0% found this document useful (0 votes)

161 views4 pagesMono Rail Beams Design

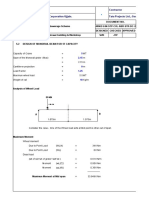

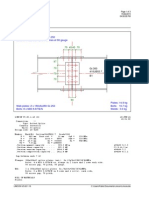

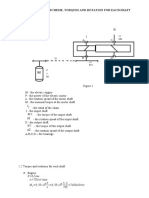

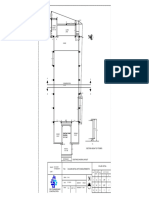

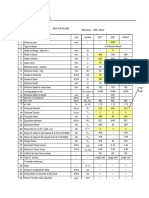

This document provides design calculations for a monorail beam used to transfer effluent at a plant. [1] Bending moments and shear forces are calculated for different load cases. [2] An ISMB 250 section is selected and its properties are checked. [3] The section is verified to have adequate moment capacity based on its plastic and buckling resistances. [4] Checks are performed to ensure the section can resist the combined bending and shear demands.

Uploaded by

pandianCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

161 views4 pagesMono Rail Beams Design

This document provides design calculations for a monorail beam used to transfer effluent at a plant. [1] Bending moments and shear forces are calculated for different load cases. [2] An ISMB 250 section is selected and its properties are checked. [3] The section is verified to have adequate moment capacity based on its plastic and buckling resistances. [4] Checks are performed to ensure the section can resist the combined bending and shear demands.

Uploaded by

pandianCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd