Professional Documents

Culture Documents

Hybrid Completion Argentina Longest Lateral CH-9 1 2015

Uploaded by

Gabriela Cuencas BCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hybrid Completion Argentina Longest Lateral CH-9 1 2015

Uploaded by

Gabriela Cuencas BCopyright:

Available Formats

| bakerhughes.

com

CASE HISTORY

Hybrid

Multistage Completion Fractured Record-setting

Lateral

Length in Argentina, Improved Efficiency

Location:

Neuquén,

Argentina

Results

■ Fractured the longest shale lateral

in Argentina

■ Completed 28 stages with zero

HSE incidents

■ Eliminated post-frac intervention

requirements and minimized pump times

and water requirements in the lower

13 stages

■ Accelerated completion times with

continuous, round-the-clock operations

Challenges

■ Extended-reach horizontal application

with a 2 016-m lateral

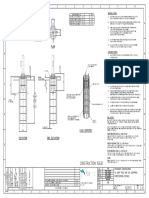

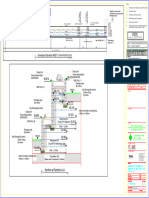

An operator in Argentina drilled the first extended strategically placed in the lower section of the well ■ Constraints around mobilization logistics

lateral well in the Vaca Muerta formation—reaching to enable stimulation without the need for post- and horizontal reach capabilities of available

a total measured depth of 5 332 m (17,493 ft) with fracturing through-tubing milling operations. IN- coiled tubing units

an extension of 2 016 m (6,614 ft)— and called on Tallic frac balls were used because they ■ Treat stages in a record-setting lateral

Baker Hughes to deliver a completion solution that disintegrate downhole to assure flow. In only 41 length as efficiently as possible

could efficiently treat 28 stages. But the availability hours, a total of 2 131 884 kg (4.7 million lb) of ■ Effectively cement the liner with a double

of coiled tubing, which is typically used to run milling proppant was delivered into the lower section of casing diameter (5 in. to XVOR 4.5 in.)

tools to remove frac plugs after plug-and-perf style the well via a continuous pumping operation.

completions, was a concern. Because no pump-downs were required for the first Baker Hughes solution

13 stages, water usage was reduced by 625 m3. ■ Worked with operator to design and deploy

To address this extended-reach application,

a hybrid completion solution

Baker Hughes designed a custom hybrid completion ■ Cemented only the section of the

After the bottom zones of the well were fractured,

solution consisting of FracPoint™ ball-activated

the Baker Hughes team fractured the upper section well designed for a plug-and-perf

sleeves with IN-Tallic™ disintegrating frac balls, and

of the well using 17 QUIK Drill composite plugs to style completion

QUIK Drill™ composite frac plugs.

create reliable stage isolation. After the final stages ■ Installed 13 FracPoint ball-activated sleeves

First, the top section of the well, designed for a plug- were fractured, the plugs were quickly drilled out with openhole packers to create stage

and-perf-style completion, was successfully using a single mill dressed with Glyphaloy™ isolation in the lower section of the well

cemented, keeping the casing clean and free of Advanced Milling Technology (AMT™) carbide, ■ Ran and set 17 QUIK Drill composite frac

densified fluids. Advanced cementing capabilities which features an engineered shape that has been plugs in the upper section of the well

and thorough planning and design helped to avoid optimized for high performance and extreme ■ Used Glyphaloy mill to remove all plugs

slurry contamination and settling in the upper durability. ■ Coordinated 24-hour, continuous operations

section of the well, while leaving the lower section of

This custom hybrid solution helped optimize

the well in an openhole state for the FracPoint

treatment efficiency and effectiveness at all lateral

sleeves.

depths, taking into consideration the operator’s

Leveraging torque and drag modeling, the Baker costs and equipment constraints. At the time of the

Hughes team successfully installed a total of 13 job, the treatment of the 2 016 m lateral marked the

FracPoint ball-activated sleeves, which were longest fractured horizontal well in Argentina.

Disclaimer of Liability: This information is provided for general information purposes only and is believed to be accurate as of the date hereof; however, Baker Hughes Incorporated and its affiliates do not make any warranties or representations of any kind regarding

the information and disclaim all express and implied warranties or representations to the fullest extent permissible by law, including those of merchantability, fitness for a particular purpose or use, title, non-infringement, accuracy, correctness or completeness of the

information provided herein. All information is furnished “as is” and without any license to distribute. The user agrees to assume all liabilities related to the use of or reliance on such information. BAKER HUGHES INCORPORATED AND ITS AFFILIATES SHALL NOT

BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, PUNITIVE, EXEMPLARY OR CONSEQUENTIAL DAMAGES FROM ANY CAUSE WHATSOEVER INCLUDING BUT NOT LIMITED TO ITS NEGLIGENCE.

© 2015 Baker Hughes Incorporated. All rights reserved. 43479 09/31/15

You might also like

- PFMEA - StampingDocument8 pagesPFMEA - StampingNimesh Mehta67% (6)

- ACS AMI FacilitatorDocument21 pagesACS AMI FacilitatorPaul Zantua57% (7)

- Winidea Build 9.17.172.0.109652 Test Report: Renesas Rh850Document2 pagesWinidea Build 9.17.172.0.109652 Test Report: Renesas Rh850mohammedNo ratings yet

- GM 1927 30 BIQS Assessment Self Assessment 2019Document20 pagesGM 1927 30 BIQS Assessment Self Assessment 2019sahil sagarNo ratings yet

- Sample Project ReportDocument24 pagesSample Project ReportPariniti Gupta100% (1)

- Planets in NakshatrasDocument6 pagesPlanets in Nakshatrasmurthyy55% (11)

- EnsurSet Offshore Malaysia ExperienceDocument2 pagesEnsurSet Offshore Malaysia ExperienceRoman RyazanovNo ratings yet

- Quality Improvement Activity - June2018 - May 2019Document1 pageQuality Improvement Activity - June2018 - May 2019KumaravelNo ratings yet

- Pdu para GdsDocument9 pagesPdu para Gdsjonathan23094530No ratings yet

- QFD TesisDocument1 pageQFD TesisGabriel VazquezNo ratings yet

- Series: Leak Detector For Manual Test BenchesDocument2 pagesSeries: Leak Detector For Manual Test BenchesDrikus OdendaalNo ratings yet

- ICPprivilegesDocument5 pagesICPprivilegesBUREAU VERITASNo ratings yet

- Section 4 - Security of Netwroks, Systems, Applications and DataDocument2 pagesSection 4 - Security of Netwroks, Systems, Applications and Datafadhil100% (1)

- Tests: Master Student MapDocument24 pagesTests: Master Student MapanhkhoixmNo ratings yet

- 7th Question PaperDocument21 pages7th Question PaperNaman KabadiNo ratings yet

- 3.1 HiracDocument2 pages3.1 Hiractejpal singhNo ratings yet

- F520Document2 pagesF520Marcos AldrovandiNo ratings yet

- Senr3918 3208 in Frame OverhaulDocument2 pagesSenr3918 3208 in Frame Overhaulmohamed ghoneemNo ratings yet

- Industrial Network Security Monitoring - ICS - NSM - POSTERDocument2 pagesIndustrial Network Security Monitoring - ICS - NSM - POSTERAni MNo ratings yet

- Practical Problem SolvingDocument1 pagePractical Problem SolvingHaris PrayogoNo ratings yet

- Practical Problem Solving (PPS) : S M A R TDocument1 pagePractical Problem Solving (PPS) : S M A R TlmqasemNo ratings yet

- Teoría Completa PDFDocument10 pagesTeoría Completa PDFIñigoNo ratings yet

- Skill Matrix 2023Document23 pagesSkill Matrix 2023Bondville ComplienceNo ratings yet

- RS 1000 RS 1500: Back-UPS Back-UPSDocument2 pagesRS 1000 RS 1500: Back-UPS Back-UPSnesadNo ratings yet

- Construction Issue: General NotesDocument1 pageConstruction Issue: General NotesShokry AlkissyNo ratings yet

- Wudpro Flyer 2020 PDFDocument7 pagesWudpro Flyer 2020 PDFPuneeth RajNo ratings yet

- Edn568 - Graphic OrganiserDocument1 pageEdn568 - Graphic Organiserapi-370174305No ratings yet

- MAHLER Process - Descr - Flow - N2 - PSADocument1 pageMAHLER Process - Descr - Flow - N2 - PSAPatrick MalmbergNo ratings yet

- Facts Sheet For TenacityDocument2 pagesFacts Sheet For TenacityRamly MyzharNo ratings yet

- PFMEA - MachiningDocument14 pagesPFMEA - Machiningmani317100% (1)

- Product Data Sheet: Motor-Mechanism - MT250 - 110..130 V AC 50/60HzDocument1 pageProduct Data Sheet: Motor-Mechanism - MT250 - 110..130 V AC 50/60HzAlexhanderNo ratings yet

- QFD For Gas OvenDocument1 pageQFD For Gas OvenEngr Jehangir Khan100% (1)

- For PresentationDocument5 pagesFor PresentationZaki AnwerNo ratings yet

- AMTED107013EN (Print)Document2 pagesAMTED107013EN (Print)Luis EduardoNo ratings yet

- Tapered-Pump CHDocument1 pageTapered-Pump CHMohamed MostafaNo ratings yet

- 05 05 01 GEM HSE HSRA Risk Assessment - Rev.0Document42 pages05 05 01 GEM HSE HSRA Risk Assessment - Rev.0Holly SmithNo ratings yet

- GENOS M e E - 15a - 300 - Aug2019Document11 pagesGENOS M e E - 15a - 300 - Aug2019cosminNo ratings yet

- For Approval: LegendDocument1 pageFor Approval: LegendBalrajNo ratings yet

- For Approval: LegendDocument1 pageFor Approval: LegendBalrajNo ratings yet

- Well Log Kuliah 1-8Document227 pagesWell Log Kuliah 1-8Adri SyawalNo ratings yet

- M42-5 Brochure EN..concret Pump PutzmeisterDocument9 pagesM42-5 Brochure EN..concret Pump PutzmeisterJuli Nugroho SuSantoNo ratings yet

- Series: Compact Leak Detector With Continuous FlowDocument2 pagesSeries: Compact Leak Detector With Continuous FlowDrikus OdendaalNo ratings yet

- Audit ProcedureDocument1 pageAudit Procedurejay thakkarNo ratings yet

- BIQS AssessmentDocument16 pagesBIQS AssessmentSabda ZentenoNo ratings yet

- ?o File:///storage/emulated/0/download/manual 0303 eDocument32 pages?o File:///storage/emulated/0/download/manual 0303 eAbdulkarim MussaNo ratings yet

- Series: Compact Leak Detector For Production TestingDocument2 pagesSeries: Compact Leak Detector For Production TestingDrikus OdendaalNo ratings yet

- PLC Panasonic FPX IngDocument20 pagesPLC Panasonic FPX IngstgpereiraNo ratings yet

- 14 - Integration Management - 2013 V5Document5 pages14 - Integration Management - 2013 V5DougNo ratings yet

- X1-Hybrid 3KW-5KW: Quick Installation GuideDocument2 pagesX1-Hybrid 3KW-5KW: Quick Installation GuidePMV DeptNo ratings yet

- DFMEA - Carrier Seal-Hood ODS - PT00138273Document4 pagesDFMEA - Carrier Seal-Hood ODS - PT00138273Laboratorio MapremecNo ratings yet

- Sais Short Air 3100-3300-5300-6300 EuDocument4 pagesSais Short Air 3100-3300-5300-6300 EuAli DiabNo ratings yet

- k3p 07AS SheetDocument2 pagesk3p 07AS SheetsoniNo ratings yet

- 9869 0135 01b - Robbins - 73-Series - Technical - Specification - EnglishDocument5 pages9869 0135 01b - Robbins - 73-Series - Technical - Specification - EnglishBhargav PagadalaNo ratings yet

- Training Need AnalysisDocument18 pagesTraining Need AnalysisSanjeet SinghNo ratings yet

- Typical Laboratory VFX Submittal REV BDocument48 pagesTypical Laboratory VFX Submittal REV BERIK FLOREZ MALDONADONo ratings yet

- KLAUS G61 M - 2 Level Dependent StackDocument4 pagesKLAUS G61 M - 2 Level Dependent StackOrianaFernandezNo ratings yet

- Project Responsible MatrixDocument1 pageProject Responsible Matrixli xian0% (1)

- A5E34928958-01en PS2HART FBDocument2 pagesA5E34928958-01en PS2HART FBesutjiadiNo ratings yet

- Polamco Product Finder PDFDocument1 pagePolamco Product Finder PDFpaula09No ratings yet

- Tosvert vfnc3 PDFDocument254 pagesTosvert vfnc3 PDFKukuh Tak TergoyahkanNo ratings yet

- Training MatrixDocument2 pagesTraining MatrixAmeerHamzaWarraichNo ratings yet

- AMG Electrical Schematic 08Document1 pageAMG Electrical Schematic 08cristian2340No ratings yet

- Problems SetDocument10 pagesProblems SetSajith KurianNo ratings yet

- API 510 Study GuideDocument3 pagesAPI 510 Study GuidedanikakaNo ratings yet

- Series 70 Overshots: Instruction Manual 1070Document8 pagesSeries 70 Overshots: Instruction Manual 1070Juan Carlos Perilla MartinNo ratings yet

- Logiq e BT11 User Guide PDFDocument192 pagesLogiq e BT11 User Guide PDFprofesorbartolomeo0% (1)

- SECTION 03310-1 Portland Cement Rev 1Document10 pagesSECTION 03310-1 Portland Cement Rev 1Abdalrahman AntariNo ratings yet

- Benefits of SwimmingDocument3 pagesBenefits of Swimmingaybi pearlNo ratings yet

- IR Beam LaunchingDocument2 pagesIR Beam LaunchingalfredoNo ratings yet

- PT3 Practices EssayDocument61 pagesPT3 Practices EssayGolden Fingers100% (3)

- Odontektomi Bahan Diskusi Od KoasDocument51 pagesOdontektomi Bahan Diskusi Od Koaspanjidrg100% (1)

- SyllabusDocument2 pagesSyllabusPrakash KumarNo ratings yet

- List of Grocery Importers in Austria Europe PDF FreeDocument11 pagesList of Grocery Importers in Austria Europe PDF FreeEmpy SumardiNo ratings yet

- Torts and Damages Lecture NotesDocument42 pagesTorts and Damages Lecture NotesMaeNo ratings yet

- Food Safety and Standards Act, 2006Document23 pagesFood Safety and Standards Act, 2006Deepam TandonNo ratings yet

- "Unadulterated" - The Organic and Ethnic - For Vegetarians and Non-VegetariansDocument21 pages"Unadulterated" - The Organic and Ethnic - For Vegetarians and Non-VegetariansShilpa PatilNo ratings yet

- WWW CDC Gov/malaria/about/biologyDocument2 pagesWWW CDC Gov/malaria/about/biologyFiik FiikNo ratings yet

- Judicial Affidavit - P:CPL PolutanDocument2 pagesJudicial Affidavit - P:CPL PolutanRain HofileñaNo ratings yet

- Worksheet. 5. Sexual Reproduction in PlantDocument4 pagesWorksheet. 5. Sexual Reproduction in PlantLeonita SwandjajaNo ratings yet

- Substation Off Line and Hot Line CommissioningDocument3 pagesSubstation Off Line and Hot Line CommissioningMohammad JawadNo ratings yet

- Korean Wellhead KWM-2014-Revision0Document20 pagesKorean Wellhead KWM-2014-Revision0DrakkarNo ratings yet

- MMFSLDocument9 pagesMMFSLsachin11hahaNo ratings yet

- FM 200Document3 pagesFM 200raviNo ratings yet

- OFLOX-OZ TabletsDocument30 pagesOFLOX-OZ TabletsSilvio BarbosaNo ratings yet

- Banana Disease 2 PDFDocument4 pagesBanana Disease 2 PDFAlimohammad YavariNo ratings yet

- Med Mantra Hospital Management Solution 0813 1Document4 pagesMed Mantra Hospital Management Solution 0813 1vvr_9No ratings yet

- Nutrition AssessmentDocument7 pagesNutrition AssessmentJoyce VitalNo ratings yet

- Cation Ion Exchange CapacityDocument1 pageCation Ion Exchange CapacityGopal MallickNo ratings yet

- Blood Stasis and What Does That MeanDocument2 pagesBlood Stasis and What Does That MeanCarl MacCordNo ratings yet