Professional Documents

Culture Documents

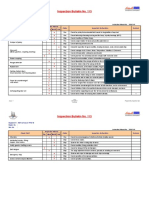

M025 DECK CRANE Operation Checklist

Uploaded by

ahmedtaher.at1920 ratings0% found this document useful (0 votes)

9 views4 pagesM025 DECK CRANE operation checklist

Original Title

M025 DECK CRANE operation checklist

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentM025 DECK CRANE operation checklist

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views4 pagesM025 DECK CRANE Operation Checklist

Uploaded by

ahmedtaher.at192M025 DECK CRANE operation checklist

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

CRANE OPERATION CHECKLIST

Vessel Name: Date:

DECK CRANE Interval Remarks

Check crane post for cracks at the base of slewing ring 1M

BOOMS & ATTACHMENTS

1M

To be checked for heavy corrosion, wear damage

Check all limits like luff up/down, boom in/out, hoist

1M

up/down & load setting

LOOSE GEAR

After Each

Blocks, sheaves, hooks, shackles, luffing & hoisting wires,

Loading/Unloading

etc. to be checked for heavy corrosion, wastage, wear, operation

damage.

Check the along length of wire for any

• 6 or more broken wires in one lay

• 3 or more broken wires in one strand in one lay

• external wear not exceed 10% of Diameter

After Each

• Waviness

Loading/Unloading

• Strand protrusion operation

• Core protrusion

• Kink

• Inner or outer corrosion

Lubricate anti twist wire, slewing gear & other greasing

1M

points

Check the pump pressure operation 1M

check slewing motor gear box oil level 1M

Check jib head sheaves for free motion & play 1M

Check hydraulic system for leaks, condition of hoses,

1M

normalcy of operating pressure, pump seal leaks etc.

Check the condition of brake disc condition and its

thickness, check the available stock for brake discs

Check emergency stop switch 1M

After Each

Check for vibration or irregular noises Loading/Unloading

operation

Land hydraulic system oil for analysis 6M

This list to be mentioned in the Monthly Work Done (Engine) Form No. M013

You might also like

- The Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerFrom EverandThe Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerRating: 5 out of 5 stars5/5 (1)

- Belt Conveyor RFBE-B1800 X 9.7Document2 pagesBelt Conveyor RFBE-B1800 X 9.7Mahmoud HanafyNo ratings yet

- Belt Conveyor RT45-BDocument2 pagesBelt Conveyor RT45-BMahmoud HanafyNo ratings yet

- Elevator Maintenance Check List Sample OTIS PDFDocument2 pagesElevator Maintenance Check List Sample OTIS PDFSohail100% (3)

- Verif Epi Protraxion Procedure enDocument4 pagesVerif Epi Protraxion Procedure eninternetNo ratings yet

- Eot Ibl Crane Yearly ChecksheetDocument3 pagesEot Ibl Crane Yearly ChecksheetAmit ThakurNo ratings yet

- IFT Forklift Inspection 1Document1 pageIFT Forklift Inspection 1HSE ENL GCLOUDNo ratings yet

- M00006-1-1520-280-PMD Main Rotor Pylon SectionDocument6 pagesM00006-1-1520-280-PMD Main Rotor Pylon SectionabuzaidNo ratings yet

- Crane & Hoist Pre-Use Inspection Checklist: Hook and Chain Assembly - Monthly InspectionDocument3 pagesCrane & Hoist Pre-Use Inspection Checklist: Hook and Chain Assembly - Monthly InspectionAde KodratNo ratings yet

- Pre Operational InspectionDocument89 pagesPre Operational InspectionGustavo ArancibiaNo ratings yet

- Eot Crane Monthly ChecksheetDocument4 pagesEot Crane Monthly ChecksheetAmit ThakurNo ratings yet

- NRG2.Types of Crane and Components PDFDocument107 pagesNRG2.Types of Crane and Components PDFMaza LufiasNo ratings yet

- EOT CRANE MAINTENANCEDocument3 pagesEOT CRANE MAINTENANCEMaku RajkumarNo ratings yet

- LuK 0069 enDocument1 pageLuK 0069 enAlanWeissNo ratings yet

- Dual Mass Flywheel - Special Tool User InstructionsDocument24 pagesDual Mass Flywheel - Special Tool User InstructionsAlanWeissNo ratings yet

- Cat Safety & Maintenance Checklist - SYKES PUMPSDocument1 pageCat Safety & Maintenance Checklist - SYKES PUMPSAlberto KelsoNo ratings yet

- Driving Commercial Vehicles Manual Class 4 Unrestricted Pre-Trip InspectionDocument7 pagesDriving Commercial Vehicles Manual Class 4 Unrestricted Pre-Trip InspectionjwNo ratings yet

- Crane and Hoist Pre Use Inspection ChecklistDocument3 pagesCrane and Hoist Pre Use Inspection ChecklistKingsley Phang67% (3)

- LY38 Ops Manual PDFDocument36 pagesLY38 Ops Manual PDForlando chullo llave100% (1)

- Time Limits/Maintenance Checks Unscheduled Maintenance Checks Inspection/CheckDocument17 pagesTime Limits/Maintenance Checks Unscheduled Maintenance Checks Inspection/CheckWalter TorenaNo ratings yet

- GROUP 2 MAJOR COMPONENTSDocument10 pagesGROUP 2 MAJOR COMPONENTSlevinton jose tobias genesNo ratings yet

- Alternator Overhaul SK-KD 18.4Document25 pagesAlternator Overhaul SK-KD 18.4Opu RoteNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpChristian VicenteNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument9 pagesGroup 2 Major Component: 1. Main PumpMauricio CalixtoNo ratings yet

- M.E.M.01.C.EN.00 - Maintenance ManualDocument10 pagesM.E.M.01.C.EN.00 - Maintenance ManualGorazdSklepičNo ratings yet

- Mm y ServicioDocument82 pagesMm y Serviciojesus francoNo ratings yet

- Lifting Supervisor Training: Slinging SAFETYDocument614 pagesLifting Supervisor Training: Slinging SAFETYSHIJAD SRAJU100% (2)

- Mine Canadian Royalties: Excavator TrainingDocument72 pagesMine Canadian Royalties: Excavator Trainingotak04No ratings yet

- BellHousing FlexaDrive Mobile Oct1618 Email 1603458036 1623769447Document24 pagesBellHousing FlexaDrive Mobile Oct1618 Email 1603458036 1623769447lwinmoethwim.titannexusNo ratings yet

- Busduct & Plug inDocument2 pagesBusduct & Plug in97faithoNo ratings yet

- Daily unloader checklistDocument1 pageDaily unloader checklistAnonymous ahdhFMaNo ratings yet

- Daily maintenance checklist for LS crusherDocument6 pagesDaily maintenance checklist for LS crusherlaxman JoshiNo ratings yet

- Overhead Crane Inspection ProceduresDocument5 pagesOverhead Crane Inspection ProceduresRonniNo ratings yet

- Part 10 Pump Problems and Repair 15Document15 pagesPart 10 Pump Problems and Repair 15Aenur RofiiqNo ratings yet

- Annual Checklist For Inspection / Preventive Maintenance of Eot CranesDocument3 pagesAnnual Checklist For Inspection / Preventive Maintenance of Eot CranesAmarnath DhageNo ratings yet

- PPE Inspection Procedure ChecklistDocument3 pagesPPE Inspection Procedure Checklistaliya azharNo ratings yet

- Grand I10 MaintainanceDocument10 pagesGrand I10 Maintainancerick slyNo ratings yet

- HEMM Excavator04Document16 pagesHEMM Excavator04miningnova2No ratings yet

- 3 ES10-10ES Daily Maintenance List (20171220) - 20181120 - 095019Document4 pages3 ES10-10ES Daily Maintenance List (20171220) - 20181120 - 095019Lacatusu MirceaNo ratings yet

- Mobile Crane Load Test Report FormDocument4 pagesMobile Crane Load Test Report FormBayuo2k100% (3)

- Daihatsu Sirion Model m300 Series Service Manual No9890 EngineDocument32 pagesDaihatsu Sirion Model m300 Series Service Manual No9890 EngineJakub TarasinNo ratings yet

- Check Valve SelectionDocument1 pageCheck Valve SelectionramkikkdNo ratings yet

- Inspection Bulletin No. 103: Impact Crusher IM - 13RDocument1 pageInspection Bulletin No. 103: Impact Crusher IM - 13RMahmoud HanafyNo ratings yet

- 5.19 JSP Power Transformer High Voltage TestDocument4 pages5.19 JSP Power Transformer High Voltage Testmuhammad.younisNo ratings yet

- Acceptance Check ListDocument2 pagesAcceptance Check ListMohamed HamdyNo ratings yet

- 41 2os03Document8 pages41 2os03Miguel Angel RodriguezNo ratings yet

- Miller Lanyard Inspection and Maintenance Proceedure PDFDocument2 pagesMiller Lanyard Inspection and Maintenance Proceedure PDFUlviyye ElesgerovaNo ratings yet

- Obm Pinion Pillow Block BoltDocument5 pagesObm Pinion Pillow Block Boltgullipalli srinivasa raoNo ratings yet

- Asphalt Plant Inspection ItemDocument2 pagesAsphalt Plant Inspection ItemsacsewNo ratings yet

- Pipe Conveyor Conveyors Pm-Check ListDocument5 pagesPipe Conveyor Conveyors Pm-Check Listgullipalli srinivasa raoNo ratings yet

- Hoist Pre-Operational Inspection Check ListDocument1 pageHoist Pre-Operational Inspection Check ListMohd Shareen Ezzry Mohd SomNo ratings yet

- Ertiga Owner's ManualDocument240 pagesErtiga Owner's ManualAnonymous Ye5VNlNo ratings yet

- Predictive Maintenance ChecklistsDocument14 pagesPredictive Maintenance Checklistsnayan vyasNo ratings yet

- Celerio Owner's ManualDocument196 pagesCelerio Owner's ManualsohailnkaziNo ratings yet

- Iind Ed Alternators (8) - MaintenanceDocument8 pagesIind Ed Alternators (8) - MaintenancetesfuNo ratings yet

- 3 EPT20-15ET Daily Maintenance List - 20181115 - 133154Document3 pages3 EPT20-15ET Daily Maintenance List - 20181115 - 133154Lacatusu MirceaNo ratings yet

- Articulated Boom Truck Student ManualDocument35 pagesArticulated Boom Truck Student ManualErc Nunez VNo ratings yet

- Scope of Work For MaintenanceDocument4 pagesScope of Work For Maintenancepirates kingNo ratings yet

- Lubrication & Periodic Maintenance - Model A Ford: Each 500 Miles Each 2,000 MilesDocument1 pageLubrication & Periodic Maintenance - Model A Ford: Each 500 Miles Each 2,000 MilesmariodanielpereyraNo ratings yet

- Nor30p Serv ManDocument187 pagesNor30p Serv Manjason_meyer_14100% (2)

- Multi-User Collaboration With Revit WorksetsDocument10 pagesMulti-User Collaboration With Revit WorksetsRafael Rafael CastilloNo ratings yet

- Unit 15 AssignmentDocument13 pagesUnit 15 Assignmentapi-339083063100% (4)

- Economical Impact of Event (Chat GPT)Document2 pagesEconomical Impact of Event (Chat GPT)esa arimbawaNo ratings yet

- Recruitment and Selection Process VIZAG STEELDocument106 pagesRecruitment and Selection Process VIZAG STEELManish Sood100% (1)

- D-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) Fuel Filter and LinesDocument3 pagesD-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) Fuel Filter and LinesMANUALES100% (1)

- Indonesia Trade Report Highlights Recovery & OutlookDocument27 pagesIndonesia Trade Report Highlights Recovery & OutlookkennydoggyuNo ratings yet

- Wiccan - The Basics of Herbs and Herbal Magic and Spells and MagickDocument5 pagesWiccan - The Basics of Herbs and Herbal Magic and Spells and Magickkhalilgib67% (3)

- CS3352 - Digital Principles and Computer Organization LaboratoryDocument55 pagesCS3352 - Digital Principles and Computer Organization Laboratoryakshaya vijay100% (6)

- The 10 Most Influential Business Women Making A Difference, 2022Document40 pagesThe 10 Most Influential Business Women Making A Difference, 2022The Inc MagazineNo ratings yet

- MOA - NDMS Enterprise Inc.Document3 pagesMOA - NDMS Enterprise Inc.merlitamartinez8No ratings yet

- BFN 111 - Week 1Document20 pagesBFN 111 - Week 1CHIDINMA ONUORAHNo ratings yet

- CBR A Drug DevelopDocument2 pagesCBR A Drug DevelopAlfieNo ratings yet

- Communication Barriers - Effects On Employees EfficiencyDocument27 pagesCommunication Barriers - Effects On Employees Efficiencyvanquish lassNo ratings yet

- Skyline Software Systems, Inc. v. Keyhole, Inc Et Al - Document No. 34Document10 pagesSkyline Software Systems, Inc. v. Keyhole, Inc Et Al - Document No. 34Justia.comNo ratings yet

- Business Description: Executive SummaryDocument4 pagesBusiness Description: Executive SummaryYudhi SugataNo ratings yet

- Dengue Fever PresentationDocument11 pagesDengue Fever Presentationhira khanNo ratings yet

- 22172/pune Humsafar Third Ac (3A)Document2 pages22172/pune Humsafar Third Ac (3A)VISHAL SARSWATNo ratings yet

- Differential RAID: Rethinking RAID For SSD ReliabilityDocument5 pagesDifferential RAID: Rethinking RAID For SSD ReliabilityRabiul SikderNo ratings yet

- Managerial Eco and Accounting FinalDocument16 pagesManagerial Eco and Accounting FinalMichael Paul GabrielNo ratings yet

- IBM Informix 4GL V7.50 - Quick Start GuideDocument2 pagesIBM Informix 4GL V7.50 - Quick Start GuideMohamed AfeilalNo ratings yet

- Construction Materials and Testing, Lab Experiment-No - 9Document10 pagesConstruction Materials and Testing, Lab Experiment-No - 9Lester de GuzmanNo ratings yet

- 2nd National Biosafety Conference Programme and AbstractsDocument56 pages2nd National Biosafety Conference Programme and AbstractsDaddie InyasisNo ratings yet

- 0076 0265 - Thy Baby Food LicenceDocument2 pages0076 0265 - Thy Baby Food LicenceSreedharanPNNo ratings yet

- How To Prevented False Breakouts?: Breakout TradingDocument3 pagesHow To Prevented False Breakouts?: Breakout Tradingimzee25No ratings yet

- 545-950 ThermaGuard 2021Document2 pages545-950 ThermaGuard 2021AbelNo ratings yet

- Mesalazine: Mesalazine (INN, BAN), Also Known As Mesalamine (USAN) or 5-Aminosalicylic AcidDocument4 pagesMesalazine: Mesalazine (INN, BAN), Also Known As Mesalamine (USAN) or 5-Aminosalicylic AcidAnkan PalNo ratings yet

- Cylinder Heads & ValvesDocument95 pagesCylinder Heads & ValvesFrank MosesNo ratings yet

- Qingdao ACT Auto Brake Disc Drum For Volkswagen Ford ToyotaDocument9 pagesQingdao ACT Auto Brake Disc Drum For Volkswagen Ford ToyotaQingdao act brake discNo ratings yet

- CoaseDocument20 pagesCoasepwalker_25100% (1)

- TDS - Cu-9 SchultzDocument2 pagesTDS - Cu-9 SchultzFabiola ArceNo ratings yet