Professional Documents

Culture Documents

Rekapan Laporan Unit Komatsu d155 Pulpis-1

Uploaded by

Reza IrwantoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rekapan Laporan Unit Komatsu d155 Pulpis-1

Uploaded by

Reza IrwantoCopyright:

Available Formats

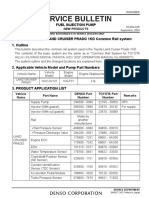

REKAPITULASI LAPORAN PEKERJAAN UNIT KOMATSU D155A-6 PULANG PISAU

PERIODE BULAN SEPTEMBER 2023

TANGGAL PEKERJAAN

No. JENIS KERUSAKAN UNIT YANG TELAH DI PERBAIKI PEKERJAAN YANG DI LAKUKAN Hours Meter Unit

MULAI SELESAI

> Check error code on display monitor

> Remove Operator seat

> Check wirring harness at ECMV Transmission

> Check condition connector socket

> Repair Pin connector socket ECMV Transmission couses not pin

ERROR Code active on display monitor - [15000L0] Transmission

connector not fixed

1 clutch Abnormal; [15SALH] Forward clutch : Fill Low & [DKH1KB] 18/09/2023 20/09/2023 4704

> Clean up all connector at ECMV Transmission

Pitch Angle Sensor: Short circuit

> Repair Connector socket for Selenoide ECMV

> Repair Cable and contactor at fill switch for activation rear gear

> Check wirring harness for pitch angle sensor

> Check pitch angle sensor - pitch angle not function

> Replace pitch angel sensor

> Check Problem unit shutdown and cant running

> Check leaking on fuel line

> Remove; Install Fuel filter

2 Unit Shutdown : Rear Fuel Piping Suply pump Broken 21/09/2023 22/09/2023 4705

> Remove fuel piping suply pump broken

> Replace; Install fuel piping suply pump

> Bleeding fuel system

> Check problem error on display monitor

> Check Connector Solenoide PCV2 at fuel suply pump

> Clean Up Connector Solenoide PCV2

3 ERROR ACTIVE on display monitor - [CA274] PCV2 Open Error > Remove; Install Fuel filter for remove fuel piping suply pump 23/09/2023 23/09/2023 4708

> Tighten fuel piping suply pump couses fuel pipng loosen

> Install fuel filter

> Bleeding fuel system

> Remove All Cable & Terminal Battery

> Remove Battery Unit Exploded

> Replace; Install Battery unit ( Battery Second Condition )

4 Battery Unit Exploded 26/09/2023 28/09/2023 4716

> Replace Terminal Battery

> Install all cable to battery unit

> Test unit

> Check error code on display monitor

> Check voltage on circuit cable(wirring harness) for activation pitch

angle

ERROR Code active on display monitor - [DBE6KK] PT Controller: > Check voltage and resistance wirring harness from battery to ECM

5 Source Voltage reduction & [DKH1KA] Pitch Angle Sensor: powertrain 18:30 , 28/09/2023 18:00 , 29/09/2023 4719

Disconnection ; Alternator Over Charging > Check voltage output from alternator to battery - voltage ove

(overcharger)

>Remove alternator assy

> Repair Alternator assy and install to unit

TOTAL HOURS METER OPERATIONAL UNIT 15

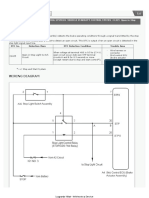

REKAPITULASI LAPORAN PEKERJAAN UNIT KOMATSU D155A-6 PULANG PISAU

PERIODE BULAN OKTOBER 2023

WAKTU DAN TANGGAL PEKERJAAN

No. JENIS KERUSAKAN UNIT YANG TELAH DI PERBAIKI PEKERJAAN YANG DI LAKUKAN Hours Meter Unit

MULAI SELESAI

> Check Leaking on area radiator

> Remove radiator grill for remove fan couses fan dent

> Remove fan radiator assy

Unit Ready Standby - Action Backlog Leaking on area radiator - > Remove and Repair Fan damage and dent

1 Bypass Hose between Upper tank radiator to Lower tank radiator > Install Fan radiator assy 08:00 , 01/10/2023 16:00 , 01/10/2023 4719

loosen & Fan Dent > Install hose radiator and clamp

> Install radiator grill

> Fill Radiator colant

> Test unit (Ok)

> Check problem unit cant start and very much error on display monitor

> Check condition and voltage battery power

> Check cable terminal battery and clean up

> Check all fuse and replace circuit braker couse corrotion condition

Power suply battery voltage missing & Very much error active on

2 > Check and clean up all socket and all connector recieptacle wirring 09:00 , 02/10/2023 15:00 , 02/10/2023 4720

display monitor - Main connector FD1 Loosen

harness on main electrical circuit - Tighten Connector FD1 Loosen

Condition ( Not Fixed )

> Repair Cable output signal and cable power input at atmoshferic

sensor couses voltage missing and cable condition corrotion (broken)

> Check leaking or hose broken on fuel line

> Check actual level on fuel tank

3 Unit Shutdown: Fuel Empty 08:00 , 03/10/2023 10:00 , 03/10/2023 4721

> Fill up fuel tank(manual) couses fuel tank empty

> Bleeding fuel system

> Check problem unit shutdown

> Remove front piping fuel suply pump couses broken

> Replace & Install front pipng suply pump

> Bleeding fuel system

> Analiyze problem unit can't runnning and error code active on display

monitor

> Measuring power suply ( voltage battery ) to ECM Engine

> Clean up main connector and wiiring harness couses dirty and

Unit Shutdown - Front fuel piping on suply pump broken; unit

corrotion conditions

problem can't running and troubleshooting Error code active on

4 > Check power input and signal at rail pressure sensor - rail pressure 10:00 , 04/10/2023 09:00 , 10/10/2023 4726

display monitor - [CA272] PCV1 open error & [CA449] Rail Press

sensor abnormaly function

Very High Error

> Replace rail pressure sensor

> Check wirring harness from ECM to PCV1

> Check power suply (voltage) input to solenoide PCV1

> Check resistance Solenoide PCV1

> Repair wirring harness to PVC1 couses abnormaly voltage input to

solenoide PCV1

> Clean up all connector cable circuit on suply pump

> Completed all cover and guard engine hood and baterai area

> Check and inspect on area engine

> Check and Inspect on area electrical panel

5 Ready Standby - Daily Check and Inspection Unit > Check and clean up battery 07:30 , 11/10/2023 08:00 : 11/10/2023 4726

> Check and Leveling all Oil and Colant radiator

> Check and Inspect leaking on under unit

> Check kosleting problem - terminal batterai (+) contact to grounding

body unit

Sparkles on area battery - Terminal power suply battery contact

6 > Remove Block Hose for AC blower 09:30 , 12/10/2023 13:00 , 12/01/2023 4728

to body unit (grounding body)

> Isolation and Reposition Block hose

> Replace Terminal battery

> Check and inspect on area engine

> Check and Inspect on area electrical panel

7 Ready Standby - Check and Inspection unit > Check and clean up battery 08:00 , 13/10/2023 08:30 , 13/10/2023 4728

> Check and Leveling all Oil and Colant radiator

> Check and Inspect leaking on under unit

> Check and inspect on area engine

> Check and Inspect on area electrical panel

8 Ready Standby - Check and Inspection unit > Check and clean up battery 09:30 , 14/10/2023 10:00 , 14/10/2023 4728

> Check and Leveling all Oil and Colant radiator

> Check and Inspect leaking on under unit

> Check Level colant radiator ( Good )

> Measuring fan rotation

> Check leaking colant and oil ( not leaking )

9 Temperature engine unit high - Radiator core dirty 15/10/2023 15/10/2023 4729

> Check Radiator core ( dirty )

> Clean up and washing radiator core

> test unit

> Check battery voltage

> Measuring voltage output from alternator to battery

Error Code is an active on display monitor - [DBE6KK] PT

10 > Remove alternator for repair to asam-asam 17/10/2023 21/10/2023 4730

Controller: Source voltage Reduction

> Install alternator to unit

> Test unit

> Washing on area under radiator core and under area engine

White smoke on area radiator core and oil leaking on rear

11 > Check oil leaking on area engine 09:30 , 22/10/2023 10:30 , 22/10/2023 4732

engine area

> Check oil leaking

> Remove hose pilot filter hydraulic couses leak (weeps)

> Replace & Install hose

Oil leaking on area engine and Left side unit - Hose Pilot filter

12 > Test and Check leaking 20:00 , 23/10/2023 12:30 , 24/10/2023 4734

Hydraulic small leaks (weeps)

> Add Hydraulic Oil

> Add Engine Oil

> Add Transmission Oil

> Check Leaking oil under engine area

> Remove hose cooling for powertrain couses leaks

> Remove Cover and deck on area cabin for remove hose and check oil

leaking

13 Area under unit oil leaking > Remove Hose pilot for lock lever and hose pilot from reducing valve 08:00 , 26/10/2023 22:00 , 26/10/2023 4738

> Replace & Install hose pilot

> Replace & Install Hose cooling Powertrain

> Add Hydraulic Oil

> Add Transmission Oil

> Check and inspect on area engine

> Check and Inspect on area electrical panel

14 Unit standby Ready - Daily Check and Inspection Unit > Check and clean up battery 08:00 , 27/10/2023 08:30 , 27/10/2023 4738

> Check and Leveling all Oil and Colant radiator

> Check and Inspect leaking on under unit

> Check and inspect on area engine

> Check and Inspect on area electrical panel

15 Unit standby Ready - Daily Check and Inspection Unit > Check and clean up battery 08:00 , 28/10/2024 08:30 , 28/10/2024 4738

> Check and Leveling all Oil and Colant radiator

> Check and Inspect leaking on under unit

> Check and inspect on area engine

> Check and Inspect on area electrical panel

16 Unit standby Ready - Daily Check and Inspection Unit > Check and clean up battery 08:00 , 29/10/2025 08:30 , 29/10/2025 4738

> Check and Leveling all Oil and Colant radiator

> Check and Inspect leaking on under unit

> Remove hose blade lift cylinder broken

> Replace and Install hose blade

17 Hose Hydraulic Blade Lift Cylinder Broken > Add Hydraulic Oil 10:00 , 30/10/2023 17:30 , 30/10/2023 4738

> Washing unit couses oil spray to cabin operator etc.

> Test unit

> Check V-Belt AC

> Check condition Air conditioner compressor - magnetic clutch stuck

18 Fan Belt broken - Air Conditioner Compressor stage 09:00 , 31/10/2023 10:30 , 03/11/2023 4739

> AC progress by vendor

> Final Check

TOTAL HOURS METER OPERATIONAL UNIT 20

REKAPITULASI LAPORAN PEKERJAAN UNIT KOMATSU D155A-6 PULANG PISAU

PERIODE BULAN NOVEMBER 2023

WAKTU DAN TANGGAL PEKERJAAN

No. JENIS KERUSAKAN UNIT YANG TELAH DI PERBAIKI PEKERJAAN YANG DI LAKUKAN Hours Meter Unit

MULAI SELESAI

> Check and inspect on area engine

> Check and Inspect on area electrical panel

1 Unit standby Ready - Daily Check and Inspection Unit > Check and clean up battery 08:00 , 04/11/2023 04/11/2023 4739

> Check and Leveling all Oil and Colant radiator

> Check and Inspect leaking on under unit

> Check and inspect on area engine

> Check and Inspect on area electrical panel

> Check and clean up battery

2 Unit standby Ready - Daily Check and Inspection Unit 08:00 , 05/11/2023 08:30 , 05/11/2023 4739

> Check and Leveling all Oil and Colant radiator

> Check and Inspect leaking on under unit

> Clean up Air cleaner assy

> Check burnning on area radiator

3 Burning on area front radiator (fire spark out on front radiator) > Washing unit 18:30 , 06/11/2023 19:30 , 06/11/2023 4742

> Check leaking fuel spray

> Fuel piping at common rail crack

> Remove fuel piping at common rail

> Replace and Install fuel piping common rail

Fuel Leaking - Fuel piping at common rail leaks (spray)

4 > Bleeding fuel system 08:30 , 07/11/2023 20:30 , 09/11/2023 4743

Work lamp malfunction

> Test running for check leaking

> Repair wirring harness for work lamp

> Replace work lamp couse work lamp not function

> Final Check unit

5 CONTINUE BREAKDOWN - AC Not Cool (WARANTY) > WARANTY PROGRESS FROM VENDOR AC 09/11/2023 13/11/2023 4744

> Check and inspect on area engine

> Check and Inspect on area electrical panel

> Check and clean up battery

6 Unit standby Ready - Daily Check and Inspection Unit 09:00 , 14/11/2023 09:30 , 14/11/2023 4748

> Check and Leveling all Oil and Colant radiator

> Check and Inspect leaking on under unit

> Clean up Air cleaner assy

> Check and analiyzed error problem ( troubleshooting)

> Check wirring harness and connector for Sensor

> Check voltage input to sensor and voltage output signal to ECM

> Remove sensor and clean up sonsor boost air pressure

Error code active on display monitor - [CA123] Chg (Boost) Air > Repair wirring harness for sensor couse cable circuit for voltage input

7 09:30 , 15/11/2023 11:30 , 15/11/2023 4749

Press Sensor Low Error broken

> Install sensor Boost air pressure

> Cllean up air cleaner

> Leveling all oil and Leveling colant radiator

> Final check and Test unit

TOTAL HOURS METER OPERATIONAL UNIT 10

You might also like

- Troubleshooting qsx15 Engine Difficult To StartDocument6 pagesTroubleshooting qsx15 Engine Difficult To StartAli ArdinNo ratings yet

- Toyota Celica 2zz OcvDocument3 pagesToyota Celica 2zz OcvRafael Olave100% (1)

- 10 Intermittentfault10Document94 pages10 Intermittentfault10libertyplusNo ratings yet

- Cat 950GDocument10 pagesCat 950GManuel BarahonaNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Toyota Land Cruiser PDFDocument10 pagesToyota Land Cruiser PDFVelasquez Javier75% (4)

- C1425 Open in Stop Light Switch CircuitDocument4 pagesC1425 Open in Stop Light Switch CircuitDaniel rodriguez alayo100% (2)

- Front Suspension Section GuideDocument19 pagesFront Suspension Section GuideMrihexNo ratings yet

- Part Catalog Bandit 400Document68 pagesPart Catalog Bandit 400Yaya MustofaNo ratings yet

- 2tz Fze 1 1Document21 pages2tz Fze 1 1andypress100% (1)

- Cummins QSB6.7 and QSB4.5 With CM850 ECM - Components TestingDocument15 pagesCummins QSB6.7 and QSB4.5 With CM850 ECM - Components TestingAnders Hedlöf100% (4)

- New Ca300 SPL 0e002527-0e999999 PDFDocument253 pagesNew Ca300 SPL 0e002527-0e999999 PDFHugo TiaNo ratings yet

- Method Statement For Testing & Commissioning of Diesel GeneratorDocument6 pagesMethod Statement For Testing & Commissioning of Diesel Generatorvin ss100% (1)

- Hermetic Compressor PDFDocument17 pagesHermetic Compressor PDFchildey100% (1)

- Practical Power System and Protective Relays CommissioningFrom EverandPractical Power System and Protective Relays CommissioningRating: 4.5 out of 5 stars4.5/5 (10)

- 1.4.1. Index - CMC4 - Plus - Ed5Document10 pages1.4.1. Index - CMC4 - Plus - Ed5Assir El Djazairi100% (1)

- Códigos Erro Motor CX350BDocument202 pagesCódigos Erro Motor CX350BGilvan FranquetaNo ratings yet

- HVAC - Design - Guide 2010 PDFDocument17 pagesHVAC - Design - Guide 2010 PDFslow_bbNo ratings yet

- Different Ways To Mount Travel TransducerDocument14 pagesDifferent Ways To Mount Travel TransducerIsa SolakNo ratings yet

- Check for poor connections, corroded terminals, terminal mating, etc.Connector Side: (bDocument6 pagesCheck for poor connections, corroded terminals, terminal mating, etc.Connector Side: (bjeremih alhegnNo ratings yet

- C1203toyota CorollaDocument3 pagesC1203toyota CorollaJose david Martinez apazaNo ratings yet

- Application Engineering Bulletin: Electronic Throttle Control Specifications Automotive Industrial G-DriveDocument3 pagesApplication Engineering Bulletin: Electronic Throttle Control Specifications Automotive Industrial G-DriveMiguel Angel Cortes PrietoNo ratings yet

- DTC P0010 Camshaft Position "A" Actuator Circuit (Bank 1) : DescriptionDocument10 pagesDTC P0010 Camshaft Position "A" Actuator Circuit (Bank 1) : Descriptionsharon truck trailerNo ratings yet

- 03 Ts 51Document4 pages03 Ts 51giovanni ampueroNo ratings yet

- ABS Warning Light Remains OnDocument7 pagesABS Warning Light Remains OnYomar NegronNo ratings yet

- Camshaft Position A ActuatorDocument6 pagesCamshaft Position A ActuatorDannyDDannyDNo ratings yet

- DTC P0182, P0183 FTT SENSOR Component DescriptionDocument4 pagesDTC P0182, P0183 FTT SENSOR Component DescriptionWillie AustineNo ratings yet

- Brake Warning Light Remains OnDocument9 pagesBrake Warning Light Remains OnYomar NegronNo ratings yet

- GDI Vertical AC Unit Preventive MaintenanceDocument4 pagesGDI Vertical AC Unit Preventive MaintenanceMousa PetrolNo ratings yet

- 2002 NostartdiagDocument19 pages2002 Nostartdiagmansoj777No ratings yet

- Fuel Filter Differential Pressure Switch Circuit - Test (RENR5096)Document3 pagesFuel Filter Differential Pressure Switch Circuit - Test (RENR5096)Josip MiškovićNo ratings yet

- OcvDocument4 pagesOcvIsmail SetiawanNo ratings yet

- P0740 Torque Converter Circuit DiagnosisDocument2 pagesP0740 Torque Converter Circuit DiagnosishitecNo ratings yet

- 5 Engine ArrangementDocument98 pages5 Engine Arrangementhendra hardyNo ratings yet

- PSCS Periodic Service Check SheetDocument5 pagesPSCS Periodic Service Check SheetkkmechNo ratings yet

- MPM 425 01 05Document3 pagesMPM 425 01 05Mousa PetrolNo ratings yet

- Daily Report 06 09 2021Document1 pageDaily Report 06 09 2021GRACIENNo ratings yet

- Laporan PPM Mip Hydraulic Pcs SertifikasiDocument8 pagesLaporan PPM Mip Hydraulic Pcs SertifikasiAbang RafanNo ratings yet

- Manual Transmission Troubleshooting GuideDocument21 pagesManual Transmission Troubleshooting GuideUgratara AutoNo ratings yet

- Engine Electrical SystemDocument45 pagesEngine Electrical SystemRaul Duran SanchezNo ratings yet

- Accent P0011 Camshaft Position-Timing Over-AdvancedDocument6 pagesAccent P0011 Camshaft Position-Timing Over-Advancedflash_24014910No ratings yet

- 01EJ5020Document3 pages01EJ5020Miguel RojasNo ratings yet

- Suction Control Valve: Toyota D-4DDocument1 pageSuction Control Valve: Toyota D-4DLucas SanabriaNo ratings yet

- E527 High Brake Pump CommandDocument6 pagesE527 High Brake Pump CommandHéctorHernándezDíazNo ratings yet

- Inspection and Preventive Maintenance: ServicereportDocument2 pagesInspection and Preventive Maintenance: ServicereportMoz KamalNo ratings yet

- Eg6001 ToyDocument3 pagesEg6001 ToyEnrique Arevalo LeyvaNo ratings yet

- MPM 573 01 49Document2 pagesMPM 573 01 49Mousa PetrolNo ratings yet

- Altronics A2-CPU D SRVC Man 04-1991 PDFDocument18 pagesAltronics A2-CPU D SRVC Man 04-1991 PDFSMcNo ratings yet

- 2021.12.24 R-ME-HC-S-020 Governor System Commissioning ProcedureDocument12 pages2021.12.24 R-ME-HC-S-020 Governor System Commissioning Procedurerotimi olalekan fataiNo ratings yet

- Loader inspection report issues and recommendationsDocument1 pageLoader inspection report issues and recommendationsCrew TabolangNo ratings yet

- Chapt 705Document31 pagesChapt 705cleberNo ratings yet

- Injection Actuation Pressure Control Valve - Test: TroubleshootingDocument10 pagesInjection Actuation Pressure Control Valve - Test: TroubleshootingsatyaNo ratings yet

- USER MANUAL Cyclon330-345Document66 pagesUSER MANUAL Cyclon330-345Renārs BērtiņšNo ratings yet

- 09 em 002Document6 pages09 em 002Zelva ChileNo ratings yet

- ECU Power Source CircuitDocument4 pagesECU Power Source CircuitZouhair WahbiNo ratings yet

- Nouveau Feuille de Calcul Microsoft ExcelDocument1 pageNouveau Feuille de Calcul Microsoft ExcelGracia SediNo ratings yet

- Overhaul Division, BangaloreDocument2 pagesOverhaul Division, Bangaloregoten25No ratings yet

- 007-Commissioning Procedure Of Fault Reorder System-R1Document9 pages007-Commissioning Procedure Of Fault Reorder System-R1SalmanEjazNo ratings yet

- GR00005400B 13aDocument315 pagesGR00005400B 13aYounk KimNo ratings yet

- Troubleshoot neutral switch issuesDocument1 pageTroubleshoot neutral switch issuesDanielNo ratings yet

- Troubleshoot electronic gaugesDocument18 pagesTroubleshoot electronic gaugesluis almonacidNo ratings yet

- Engine WIll Not Crank or Cranks QST 30Document3 pagesEngine WIll Not Crank or Cranks QST 30hinggasetiawan46No ratings yet

- Brake Warning Light Does Not Come OnDocument3 pagesBrake Warning Light Does Not Come OnYomar NegronNo ratings yet

- Engine Electrical System OverviewDocument51 pagesEngine Electrical System OverviewnahomNo ratings yet

- SECTION 413-01 Instrument ClusterDocument6 pagesSECTION 413-01 Instrument Clustermail4281No ratings yet

- Maintenance Report #44799 - VC650-150TECHDocument19 pagesMaintenance Report #44799 - VC650-150TECHelazzouziayoub98No ratings yet

- Speed Timing SensorsDocument7 pagesSpeed Timing SensorsBishoo ShenoudaNo ratings yet

- 001.GOH ENGINE DRESSTA TD25M-Extra 1Document3 pages001.GOH ENGINE DRESSTA TD25M-Extra 1Reza IrwantoNo ratings yet

- Sertifikat Attendance - DJATMIKO NUGROHO I.Document1 pageSertifikat Attendance - DJATMIKO NUGROHO I.Reza IrwantoNo ratings yet

- 007 - VOLVO LOADER L120Gz (NUSA)Document9 pages007 - VOLVO LOADER L120Gz (NUSA)Reza IrwantoNo ratings yet

- 003 - Unit 09 RebuildDocument6 pages003 - Unit 09 RebuildReza IrwantoNo ratings yet

- 003 - Unit 09 RebuildDocument6 pages003 - Unit 09 RebuildReza IrwantoNo ratings yet

- COMMISIONINGDocument2 pagesCOMMISIONINGReza IrwantoNo ratings yet

- 003 - Unit 09 RebuildDocument6 pages003 - Unit 09 RebuildReza IrwantoNo ratings yet

- Error notifications list and OFTP2 communication parametersDocument1 pageError notifications list and OFTP2 communication parametersReza IrwantoNo ratings yet

- AS2 EDI Communication NewFormDocument3 pagesAS2 EDI Communication NewFormReza IrwantoNo ratings yet

- Fisher 2052 Diaphragm Rotary Actuator: Scope of ManualDocument20 pagesFisher 2052 Diaphragm Rotary Actuator: Scope of Manualgermanmorales58No ratings yet

- AC Machine FundamentalsDocument24 pagesAC Machine FundamentalsKimsairng CheaNo ratings yet

- 7 Climate Control Air Handling Unit 2020Document2 pages7 Climate Control Air Handling Unit 2020Fahri Husaini NstNo ratings yet

- What Causes Engine Blow-By?: 6 AnswersDocument4 pagesWhat Causes Engine Blow-By?: 6 AnswersAmir Bambang YudhoyonoNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: Attaching The Nose GearDocument1 pageVan'S Aircraft, Inc.: Figure 1: Attaching The Nose GearMark Evan SalutinNo ratings yet

- MOONS HB stepping motor型錄Document65 pagesMOONS HB stepping motor型錄luck147258369No ratings yet

- MF VD: Dimensioni D'Ingombro - Overall DimensionsDocument2 pagesMF VD: Dimensioni D'Ingombro - Overall DimensionsDanilo TorresNo ratings yet

- Motorized Gyroscope Apparatus 1Document7 pagesMotorized Gyroscope Apparatus 1Rickson Viahul Rayan CNo ratings yet

- Toyota Camshaft PDFDocument6 pagesToyota Camshaft PDFChristian RedinNo ratings yet

- DLCLesson 1Document80 pagesDLCLesson 1statisticssalesNo ratings yet

- Diesel Locomotive Power Pack Assembly ReportDocument32 pagesDiesel Locomotive Power Pack Assembly Reportshivam pandeyNo ratings yet

- ClistDocument4 pagesClist23174 ThenabaduNo ratings yet

- 4.0 Shaft, Axle & BearingDocument75 pages4.0 Shaft, Axle & BearingphyrdowsNo ratings yet

- CPVS QRS 20 30HP Insruction 2012 05 - 2200780027Document35 pagesCPVS QRS 20 30HP Insruction 2012 05 - 2200780027KM KarthikNo ratings yet

- HS1L DatasheetDocument8 pagesHS1L DatasheetBlAdE 12No ratings yet

- Hvac Hvac E20 E20Document1 pageHvac Hvac E20 E20Shashank GinjupalliNo ratings yet

- Imagebroschuere ENGDocument16 pagesImagebroschuere ENGmahotkatNo ratings yet

- Instructions For Automatic Lubricating Oil Filters: Operating InstructionDocument14 pagesInstructions For Automatic Lubricating Oil Filters: Operating InstructionSmart Lau100% (1)

- Manual de Ford Edge Timming ChainDocument17 pagesManual de Ford Edge Timming ChainJorge Antonio GuillenNo ratings yet

- Iti Books PDFDocument4 pagesIti Books PDF698rickyNo ratings yet

- RFI-3410 - Daily Fit Up Inspection Report-OKDocument92 pagesRFI-3410 - Daily Fit Up Inspection Report-OKnguyennamxmNo ratings yet

- Jet Engine Air Intakes: Basic Gas TurbineDocument41 pagesJet Engine Air Intakes: Basic Gas TurbineInterogator5No ratings yet

- Standards For Efficiency of Electric Motors: IEEE Industry Applications Magazine March 2011Document9 pagesStandards For Efficiency of Electric Motors: IEEE Industry Applications Magazine March 2011Ahmet Yasin BaltacıNo ratings yet