib Asst. Manager - HSE 2 Ahmed Helmy Project Manager

3 Imran Kamaltheen Sr. Engineer – ELE

Ref. No: ASEMECO-J1657-RA065-R0 18-03-2018 Page |1

Document No : MSAR-MEP-GEN-

Revision No : 0

Date : 18 March 2018

Page No : Page 2 of 12

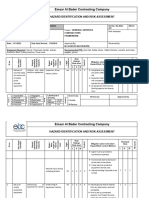

Risk Final

Residual Additio

Rating Risk Legal & Other

Activity Hazard Risk L S Existing Control L S Risk nal L S Ref. Doc.

LxS

LxS Control LxS Req.

(H/M/L) (H/M/L)

(H/M/L)

UAE Ministerial

Resolution/Decision

Eye injuries Maintain

(Directive) No. (32) of

from housekeeping

Flying 1982 concerning Tool Box

blowing Tool Box Talk

particles 3 4 12 (H) 1 3 3 (L) methods and Talk

sand PPE should be worn

and Dust precautionary records

particles on are- Goggles and dust

measures to protect

site. mask.

workers from work

hazards.

UAE Ministerial

Body Injury Maintain Resolution/Decision

Access/Egr Slip, Trip

due to fall housekeeping (Directive) No. (32) of

on the Tool Box Talk 1982 concerning Tool Box

ess to the and Fall

sharp 3 4 12 (H) PPE should be worn 1 3 3(L) methods and Talk

on the

work area edges/ are-Safety Shoe and precautionary records

same level

uneven helmet. measures to protect

surface workers from work

hazards.

UAE Ministerial

Maintain good

Minor Resolution/Decision

housekeeping

Laceration, (Directive) No. (32) of

Proper storage of

Protrudin bruise or 1982 concerning Tool Box

material s in

g/Sharp bodily 2 3 6(M) 1 2 2(L) methods and Talks

designated area

edges injuries precautionary records

PPE should be worn

from sharp measures to protect

are - Hemet safety

edges workers from work

shoe, Gloves.

hazards

Ref. No: ASEMECO-J1657-RA065-R0 18-03-2018 Page |2

Document No : MSAR-MEP-GEN-

Revision No : 0

Date : 18 March 2018

Page No : Page 3 of 12

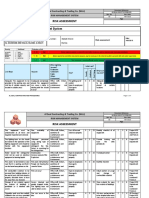

Risk Final

Residual Additio

Rating Risk Legal & Other

Activity Hazard Risk L S Existing Control L S Risk nal L S Ref. Doc.

LxS LxS Control LxS Req.

(H/M/L) (H/M/L) (H/M/L)

Assess load, Individual,

Physical condition

before start activity.

Proper lifting /

handling techniques.

Use proper tools for

lifting & never stand

below facing overhead

to uplift material

Use appropriate

Back accessories to lift

Injury, material such as

Muscular mechanical trolley. UAE Ministerial

or nerves Provide good working Resolution/Decision

injury, area with necessary (Directive) No. (32) of

Induction

Hernia, environmental 1982 concerning

Manual records/

Fracture, 3 4 12(H) arrangement (Proper 1 3 3(L) methods and

handling TBT

Cut and lighting, Ventilation, precautionary

Records

abrasion. protruded nail free measures to protect

Material access / egress, etc.) workers from work

or Provide training, hazards.

Property instruction and

Damage information to

employee.

PPE should be worn

are -safety (shoe,

helmet, coverall, vest,

goggle, hand gloves,

etc.)

Wear cut resistant

hand gloves to handle

sharp edge material

Provision of TBT

Ref. No: ASEMECO-J1657-RA065-R0 18-03-2018 Page |3

Document No : MSAR-MEP-GEN-

Revision No : 0

Date : 18 March 2018

Page No : Page 4 of 12

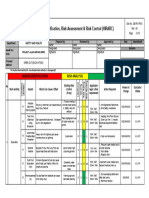

Risk Final

Rating Residual Risk

Additio

Risk Legal & Other

Activity Hazard Risk L S Existing Control L S nal L S Ref. Doc.

LxS Control LxS Req.

LxS

(H/M/L) (H/M/L)

(H/M/L)

Job relevant RA shall

be communicated to

all concern crew prior

to commence the task.

Installed cradle/chain

hoist along with

supports, webbing

Electricity sling, D, Shackles shall

be certified by third

party. UAE Ministerial

Serious

The supervision to Resolution/Decision

personnel

Fall from ensure the load is fully (Directive) No. (32) of

Injuries

Working in height secured, cross checked 1982 concerning Induction

Disability 3 5 15(H) 1 5 5(M) methods and records/

cradle prior to lifting &

shifting. precautionary PTW

Property The load (tiles 1MX3M,

measures to protect

Fall of workers from work

Damaged

materials 6MM, 48KG) shall not

hazards.

from be position above the

height cradle instead

vertically suspend

externally.

Deployment of cradle

operator and

technicians to cradle

as per the certification.

While lifting & shifting

of tiles it shouldn’t be

Ref. No: ASEMECO-J1657-RA065-R0 18-03-2018 Page |4

Document No : MSAR-MEP-GEN-

Revision No : 0

Date : 18 March 2018

Page No : Page 5 of 12

rested on the cradle.

No operation of cradle

when wind speed

>38km/h.

Proper communication

between operatives

and supervision.

Consider the pinch

point and shall not

hold the materials

instead use tag lines at

both the end.

Only certified operator

shall operate

equipment.

Provision of life line

and full body safety

harness shall be used.

Obtain Permit to

Work (PTW), if

applicable.

Isolation of

underneath area by

barricading / signage

/ flagman

Provision of safe

access / egress to the

cradle

No overloading and

loose materials on

the cradle.

Assess load,

Individual, Physical

condition before start

activity.

Crossing from

Ref. No: ASEMECO-J1657-RA065-R0 18-03-2018 Page |5

Document No : MSAR-MEP-GEN-

Revision No : 0

Date : 18 March 2018

Page No : Page 6 of 12

balcony to cradle is

strictly prohibited,

Provide fall

protection (life line

while working close

to edge) at unloading

area and avoid over

reaching.

Use appropriate PPE

i.e. safety (shoe,

helmet, coverall, vest,

goggle, hand gloves,

etc.)

Must use Industrial

socket.

Insulated cables

should be used and

checked regularly for

Burns & any kind of damage.

possible Frequent Inspection UAE Ministerial

shock and tagging system to Resolution/Decision

resulting in be followed. (Directive) No. (32) of Tool Box

lacerations Competent electrician 1982 concerning talks/

Short

& bruising 3 5 15(H) must repair tools. 1 4 4 (L) methods and

Circuit Do not overload Training

to body precautionary

parts. cables. measures to protect Records

Fatality/ Disconnect power workers from work

prior any repair works

Electrocuti hazards.

Fire extinguisher to be

on, shock.

kept handy.

Ref. No: ASEMECO-J1657-RA065-R0 18-03-2018 Page |6

Document No : MSAR-MEP-GEN-

Revision No : 0

Date : 18 March 2018

Page No : Page 7 of 12

Risk Final

Residual Additio

Rating Risk Legal & Other

Activity Hazard Risk L S Existing Control L S Risk nal L S Ref. Doc.

LxS LxS Control

LxS Req.

(H/M/L) (H/M/L) (H/M/L)

Housekeeping to

be done in a

Fire, regular basis.

Waste to be UAE Ministerial

property

collected in the Resolution/Decisio

damage designated area n (Directive) No.

and provided by main (32) of 1982

Housekeep personal Personal contractor. concerning

Tool Box

ing injury Injury 2 4 8(M) Chemical waste 1 3 3(L) methods and

Talk

due to must be disposed precautionary

slip, trip as per main measures to

contractor protect workers

and fall

provision from work

hazard. hazards.

Usage of PPE’s

such as hand

gloves, goggles,

safety shoes,

safety helmet,

mask.

Ref. No: ASEMECO-J1657-RA065-R0 18-03-2018 Page |7

Document No : MSAR-MEP-GEN-

Revision No : 0

Date : 18 March 2018

Page No : Page 8 of 12

Risk Final

Residual Additio

Rating Risk Legal & Other

Activity Hazard Risk L S Existing Control L S Risk nal L S Ref. Doc.

LxS LxS LxS Req.

Control

(H/M/L) (H/M/L) (H/M/L)

Follow Main

contractor

instruction in foggy

day.

In case of heavy fog

stop the work for

temporary basis. Work

UAE Ministerial

Shift changing to timing

Foggy Low Resolution/Decision

avoid fog. can be

weather , (Directive) No. (32) of

Exposure visibility Frequent breaks

change 1982 concerning Tool Box

to extreme Heavy Dehydratio Adequate drinking

2 3 6 (M) 1 3 3 (L) d during 1 3 3 (L) methods and Talk /

weather winds , n Personal water

conditions peak precautionary Training

Hot injury. facility/energy

summer measures to protect

Summer drinks.

workers from work

Usage of safety time

hazards.

goggles, chin strap,

safety helmet,

Mask

Proper clothing to

avoid weather

conditions.

Tool Box Talk

Ref. No: ASEMECO-J1657-RA065-R0 18-03-2018 Page |8

Document No : MSAR-MEP-GEN-

Revision No : 0

Date : 18 March 2018

Page No : Page 9 of 12

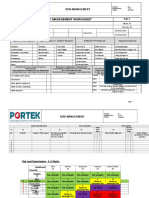

Environmental Aspect & Impact Analysis

Residual

Risk

Risk

Activity Rating Legal & other

Hazard / Aspect Risk / Impact L S Mitigation/ Control L S Rating Ref. Doc.

(Routine) LxS Req.

LxS

H/M/T H/M/T

Waste segregation Federal Law No.

Generation of Land Provision of recycling (24) Of 1999 for the

Induction

waste Contamination 3 4 12(H) General waste collection 1 3 3(L) Protection and

records

Air pollution and disposal (main Development of the

contractor) Environment

Avoid spread of dust.

Dampen dust before

Federal Law No.

cleaning

(24) Of 1999 for the

Dust particles Tool Box Talk Tool box talk

Air pollution 4 4 16(H) 1 2 2(L) Protection and

Use appropriate PPE i.e. records

Development of the

safety (shoe, helmet, Environment

Working in coverall, vest, goggle,

hand gloves… etc.)

Cradle

Minimize the use to

conserve natural Federal Law No.

Usage of electricity resources. (24) Of 1999 for the

Resource Tool box talk

& water 3 4 12(H) Switch off light when not 1 4 4(L) Protection and

depletion records

is use Development of the

Awareness among Environment

employees.

Ref. No: ASEMECO-J1657-RA065-R0 18-03-2018 Page |9

Document No : MSAR-MEP-GEN-

Revision No : 0

Date : 18 March 2018

Page No : Page 10 of 12

Residual

Risk

Activity Risk Legal & other

Hazard / Aspect Risk / Impact L S Rating Mitigation/ Control L S Ref. Doc.

(Routine) Rating Req.

LxS

LxS

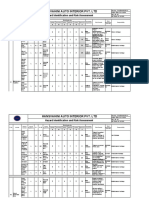

Periodical Maintenance of

power tool

Regular replacement of Federal Law No. (24)

spare parts Of 1999 for the

Air Pollution Toolbox Talk

Noise 4 3 12(H) Use of appropriate PPE 1 3 3(L) Protection and

Records

(Ear Plugs / Ear Muffs, Development of the

mask, shoe, helmet, Environment

coverall, vest, goggle,

hand gloves… etc.)

Waste segregation Federal Law No.

Land

Generation of Provision of recycling (24) Of 1999 for the

Contamination Tool box talk

hazardous waste 3 4 12(H) Hazardous waste 1 3 3(L) Protection and

records

collection and disposal Development of the

Air pollution

(main contractor) Environment

Periodical Maintenance of

the power tool

Working in Regular replacement of Federal Law No.

spare parts (24) Of 1999 for the

cradle Generation of Heat Air Pollution Toolbox Talk

4 4 16(H) Use of appropriate PPE 1 2 2(L) Protection and

Records

(Ear Plugs / Ear Muffs, Development of the

mask, shoe, helmet, Environment

coverall, vest, goggle,

hand gloves… etc.)

Use of Fire Blanket to

protect spark over at

work place

Maintain House-Keeping

Keep adequate and Federal Law No.

appropriate Fire Fighting (24) Of 1999 for the

Smoke Air Pollution Toolbox Talk

4 3 12(H) equipment’s at work 1 3 3(L) Protection and

Records

place Development of the

Use of appropriate PPE Environment

(Ear Plugs / Ear Muffs,

mask, shoe, helmet,

coverall, vest, goggle,

hand gloves… etc.)

Ref. No: ASEMECO-J1657-RA065-R0 18-03-2018 P a g e | 10

Document No : MSAR-MEP-GEN-

Revision No : 0

Date : 18 March 2018

Page No : Page 11 of 12

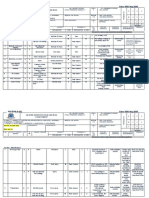

Risk Rating

1-4 – Low - Acceptable|5-10- Medium – Acceptable with controls |11-25 –High – Not Acceptable

RISK RATING = SEVERITY X LIKELIHOOD

LIKELIHOOD Rare Unlikely Possible Likely Almost certain

Remote possibility Could happen but rare Could happen occasionally Could happen often Could happen frequently

SEVERITY (once in a year) (Once in Six month ) (Twice a month ) ( More than twice a month ) (Every day)

1 2 3 4 5

Insignificant Environmental

/ Occupational Health & Acceptable Acceptable Acceptable Acceptable Acceptable with controls

1

Safety effect (Near-Miss 1 2 3 4 5

Reports)

Minor Environmental effect

/Minor injuries/ Minor Acceptable Acceptable Acceptable with controls Acceptable with controls Acceptable with controls

2

property damage(First Aid 2 4 6 8 10

Cases)

Moderate environmental

effect / Injuries with loss Acceptable Acceptable with controls Acceptable with controls Not Acceptable Not Acceptable

3

of less than 3 days 3 6 9 12 15

/Resource wastage

Major environmental

effects which affect marine

life, flora, fauna/ Acceptable Acceptable with controls Not Acceptable Not Acceptable Not Acceptable

4

reportable accidents / 4 8 12 16 20

Partial disability/Major

property damage

Catastrophic

Global issues / resource

depletion / Fatal to Human

Acceptable with controls Acceptable with controls Not Acceptable Not Acceptable Not Acceptable

Life / Fatal to Environment / 5

5 10 15 20 25

Annihilation (Catastrophic

Ecological Destruction)

/Permanent disability

Ref. No: ASEMECO-J1657-RA065-R0 18-03-2018 P a g e | 11

Document No : MSAR-MEP-GEN-

Revision No : 0

Date : 18 March 2018

Page No : Page 12 of 12

Acknowledgements: I Acknowledge that I have read and fully understand the requirements Date:

contained herein. In the event of any variation in the task or procedures used ,a revised

work method statement is required No:

Date Name Signature Date Name Signature

Ref. No: ASEMECO-J1657-RA065-R0 18-03-2018 P a g e | 12

You might also like

- Task Risk AssesmentDocument3 pagesTask Risk Assesmentafsalkareem100% (1)

- Risk Assessment 004 NGSCHDocument2 pagesRisk Assessment 004 NGSCHsheraaz87100% (1)

- OHS-PR-09-03-F02 HIRA - 004 Mobilization and Preparation of Site Offices Rev. 2021Document6 pagesOHS-PR-09-03-F02 HIRA - 004 Mobilization and Preparation of Site Offices Rev. 2021MuhammadAsimMuneerNo ratings yet

- Daily HSE ReportDocument4 pagesDaily HSE ReportSayeed MalikNo ratings yet

- Job Hazard Analysis: Format For JHA WorksheetDocument3 pagesJob Hazard Analysis: Format For JHA WorksheetWaseem AhmadNo ratings yet

- Laying of Road Crossing Duct For Irrigation WorksDocument9 pagesLaying of Road Crossing Duct For Irrigation Workssajin0% (2)

- Risk Assessment KFA - SW15A Bybass LineDocument26 pagesRisk Assessment KFA - SW15A Bybass LineAnandha BharathiNo ratings yet

- OHS-PR-09-03-F02 HIRA - 005 Light Materials and Equipment Loading - Unloading Rev. 2021Document6 pagesOHS-PR-09-03-F02 HIRA - 005 Light Materials and Equipment Loading - Unloading Rev. 2021MuhammadAsimMuneerNo ratings yet

- g11 Hope Module 4Document15 pagesg11 Hope Module 4Nicole Macarat Margin100% (1)

- Natural Cleanising TechniquesDocument88 pagesNatural Cleanising TechniquesPetra JobovaNo ratings yet

- Hazard Identification Risk Assessment Risk Control (HIRARC) - Submain Cable Ladder/tray InstallationDocument2 pagesHazard Identification Risk Assessment Risk Control (HIRARC) - Submain Cable Ladder/tray InstallationYasHie PwincsZaNo ratings yet

- Generic Hirac - Risk Assessment Level 1Document3 pagesGeneric Hirac - Risk Assessment Level 1Anonymous dFaBw2O7KM100% (1)

- Physiology - Nervous System - MCQDocument13 pagesPhysiology - Nervous System - MCQadham100% (1)

- RA 023 Risk Assessment - FireDocument4 pagesRA 023 Risk Assessment - Firethomson100% (4)

- Risk Management WorksheetDocument5 pagesRisk Management WorksheetMuhammad Nur100% (1)

- Risk Assessment Restoration and Modification Works at LS IW28Document20 pagesRisk Assessment Restoration and Modification Works at LS IW28Anandha BharathiNo ratings yet

- Risk Assessment High Strain Dynamic Testing of PilesDocument4 pagesRisk Assessment High Strain Dynamic Testing of PilesYaba88% (8)

- MTA2018-JHA-012 Air Compressor OperationDocument10 pagesMTA2018-JHA-012 Air Compressor OperationKelvin TanNo ratings yet

- Risk Assessment Concrete Cutting - 01Document5 pagesRisk Assessment Concrete Cutting - 01kapsarcNo ratings yet

- Watson's Caritas Processes® As A Framework For Spiritual End of Life CareDocument6 pagesWatson's Caritas Processes® As A Framework For Spiritual End of Life CareMarc Andreo MalalaNo ratings yet

- ER06 BunkeringDocument2 pagesER06 BunkeringNang D. VuNo ratings yet

- Chinese Face ReadingDocument6 pagesChinese Face ReadingGloria GarzaNo ratings yet

- Form 1 LGU Profile PDFDocument6 pagesForm 1 LGU Profile PDFArt Henrhey Bulic50% (2)

- Pranayama Yoga The Ultimate Guide For EveryoneDocument8 pagesPranayama Yoga The Ultimate Guide For Everyoneshiv yogaNo ratings yet

- Hansvahini Auto Interior Pvt. LTD: Hazard Identification and Risk AssessmentDocument6 pagesHansvahini Auto Interior Pvt. LTD: Hazard Identification and Risk AssessmentAtul SharmaNo ratings yet

- Constuction of RCC Telecom Chamber For Telecom WorksDocument14 pagesConstuction of RCC Telecom Chamber For Telecom WorkssajinNo ratings yet

- S-000-1360-0001V - 1 General Specification For PipingDocument28 pagesS-000-1360-0001V - 1 General Specification For PipingLuong AnhNo ratings yet

- Ra-62-R0-Hot WorkDocument18 pagesRa-62-R0-Hot WorkAbrar AhmedNo ratings yet

- PT XXXX Yyyyyy ZZZZZZZZ Form Penilaian Resiko: H&S RepresentativeDocument1 pagePT XXXX Yyyyyy ZZZZZZZZ Form Penilaian Resiko: H&S RepresentativeRifqi Thefandika RisandyNo ratings yet

- Risk Assessment - Rev01 8 4 2020-2Document14 pagesRisk Assessment - Rev01 8 4 2020-2shaibaz chafekar100% (1)

- 8 Flushing and Chemical Cleaning MS-AC-08Document3 pages8 Flushing and Chemical Cleaning MS-AC-08Marwan NizarNo ratings yet

- 01 Hirarc RegisterDocument1 page01 Hirarc RegisterMohd IzNo ratings yet

- 006 - PackingDocument1 page006 - PackingRatu TyasNo ratings yet

- Risk Assessment For Scaffolding Works Rev. 1Document15 pagesRisk Assessment For Scaffolding Works Rev. 1muhammad.younisNo ratings yet

- HIRA - Work at HeightDocument2 pagesHIRA - Work at HeightBhagat DeepakNo ratings yet

- Scaffolding Erection, Alteration and DismantlingDocument21 pagesScaffolding Erection, Alteration and DismantlingshijpulkNo ratings yet

- WI - Risk ManagementDocument4 pagesWI - Risk ManagementAmit PunjabiNo ratings yet

- Ejemplo 8D Nissan 3.2Document1 pageEjemplo 8D Nissan 3.2francisco rafael vizcaino ramirezNo ratings yet

- 3.2 HIRA Register - BlankDocument3 pages3.2 HIRA Register - Blankshobha shelarNo ratings yet

- L3-001-EMG-03 Emergency Incident Management.Document23 pagesL3-001-EMG-03 Emergency Incident Management.Nothing is ImpossibleNo ratings yet

- Manhole Construction - ShoringDocument1 pageManhole Construction - Shoringasr.engineering2023No ratings yet

- RA LBC 007 Risk Assessment Concrete WorksDocument8 pagesRA LBC 007 Risk Assessment Concrete WorksMohammad Al Masa'dehNo ratings yet

- Ra-Me-02 - Fire Fighting SystemDocument13 pagesRa-Me-02 - Fire Fighting Systemasamrat582No ratings yet

- Manhole Construction - ExcavationDocument1 pageManhole Construction - Excavationasr.engineering2023No ratings yet

- EHS ManualDocument78 pagesEHS ManualSagar BahirjeNo ratings yet

- HSE Incident ReportDocument1 pageHSE Incident Reportshifo41No ratings yet

- Crane SafetyDocument9 pagesCrane SafetyAzadh MoosaNo ratings yet

- HIRA TECHNOX Rev 04Document12 pagesHIRA TECHNOX Rev 04jogender kumarNo ratings yet

- HIRA-Underground WaterproofingDocument5 pagesHIRA-Underground WaterproofingBhagat DeepakNo ratings yet

- Pt. Tirta Fresindo Jaya: Plant CianjurDocument6 pagesPt. Tirta Fresindo Jaya: Plant CianjurgonggoprioNo ratings yet

- 22-RA FORM OP-20-01 Camp Engine RepalcmetnDocument1 page22-RA FORM OP-20-01 Camp Engine Repalcmetnelnaas1993No ratings yet

- 017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)Document3 pages017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)siswanto sugengNo ratings yet

- Environmental Risk Assessment Register: - Cause - EffectDocument1 pageEnvironmental Risk Assessment Register: - Cause - EffectTJP SHENo ratings yet

- Accident ReportDocument3 pagesAccident ReportEko SpdNo ratings yet

- RPSG-IMS-HS-F - 01 - Hazard Observation CardDocument2 pagesRPSG-IMS-HS-F - 01 - Hazard Observation CardRocky BisNo ratings yet

- Faculty of Engineering Diponegoro University Document No: Hazard Identification Risk Assessment Control (HIRAC)Document12 pagesFaculty of Engineering Diponegoro University Document No: Hazard Identification Risk Assessment Control (HIRAC)Andhika SetaNo ratings yet

- Hazard Identification, Risk Assessment & Risk Control Register - Form No. 02Document1 pageHazard Identification, Risk Assessment & Risk Control Register - Form No. 02gkNo ratings yet

- GRP-MAS-FOR-008-01 Road CleaningDocument3 pagesGRP-MAS-FOR-008-01 Road CleaningSifiso MayisaNo ratings yet

- Copy Risk Assessment KFA - IWPTDocument19 pagesCopy Risk Assessment KFA - IWPTAnandha BharathiNo ratings yet

- Risk Assesment - FormatDocument3 pagesRisk Assesment - FormatSIBINNo ratings yet

- Grand Toolbox (Monthly)Document3 pagesGrand Toolbox (Monthly)Suresh Praba PNo ratings yet

- Environmental Aspect / Impact Register - Form No. 01: Engineering & Construction Co. L.L.CDocument1 pageEnvironmental Aspect / Impact Register - Form No. 01: Engineering & Construction Co. L.L.CgkNo ratings yet

- RA - ExcavationDocument3 pagesRA - ExcavationKlizman AmineNo ratings yet

- Auxiliary Machinery Operations (Amo 0001-0037)Document60 pagesAuxiliary Machinery Operations (Amo 0001-0037)SonNo ratings yet

- IM-CO-FO-88 SUMMARY INSPECTION REPORT OF THE RIG PIONEER 53 - CANACOL OCT 2018 - RevDocument28 pagesIM-CO-FO-88 SUMMARY INSPECTION REPORT OF THE RIG PIONEER 53 - CANACOL OCT 2018 - RevJUAN JOSE VESGA RUEDANo ratings yet

- Report of Repair Works and Modification in The Pump 48-P-0-0200 24 12 2018Document6 pagesReport of Repair Works and Modification in The Pump 48-P-0-0200 24 12 2018Jalal NorriNo ratings yet

- Nutrition For Preschoolers (NTLC) WordDocument6 pagesNutrition For Preschoolers (NTLC) WordKeerthana VNo ratings yet

- Dissertation PDFDocument253 pagesDissertation PDFsunkissedchiffonNo ratings yet

- Labour WelfareDocument10 pagesLabour WelfareSakshiNo ratings yet

- Case Study,,,,,,pneumoniaDocument52 pagesCase Study,,,,,,pneumoniaJaillah Reigne Cura0% (1)

- Medical and Pharmacy Abbreviations (Sig Codes) : Abbreviation Meaning(s) CategoryDocument3 pagesMedical and Pharmacy Abbreviations (Sig Codes) : Abbreviation Meaning(s) Categoryscope 3901No ratings yet

- Jurnal Gingivitis Vivian 190631174Document5 pagesJurnal Gingivitis Vivian 190631174VivianNo ratings yet

- Unit 4Document3 pagesUnit 4Lê Thị Ngọc AnhNo ratings yet

- MTC Synergy SDN BHD - May 2021 ProfileDocument19 pagesMTC Synergy SDN BHD - May 2021 Profilemuhamadrafie1975No ratings yet

- Let'S Do This!: Activity 1 Lifestyle EvaluationDocument2 pagesLet'S Do This!: Activity 1 Lifestyle EvaluationracmaNo ratings yet

- Akkermansia Wikipedia Page Safari - Sep 18 2022Document1 pageAkkermansia Wikipedia Page Safari - Sep 18 2022Rodrigo FerreiraNo ratings yet

- Trends1 Aio VG MP AkDocument8 pagesTrends1 Aio VG MP Akelisabethar0721No ratings yet

- Growth Performance, Intestinal Morphology and Nonspecific Immunity Response of Nile TilapiaDocument39 pagesGrowth Performance, Intestinal Morphology and Nonspecific Immunity Response of Nile Tilapialaraib fatimaNo ratings yet

- Folic Acid: Bda Food Fact SheetDocument2 pagesFolic Acid: Bda Food Fact SheetEshan Atharizz SetiawanNo ratings yet

- CV - Abdullah Shafei 2022Document1 pageCV - Abdullah Shafei 2022abdullah shafeiNo ratings yet

- Rule V - Operations and Structure of BucorDocument52 pagesRule V - Operations and Structure of BucorAlper PugoyNo ratings yet

- Sylvia Lavin - Architecture in Extremis PDFDocument12 pagesSylvia Lavin - Architecture in Extremis PDFXiaoying Ma100% (1)

- Petrocchi & CheliDocument16 pagesPetrocchi & ChelimarianalfernNo ratings yet

- Abuse Project Rubric Unit 2Document2 pagesAbuse Project Rubric Unit 2api-497493358100% (1)

- CF Host Dept List 2023 24 v12Document111 pagesCF Host Dept List 2023 24 v12Antal Dorin CristianNo ratings yet

- Advancement in The Recently Development of Sublingual Tablet For Various Diseases A ReviewDocument7 pagesAdvancement in The Recently Development of Sublingual Tablet For Various Diseases A ReviewEditor IJTSRDNo ratings yet

- University of Central Punjab: Course Title: Performance StrategyDocument4 pagesUniversity of Central Punjab: Course Title: Performance StrategyAyesha HamidNo ratings yet

- Introduction To Survey Methods: Prof. Dr. John T. ArokiasamyDocument41 pagesIntroduction To Survey Methods: Prof. Dr. John T. ArokiasamyThulasi tootsieNo ratings yet

- 350 SDS 22feb2023Document8 pages350 SDS 22feb2023Ying CeNo ratings yet