Professional Documents

Culture Documents

Hes B - 041-03

Uploaded by

Preetam KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hes B - 041-03

Uploaded by

Preetam KumarCopyright:

Available Formats

Date of Issue 2003/09/15

Product HES Office

HES

HES

B 041-03

C REV7

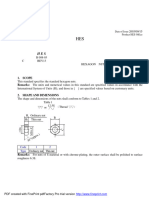

FLANGED HEAD BOLTS (SH TYPE)

1. SCOPE

This standard specifies the standard flanged head bolt of SH type (*1) (hereinafter referred to as "the

bolt").

Note (*1): The SH type refers to the small-head type flanged bolt.

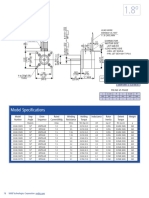

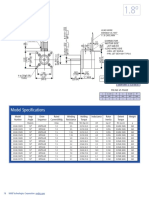

2. SHAPE AND DIMENSIONS

Shape and dimensions of bolt shall conform to Fig. 1 and Table 1.

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

(*2)

6.3S

(

Thread

3.2S

)

5.5 + 0.15 L unit: mm

Approx. pitch dia.

1 + 0.15

0

8 -0.2

M6 x 1.0

.

in

SR 18 +2P

M

10 A

25

to 0

0.

1 5

11.0 Max.

11.0)

10.0Min.

(*3)

(

A Approx.2

6.8Max.

15o to 20o HES A 3003

(as-rolled end)

a b +0.008

8.87

0

1.5 Min.

o

1 Max.

a-b=0.3 Max.

SECTION AA

Fig. 1

Table 1 Unit: mm

L

Reference Dimension Tolerance

8, 10, 12, (14), 16, (18), 20, (22), 25, 28, 32, 35, 40, 45 Shall conform

50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100, 110, 115, 125, 140 to HES B 100.

Notes:

(*2) The thread end face is excluded.

(*3) This dimension is the fillet transition diameter where the underhead fillet contacts the bearing

surface.

Remarks:

1. The L dimensions in ( ) should not be used, if possible.

2. Only the bolt with pitch diameter body shall apply.

3. Bolts with S + X1 > L shall have continuous-thread studs.

X1 S

L

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

3. MATERIAL AND MECHANICAL PROPERTIES

Materials and mechanical properties of the bolts shall conform to Table 2.

Table 2

Code 0

Strength Division 8.8

Shall conform to HES D 3211 (MECHANICAL

Mechanical Properties

PROPERTIES OF STEEL BOLTS AND SCREWS).

Shall conform to HES A 1002 (SELECTION REFERENCE

Material

OF STEEL BOLT MATERIALS).

Remarks: A fracture of bolt shall occur in the threads or body, not at the junction of head and body.

4. SURFACE TREATMENT

Surface treatment on bolts shall conform to Table 3.

Table 3

Code 0 2 7 (*4)

Surface Treatment MFZn2-B MFCr2 MFZn2-K

Note (*4): Use should be avoided, if possible

Remarks: Plating shall conform to HES D 2003 {ELECTROPLATING (FOR CORROSION

PREVENTION, RUST PREVENTION AND DECORATION)}.

5. THREADS

a) Threads shall conform to HES A 1003 (SCREW THREADS) and accuracy shall be 6g.

b) After plating threads, the limit of sizes of the major diameter, pitch diameter, and minor diameter

shall not transgress the maximum material limits for position h. However, the dimensions before plating

shall be within the specified value of 6g.

c) When the screw is threaded up to under the head, the distance from under the head to the threaded end

(X1) shall be three ridges maximum including X.

6. INSPECTION

Bolt inspection shall conform to HES D 3211 (MECHANICAL PROPERTIES OF STEEL BOLTS AND

SCREWS).

7. APPEARANCE

a) The top of the bolt head shall be free from unsightly shear marks.

b) The bolt appearance shall comply with the surface roughness specified in Section 2. Further, it

shall be free from quench cracks, as well as defects affecting functions, such as flaws, flashes, and burrs.

8. DESIGNATION AND PART NUMBER

Designation: BOLT, FLANGE SH d x L

Example: BOLT, FLANGE SH 6 x 20

Part number:

9 6 0 0 1 0 6 0

L Surface treatment

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

Remarks:

1. When d or L contains fewer digits than specified, 0 or 00 shall be added before the numeral code.

Example: L = 20 mm 020

2. Even if the eleventh and twelfth digits are "-00", they shall not be omitted.

Example: (BOLT, FLANGE SH 6 x 20 MFZn2-B)

96001-06020-00

Must not be omitted.

9. DRAWING INDICATION

When applying parts covered in this standard, no part drawing is required.

Applicable standards

HES A 1002-01 Selection reference of steel bolt materials

HES A 1003-03 SCREW THREADS

HES A 3003-99 CHAMFER OF THREAD END

HES B 100-99A DIMENSIONAL TOLERANCES FOR THREADED FASTENERS

HES D 2003-03 ELECTROPLATING (FOR CORROSION PREVENTION, RUST PREVENTION

AND DECORATION)

HES D 3211-99A MECHANICAL PROPERTIES OF STEEL BOLTS AND SCREWS

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

Revision Record

Year Rec Issue NewsNo Prep Conf Appvl Remarks

78 EST 78/09/05 78012 Shimazaki Shimane Endo

84 REV1 84/12/12 84016 Goudo Tomino Ota

84 Rewrite 89/02/16 89002 Kunichika Goudo Katagiri Introduction of SI 1st stage

90 REV2 90/06/06 90014 Oooka Goudo Katagiri Addition of basic dimension 15

91 REV3 91/01/09 91001 Oooka Goudo Morita Addition of basic dimension 8

91 Rewrite 91/10/29 91034 Tashiro Goudo Morita Introduction of SI 2nd stage

92 REV4 92/03/31 92010 Tashiro Goudo Morita Addition of SAE10B23M

94 REV5 94/02/24 94004 Tashiro Shimada Yamada Review of thread end shape

94 Rewrite 94/04/01 94010 Tashiro Shimada Yamada Correction of errors

94 Rewrite 95/03/14 ----- Tanaka Shimada Yamada Data transfer to PC

96 REV6 96/11/18 96022 Tashiro Shimada Morizumi

96 Rewrite 98/06/30 96022 Tashiro Shimada Honda Data transfer to Notes DB

99 Correction 99/08/03 99011 Tashiro Naya Tomino Correction of errors

03 REV7 03/09/15 03015-23 Okada Tomino Suganuma Change to ISO class

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

You might also like

- Cat 297C C3.4 DIT Engine Overhaul Specifications PDFDocument48 pagesCat 297C C3.4 DIT Engine Overhaul Specifications PDFWilpower WilpowersNo ratings yet

- Atienza, Arjay M. ST - Anne College Lucena Inc. Roof Framing PlanDocument1 pageAtienza, Arjay M. ST - Anne College Lucena Inc. Roof Framing PlanAtienza ArjayNo ratings yet

- Mazda CX-7 Modelo 2007Document19 pagesMazda CX-7 Modelo 2007gerber damianNo ratings yet

- Maintenance Manual For Sulzer Diesel Engines Rta76Document412 pagesMaintenance Manual For Sulzer Diesel Engines Rta76miloslakovic96% (23)

- Caracteristicas de Motor ff030pk PDFDocument1 pageCaracteristicas de Motor ff030pk PDFMelanie EstefaniaNo ratings yet

- Torque Chart For ASTM A193 Grade B7 StudsDocument3 pagesTorque Chart For ASTM A193 Grade B7 Studssarip83100% (4)

- 450 500 Exc Six Days XC-W ServiceDocument313 pages450 500 Exc Six Days XC-W ServiceBrett MNo ratings yet

- 340fte17313 50Document47 pages340fte17313 50sesoto100% (1)

- Chrysler Edg-Ed3 Dohc 2.4L 16VDocument5 pagesChrysler Edg-Ed3 Dohc 2.4L 16Vferran_alfonsoNo ratings yet

- All Terrain Crane 2: ModelDocument47 pagesAll Terrain Crane 2: ModelAL ZALZALAH GROUPNo ratings yet

- Anchor PocketDocument1 pageAnchor Pocketade prayudiNo ratings yet

- D3529 17300 2Document1 pageD3529 17300 2stinkzNo ratings yet

- Enee490 HW5Document3 pagesEnee490 HW5Laura PhamNo ratings yet

- Tss Motion SensorsDocument2 pagesTss Motion SensorsMara FelipeNo ratings yet

- SLP Cavities 2018 Rev.1Document4 pagesSLP Cavities 2018 Rev.1Tord MartinsenNo ratings yet

- Honda K20A Conrod PDFDocument1 pageHonda K20A Conrod PDFJohnJulienGraymondNo ratings yet

- 17PM K233 NMBDocument1 page17PM K233 NMBYonatan Reyes JaimeNo ratings yet

- 17PM K016V NMBDocument2 pages17PM K016V NMBMourad BejaNo ratings yet

- CM100RX-24A NDocument8 pagesCM100RX-24A NLITMAS TECHNOLOGYNo ratings yet

- D697818,820Document1 pageD697818,820suraj pandeyNo ratings yet

- 16py Q207 NMBDocument1 page16py Q207 NMBJulio Cezar Berte SilvaNo ratings yet

- 2SC2837Document2 pages2SC2837Javier LiardoNo ratings yet

- KSTLDocument70 pagesKSTLzacklawsNo ratings yet

- R O A D: Site Development PlanDocument1 pageR O A D: Site Development PlanJeoward Juguilon EleriaNo ratings yet

- Ra3.2 Ra1.6: Napomena: Ostre Ivice Oboriti 0.5X45° Kolicina: 1 KomDocument1 pageRa3.2 Ra1.6: Napomena: Ostre Ivice Oboriti 0.5X45° Kolicina: 1 KomdbaNo ratings yet

- np97 100Document4 pagesnp97 100LEBN ZAKMOTNo ratings yet

- Gym CombinedDocument11 pagesGym CombinedMarielle Anne SantiagoNo ratings yet

- S1G 915 CombinedDocument2 pagesS1G 915 CombinedDương LêNo ratings yet

- Muzzafar Nagar ModelDocument1 pageMuzzafar Nagar Modeldeepak kashyapNo ratings yet

- Sea Logistic SchemeDocument1 pageSea Logistic SchemeTridibansu MandalNo ratings yet

- ART360-361 Foundation InchDocument1 pageART360-361 Foundation InchNicoleta DobreNo ratings yet

- CDD Lot Registration As of December 15 2021Document1 pageCDD Lot Registration As of December 15 2021Felileo BeltranNo ratings yet

- Planetary GearboxDocument13 pagesPlanetary GearboxAnonymous erirwceNo ratings yet

- 23 YARIS (Except TMMF Made From Nov. 2008 Production) (Cont. Next Page)Document2 pages23 YARIS (Except TMMF Made From Nov. 2008 Production) (Cont. Next Page)MaiChiVuNo ratings yet

- PTV09 Series - 9 MM Potentiometer: FeaturesDocument4 pagesPTV09 Series - 9 MM Potentiometer: FeaturesMuabdib AtreidesNo ratings yet

- Application Sheet: Series CT SeriesDocument2 pagesApplication Sheet: Series CT SeriesGonzalo Hernández MelladoNo ratings yet

- 3.50 M Span VRB Typical Drawing Of: Wing WallDocument1 page3.50 M Span VRB Typical Drawing Of: Wing WallUma KantNo ratings yet

- Lytv/Tiv Tivat, Montenegro: Lasti 1H (Last1H) Pinuk 1D (Pinu1D) RNP Arrivals (All Rwys)Document23 pagesLytv/Tiv Tivat, Montenegro: Lasti 1H (Last1H) Pinuk 1D (Pinu1D) RNP Arrivals (All Rwys)Tweed3ANo ratings yet

- 23LM C202V NMBDocument1 page23LM C202V NMBCairineLopesNo ratings yet

- 23LM C202V NMBDocument1 page23LM C202V NMBCairineLopesNo ratings yet

- ArcheryDocument1 pageArcheryRhome OstonalNo ratings yet

- BCR 8 CMDocument5 pagesBCR 8 CMapi-3747180No ratings yet

- PLATE BT ModelDocument1 pagePLATE BT Modelrenz calderonNo ratings yet

- PM20S Stepper MotorDocument1 pagePM20S Stepper MotorNitish KumarNo ratings yet

- G1338 Series: (127 x127 X 38 MM)Document1 pageG1338 Series: (127 x127 X 38 MM)po truongNo ratings yet

- (Cont. Next Page) 18 GS 430 / GS 300: Abs, TRC and VSCDocument2 pages(Cont. Next Page) 18 GS 430 / GS 300: Abs, TRC and VSCАнастасияNo ratings yet

- Eng - Leo 1600 - Su - E8 - 210430Document8 pagesEng - Leo 1600 - Su - E8 - 210430MarcNo ratings yet

- SI-6) - ENG - LEO 1600 - SU - E8 - 200605 - LowDocument8 pagesSI-6) - ENG - LEO 1600 - SU - E8 - 200605 - LowNicolas RodriguezNo ratings yet

- FS12UMA-4A: PreliminaryDocument4 pagesFS12UMA-4A: PreliminaryIman AkbariNo ratings yet

- Hydro DAX V Series Technical Data DE EN 2020 08 28Document4 pagesHydro DAX V Series Technical Data DE EN 2020 08 28veeresh R SNo ratings yet

- Godrej 24: Tower - BDocument1 pageGodrej 24: Tower - Bpriyabrat.77No ratings yet

- Tower 52M-20M2-4legDocument33 pagesTower 52M-20M2-4legBechir Ousseini GarbaNo ratings yet

- 4103 TOYO20 92DJ 1300 027 - Rev 1 - Sht001Document5 pages4103 TOYO20 92DJ 1300 027 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- Page 001Document1 pagePage 001Jeremiah RamosNo ratings yet

- Datasheet CROMA AMPLIF TV Sony KV27Document1 pageDatasheet CROMA AMPLIF TV Sony KV27Javier Ventura ValenciaNo ratings yet

- 8460cb20-40h Drawing 1Document1 page8460cb20-40h Drawing 1Janos HallaNo ratings yet

- Cxa L0612Document2 pagesCxa L0612Naresh KumarNo ratings yet

- Ansox Industry: XXX S.S. Jadhav A4 013 8250 00 XDocument1 pageAnsox Industry: XXX S.S. Jadhav A4 013 8250 00 XHimanshu MishraNo ratings yet

- 2018 Data Sheet Altera M 15.10.8 ENGDocument5 pages2018 Data Sheet Altera M 15.10.8 ENGНик НиксовNo ratings yet

- PARKING ALLOCATION 2023 - 2ndDocument1 pagePARKING ALLOCATION 2023 - 2ndRRMF EcoprimeNo ratings yet

- LCM1601BDocument1 pageLCM1601BJosueFNo ratings yet

- K.M. L.L. K.M. L.L. K.M. L.L.: Produced by An Autodesk Student VersionDocument1 pageK.M. L.L. K.M. L.L. K.M. L.L.: Produced by An Autodesk Student VersionSaif AshrafNo ratings yet

- U01 Antenna 02102022Document2 pagesU01 Antenna 02102022dinosbgNo ratings yet

- TPZ Double DWGDocument1 pageTPZ Double DWGGunawanta GirsangNo ratings yet

- Data Sheet LCD Chip On Glass 14 PinesDocument12 pagesData Sheet LCD Chip On Glass 14 PinesJhonatan Alcazar VargasNo ratings yet

- SBKP Adc-Sbkp Adc 20170525Document2 pagesSBKP Adc-Sbkp Adc 20170525Matheus Brandt100% (1)

- Hes D6501-03 General Test Methods For CoatingDocument28 pagesHes D6501-03 General Test Methods For CoatingPreetam KumarNo ratings yet

- Hes D6001-99 General Test Methods For PlatingDocument39 pagesHes D6001-99 General Test Methods For PlatingPreetam KumarNo ratings yet

- Hes A3032-99a Specification Standard of Hydrogen EmbrittleDocument3 pagesHes A3032-99a Specification Standard of Hydrogen EmbrittlePreetam KumarNo ratings yet

- Hes A3003-03 Chamfer of Thread EndDocument5 pagesHes A3003-03 Chamfer of Thread EndPreetam Kumar100% (1)

- Hes B008-03 Hexagon NutsDocument5 pagesHes B008-03 Hexagon NutsPreetam KumarNo ratings yet

- Collar Pivot 38 MMDocument1 pageCollar Pivot 38 MMPreetam KumarNo ratings yet

- Axle Push Lever - B - 97Document1 pageAxle Push Lever - B - 97Preetam KumarNo ratings yet

- Axle Push Lever - 21CDocument1 pageAxle Push Lever - 21CPreetam KumarNo ratings yet

- Collar Muffler MountDocument1 pageCollar Muffler MountPreetam KumarNo ratings yet

- Axle 4LSDocument1 pageAxle 4LSPreetam KumarNo ratings yet

- Axle Push Lever - BK-7Document1 pageAxle Push Lever - BK-7Preetam KumarNo ratings yet

- Axle Push Lever - BK - 44Document1 pageAxle Push Lever - BK - 44Preetam KumarNo ratings yet

- Yz426f 2001Document63 pagesYz426f 2001Cristian Cerna100% (1)

- No. Muser Material Part Number Qty Unit Harga Merek: MK 499638A Mk355498Document7 pagesNo. Muser Material Part Number Qty Unit Harga Merek: MK 499638A Mk355498acongNo ratings yet

- Main Valve Block, InstallationDocument8 pagesMain Valve Block, InstallationWesley MonsaNo ratings yet

- Komatsu Wheel Loaders Wa150pz 5 Shop ManualDocument20 pagesKomatsu Wheel Loaders Wa150pz 5 Shop Manualjoan100% (50)

- 22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- Reemplazo de Rodamientos 1203 - 1803Document21 pagesReemplazo de Rodamientos 1203 - 1803Robinson SmithNo ratings yet

- Clutch Fundamentals: © 2012 Delmar, Cengage LearningDocument24 pagesClutch Fundamentals: © 2012 Delmar, Cengage Learningshreyas jadhavNo ratings yet

- Ultimatic 125 Nozzle Series Maintenance and Service ProcedureDocument8 pagesUltimatic 125 Nozzle Series Maintenance and Service ProcedureAlejandro Ibáñez MingoranceNo ratings yet

- Shop ItemsDocument31 pagesShop ItemsAmol ChoreNo ratings yet

- Hydraulic Tools Crimp Cut Bend PunchDocument22 pagesHydraulic Tools Crimp Cut Bend PunchMike FinazziNo ratings yet

- 2011 A8 Power TransmissionDocument60 pages2011 A8 Power Transmissionzaka_cz100% (3)

- NoteDocument2 pagesNoteMasoodMiyanNo ratings yet

- What Is Pilot Wire in Electrical Engineering - QuoraDocument3 pagesWhat Is Pilot Wire in Electrical Engineering - Quoramarkigldmm918No ratings yet

- DESIGN OF POWER SCREWDocument6 pagesDESIGN OF POWER SCREWJohn Kisser AbilgosNo ratings yet

- SR841/SR842 (B706) : This Parts Catalog Includes MB No. 1 To 10Document63 pagesSR841/SR842 (B706) : This Parts Catalog Includes MB No. 1 To 10OFBA srlNo ratings yet

- Product Line Overview2016-2017Document83 pagesProduct Line Overview2016-2017Dildar Alam Rasel100% (1)

- 12-13 (19) 56013313 - Vpa Lift Cylinder 080421 Ett09229Document2 pages12-13 (19) 56013313 - Vpa Lift Cylinder 080421 Ett09229ESRANo ratings yet

- Masoneilan: 8013 Series Electropneumatic PositionerDocument6 pagesMasoneilan: 8013 Series Electropneumatic PositionerDiego100% (1)

- FreestarDocument8 pagesFreestarDaniel GonzalezNo ratings yet

- Estimate UP80CT6465Document11 pagesEstimate UP80CT6465Akanksha2212910% (1)

- Wraith Axid9020Document48 pagesWraith Axid9020tri edy utomoNo ratings yet

- Kawasaki VN IiDocument28 pagesKawasaki VN IiFrancis WongNo ratings yet