Professional Documents

Culture Documents

TS - V-SHAPE CROSS ARMS & TOP HAMPERS & D Strap

Uploaded by

Ashim BhowmickOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TS - V-SHAPE CROSS ARMS & TOP HAMPERS & D Strap

Uploaded by

Ashim BhowmickCopyright:

Available Formats

Part:2: PSPCL’s Requirements 447

49. V-SHAPE CROSS ARMS & TOP HAMPERS & D Strap

1. SCOPE: This specification covers the design, manufacture/ fabrication, testing before dispatch

at manufacturer’s premises, delivery at site (F.O.R. Destination at any place in Punjab) of V-

Shape Cross Arms, & Top Hampers to be used in HT/LT Lines of distribution system in Punjab

State Power Corporation Limited as per Schedule of requirement given below:

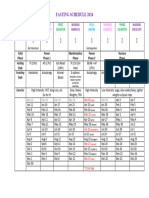

2. SCHEDULE OF REQUIREMENT:

Sr. Description

No.

1. GI Mild Steel Angle Iron 65x65x6mm V Shape Cross Arms as per drawing

attached as Annexure-Drg.-1, manufactured from Prime Mild Steel Angle

conforming to IS: 2062/1992 (Grade A Quality) and section details as per IS:

808/1989 & tolerances as per IS: 1852/ 1985. The edge cutting of Cross Arms

should be smooth and at right angle. The seam welding of joints should be

continuous and uniform on one side. The fabricated Cross Arms should have level

surface.

2 GI Top Hampers as per drawing attached as Annexure-Drg.-4, manufactured from

Prime M.S. Flat (50x6mm) conforming to IS: 2062/1992 (with latest editions)

Grade – A quality and section details as per IS: 1730/1971 & tolerances as per IS:

1852/ 1985. The seam welding of joints should be continuous and uniform on one

side. The edge cutting of Top Hamper should be smooth and at right angle.

GI M.S.D Straps as per drawing attached as Annexure-Drg-5, manufactured from

M.S. Flat(40X6mm) conforming to IS: 2062/1992 (with latest editions) Grade – A

3. quality and sectional details as per IS:1730/1989 and tolerance as per IS:

1852/1985. The edge cutting of D Straps should be smooth and at right angle.

3. TESTS:

The above fabricated items shall be procured from reputed manufacturer, who has adequate

manufacturing/ in-house testing facility as per the relevant Indian Standard specifications. Apart

from visual inspection/ dimension check, all the tests shall be performed on material at the

manufacturer’s works as per relevant Indian Standards as detailed above.

4. PLACE OF MANUFACTURE & INSPECTION:

Place of manufacture, testing and inspection of the material must be clearly stated by the tenderer.

5. INSPECTION AND TESTS:

The PSPCL shall inspect, examine and test the material through its representative or through an

outside agency nominated by PSPCL at the manufacturer’s/ supplier’s works during or after the

manufacture of material prior to dispatch on receipt of a clear notice of minimum two weeks in

advance to be reckoned from the date of receipt by the purchaser. The Contractor/ Supplier shall

provide all facilities as may be required to carry out the test in accordance with the approved

standards, free of cost. All testing instruments and appliances will be made available by the

supplier and the material consumed/ destroyed during testing will be to the account of tenderer.

Apart from visual inspection/ dimensional check, all the tests as per relevant ISS along with

latest editions and amendments shall be performed on the material at manufacturer’s works.

TE No. 74/CE/Distribution Projects/RDSS/2023-24

Part:2: PSPCL’s Requirements 448

6. TOLERANCE:

A tolerance of ± 2.0% (two percent) of the ordered quantity shall be allowed against shortages to

complete the order.

7. PAST PERFORMANCE:

The past performance of the firm, on whom order has been placed by this office for this material

or similar other fabricated items in the past, shall be taken into consideration while deciding the

case. The firms with unsatisfactory performance, are likely to be ignored even if otherwise found

technically acceptable and coming within zone of consideration.

8. RAW MATERIAL:

The raw material shall be of best quality of its kind obtainable in the market and shall conform to

specific details laid down in relevant Indian Standard Specifications with latest amendments, if

any. The supplier/ contractor shall be responsible for the procurement of best quality of raw

material required for the manufacture of goods to be supplied against this tender enquiry.

9. ACCEPTANCE OF TENDERS:

The competent authority may distribute the quantities to be procured on more than one firm.

10. RANDOM CHECKING:

On receipt of material in store, the PSPCL may check the material. If any shortage/ deviation

from declared weight/ size/ specification is noticed, the same will be reported immediately by the

consignee to the supplier, under intimation to all concerned. On receipt of such intimation from

consignee, the Chief Engineer/ S&W, PSPCL, Patiala shall fix a date & time for joint

verification under intimation to the supplier & all concerned giving a minimum 10 days time.

The checking shall be carried out in the presence of firm’s representative at Destination Station.

If the representative of the firm does not happen to be present at the destination for joint

verification on the specific date and time so fixed, then the purchaser/ representative of the

PSPCL shall be at liberty to do joint verification in the absence of firm’s representative and

shortages/ discrepancies so detected in a particular size shall be applied on the full lot.

In case of shortage/ discrepancies, in a particular lot supplied to various consignees, are also

noticed by different consignees, the above procedure shall be followed for joint verification by

each and all consignees. The maximum shortages/ discrepancies detected in a particular size by

any of the consignees shall be applied to entire lot of material supplied to various consignees. In

case of any failure of material during random checking, PSPCL reserves the right to reject the

entire lot at the risk and cost of the supplier.

In case of repeated shortages/ discrepancies, the firm shall be liable for suspension of business

dealings/ black listing. This is without prejudice to other rights arising/ accruing to the purchaser

under various clauses of this tender specification and purchase order-cum-contract agreement.

Note:

1. In case of conflict between these technical specifications and general instructions

contained in Schedule ‘E’ of tender specifications, the former will overrule the later.

2. No change/ relaxations shall be allowed in the provisions of this technical specification/

drawings while making supplies. The offers of the bidders to offer material of some other

specifications shall be rejected.

TE No. 74/CE/Distribution Projects/RDSS/2023-24

Part:2: PSPCL’s Requirements 449

TE No. 74/CE/Distribution Projects/RDSS/2023-24

You might also like

- The Contractor Payment Application Audit: Guidance for Auditing AIA Documents G702 & G703From EverandThe Contractor Payment Application Audit: Guidance for Auditing AIA Documents G702 & G703No ratings yet

- 16 400 220 132KV C R PanelsDocument87 pages16 400 220 132KV C R PanelsShatrughna SamalNo ratings yet

- sf6 CBDocument24 pagessf6 CBNaushad AliNo ratings yet

- Breaker SpecifiDocument27 pagesBreaker SpecifiankitrajNo ratings yet

- Sti 2062Document7 pagesSti 2062fyzmfaNo ratings yet

- CABLE SPEC TECH DETAILSDocument4 pagesCABLE SPEC TECH DETAILSkeyurNo ratings yet

- Gen - Req. of SpecificationsDocument9 pagesGen - Req. of SpecificationsSagar SinghNo ratings yet

- Jhlasalle 014300 Quality AssuranceDocument5 pagesJhlasalle 014300 Quality AssurancePonz MadianoNo ratings yet

- Transformer 20mvaDocument102 pagesTransformer 20mvassvasavaongcNo ratings yet

- 13 S e Opgw Final With Boq 2Document63 pages13 S e Opgw Final With Boq 2Ivan Dario QuirogaNo ratings yet

- Deaerator Fabrication BHPVL Tender SpecDocument52 pagesDeaerator Fabrication BHPVL Tender SpecVijay SekharNo ratings yet

- Tender Technical Specification For Supply, Erection (Including Civil Work), Commissioning & Testing of 11Kv Rmu (Ring Main Unit) at Khajod Under Althan S/DN of Piplod DivisionDocument44 pagesTender Technical Specification For Supply, Erection (Including Civil Work), Commissioning & Testing of 11Kv Rmu (Ring Main Unit) at Khajod Under Althan S/DN of Piplod DivisionHossam AlzubairyNo ratings yet

- 24 66 11 KV 5 MVA Transformer With Amendment PDFDocument100 pages24 66 11 KV 5 MVA Transformer With Amendment PDFNirmal mehtaNo ratings yet

- Meghalaya Energy Corpration Limited Meghalaya Energy Corpration Limited Meghalaya Energy Corpration LimitedDocument20 pagesMeghalaya Energy Corpration Limited Meghalaya Energy Corpration Limited Meghalaya Energy Corpration Limitedarjun kumarNo ratings yet

- 22KV RMU Tender for Surat AreaDocument51 pages22KV RMU Tender for Surat Areascada enggNo ratings yet

- Outdoor Type Package SubstationDocument41 pagesOutdoor Type Package Substationapjbalamurugan100% (1)

- 22 66 KV LA R4 Jan 11 PDFDocument17 pages22 66 KV LA R4 Jan 11 PDFDin CuyNo ratings yet

- 005 - 01 7-0001-CFD-RQ - C - SowDocument11 pages005 - 01 7-0001-CFD-RQ - C - Sowshaikhsajid242No ratings yet

- Total Technical Specs PDFDocument259 pagesTotal Technical Specs PDFBhavesh KeraliaNo ratings yet

- General Technical Specification: © 2007 MECON Limited All Rights ReservedDocument5 pagesGeneral Technical Specification: © 2007 MECON Limited All Rights ReservedAK TRIPATHINo ratings yet

- 06 - TS OPGW 24 FibreDocument73 pages06 - TS OPGW 24 FibreAHMED YOUSEFNo ratings yet

- PCPL 0532 3 407 04 03Document1 pagePCPL 0532 3 407 04 03tceterexNo ratings yet

- JSS 6850-22Document8 pagesJSS 6850-22Minal ParapannawarNo ratings yet

- Inspection Procedure For ContractDocument24 pagesInspection Procedure For ContractVijaya PatilNo ratings yet

- IPR Negative Ion NBI Water SystemDocument51 pagesIPR Negative Ion NBI Water SystemKarthick KumarNo ratings yet

- C VDocument32 pagesC VASHISH CHAURASIANo ratings yet

- 11kV HT Kiosk SpecificationDocument35 pages11kV HT Kiosk Specification10derNo ratings yet

- INSPECTION AND TEST PLAN (ITP) FOR CONTROL VALVESDocument15 pagesINSPECTION AND TEST PLAN (ITP) FOR CONTROL VALVESzakariaNo ratings yet

- Sti4923 8 PDFDocument7 pagesSti4923 8 PDFkprasad_56900No ratings yet

- Fabrication, Inspection, Testing and Supply of Stainless Steel DrumsDocument17 pagesFabrication, Inspection, Testing and Supply of Stainless Steel DrumsAmitNo ratings yet

- Portable Crusher - 100TPH MOHDocument16 pagesPortable Crusher - 100TPH MOHmohammedNo ratings yet

- Technical Specifications For Reduction Retort Bottom SectionDocument5 pagesTechnical Specifications For Reduction Retort Bottom SectionSharat ChandraNo ratings yet

- Technical Specification Section - Viii: 1. General Information and Scope 1.1 ScopeDocument19 pagesTechnical Specification Section - Viii: 1. General Information and Scope 1.1 ScopeMl JainNo ratings yet

- E & I Tender WorkDocument9 pagesE & I Tender Workmanojjuvali100% (1)

- GAIL Scraper Launcher Bid DocumentsDocument54 pagesGAIL Scraper Launcher Bid DocumentsjabarcanNo ratings yet

- Administration of Ut of Daman & Diu Electicity Deaprtment,: Technical SpecificationsDocument102 pagesAdministration of Ut of Daman & Diu Electicity Deaprtment,: Technical Specificationsmanoj semwalNo ratings yet

- GETCO Power Transformer SpecificationDocument116 pagesGETCO Power Transformer SpecificationPB MehtaNo ratings yet

- Technical Specifications Section-I 1. General Information 1.1Document12 pagesTechnical Specifications Section-I 1. General Information 1.1Jayant KambleNo ratings yet

- Bec TechDocument2 pagesBec TechJainil GajjarNo ratings yet

- AHU Design GuideDocument37 pagesAHU Design Guidesachin100% (1)

- SA02-16 - General Requirement RTUDocument60 pagesSA02-16 - General Requirement RTUhiryanizamNo ratings yet

- PIP STS03600 (Nonshrink Cementitous Grout Specification)Document8 pagesPIP STS03600 (Nonshrink Cementitous Grout Specification)Javad Monfared100% (1)

- Bidding Document For Passenger and Cargo LiftsDocument51 pagesBidding Document For Passenger and Cargo Liftsderibe sisayNo ratings yet

- Annexure - III Recirculation Tank Pkl1Document35 pagesAnnexure - III Recirculation Tank Pkl1ANIMESH JAINNo ratings yet

- Cable Laying Specification - Technical Specification - 2Document39 pagesCable Laying Specification - Technical Specification - 2ankur kumarNo ratings yet

- 1363 Scheme of Testing of Hexagonal Bolts & NutsDocument7 pages1363 Scheme of Testing of Hexagonal Bolts & Nutsjra9090No ratings yet

- ITB - QA - QC of 8S and 14S Flowlines ConstructionDocument17 pagesITB - QA - QC of 8S and 14S Flowlines ConstructionChukwuma Emmanuel OnwufujuNo ratings yet

- Enquiry Cum Scope of Supply & Technical Specifications of Tender ITEM NO:-10 QUANTITY: - 1 EA (Each) Item DescriptionDocument5 pagesEnquiry Cum Scope of Supply & Technical Specifications of Tender ITEM NO:-10 QUANTITY: - 1 EA (Each) Item Descriptionpramodyad5810No ratings yet

- Battery Charger TS Rev-0-31.12.22Document29 pagesBattery Charger TS Rev-0-31.12.22DEVI PRASAD GREENSECURENo ratings yet

- Annexure - ' D ' Technical Specification For Insulator Pins (Pins For 11,22 and 33 KV Insulators)Document8 pagesAnnexure - ' D ' Technical Specification For Insulator Pins (Pins For 11,22 and 33 KV Insulators)sbmarali7839No ratings yet

- EIL Spec For Instrumentation WorksDocument85 pagesEIL Spec For Instrumentation WorksRatnam Sk93% (15)

- Quality Control Manual ProceduresDocument6 pagesQuality Control Manual ProcedureschandraNo ratings yet

- NY Supplier Quality Requirements and InstructionsDocument9 pagesNY Supplier Quality Requirements and InstructionspacifficNo ratings yet

- Double Flap NRV SPECDocument7 pagesDouble Flap NRV SPECtarunchauhan1No ratings yet

- 0 Line 13 Conductor Zebra Used in Transmission LinesDocument9 pages0 Line 13 Conductor Zebra Used in Transmission LinesPavithra ShivanNo ratings yet

- GETCO 400kV Transmission Line Technical SpecificationDocument30 pagesGETCO 400kV Transmission Line Technical SpecificationdineshksenthilNo ratings yet

- Sprinkler Irrigation System TenderDocument6 pagesSprinkler Irrigation System TenderMahesh Savandappa0% (1)

- Astm D 664 - 07Document8 pagesAstm D 664 - 07Alfonso MartínezNo ratings yet

- Advanced Presentation Skills: Creating Effective Presentations with Visuals, Simplicity and ClarityDocument15 pagesAdvanced Presentation Skills: Creating Effective Presentations with Visuals, Simplicity and ClarityGilbert TamayoNo ratings yet

- Inertial Reference Frames: Example 1Document2 pagesInertial Reference Frames: Example 1abhishek murarkaNo ratings yet

- Service Parts List: 54-26-0005 2551-20 M12™ FUEL™ SURGE™ 1/4" Hex Hydraulic Driver K42ADocument2 pagesService Parts List: 54-26-0005 2551-20 M12™ FUEL™ SURGE™ 1/4" Hex Hydraulic Driver K42AAmjad AlQasrawi100% (1)

- 4 TheEulerianFunctions - 000 PDFDocument16 pages4 TheEulerianFunctions - 000 PDFShorouk Al- IssaNo ratings yet

- Komatsud65ex 16dozerbulldozerservicerepairmanualsn80001andup 200727063646Document26 pagesKomatsud65ex 16dozerbulldozerservicerepairmanualsn80001andup 200727063646juan santa cruzNo ratings yet

- Apps Tables Excel FRMTDocument4 pagesApps Tables Excel FRMTSunil ReddyNo ratings yet

- Lecture 29: Curl, Divergence and FluxDocument2 pagesLecture 29: Curl, Divergence and FluxKen LimoNo ratings yet

- SMEs, Trade Finance and New TechnologyDocument34 pagesSMEs, Trade Finance and New TechnologyADBI EventsNo ratings yet

- U-KLEEN Moly Graph MsdsDocument2 pagesU-KLEEN Moly Graph MsdsShivanand MalachapureNo ratings yet

- Athenaze 1 Chapter 7a Jun 18th 2145Document3 pagesAthenaze 1 Chapter 7a Jun 18th 2145maverickpussNo ratings yet

- Final Annotated BibiliographyDocument4 pagesFinal Annotated Bibiliographyapi-491166748No ratings yet

- Inventory Storage and Retrieval System PatentDocument15 pagesInventory Storage and Retrieval System PatentdevanasokaNo ratings yet

- Jotrun TDSDocument4 pagesJotrun TDSBiju_PottayilNo ratings yet

- Stellar Structure and EvolutionDocument222 pagesStellar Structure and Evolutionjano71100% (2)

- Moon Fast Schedule 2024Document1 pageMoon Fast Schedule 2024mimiemendoza18No ratings yet

- 02 MortarsDocument2 pages02 MortarsTarun kumar DigarseNo ratings yet

- Akhmatova, Anna - 45 Poems With Requiem PDFDocument79 pagesAkhmatova, Anna - 45 Poems With Requiem PDFAnonymous 6N5Ew3No ratings yet

- Characteristics and Guidelines of PublicspaceDocument3 pagesCharacteristics and Guidelines of PublicspaceJanani SurenderNo ratings yet

- Geometric Sculpture From 72 PencilsDocument5 pagesGeometric Sculpture From 72 PencilsHugo Iván Gonzalez CruzNo ratings yet

- Class 7thDocument24 pagesClass 7thPriyaNo ratings yet

- 10 Tips To Support ChildrenDocument20 pages10 Tips To Support ChildrenRhe jane AbucejoNo ratings yet

- BOQ - Hearts & Arrows Office 04sep2023Document15 pagesBOQ - Hearts & Arrows Office 04sep2023ChristianNo ratings yet

- GRP Product CatalogueDocument57 pagesGRP Product CatalogueMulyana alcNo ratings yet

- 8.4 Example: Swiss Market Index (SMI) : 188 8 Models of VolatilityDocument3 pages8.4 Example: Swiss Market Index (SMI) : 188 8 Models of VolatilityNickesh ShahNo ratings yet

- Time Table Semester II 2019-2020Document18 pagesTime Table Semester II 2019-2020Shiv Kumar MeenaNo ratings yet

- Classroom Observation Form 1Document4 pagesClassroom Observation Form 1api-252809250No ratings yet

- Klein & Kulick Scandolous ActsDocument20 pagesKlein & Kulick Scandolous ActsClaudia Costa GarcíaNo ratings yet

- MECHANICAL PROPERTIES OF SOLIDSDocument39 pagesMECHANICAL PROPERTIES OF SOLIDSAbdul Musavir100% (1)

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet