Professional Documents

Culture Documents

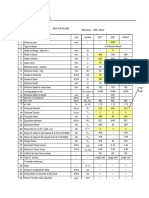

Corbel Design

Uploaded by

Tai NguyenOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Corbel Design

Uploaded by

Tai NguyenCopyright:

Available Formats

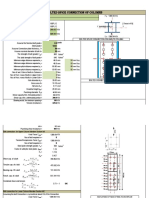

INPUT DATA Project: Fish Market

Level: LGF Check Location: 5-G

INPUT

Ultimate Force V 312 kN Concrete cover Cover btm 30 mm

N 0 kN Cover top 46 mm

Level arm L1 150 mm Cover side 30 mm

L2 300 mm Bars bending diameter 5d

L3 300 mm (d=Ubars diameter) 80 mm

L4 325 mm Tension factor fst,t 0.85

L5 52 mm Compression factor fst,c 0.65

b 1000 mm Tie bars AD dAD N16

Bearing length w 100 mm Tie bars BC dBC N16

Concrete Strength f'c 40 Mpa

Yiel strength fsy 500 Mpa

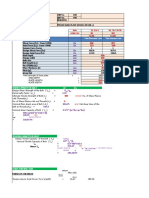

RESULT

The Forces in the truss member can be determined :

Compression AB 451 kN

e 6 mm Tension AD 325 kN

L6 194 mm Tension BC 312 kN

a 202 mm

θ 44 degrees

Design of tension tie

Reinforcement require for

Tie AD As,AD 765 mm2 4 N16 Ubars at Corbel

Tie BC As,BC 734 mm2 4 N16

Maximum design stress in Strut

L5 = side cover + dUbar(BC) + e bs 0.6 Stress limits ff'c 14.28 Mpa

L6 = L3 - Top cover - 1/2*dUbar(AD) - dUbar(BC)-e Require thickness of Strut Strut AB tAB 31.6 mm

Tie BC e = Bending radius - (Bending radius + Bar diameter/2)/Sqrt(2) Strut BD tBD 0.0 mm

Tie CF As,CF Strut CD tCD 0.0 mm

Tie EF As,EF 0 mm2 ### N0 Stirrup as Plan Strut DE tDE 0.0 mm

Strut BE tBE 0.0 mm

You might also like

- Calculation For Column Base Plate (H-Shape)Document9 pagesCalculation For Column Base Plate (H-Shape)Syafiruddin CokiNo ratings yet

- Column Base Plate (Hinge Type)Document9 pagesColumn Base Plate (Hinge Type)harishduttNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- 2b. Shear Connection - BTOB (M Project) - 0618Document210 pages2b. Shear Connection - BTOB (M Project) - 0618Omprakash Khodke100% (1)

- Calculation For Moment Connection - Type ADocument15 pagesCalculation For Moment Connection - Type ANitesh SinghNo ratings yet

- End Plate Moment ConnectionDocument3 pagesEnd Plate Moment ConnectionIndustry Standard Structural DesignNo ratings yet

- Fixed Normal 575Document8 pagesFixed Normal 575mohanNo ratings yet

- Base Plate Design BS CodeDocument3 pagesBase Plate Design BS CodeFodor ZoltanNo ratings yet

- Completed Steel Connection Design - June 6,2021Document3 pagesCompleted Steel Connection Design - June 6,2021Prakash Singh RawalNo ratings yet

- Base Plate DesignDocument4 pagesBase Plate DesignAbhay ThakurNo ratings yet

- Concentrically Loaded ColumnsDocument4 pagesConcentrically Loaded ColumnsOmar TariqNo ratings yet

- Beam DesignDocument2 pagesBeam DesignBilal A BarbhuiyaNo ratings yet

- Base Plate Design BSDocument4 pagesBase Plate Design BSvinujohnpanickerNo ratings yet

- From RCC Col To Steel ColDocument9 pagesFrom RCC Col To Steel ColJanya AssociatesNo ratings yet

- Base Plate Design (From RCC ColDocument9 pagesBase Plate Design (From RCC ColJanya AssociatesNo ratings yet

- EndPl MomConn LSDDocument54 pagesEndPl MomConn LSDTony RoseNo ratings yet

- UB406X178X85Document5 pagesUB406X178X85Uday UdmaleNo ratings yet

- TiebeamDocument9 pagesTiebeamAdhe NurhamsahNo ratings yet

- Monorail Stopper Design For 73-My-4412: Input DataDocument4 pagesMonorail Stopper Design For 73-My-4412: Input Datarajasekhar.cheruvu8635No ratings yet

- UB 610 X 179 - BP - PinnedDocument3 pagesUB 610 X 179 - BP - PinnedArivoli JayaramanNo ratings yet

- Design of Ss Connection v.2Document68 pagesDesign of Ss Connection v.2markespinoNo ratings yet

- Beam Splice Connection With End Plate CalculationDocument76 pagesBeam Splice Connection With End Plate CalculationFajar Alam HudiNo ratings yet

- EndPl MomConn LSDDocument54 pagesEndPl MomConn LSDsilroy d'saNo ratings yet

- Type FRB1. 333 Ton Free Sliding Bearing DesignDocument8 pagesType FRB1. 333 Ton Free Sliding Bearing DesignAnkush SharmaNo ratings yet

- Base Plate Design1Document24 pagesBase Plate Design1John Paul UmaliNo ratings yet

- Base Plate - Silo Supporting R1Document10 pagesBase Plate - Silo Supporting R1soumi bhattacharyaNo ratings yet

- 4.T&Angle-Brace Connection (M Project) - 0618Document49 pages4.T&Angle-Brace Connection (M Project) - 0618Omprakash KhodkeNo ratings yet

- Base Plate DesignDocument21 pagesBase Plate Designtitir bagchi100% (1)

- Bolt Design Based On BS Code:: Input DataDocument14 pagesBolt Design Based On BS Code:: Input DataSURIYANo ratings yet

- T Beam To BS 8110Document11 pagesT Beam To BS 8110Samitha SoysaNo ratings yet

- Moment Connection With Haunch Flush EndDocument78 pagesMoment Connection With Haunch Flush EndFilip Risteski0% (1)

- Aisc 14 Edition (Asd) : 14/jan/16 SN SN 0 1Document2 pagesAisc 14 Edition (Asd) : 14/jan/16 SN SN 0 1GousePeerzadeNo ratings yet

- Calculations: Project: of Section: File/ref No: Designed: Date: Checked: DateDocument6 pagesCalculations: Project: of Section: File/ref No: Designed: Date: Checked: DateWintun73No ratings yet

- Nsba PlateDocument24 pagesNsba Platebayu_23RNo ratings yet

- Beams TB1Document3 pagesBeams TB1mangeshNo ratings yet

- He800b PDFDocument5 pagesHe800b PDFUday UdmaleNo ratings yet

- Anchor Bolt Design, IS Code LSDDocument33 pagesAnchor Bolt Design, IS Code LSDamlan jyoti ChakravortyNo ratings yet

- 6952-4.T&Angle-Brace Connection (Knee Brace) (M Project) - 0618Document81 pages6952-4.T&Angle-Brace Connection (Knee Brace) (M Project) - 0618Omprakash KhodkeNo ratings yet

- Column Splice End Plate DesignDocument3 pagesColumn Splice End Plate DesigninnovativekarthiNo ratings yet

- Beam Basic Data Pb1Document14 pagesBeam Basic Data Pb1acchanduNo ratings yet

- Anchor Bolt& Base Plate DesignDocument28 pagesAnchor Bolt& Base Plate Designtirentyren1No ratings yet

- Vertical Bracing With End Plate ConnectionDocument85 pagesVertical Bracing With End Plate ConnectionFajar Alam HudiNo ratings yet

- HBDocument81 pagesHBFajar Alam HudiNo ratings yet

- Design of Shear Connection Between Beam To Beam:: As Per AISC 13 Edition (ASD)Document13 pagesDesign of Shear Connection Between Beam To Beam:: As Per AISC 13 Edition (ASD)rohitnrg0% (1)

- Design For 3-Pile GroupDocument4 pagesDesign For 3-Pile GroupP&D CIRCLE PWDNo ratings yet

- Punching Shear Cal - R3Document2 pagesPunching Shear Cal - R3phncNo ratings yet

- Beam To Beam-Fin PlateDocument105 pagesBeam To Beam-Fin PlateGasthuri Devi100% (1)

- Fixed Base PlateDocument15 pagesFixed Base PlateCharit DandriyalNo ratings yet

- Beam Design Beam Mark:B1 Similar Beams:: Sl. NoDocument3 pagesBeam Design Beam Mark:B1 Similar Beams:: Sl. NopandianNo ratings yet

- Column With Biaxial MomentDocument18 pagesColumn With Biaxial MomentvibishnanNo ratings yet

- CN 05Document3 pagesCN 05GousePeerzadeNo ratings yet

- Design Calculation For Splice & Bottom Plate of Vertical Column MembersDocument4 pagesDesign Calculation For Splice & Bottom Plate of Vertical Column Membersinnovativekarthi100% (1)

- Column Base Plate (Hinge Type)Document14 pagesColumn Base Plate (Hinge Type)Mesgina G-herNo ratings yet

- RC - Corbel DesignDocument2 pagesRC - Corbel DesignMyat Thu Zar KhineNo ratings yet

- Design For 3-Pile GroupDocument4 pagesDesign For 3-Pile GroupHemam PrasantaNo ratings yet

- Input Rev. NO: L + (c1 + c2) TWDocument6 pagesInput Rev. NO: L + (c1 + c2) TWMudasir MughalNo ratings yet

- Rafter To Rafter ConnectionDocument15 pagesRafter To Rafter ConnectionKhanthavel100% (1)

- Vaccum Pump DatasheetDocument6 pagesVaccum Pump DatasheetQuietRideNo ratings yet

- Hero Honda Presentation 2ADocument9 pagesHero Honda Presentation 2AShalini ThakurNo ratings yet

- WholesaleProductGuide Release6Document165 pagesWholesaleProductGuide Release6panchoNo ratings yet

- Maytag Stack Dryer 10534324Document21 pagesMaytag Stack Dryer 10534324Angel MartinezNo ratings yet

- Fabrication of Automatic Spring Rolling MachineDocument45 pagesFabrication of Automatic Spring Rolling MachineANAND KRISHNANNo ratings yet

- Road Safety Audit Report: Maitighar-Tinkune SectionDocument19 pagesRoad Safety Audit Report: Maitighar-Tinkune SectionPadma Shahi0% (1)

- Mini Led DRLDocument12 pagesMini Led DRLEntony FinelliNo ratings yet

- NOV Pump JWS-400 Parts ManualDocument16 pagesNOV Pump JWS-400 Parts ManualHary WijayaNo ratings yet

- Garcia 45 Chloe InventoryDocument6 pagesGarcia 45 Chloe InventoryBreno MachadoNo ratings yet

- AGS 2 Automated General Purpose ScannerDocument2 pagesAGS 2 Automated General Purpose Scannerkiki270977No ratings yet

- SP 36Document8 pagesSP 36nareshNo ratings yet

- Gas Turbine1Document13 pagesGas Turbine1Saurabh BarangeNo ratings yet

- Class NK PSC Checklist For RussiaDocument2 pagesClass NK PSC Checklist For RussiaHarman SandhuNo ratings yet

- Stuska Water BrakesDocument4 pagesStuska Water BrakesAngel GiacconeNo ratings yet

- INTERSECTIONSDocument5 pagesINTERSECTIONSsydney augustNo ratings yet

- Doosan Engine Dl08 Shop ManualDocument10 pagesDoosan Engine Dl08 Shop Manualrichard100% (53)

- Diesel-Electric Model 3 Mobile Harbor Cranes: Accessing More PerformanceDocument11 pagesDiesel-Electric Model 3 Mobile Harbor Cranes: Accessing More PerformancePrekelNo ratings yet

- 12g, 120g, 130g & 140g Motor Graders Power Shift TransmissioDocument13 pages12g, 120g, 130g & 140g Motor Graders Power Shift TransmissioJuan Gonzalez100% (1)

- Symbols Used in Hydraulics and Pneumatics SystemDocument8 pagesSymbols Used in Hydraulics and Pneumatics SystemVishal DeshpandeNo ratings yet

- 7389m - Gearbox Service ManualDocument74 pages7389m - Gearbox Service ManualNyein KoNo ratings yet

- Thank You For Your Carbjetkits Purchase: Installing Needle ShimsDocument2 pagesThank You For Your Carbjetkits Purchase: Installing Needle ShimsKenneth Roy SaplacoNo ratings yet

- Service Manual ET3000 CATDocument410 pagesService Manual ET3000 CATChristian Bedoya100% (8)

- Lesson 6. Directional Control ValvesDocument18 pagesLesson 6. Directional Control ValvesYunah VelosoNo ratings yet

- SAR Docs RetentionDocument40 pagesSAR Docs RetentionHopper Hill KimberlyNo ratings yet

- 5 Qms Document Master List - Asset Resources Management (Fleet)Document2 pages5 Qms Document Master List - Asset Resources Management (Fleet)Safix YazidNo ratings yet

- V20 120kW Product DescriptionDocument4 pagesV20 120kW Product DescriptionAndrei PopovNo ratings yet

- Cat00000 PSRPT 2020-05-18 15.01.25 PDFDocument16 pagesCat00000 PSRPT 2020-05-18 15.01.25 PDFArturo A Maldonado OrtizNo ratings yet

- Bar Exam Questions in Insurance LawDocument11 pagesBar Exam Questions in Insurance LawPing ArtVill100% (1)

- CESSNA Specification and Description2118Document26 pagesCESSNA Specification and Description2118MrCoolSwimmerNo ratings yet

- Clg835-Yuchai PartesDocument231 pagesClg835-Yuchai Partesjuliana100% (2)