Professional Documents

Culture Documents

FIBRE TO FABRIC Key Lesson

Uploaded by

GAMAN CHILAKAOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FIBRE TO FABRIC Key Lesson

Uploaded by

GAMAN CHILAKACopyright:

Available Formats

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

FIBRE TO FABRIC

Table of contents

FIBRE TO FABRIC

FIBRES

History of clothing 3

Fibre and fabric 3

Types of fibres 3

Natural fibres 3

Synthetic fibres 3

Types of natural fibres 3

Some plant fibres

Cotton Fibre 4

Ginning 4

Jute Fibre 5

The story of jute 5

Making yarn from fibres 5

Spinning 5

Conversion of Yarn to Fabric 6

Weaving 6

Knitting 7

Other useful plant fibres 7

Coir 7

Silk cotton 7

Hemp 7

SOME ANIMAL Fibres

Wool 8

Animals that yield Wool 8

From fibres to wool 9

Rearing of Sheep 9

Selective Breeding 9

Processing Fibres into Wool 9

Step I: Shearing 10

1 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

Step II: Scouring 10

Step III: Sorting 10

Step IV: Cleaning of burrs 11

Step V: Dyeing 11

Step VI: Straightening, Combing and Rolling 11

Silk 12

Discovery of silk 12

Types of Silk 13

Properties of Silk 13

Life Cycle of Silk Moth 13

From Cocoon to Silk 14

Rearing Silkworms 15

Processing Silk 16

2 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

FIBRES

The basic necessities for human beings are food, shelter and clothing. Let us discuss

about clothes and why they are important.

Clothes guard our body from external environment. They protect us from insect bite

and they make us look good.

Depending on the climate of the place people wear different clothes. Clothes are

made of different types of materials.

For example: Cotton sari is made of cotton, Leather jacket is made of leather,

Sweater is made of wool, etc.

History of clothing

In the beginning of civilization, people used bark, leaves and animal fur as clothes.

When people settled down as farmers, they used woven vines and animal fleece as

clothes. In the next stage, flax and cotton were woven into clothes. In those times,

people just draped the fabric to cover themselves. People started wearing stitched

clothes only after the needle was invented.

Even today, in older cultures like India, you see people wearing unstitched garments

like turbans, saris and dhotis.

Fibre and fabric

Fabrics are made up of strands called yarns, which are made from even thinner

strands, called fibres.

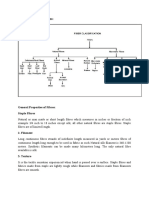

Types of fibres

Fibres can be classified as natural fibres and synthetic fibres.

Natural fibres

The fibres obtained from natural sources, i.e. plants and animals are called Natural

fibres.

Example: Cotton, jute, silk, wool, etc.

Synthetic fibres

These are man-made fibres. The fibres which are synthesized in industry from simple

chemicals obtained from petroleum are called synthetic fibres.

Example: Nylon, Polyester, Acrylic, etc.

Types of natural fibres

Natural fibres can be classified into two types – Plant fibres and Animal fibres.

Plant fibres

Fibres obtained from plant sources are called plant fibres.

Example: Cotton, Jute, coir, and linen.

3 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

Animal fibres

Fibres obtained from animal sources are called animal fibres.

Example: Wool and Silk.

SOME PLANT FIBRES

Cotton Fibre

Cotton fibre is obtained from cotton plants that grow in black soil in a warm climate.

In India, cotton is grown in Gujarat, Maharashtra, Andhra Pradesh, Telangana,

Punjab, Haryana, Karnataka, Tamil Nadu, Rajasthan, Orissa and Madhya Pradesh.

The cotton plant bears fruits about the size of a lemon, called cotton bolls. The bolls

are full of seeds and cotton fibre. They burst open when they are ripe. The cotton

fibres are collected by hand from the ripe cotton bolls. This process is called picking.

Next, the cotton fibres are separated from the seeds by combing them.

Ginning

The process of removing seeds from cotton is known as ginning. Earlier, ginning was

done by hand, but nowadays, a machine is used.

4 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

Jute Fibre

The story of jute

There is an interesting story about jute.

Long long ago a man was grazing his cattle in the forest near his village. Suddenly it

started raining. It did not stop for days. He saved himself by climbing on to a tree.

Almost all the forest got submerged in floods. After a couple of weeks he got down

from the tree and walked through soaked plants in the mud. He observed that peels

of plants stuck to his legs. He went home and removed those peelings from his body.

One day his wife saw the dried peels and noticed that they were so strong and spun

a thread out of it. Thus evolved the jute fibre.

In our state in the districts of Visakhapatnam, Srikakulam and Vijayanagaram jute is

widely grown.

Jute fibre comes from jute plants, which are mainly grown in places that have high

temperatures and plenty of rainfall. Jute is cultivated during the rainy season. In

India, jute is cultivated in West Bengal, Bihar, Andhra Pradesh, Uttar Pradesh, Assam,

Chhattisgarh and Tripura.

The jute plant is generally harvested when it is in the flowering stage. The stems of

jute plants are soaked in water for a few days until they start rotting. Then the fibres

are separated by hand from the rotting stems.

Making yarn from fibres

To make fabrics, all these fibres are first converted into yarns through a process

called spinning.

Spinning

The process of making yarn from fibres is called spinning. In this process, fibres from

a mass of cotton wool are drawn out and twisted. This brings the fibres together to

form a yarn. A simple device used for spinning is a hand spindle, also called takli.

Another hand operated device used for spinning is charkha.

5 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

Use of charkha was popularized by Mahatma Gandhi as part of the Independence

movement. He encouraged people to wear clothes made of homespun yarn and

reject imported cloth made in the mills of Britain.

Spinning of yarn on a large scale is done with the help of spinning machines. After

spinning, yarns are used for making fabrics.

Conversion of Yarn to Fabric

There are many ways by which fabrics are made from yarns. The two main processes

that are mostly used are weaving and knitting.

Weaving

The process of arranging two sets of yarns together perpendicular to each other to

make a fabric is called weaving. Fabrics are woven on looms. These looms may be

operated by hand or by power. The looms that are operated by hand are called

handlooms and that run by machines are called powerlooms.

6 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

Knitting

Knitting is a process that makes use of a single yarn to make a piece of fabric. That is

why, if you pull a single yarn from a torn woolen garment, it keeps unraveling.

Knitting can be done by hand or on machines.

Other useful plant fibres

Coir

Coconut fibre can be woven into fabric called coir. Coir is too rough to be made into

garments. It is mostly used to make doormats, carpets and other flooring material.

Silk cotton

Silk cotton is obtained from kapok tree. The fruits of this tree contain fibres. These

fibres are light and fluffy. Silk cotton is commonly used as stuffing in pillows, sleeping

bags and life jackets.

Hemp

Another important plant fibre is hemp. Hemp fibre is obtained from the stems of

hemp plant. It is mostly used to make ropes, carpets, clothes and papers and nets.

7 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

SOME ANIMAL FIBRES

Fibres obtained from animals are - wool and silk.

Wool

Wool is the animal fibre. Wool is obtained from the fleece (hair) of sheep, yak, goat

and some other animals. These animals bear a thick coat of hair on their body. Such

animals generally live in cold climates. Hair traps lot of air and keeps them warm as

air is a bad conductor of heat. It prevents the warmth of the body from escaping and

also prevents the coldness of the surroundings from entering.

Feel the hair on your body and arms and those on your head. Do you find any

difference? Which one seems coarse and which one is soft?

The hairy skin of the sheep has two types of fibres that form its fleece: (i) the coarse

beard hair, and (ii) the fine soft under-hair close to the skin. The fine hair provide the

fibres for making wool. Some breeds of sheep possess only fine under-hair.

Animals that yield Wool

8 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

Several breeds of sheep are found in different parts of our country. However, the

fleece of sheep is not the only source of wool. Apart from sheep, wool also comes

from the Angora goat, yak, llama, alpaca, and camels. Sheep wool is more commonly

available in India. In Tibet and Ladakh, yak wool is more common, whereas in Jammu

and Kashmir, it is the angora wool. The famous Pashmina shawls come from the soft

under fur of the Kashmiri goat. The fur (hair) on the body of camels is also used as

wool. Llama and Alpaca, found in South America, also yield wool.

From fibres to wool

For obtaining wool, sheep are reared. Their hair is cut and processed into wool.

Rearing of Sheep

Rearing of Sheep is a branch of animal husbandry. Sheep are reared mainly for their

meat, wool, and milk. Sheep are herbivores and prefer grass and leaves. However,

shepherds also feed them mixtures of pulses, corn, Jowar, oil cakes and minerals. In

winter, sheep are kept indoors and fed on leaves, grain and dry fodder. In India

sheep are reared in the hills of Jammu and Kashmir, Himachal Pradesh, Arunachal

Pradesh and Sikkim, and in the plains of Haryana, Punjab, Rajasthan and Gujarat.

Selective Breeding

The process of selecting parents for obtaining special characters in their offspring is

called Selective breeding.

For example, some breeds of sheep possess only fine under-hair which provides the

fibres for making wool. Their parents are specially chosen to give birth to sheep

which have only soft under-hair.

Sheep are reared in many parts of our country for wool. The following table gives the

names of some breeds of sheep reared in our country for producing wool. The

quality and texture of the fibres obtained from them is also indicated in the table.

Certain breeds of sheep have thick coat of hair on their body which yields good

quality wool in large quantities. These sheep are “selectively bred” with one parent

being a sheep of good breed. Once the reared sheep have developed a thick growth

of hair, hair is shaved off for getting wool.

Some Indian breeds of sheep

S. No. Name of breed Quality of wool State where found

1. Lohi Good quality wool Rajasthan, Punjab

2. Rampur bushair Brown fleece Uttar Pradesh, Himachal Pradesh

3. Nali Carpet wool Rajasthan, Haryana, Punjab

4. Bakharwal For woollen shawls Jammu and Kashmir

9 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

5. Marwari Coarse wool Gujarat

6. Patanwadi For hosiery Gujarat

Processing Fibres into Wool

The process of making fibre into wool involves the following steps:

Step I: Shearing

The fleece of the sheep along with a thin layer of the skin is removed from its body.

This process is called Shearing. In olden days this was done using a pair of metal

blades called shear. But now-a-days machine is used to cut off the fleece. Generally

sheep are sheared in warm weather, usually spring, as they don’t require their

woolly coats to keep them warm. Shearing doesn’t hurt the sheep as the uppermost

layer of the skin is dead (This is similar to shaving of hair or beards).

Step II: Scouring

The sheared skin with hair is thoroughly washed in tanks to remove grease, dust and

dirt. This is called scouring. Now-a-days scouring is done by machines.

Step III: Sorting

Sorting is done after scouring to separate hair of different textures and types. Some

parts of the sheep’s coat have better hair than others. The good quality wool from

the shoulders and sides of the sheep is used for clothing, while the more inferior

quality comes from the lower legs, and is used to make rugs.

10 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

Step IV: Cleaning of burrs

After sorting, the small fluffy fibres, called burrs, are picked out from the hair. The

fibres are scoured again and dried. This is the wool ready to be drawn into fibres.

Step V: Dyeing

Since the natural fibres are mostly black, brown or white in color they can be dyed in

various colours. Woollen fibres are first bleached and then dyed with different

colours.

Step VI: Straightening, Combing and Rolling

Once the dyeing process is complete, the fibres are straightened, combed and rolled

into yarn. Longer fibres are made into wool for sweaters, while the shorter fibres are

spun and woven into woollen cloth.

11 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

Knitting

Knitting of woolen fabrics is done by using needles. Wool can be knit easily because it

has a natural bend or crimp on it. By making knots and loops and rings of long

threads of yarn, woolen fabrics are knitted.

Weaving

Weaving is done on looms. Woolen threads are stretched from the top of loom to

the bottom. These are called warp threads. The threads that go side to side are weft

threads. A shuttle like a big needle takes the weft threads over and under warp

threads. One more important part of the loom is the harness. The harness lifts every

other warp thread so that the weft threads go over one and under the next. All types

of yarn whether cotton or silk or wool etc. are woven in this manner.

Occupational Hazards

12 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

Workers in wool industry face occupational hazards. Risks that can be life

threatening to workers due to their occupation are called occupational hazards. They

get infected by a bacterium called anthrax, which causes a fatal blood disease called

sorter’s disease.

Silk

Discovery of silk

Silk is known to mankind since 27th century B.C., the discovery of silk is credited to a

Chinese Queen Xi Ling Shi, at the age of 14 when she was already married to the

Emperor Huang Ti, also known as “Yellow Emperor”. As stated by Confucius, the

queen was once sitting under the Mulberry tree, sipping a warm cup of tea. One of

the cocoons fell right into her cup, the young queen was familiar with the object

because of remarkable growth of silkworms in the area, but she had never touched

or examined it. As the tea was hot, the fibres of cocoon began to separate in the tea

solution. The empress thought of weaving the thread thus leading to the discovery of

silk. Hence a new fabric was discovered and became a token of wealth for Chinese

empire.

The Chinese traded silk in return for gold, silver and wool. Technique of obtaining silk

was closely guarded in the Chinese kingdom for almost 30 centuries. The Great Silk

Road, mentions of which can be found in 300 BC literature, was a result of Chinese

silk trade with Roman Empire. All the pilgrims and travelers were checked at the

Chinese borders, a tough punishment was declared if they were found in possession

of silk cocoons, eggs or silkworms. The monopoly of China over silk came to an end

when a Chinese princess married the King of Khotan, the princess brought silkworm

eggs and mulberry tree seeds in her traditional headdress. Soon the knowledge of

procuring silk penetrated to India and Persia.

However, the discussion of Silk fabrics in Vedic literature and the newly found silk

pieces in the areas around Indus Valley Civilization prove the silk production was also

done in the areas around Sind since significantly ancient times.

Types of Silk

Different types of silk moths which look very different from one another yield

different types of silk yarn which are different in texture (coarse, smooth, shiny, etc.),

such as mulberry silk, tassar silk, eri silk and mooga silk. The most common silk moth

is the mulberry silk moth. Its scientific name is Bombyx mori.

Properties of Silk

Silk obtained from mulberry silk moth is soft, lustrous, and elastic and can be dyed in

beautiful colours. This soft silk thread is as strong as comparable to a steel thread.

Let us discuss about the life cycle of mulberry silk moth.

13 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

Life Cycle of Silk Moth

The female silk moth lays eggs, from

which the larvae are hatched which are

called caterpillars or silkworms. These

silkworms feed on fresh mulberry leaves

and grow in size. When the caterpillar is

ready to enter the next stage of its life

history called pupa, it first weaves a net

to hold itself. Then it swings its head

from side to side in the form of eight

(8). During these movements of the

head, the caterpillar secretes fibre

made of a protein which hardens on Pupa

exposure to air and becomes silk fibre.

Soon the caterpillar completely covers

itself by silk fibres and turns into pupa.

This covering is known as cocoon. The further development of the pupa into moth

continues inside the cocoon. The silk yarn (thread) is obtained from the cocoon of

the silk moth.

14 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

From Cocoon to Silk

For obtaining silk, moths are reared and their cocoons are collected to get silk

threads. The rearing of silk worms for obtaining silk is called Sericulture.

Rearing Silkworms

Silkworms are reared under suitable conditions of temperature and humidity to

obtain silk threads from their cocoons.

15 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

Moth to egg

When the silk moth emerges from the cocoon it is ready to mate. It will not eat

during this stage, it doesn't have any mouth parts. Its only purpose at this stage is to

mate. The male silkworm is smaller than the female and is very active. The female

barely moves, her energy is kept for laying eggs. Once copulated, the pair can stay

together for 12 to 24 hours. The male will seek another mate. The female silk moth

lays hundreds of eggs (seeds) at a time (around 500 eggs and dies). These are stored

on strips of cloth or paper and sold to silkworm farmers. The farmers keep eggs

under hygienic conditions and under suitable conditions of temperature and

humidity.

Egg to cocoon

Mulberry leaves are the staple diet of silkworms. When the mulberry tree bears a

fresh crop of leaves, the eggs are warmed suitably so that the larvae hatch from

them. The larvae, caterpillars or silkworms are then stored in clean bamboo trays

(Chandrikalu) and are fed freshly chopped mulberry leaves. They eat day and night,

and grow enormously in size.

After 25 to 30 days, the caterpillars stop eating and move to a tiny chamber of

bamboo in the tray to spin cocoons. Small racks or twigs may be provided in the trays

to which cocoons get attached. The caterpillar or silkworm spins the cocoon

(Pattukayalu) inside which develops the silk moth. After 2-3 weeks, young moths

(Chilakalu) come out from the cocoons and fly away. So, within 2-3 days of formation

of cocoon, one should remove the cocoons from the tray.

16 | Page SRI CHARITHA

PRAGNYA MONTESSORI SCHOOL BIOLOGY FIBRE TO FABRIC

Processing Silk

Cocoon to silk fibre

Extracting silk from the cocoon is called processing silk.

The first step is to separate the silk fibre from the cocoon. For this, they need to be

exposed to warmth. Piles of cocoons are kept under the sun, boiled or exposed to

steam (stiffling). The warmth causes the silk fibre to separate from the rest of the

cocoon.

The next step is called reeling the silk, which is the process of delicately unwinding

the fibre from the cocoon. Reeling is done in special machines, which unwind the

threads or fibres of silk from the cocoon. The silk fibres are bleached and dyed into

many shades.

Reeling to weaving

The silk fibres are then spun into silk threads, which are woven into silk cloth by

weavers.

17 | Page SRI CHARITHA

You might also like

- Field Guide to Fabrics: The Complete Reference Tool to Understanding FabricFrom EverandField Guide to Fabrics: The Complete Reference Tool to Understanding FabricRating: 5 out of 5 stars5/5 (2)

- Fibre To Fabric NotesDocument7 pagesFibre To Fabric NotesMidhun Bhuvanesh.B 7ANo ratings yet

- Fibre To FabricDocument68 pagesFibre To Fabricprincess clubNo ratings yet

- Textiles, for Commercial, Industrial, and Domestic Arts Schools: Also Adapted to Those Engaged in Wholesale and Retail Dry Goods, Wool, Cotton, and Dressmaker's TradesFrom EverandTextiles, for Commercial, Industrial, and Domestic Arts Schools: Also Adapted to Those Engaged in Wholesale and Retail Dry Goods, Wool, Cotton, and Dressmaker's TradesNo ratings yet

- Types of Fibres - Class 6, Fibre To FabricDocument5 pagesTypes of Fibres - Class 6, Fibre To FabricPriyaNo ratings yet

- Class 6 Chemistry Fibre To FabricDocument9 pagesClass 6 Chemistry Fibre To FabricSachin SharmaNo ratings yet

- CBSE CLASS 7 Fibre To Fabric PDFDocument17 pagesCBSE CLASS 7 Fibre To Fabric PDFManoj JaiswalNo ratings yet

- Yarn AssignmentDocument22 pagesYarn Assignmentsarwat yaseenNo ratings yet

- Fibre To Fabric (G6) : Handout I. Short Answer QuestionsDocument4 pagesFibre To Fabric (G6) : Handout I. Short Answer Questionsdon shiphrahNo ratings yet

- Fibre To FabricDocument4 pagesFibre To FabricPranav ShindeNo ratings yet

- Exp SC 6 - Chapter 03Document11 pagesExp SC 6 - Chapter 03megamind publicationNo ratings yet

- Fibre To FabricDocument2 pagesFibre To FabricmailtomicaiahNo ratings yet

- Bijendra Public School: Class - 6 Subject - SCIENCE Chapter - 3 Fibre To FabricDocument4 pagesBijendra Public School: Class - 6 Subject - SCIENCE Chapter - 3 Fibre To Fabricsmitha_gururaj100% (1)

- Chapter - 3: Fibre To FabricDocument42 pagesChapter - 3: Fibre To FabricPHYSICS HACKNo ratings yet

- Chapter - 3 Class - VI Fibre To FabricDocument24 pagesChapter - 3 Class - VI Fibre To Fabricamit lakraNo ratings yet

- Fibre To Fabric Notes 1Document3 pagesFibre To Fabric Notes 1Mohan Reddy KothapetaNo ratings yet

- A Shirt in The Market SST Project Class 7Document10 pagesA Shirt in The Market SST Project Class 7prakharalokguptaNo ratings yet

- CBSE 7 Chemistry Revision Notes Fibre To FabricDocument2 pagesCBSE 7 Chemistry Revision Notes Fibre To FabricDraksha ChimurkarNo ratings yet

- Fibre To FabricDocument33 pagesFibre To FabricShiney KoshyNo ratings yet

- Fiber, Yarn, Fabrics 3Document18 pagesFiber, Yarn, Fabrics 3Mahadi HabibNo ratings yet

- Textile FiberDocument159 pagesTextile Fiberfayeraleta2024No ratings yet

- Fibre To Fabric Class 6 Notes.Document3 pagesFibre To Fabric Class 6 Notes.amritha mishraNo ratings yet

- Pharmacognosy Chapter 6 Plants Used As Surgical Dressings NotesDocument11 pagesPharmacognosy Chapter 6 Plants Used As Surgical Dressings NotesAbhishek palNo ratings yet

- L3Fibre To FabricDocument2 pagesL3Fibre To FabricSHAHANA RIZVI TGTNo ratings yet

- Grade 6 Fibre To Fabric Sample QuestionsDocument3 pagesGrade 6 Fibre To Fabric Sample Questionsmohamedaahil12318No ratings yet

- Textile IndustryDocument21 pagesTextile IndustrygnvfdhgNo ratings yet

- Properties Natural FibresDocument46 pagesProperties Natural FibresanishaNo ratings yet

- Science 3Document8 pagesScience 3Cris CNo ratings yet

- Introduction To Textile Raw MaterialDocument25 pagesIntroduction To Textile Raw Materialapi-377494790% (21)

- Textile Raw MaterialDocument3 pagesTextile Raw Materialmian487No ratings yet

- FibreDocument5 pagesFibreamp1279No ratings yet

- Science Chapter 3 Fibre To FabricDocument5 pagesScience Chapter 3 Fibre To Fabricsaangee.inNo ratings yet

- Introduction To YarnDocument18 pagesIntroduction To YarnAbhradeep BhattacharjeeNo ratings yet

- Fabric Powerpoint 19Document55 pagesFabric Powerpoint 19Japhet GatchoNo ratings yet

- SilkDocument6 pagesSilkshevy101No ratings yet

- Final ReportDocument30 pagesFinal ReportTagaBukidDotNetNo ratings yet

- Jute and Sugarcane FibreDocument7 pagesJute and Sugarcane Fibreyogeshgavit208No ratings yet

- Classification of FibresDocument12 pagesClassification of FibresARYAN RATHORENo ratings yet

- Learning Outcomes of This Lecture: The Students Will Be Able ToDocument36 pagesLearning Outcomes of This Lecture: The Students Will Be Able Totech surgeonsNo ratings yet

- 6 Fibre To Fabric: Z Z Z Z ZDocument12 pages6 Fibre To Fabric: Z Z Z Z ZAshfaque AhmedNo ratings yet

- FIBERDocument9 pagesFIBERnaivaanNo ratings yet

- Textile Project NiDS PDFDocument40 pagesTextile Project NiDS PDFnidspune.inNo ratings yet

- 6 Fibre To Fabric: 84:: Home ScienceDocument11 pages6 Fibre To Fabric: 84:: Home ScienceBiplab SadhukhanNo ratings yet

- Class 6 Science Chapter 3 Revision NotesDocument3 pagesClass 6 Science Chapter 3 Revision NotesNandini JhaNo ratings yet

- c3 Fibre To Fabric NotesDocument5 pagesc3 Fibre To Fabric NotesNAVNEETA AGARWALNo ratings yet

- Engleski TTF Skripta 1 SemestarDocument6 pagesEngleski TTF Skripta 1 SemestarAndrea VekarićNo ratings yet

- Science Assignment 2 Class VIIDocument2 pagesScience Assignment 2 Class VIIsanjeetsksNo ratings yet

- Ntural and Man Made FibreDocument46 pagesNtural and Man Made FibreRemyaNo ratings yet

- Textile FibresDocument44 pagesTextile FibresMadhu MathiNo ratings yet

- Khadi Extended DocumentationDocument14 pagesKhadi Extended DocumentationarchaggNo ratings yet

- Fibre To FabricDocument10 pagesFibre To FabricNayanika VermaNo ratings yet

- A Treatise On Cotton FiberDocument5 pagesA Treatise On Cotton FiberRobotrixNo ratings yet

- Fibre To FabricDocument18 pagesFibre To FabricshaNo ratings yet

- L 1 F: T C C: Esson Ibres Heir Lassification AND HaracteristicsDocument11 pagesL 1 F: T C C: Esson Ibres Heir Lassification AND HaracteristicsMuhamad RafiqNo ratings yet

- 7th Chemistry DLP Study Package FinalDocument101 pages7th Chemistry DLP Study Package FinalAdityaNo ratings yet

- Fiber Textile Fashion IndustriesDocument33 pagesFiber Textile Fashion IndustriesRishi KumarNo ratings yet

- How Silk Is MadeDocument8 pagesHow Silk Is Madesandeep_mittal62100% (1)

- Fabric & FormDocument29 pagesFabric & FormShruti SoganiNo ratings yet

- Importance of Fibers in Textiles: Kavitha RajanDocument44 pagesImportance of Fibers in Textiles: Kavitha RajankavineshpraneetaNo ratings yet

- Easy Knit SlippersDocument7 pagesEasy Knit Slippersapi-3738964100% (2)

- Solutions For Class 6 Science Chapter 3 Fibre To FabricDocument7 pagesSolutions For Class 6 Science Chapter 3 Fibre To FabricRajendra PatelNo ratings yet

- Q601 Parts List - 100913Document26 pagesQ601 Parts List - 100913AstraluxNo ratings yet

- Pattern Zefirka - VLG BunnyDocument5 pagesPattern Zefirka - VLG BunnyBianka SeligaNo ratings yet

- BRK0502 025928M 1 PDFDocument1 pageBRK0502 025928M 1 PDFMre LbnsNo ratings yet

- Ist 531 Final Video Script BasirDocument5 pagesIst 531 Final Video Script Basirapi-312391086No ratings yet

- Japanese Inspired KnitsDocument8 pagesJapanese Inspired KnitsInterweave40% (20)

- Garment CheckerDocument29 pagesGarment Checkerzeeshan_220No ratings yet

- Daydream Tote Pattern and InstructionsDocument13 pagesDaydream Tote Pattern and InstructionsLawren Fowlkes100% (1)

- Equinox: Wolf & Faun KnitsDocument5 pagesEquinox: Wolf & Faun KnitsRoganNo ratings yet

- "Christmas Wreath": With SantaDocument25 pages"Christmas Wreath": With SantaDiana GarciaNo ratings yet

- Crochet Among Us Dead Body Amigurumi Free PatternDocument14 pagesCrochet Among Us Dead Body Amigurumi Free PatternJustyna Janicka100% (1)

- Baby YodaDocument13 pagesBaby YodaNaye Parra100% (2)

- PATRON BLUSA CrochetDocument5 pagesPATRON BLUSA CrochetcoconitaNo ratings yet

- Raorte. (RSR - Ro.: UtilizationDocument7 pagesRaorte. (RSR - Ro.: UtilizationNabil HasanNo ratings yet

- Free Pattern: Little COWDocument8 pagesFree Pattern: Little COWWork workNo ratings yet

- Best Practices in WeavingDocument12 pagesBest Practices in WeavingRajesh RamanNo ratings yet

- Claim Complaint Template NEW!!!!!Document12 pagesClaim Complaint Template NEW!!!!!Lawrence IrudiasamyNo ratings yet

- MIS Dashboard - 14.2.23Document10 pagesMIS Dashboard - 14.2.23sky textiles300No ratings yet

- Picking Is The Second Primary Motion in Weaving. The Action of Inserting Weft Yarn Through The Warp Yarns Is Called PickingDocument6 pagesPicking Is The Second Primary Motion in Weaving. The Action of Inserting Weft Yarn Through The Warp Yarns Is Called PickingShariful HasanNo ratings yet

- Uster Yarn Standard Table For Knitting Yarn: Coun T (N E) Y Arn Char Ctris TicsDocument1 pageUster Yarn Standard Table For Knitting Yarn: Coun T (N E) Y Arn Char Ctris Ticslalit kashyap0% (1)

- Crochet Doll Fiona Amigurumi Free PDF PatternDocument6 pagesCrochet Doll Fiona Amigurumi Free PDF PatternTanja BauerNo ratings yet

- 1 Persian CarpetsDocument2 pages1 Persian CarpetswhizwebadilNo ratings yet

- Fabric ConstructionDocument35 pagesFabric ConstructionRemya SujithNo ratings yet

- Jacquard Shedding MechanismDocument12 pagesJacquard Shedding MechanismtusharNo ratings yet

- GRD 7-8 Test DressmakingDocument6 pagesGRD 7-8 Test DressmakingMa'am Phine100% (2)

- A Study of Textile and FabricsDocument55 pagesA Study of Textile and Fabricsshyam soni100% (1)

- G.S. ProjectDocument38 pagesG.S. ProjectSamiksha SarkarNo ratings yet

- Free R0265 Socken Struktur - USDocument2 pagesFree R0265 Socken Struktur - USrezgsfsfgNo ratings yet

- Crocheted Fish PDFDocument10 pagesCrocheted Fish PDFAleyda Bonfil LeónNo ratings yet

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (58)

- Pale Blue Dot: A Vision of the Human Future in SpaceFrom EverandPale Blue Dot: A Vision of the Human Future in SpaceRating: 4.5 out of 5 stars4.5/5 (588)

- Challenger: A True Story of Heroism and Disaster on the Edge of SpaceFrom EverandChallenger: A True Story of Heroism and Disaster on the Edge of SpaceNo ratings yet

- Hero Found: The Greatest POW Escape of the Vietnam WarFrom EverandHero Found: The Greatest POW Escape of the Vietnam WarRating: 4 out of 5 stars4/5 (19)

- When the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachFrom EverandWhen the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachRating: 3.5 out of 5 stars3.5/5 (6)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyFrom EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- The End of Craving: Recovering the Lost Wisdom of Eating WellFrom EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellRating: 4.5 out of 5 stars4.5/5 (83)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationFrom EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationRating: 4.5 out of 5 stars4.5/5 (46)

- Dealers of Lightning: Xerox PARC and the Dawn of the Computer AgeFrom EverandDealers of Lightning: Xerox PARC and the Dawn of the Computer AgeRating: 4 out of 5 stars4/5 (88)

- Nutrition 101: Understanding the Science and Practice of Eating WellFrom EverandNutrition 101: Understanding the Science and Practice of Eating WellRating: 4.5 out of 5 stars4.5/5 (22)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- Fallout: The Hiroshima Cover-up and the Reporter Who Revealed It to the WorldFrom EverandFallout: The Hiroshima Cover-up and the Reporter Who Revealed It to the WorldRating: 4.5 out of 5 stars4.5/5 (83)

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreFrom EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreRating: 4.5 out of 5 stars4.5/5 (33)

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureFrom EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureRating: 5 out of 5 stars5/5 (125)

- Packing for Mars: The Curious Science of Life in the VoidFrom EverandPacking for Mars: The Curious Science of Life in the VoidRating: 4 out of 5 stars4/5 (1396)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- From Darwin to Derrida: Selfish Genes, Social Selves, and the Meanings of LifeFrom EverandFrom Darwin to Derrida: Selfish Genes, Social Selves, and the Meanings of LifeRating: 4 out of 5 stars4/5 (2)

- The Future of Geography: How the Competition in Space Will Change Our WorldFrom EverandThe Future of Geography: How the Competition in Space Will Change Our WorldRating: 4 out of 5 stars4/5 (6)

- The One-Straw Revolution: An Introduction to Natural FarmingFrom EverandThe One-Straw Revolution: An Introduction to Natural FarmingRating: 4.5 out of 5 stars4.5/5 (272)