Professional Documents

Culture Documents

Visio-Quy Trinh San Xuat Soi

Uploaded by

JoeKailCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Visio-Quy Trinh San Xuat Soi

Uploaded by

JoeKailCopyright:

Available Formats

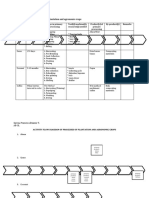

Fiber testing

Opening

Mở kiện

Pre-cleaning

Máy xé Làm sạch bông sơ

tới trộn bộ

bông

Mixing

Trộn bông

Blending 1. opening

Pha trộn 2. cleaning

3. mixing or blending

4. microdust removal

Buồng

5. uniform feed to the carding machine

thổi

6. Recycling the waste

LAP formation

Fine-cleaning

Làm sạch kỹ

1. to open the flocks into individual fibres

2. cleaning or elimination of impurities

3. reduction of neps

4. elimination of dust

Chải

Carding 5. elimination of short fibres

thô

6. fibre blending

7. fibre orientation or alignment

8. sliver formation

Chuẩn

bị chải

(ghép Combing-

thô – 1 Preperation

2 times lần) 1. elimination of short

fibres

2. elimination of

Chải kỹ remaining impurities

Combing-Comber 3. elimination of neps

2 times

1. Through doubling the slivers are made even

2. doubling results in homogenization(blending)

3. through draft fibres get parallelised

Ghép Drawing frame

4. hooks created in the card are straightened

5. through the suction, intensive dust removal

6. autoleveller maintains absolute sliver fineness

1. Attenuation- drafting the sliver into roving

Roving- Roving

2. twisting the drafted strand

frame (Twisting)

3. winding the twisted roving on a bobbin

Sợi con Ring Spinning ComforSpinning Rotor Spinning

Winding

Laboratory Twisting

You might also like

- Textiles: From Spinning to WeavingDocument24 pagesTextiles: From Spinning to Weavingsarwat yaseenNo ratings yet

- Define The Following TermsDocument8 pagesDefine The Following TermsJethro MiñanoNo ratings yet

- CC Sanitary Pads From Banana Fibers FINALDocument2 pagesCC Sanitary Pads From Banana Fibers FINALTanzia RahmanNo ratings yet

- Bijendra Public School: Class - 6 Subject - SCIENCE Chapter - 3 Fibre To FabricDocument4 pagesBijendra Public School: Class - 6 Subject - SCIENCE Chapter - 3 Fibre To Fabricsmitha_gururaj100% (1)

- Lect4 - Carding Machine 1Document16 pagesLect4 - Carding Machine 1Mina Samy abd el zaher75% (4)

- Introduction of Textile - Impulse FinalDocument31 pagesIntroduction of Textile - Impulse FinalAniket MaheshwariNo ratings yet

- Drafting Waves of SliversDocument4 pagesDrafting Waves of Sliversnalaka.sampathNo ratings yet

- Surgical DressingDocument18 pagesSurgical DressingHashim MohammedNo ratings yet

- Yarn Manufacturing TechnologyDocument6 pagesYarn Manufacturing Technologyshahadat hossainNo ratings yet

- Effect of Raising and Finishing ProcessDocument10 pagesEffect of Raising and Finishing ProcessShahin ghasemi nezhadNo ratings yet

- Fabric: According To Methods of ProductionDocument10 pagesFabric: According To Methods of Productiontajul tamimNo ratings yet

- Blow RoomDocument4 pagesBlow RoomSuman Debnath IfNo ratings yet

- Assignment of Yern Formation: SUBJECT: Object of Blow Room and CardingDocument4 pagesAssignment of Yern Formation: SUBJECT: Object of Blow Room and CardingSuman Debnath IfNo ratings yet

- Module 2 (Fibre - Fabric) : Indirect System Direct System Universal SystemDocument21 pagesModule 2 (Fibre - Fabric) : Indirect System Direct System Universal SystemKAWSER RAFINo ratings yet

- Primary Processing CRSC 2Document4 pagesPrimary Processing CRSC 2Ian FloresNo ratings yet

- CORN SAMPLING - Infographic - ENG - 2 PagesDocument2 pagesCORN SAMPLING - Infographic - ENG - 2 PagessandiirisyaNo ratings yet

- 321 E Lesson 23 1Document11 pages321 E Lesson 23 1OUSMAN SEIDNo ratings yet

- 8 Eng 4 Et v1 s1 LessonDocument12 pages8 Eng 4 Et v1 s1 LessonAftab AnsariNo ratings yet

- Textile Science Course SyllabusDocument6 pagesTextile Science Course SyllabusSamantha KachelNo ratings yet

- Knitted Fabric Manufacturing: The Process of Inter-Looping YarnsDocument32 pagesKnitted Fabric Manufacturing: The Process of Inter-Looping YarnsMarsimoy Abdiikeet BedaneNo ratings yet

- ComberDocument4 pagesComberawaismehmoodkhan.213No ratings yet

- Fundamentals of Textile and ClothingDocument24 pagesFundamentals of Textile and Clothingmitesh shahNo ratings yet

- FIBRE TO FABRIC Key LessonDocument17 pagesFIBRE TO FABRIC Key LessonGAMAN CHILAKANo ratings yet

- Basic Yarn Manufacturing Processes ExplainedDocument1 pageBasic Yarn Manufacturing Processes ExplainedsamukriNo ratings yet

- Health TeachingDocument2 pagesHealth TeachingSheryl Ann Barit PedinesNo ratings yet

- EagleBurgmann - E06092 - E2 - Mechanical Seals For Sorters - 03.11Document2 pagesEagleBurgmann - E06092 - E2 - Mechanical Seals For Sorters - 03.11munhNo ratings yet

- Fibre To FabricDocument230 pagesFibre To FabricYashasvi RaraNo ratings yet

- Name: Marks: /100 /15%Document2 pagesName: Marks: /100 /15%Meilinda Kumala DewiNo ratings yet

- 04 StorageDocument57 pages04 StorageDaniela BernalNo ratings yet

- Color and Texture in Weaving BLADDocument8 pagesColor and Texture in Weaving BLADInterweave75% (4)

- Friction SpinningDocument42 pagesFriction SpinningAnonymous Pt7NHkat9No ratings yet

- 4 Basic Weft Knit StructureDocument2 pages4 Basic Weft Knit StructureSujon Mahbubul86% (7)

- COMPACT YARNS' UNIQUE STRUCTURE OFFERS ADVANTAGES IN PROCESSINGDocument6 pagesCOMPACT YARNS' UNIQUE STRUCTURE OFFERS ADVANTAGES IN PROCESSINGBilal AhmedNo ratings yet

- Unit V CMS-1-23Document23 pagesUnit V CMS-1-23raj6062No ratings yet

- Fibre To Fabric (G6) : Handout I. Short Answer QuestionsDocument4 pagesFibre To Fabric (G6) : Handout I. Short Answer Questionsdon shiphrahNo ratings yet

- Textile FiberDocument159 pagesTextile Fiberfayeraleta2024No ratings yet

- Wheat DebranningDocument20 pagesWheat DebranningByron DanielNo ratings yet

- Capability Development of Bag FiltersDocument35 pagesCapability Development of Bag Filtersraja sharma100% (1)

- Microtomy and SectioningDocument2 pagesMicrotomy and SectioningMimi DominguezNo ratings yet

- Research About Fibers in Composite MaterialsDocument7 pagesResearch About Fibers in Composite MaterialsArturo Herrera HdzNo ratings yet

- Exp 01 CorrectedDocument14 pagesExp 01 CorrectedIstiak Ahmed TussharNo ratings yet

- Process Involve in Production of CottonDocument1 pageProcess Involve in Production of CottonmaryamNo ratings yet

- Group DDocument1 pageGroup DIsrael PopeNo ratings yet

- Spinning Process ExplainedDocument4 pagesSpinning Process ExplainedTharushi NiwarthanaNo ratings yet

- Mill DirectoryDocument12 pagesMill DirectoryjasleenthukralNo ratings yet

- A Brief Introduction To Fabrics: ImpulseDocument44 pagesA Brief Introduction To Fabrics: ImpulseAniket MaheshwariNo ratings yet

- A Brief Introduction To Fabrics: ImpulseDocument44 pagesA Brief Introduction To Fabrics: ImpulseAniket MaheshwariNo ratings yet

- R&P (AutoRecovered) (AutoRecovered)Document21 pagesR&P (AutoRecovered) (AutoRecovered)RAYMOND URASSANo ratings yet

- PillingDocument3 pagesPillingইসলামিক টিভিNo ratings yet

- Fabric Fundamentals: (Industrial Visit)Document23 pagesFabric Fundamentals: (Industrial Visit)NISHTHANo ratings yet

- MethodologyDocument4 pagesMethodologycuteprettykhlea sebuaNo ratings yet

- Arti Inggris 2Document3 pagesArti Inggris 2alisianalestariNo ratings yet

- 3: How Do They Clean Wool?Document1 page3: How Do They Clean Wool?ECNo ratings yet

- TLE Home Economics: Sews Household Linens Using Appropriate Tools and MaterialsDocument4 pagesTLE Home Economics: Sews Household Linens Using Appropriate Tools and MaterialsMa Junnicca MagbanuaNo ratings yet

- Warping Calculation - Calculation For Direct Warping and Sectional Warping - Tex 1Document4 pagesWarping Calculation - Calculation For Direct Warping and Sectional Warping - Tex 1GOWTHAM CHANDRUNo ratings yet

- Knitting Action and EtcDocument38 pagesKnitting Action and Etcshahadat hossainNo ratings yet

- GR - 3 - Evs - Rws - 5-AkDocument4 pagesGR - 3 - Evs - Rws - 5-AkAnjana SaiNo ratings yet

- Sequence of Process in Worsted SpinningDocument4 pagesSequence of Process in Worsted SpinningArunraj Arumugam100% (4)

- Spinning Technology HandbookDocument199 pagesSpinning Technology HandbookJalal Uddin RumiNo ratings yet

- Patco: Blowroom SolutionsDocument4 pagesPatco: Blowroom SolutionsSahlu Klemewerk DagetNo ratings yet

- Recycling of Textile Materials - Bojana VoncinaDocument37 pagesRecycling of Textile Materials - Bojana VoncinaRobertoNo ratings yet

- SWOT Analysis of Viyellatex Spinning LimitedDocument81 pagesSWOT Analysis of Viyellatex Spinning LimitedHossain RanaNo ratings yet

- 2007-4-18-An Investigation On Energy Consumption in Yarn Production With Special Reference To Ring SpinningDocument8 pages2007-4-18-An Investigation On Energy Consumption in Yarn Production With Special Reference To Ring SpinningAqeel AhmedNo ratings yet

- Textile Dictionary by Md. Jakir HossenDocument152 pagesTextile Dictionary by Md. Jakir HossenMd. Jakir HossenNo ratings yet

- WoolDocument69 pagesWoolnitishkohli100% (5)

- Jun. 2019 Jun. 2019: We Reserve Our Right To Modify Them at Any Time, To Be Confirmed by Authorized SpecificationDocument8 pagesJun. 2019 Jun. 2019: We Reserve Our Right To Modify Them at Any Time, To Be Confirmed by Authorized SpecificationJuan Francisco Rubio JovelNo ratings yet

- Objective of Internship: Assignment - 1Document111 pagesObjective of Internship: Assignment - 1divyagaba2150% (2)

- Textile Internship - Usha YarnsDocument49 pagesTextile Internship - Usha YarnsROHAN GIREESHNo ratings yet

- NamdaDocument3 pagesNamdaJanNo ratings yet

- RKM DetailsDocument7 pagesRKM DetailsDurairaj.N90% (10)

- SEF201 Mod3Document79 pagesSEF201 Mod3Arka MitraNo ratings yet

- Financial Planning for BeginnersDocument48 pagesFinancial Planning for Beginnersthen12345No ratings yet

- The Rieter Manual of Spinning v-2 (Blowroom & Carding) - DikonversiDocument9 pagesThe Rieter Manual of Spinning v-2 (Blowroom & Carding) - DikonversiFajar Noor SidiqNo ratings yet

- Organizational Study of Mannan Cotton Spinning MillDocument33 pagesOrganizational Study of Mannan Cotton Spinning MillMukarram Ali KhanNo ratings yet

- Itma 2019 E-CatalogueDocument902 pagesItma 2019 E-CatalogueSaad8808No ratings yet

- Working Principle of Carding MachineDocument12 pagesWorking Principle of Carding Machinemdnadim100% (1)

- Spinning PDFDocument199 pagesSpinning PDFNgọc Bảo NguyễnNo ratings yet

- Project Report On Employee Absenteeism: An Empirical Study of Workers at Aarti InternationalDocument93 pagesProject Report On Employee Absenteeism: An Empirical Study of Workers at Aarti InternationalkulveerNo ratings yet

- PPTDocument56 pagesPPTSomalika Banerjee100% (2)

- Textil Industry FinDocument48 pagesTextil Industry FinTicu Ana-MariaNo ratings yet

- Rotor SpinningDocument92 pagesRotor SpinningSeeum SiddiquiNo ratings yet

- Break Even Point Summer Trining ReportDocument27 pagesBreak Even Point Summer Trining ReportMohit SinghNo ratings yet

- Advanced Carding 2022Document4 pagesAdvanced Carding 2022israel mwangoNo ratings yet

- CARDING (Textile) Process ParametersDocument4 pagesCARDING (Textile) Process ParametersKavudham ASNo ratings yet

- Yield of Yarn from Pakistani Cotton ReviewDocument1 pageYield of Yarn from Pakistani Cotton ReviewAwais ImranNo ratings yet

- Denim PresentationDocument25 pagesDenim PresentationAbdullah Al HafizNo ratings yet

- CombingDocument3 pagesCombingArunraj ArumugamNo ratings yet