Professional Documents

Culture Documents

DVTP-R-50's Operation Menu

Uploaded by

Pablo VeraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DVTP-R-50's Operation Menu

Uploaded by

Pablo VeraCopyright:

Available Formats

重庆爱晟电力设备有限公司

CHONGQING ASSEN POWER EQUIPMENT CO.,LTD

Flow Chart:

Add:No.31-7 CENTRE PLAZA,SHAPINGBA DISTRICT,CHONGQING,CHINA

Tel/Fax: 00862388703683

https://www.assenpe.com

重庆爱晟电力设备有限公司

CHONGQING ASSEN POWER EQUIPMENT CO.,LTD

Structure Chart:

Add:No.31-7 CENTRE PLAZA,SHAPINGBA DISTRICT,CHONGQING,CHINA

Tel/Fax: 00862388703683

https://www.assenpe.com

重庆爱晟电力设备有限公司

CHONGQING ASSEN POWER EQUIPMENT CO.,LTD

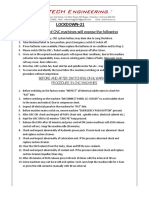

Operation:

I Installation

1.Connect hoses between the inlet MV02 of the purifier to the

outlet (usually at bottom) of the tank, the outlet MV01 of the purifier

to the inlet (usually at top) of the tank.

2.Open the drain valve MV13 of condenser,close the drain valve

until the liquid in the condenser is drained.

3.Connect the three-phase three-wire 380V / 50HZ power supply

and ground cable to the terminal block, Open circuit breaker QS1, QS2

and QS3. The power indicator on the control panel should be light on.

4.If the power indicator is off, troubleshooting is required

according to the PR indicator in the cabinet. The purifier will stop

automatically when phase sequence, over-voltage and under-voltage

power failure occurs.

5.Turn on the “outlet pump” select switch and Turn off the “outlet

pump” select switch immediately. Observe whether the direction is in

the same as the arrow on the pump body.

6.If the motor is turned incorrect, disconnect the power supply

and exchange the wiring of any two terminals of the pump motor

cable. The motor’s direction to be set correctly before leaving the

Add:No.31-7 CENTRE PLAZA,SHAPINGBA DISTRICT,CHONGQING,CHINA

Tel/Fax: 00862388703683

https://www.assenpe.com

重庆爱晟电力设备有限公司

CHONGQING ASSEN POWER EQUIPMENT CO.,LTD

factory. This operation is only needed when the motor or cabinet is

rewired.

7.Check direction of the vacuum pump and Roots pump by

checking the oil outlet pump’s direction. The motor’s direction to be

set correctly before leaving the factory. This operation is only needed

when the motor or cabinet is rewired.

8.Turn on the vacuum pump. After running for 5 minutes, check

whether the oil level of vacuum pump and roots pump is within the

allowable range.

9.Select the operating mode "Manual or Auto". Set to "Manual"

at the factory.

10.Enter the "Set" menu to set operation parameters. At the

factory, heating temperature is set to 60 ° C.

II Running

1.Open the oil inlet valve MV02 and the cycle valve MV03.

2.Turn on the “Auto/vacuum pump” select switch. The PLC

automatically opens the oil pump, the oil inlet solenoid and the oil

pump (P03) as needed.

3.Pay attention to the foam level in the degassing chamber when

Add:No.31-7 CENTRE PLAZA,SHAPINGBA DISTRICT,CHONGQING,CHINA

Tel/Fax: 00862388703683

https://www.assenpe.com

重庆爱晟电力设备有限公司

CHONGQING ASSEN POWER EQUIPMENT CO.,LTD

the purifier is in operation early. When the foam level is higher than

the center of the sight glass, the air valve MV07 should be partially

opened until the foam level is below the sight glass. Purifier with

automatic foam eliminator system do not need to do this.

4.Turn on “Heater 1” or “Heater 2” select switch as needed.

5.During the internal circulation, the foam level will gradually

become less, this time can be slightly closed valve MV07, but the foam

level is always lower than the center of the sight glass. Purifier with

automatic foam eliminator system do not need to do this.

6.When the foam in the degassing chamber disappears, open the

oil outlet valve(MV01), partially or completely close the cycle valve

MV03.

III Stop

1.Turn off the “heater 1” and the “heater 2” and wait for more

than 1 minute.

2.Turn off the “Auto/vacuum pump” select switch and close the

oil inlet valve MV02, and open the air valve MV07.

3.If you want to pump out the oil in the vacuum chamber, turn

on the "Outlet pump" select switch. Turn off the "Outlet pump" select

Add:No.31-7 CENTRE PLAZA,SHAPINGBA DISTRICT,CHONGQING,CHINA

Tel/Fax: 00862388703683

https://www.assenpe.com

重庆爱晟电力设备有限公司

CHONGQING ASSEN POWER EQUIPMENT CO.,LTD

switch when the oil in the vacuum chamber is drained.

4.After the Vacuum gauge pointer return to 0Mpa, close the air

valve MV07 and the oil outlet valve MV01.

5.Switch off power supply to the purifier.

IV Use the inlet pump alone(for oil transfer)

1.Purifier with oil inlet pump, can be used separately when the oil

does not need to be degassed (eg. transfer oil between tank or empty

oil of transformer).

2.Open oil inlet valve (MV02) and oil outlet valve (MV01).

3.Turn on the “Heater 2” select switch and keep the “Vacuum

pump”, ”Outlet pump”, ”Heater 1” select switch in the off position.

After the machine starts running, observe the working pressure vale,

vacuum degree, temperature and oil foaming status in the vacuum

separation chamber, if no abnormal situation happened over 15 minutes,

the operator can leave the machine and let it run automatically.

Before leaving the machine for auto-running, please note below:

■ If the machine is mobile type, please make sure the casters are steady

Add:No.31-7 CENTRE PLAZA,SHAPINGBA DISTRICT,CHONGQING,CHINA

Tel/Fax: 00862388703683

https://www.assenpe.com

重庆爱晟电力设备有限公司

CHONGQING ASSEN POWER EQUIPMENT CO.,LTD

and will not move by itself to avoid any danger.

■ The equipment does not have any abnormal vibration and noise.

■ Remember to check the vacuum pump oil and roots pump oil is on

a normal level(middle level) as below, if oil quantity is not enough, please

add vacuum pump oil accordingly.

Maintenance

a.Troubleshooting

Phenomenon Reason Method

1.QS1 is not 1. Connect QS1

connected 2. Power failure according to

Power indicator is 2. Power supply is out PR indicator

off, HMI is not of phase, overvoltage 3. Replace fuse F1 or F2

displayed or undervoltage

3.The fuse F1 or F2 is

blown

Power indicator is Power indicator is Replace power indicator

off, HMI is displayed broken

1. HMI is broken 1. Replace HMI

Power indicator is

2. PLC controller is 2. Replace PLC controller

on, HMI is displayed

broken

Add:No.31-7 CENTRE PLAZA,SHAPINGBA DISTRICT,CHONGQING,CHINA

Tel/Fax: 00862388703683

https://www.assenpe.com

重庆爱晟电力设备有限公司

CHONGQING ASSEN POWER EQUIPMENT CO.,LTD

The machine does 1. Emergency stop 1. Reset or replace the

not start, the HMI is button is pressed or emergency stop button

displayed, and damaged 2. Check the PLC

there is no fault 2.PLC is broken

prompt

1.Vacuum pump 1.Troubleshoot the vacuum

motor overload pump motor overload

Machine does not

2.The thermal relay 2.Recalibrate the thermal relay

start, HMI displays

FR1 is too low. FR1

"03 Vacuum pump

3. Thermal relay FR1 is 3. Replace thermal relay FR1

motor overload,

broken 4. Replace the vacuum pump

reset FR1"

4.The vacuum pump motor

motor is broken

1. Roots pump motor 1. Troubleshooting roots pump

overload motor overload

Machine does not

2.The thermal relay 2. Recalibrate the thermal relay

start, HMI displays

FR2 calibration value is FR2

"04 Roots pump

too low 3. Replace thermal relay FR2

motor overload,

3. Thermal relay FR2 is 4. Replace roots pump motor

reset FR2"

broken

Add:No.31-7 CENTRE PLAZA,SHAPINGBA DISTRICT,CHONGQING,CHINA

Tel/Fax: 00862388703683

https://www.assenpe.com

重庆爱晟电力设备有限公司

CHONGQING ASSEN POWER EQUIPMENT CO.,LTD

4.Roots pump motor

is broken

1. Oil pump motor 1.Troubleshoot oil pump

overload motor overload

2.The thermal relay 2. Recalibrate thermal relay

Machine does not

FR3 calibration value is FR3

start, HMI displays

too low 3. Replace thermal relay FR3

"05 Oil pump motor

3. Thermal relay FR3 is 4. Replace the oil pump motor

overload, reset FR3"

broken

4.Oil pump motor is

broken

1.The oil outlet valve 1. Open the oil outlet valve

MV02 or MV03 is not 2. Replace the fine filter (FL02,

Machine does not

opened FL03)

start, HMI displays

2.Fine filter blocking 3. Replace the pressure switch

"02 Please replace

(FL02, FL03) (PS01)

the fine filter

3. Pressure switch

element"

(PS01) is broken

Machine does not 1. High condenser 1. Drain the condenser liquid

start, HMI displays liquid level 2. The condenser liquid level

Add:No.31-7 CENTRE PLAZA,SHAPINGBA DISTRICT,CHONGQING,CHINA

Tel/Fax: 00862388703683

https://www.assenpe.com

重庆爱晟电力设备有限公司

CHONGQING ASSEN POWER EQUIPMENT CO.,LTD

"01 Please drain 2. The condenser switch float is installed vertically

condenser" liquid level switch is downwards

installed in the wrong 3. Replace the condenser level

position switch (FS04)

3.Condenser level

switch (FS04) is broken

Routine maintenance procedures

a.Check Filter

After the filter element has been working for a period of time, when

the pressure difference through the filter element increases to the limit

specified by the design due to the blockage of the dirt, the filter

element must be maintained, including cleaning or replacement. The

material and structure of the filter element determine whether it can

be cleaned and the cleaning method.

Note: Among the filter elements used by DVTP plant, the Primary filter

can be reused by cleaning and it doesn’t need to be replaced. The fine

filter element FL02, FL03 and the vacuum pump oil filter element

cannot be cleaned and must be replaced.

Add:No.31-7 CENTRE PLAZA,SHAPINGBA DISTRICT,CHONGQING,CHINA

Tel/Fax: 00862388703683

https://www.assenpe.com

重庆爱晟电力设备有限公司

CHONGQING ASSEN POWER EQUIPMENT CO.,LTD

R1.Cleaning and replacement of primary filter element

When the vacuum degree reaches -0.07~-0.1Mpa, the oil viscosity is

low, the liquid level control ball valve (MV12) is fully opened, and the

oil inlet speed is still slower than the oil pump oil discharge speed, you

should shut down and take the pr-filter out for maintenance . The filter

element can be cleaned in gasoline or alkaline cleaning fluid, and

compressed air is used to blow away the dirt attached to the mesh

from the inside to the outside. Before installation, check whether the

filter is damaged, and replace it if any damage is found.

R2. How to replace FL02 and FL03 fine filter elements

a. Close the ball valve(MV02) of the inlet pipe, and open the outlet

valve (MV01) and air supply valve(MV09)

b. Start the oil pump and drain off the oil from the filter as much as

possible.(Judge by observing the outlet pvc pipe)

c. Turn off the machine after confirming that there is no oil in it.

d. Unscrew the flange bolts and remove the flange cover.

e. Take out the filter element, After unscrewing the filter element, pay

attention to check whether the "O"-ring under the fixed thread of the

filter element can continue to be used.

Add:No.31-7 CENTRE PLAZA,SHAPINGBA DISTRICT,CHONGQING,CHINA

Tel/Fax: 00862388703683

https://www.assenpe.com

重庆爱晟电力设备有限公司

CHONGQING ASSEN POWER EQUIPMENT CO.,LTD

f. Install and tighten the new filter element. Be careful not to

contaminate the filter element during installation.

g. Install the original flange cover.

Maintenance Schedule

Item Time Note

Check the fault indicator Everyday

Check every instruments Everyday

Check if the inlet and outlet pipes Every week

are damaged? The sealing is

good?

Replace pr-filter FL01 See R1

Replace filter filter FL02,FL03 See R2

After the vacuum pump Be sure to replace the

oil is emulsified or the vacuum pump oil and

Replace the vacuum pump oil vacuum pump runs for vacuum pump oil filter

and vacuum pump oil filter FL04 more than 100 hours element in time, otherwise

the vacuum pump will be

damaged.

When maintaining or

Clean the dirt or rust inside of the

replacing the filter

filter cartridge

element

Check the condition of the hose Every week

and each seal

Check the pressure switch Every 6 months

Check instrument’s accuracy Every 2 years

Add:No.31-7 CENTRE PLAZA,SHAPINGBA DISTRICT,CHONGQING,CHINA

Tel/Fax: 00862388703683

https://www.assenpe.com

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Start Permissives & Interlocks For EquipmentsDocument7 pagesStart Permissives & Interlocks For EquipmentsSatyaranjan mahapatra100% (1)

- APENDIXDocument12 pagesAPENDIXErwinNo ratings yet

- Pump Control Model FPC 30010Document4 pagesPump Control Model FPC 30010vstojnicNo ratings yet

- HHP Loco Trouble ShootingDocument5 pagesHHP Loco Trouble ShootingSiddu BiradarNo ratings yet

- Pump Manuals - Op-MV600Document6 pagesPump Manuals - Op-MV600kuladeepkatragaddaNo ratings yet

- Booster PumpDocument5 pagesBooster Pumpbryesanggalang0% (1)

- Dielectric OilDocument2 pagesDielectric OilMohammed Imran100% (1)

- Prensa de 15 Ton PGC1500Document16 pagesPrensa de 15 Ton PGC1500abdielNo ratings yet

- JockeyDocument4 pagesJockeyKrausserRudolfNo ratings yet

- TORNATECH JP Manual EnglishDocument14 pagesTORNATECH JP Manual EnglishWalid AHMED MOUNIR MORSYNo ratings yet

- Ste - CNC & Robot Lockdown-21 - ProcedureDocument2 pagesSte - CNC & Robot Lockdown-21 - ProcedurejaganksNo ratings yet

- Turbine Operation SequenceDocument3 pagesTurbine Operation SequenceTitas titasNo ratings yet

- Instructions For Operating Diesel Engine GeneratorDocument3 pagesInstructions For Operating Diesel Engine GeneratorRizzdaron TikingNo ratings yet

- Quick Trouble Shooting Guidelines For Three Phase Locomotives Electric Loco Shed, Lallaguda South Central RailwayDocument5 pagesQuick Trouble Shooting Guidelines For Three Phase Locomotives Electric Loco Shed, Lallaguda South Central Railwayjohn peterNo ratings yet

- Oil Test Kit Instruction Manual & Test CertificateDocument5 pagesOil Test Kit Instruction Manual & Test Certificateraju289No ratings yet

- Write Up On Interlock SchemesDocument3 pagesWrite Up On Interlock SchemesSatyaKrishna PallaNo ratings yet

- E-101 Procedure For Running Emergency GeneratorDocument3 pagesE-101 Procedure For Running Emergency GeneratorAnkit Kumar SinghNo ratings yet

- Check The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001Document5 pagesCheck The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001jose Alberto uribe Minier100% (1)

- Chiller User ManualDocument14 pagesChiller User ManualAlejandro SotoNo ratings yet

- U212ENDocument2 pagesU212ENCarlos OlivaNo ratings yet

- GT 601Document101 pagesGT 601Muaaz KhanNo ratings yet

- Diesel Pump of The Desmi GroupDocument10 pagesDiesel Pump of The Desmi Groupngocdhxd92No ratings yet

- Service Manual 6000 SeriesDocument13 pagesService Manual 6000 SeriesKarna PatelNo ratings yet

- 영문TC-15 Manual,PaintingdurabilitytesterDocument5 pages영문TC-15 Manual,PaintingdurabilitytesterHanbo ENC Vina Công ty TNHHNo ratings yet

- 155 17-O2 PDFDocument152 pages155 17-O2 PDFArshad MahmoodNo ratings yet

- Watermicronworld AWG-C 5,000liter Prer Day - Operation ManualDocument16 pagesWatermicronworld AWG-C 5,000liter Prer Day - Operation ManualRobert RainmanNo ratings yet

- JOBO CPP-3 Manual GB V1.1 26.03.13 PDFDocument11 pagesJOBO CPP-3 Manual GB V1.1 26.03.13 PDFMarian TudorNo ratings yet

- 951-130-172-MKU - MKF - 122-1 - 122 - 2 Pump UnitsDocument5 pages951-130-172-MKU - MKF - 122-1 - 122 - 2 Pump Unitsli geneNo ratings yet

- Operation and Maintenance Manual For ModelsDocument33 pagesOperation and Maintenance Manual For ModelstgffcgfgNo ratings yet

- Coolant-Pump Motor Replacement HPR and HSD: Field Service BulletinDocument15 pagesCoolant-Pump Motor Replacement HPR and HSD: Field Service BulletinAung Naing OoNo ratings yet

- Power Plant Boiler Check List - CEHPSOPDocument33 pagesPower Plant Boiler Check List - CEHPSOPVuong BuiNo ratings yet

- Service Manual HMK 300 LC-3 - ElectricalDocument103 pagesService Manual HMK 300 LC-3 - ElectricalBimbo Jimbo100% (3)

- Rear Panel Layout: Description ItemDocument4 pagesRear Panel Layout: Description ItemHector CabreraNo ratings yet

- Dkg-207 Amf and Remote Start Unit Installation and Operating InstructionsDocument4 pagesDkg-207 Amf and Remote Start Unit Installation and Operating InstructionsBambang Ardiansyah SetiadyNo ratings yet

- MIB 503 Separation System, Module - Operating Instructions - 2018Document18 pagesMIB 503 Separation System, Module - Operating Instructions - 2018Centrifugal SeparatorNo ratings yet

- Power Plant Emergency InsructionDocument14 pagesPower Plant Emergency InsructionbatporaNo ratings yet

- Alfa 164 Motronic Self-DiagnosisDocument5 pagesAlfa 164 Motronic Self-DiagnosisErnesto PalaciosNo ratings yet

- Restore Power in Case of BlackoutDocument5 pagesRestore Power in Case of Blackoutadityasahay100% (2)

- 03 Start, Stop and OperationDocument8 pages03 Start, Stop and Operationhmandioussama1No ratings yet

- Bomba Watson Marlow PDFDocument13 pagesBomba Watson Marlow PDFRonald SalasNo ratings yet

- Oceanpower Ice Cream Machines Maintenance ManualDocument15 pagesOceanpower Ice Cream Machines Maintenance ManualHector AraujoNo ratings yet

- SipartDocument68 pagesSipartsanjay sharmaNo ratings yet

- CS563Document44 pagesCS563Jose Luis Garcia BlancoNo ratings yet

- 2 .1.1. Pre-Start Operations: Check Out The Fuel Oil Supply System StateDocument7 pages2 .1.1. Pre-Start Operations: Check Out The Fuel Oil Supply System StateJonas NordvikNo ratings yet

- Safety Operation OKDocument49 pagesSafety Operation OKmohammad100% (1)

- Controller - Electric Pump YDDocument5 pagesController - Electric Pump YDAnonymous Qv0j6jNo ratings yet

- Sistem Refrigerasi Epm (Cold Room - Staging Room)Document33 pagesSistem Refrigerasi Epm (Cold Room - Staging Room)Paskah Dwi Deborah HarahapNo ratings yet

- Instructivo F4Document39 pagesInstructivo F4victor laraNo ratings yet

- Identifying Compressor Mechanical FailuresDocument13 pagesIdentifying Compressor Mechanical FailuresDesiderio BourdetNo ratings yet

- Maintenance Manual SDR-1500Document47 pagesMaintenance Manual SDR-1500Jaipal S. Nagi100% (4)

- FEE 512 Tutorial 1Document5 pagesFEE 512 Tutorial 1BILLYNo ratings yet

- TPCK Series Immersible Pump: Instruction ManualDocument8 pagesTPCK Series Immersible Pump: Instruction ManualThiago Teixeira PiresNo ratings yet

- Nfv-Bilge Water Separator PPT - BWS 10000: Operator ManualDocument16 pagesNfv-Bilge Water Separator PPT - BWS 10000: Operator ManualAnbarasan AnandhanNo ratings yet

- Ways of Starting and Testing Emergency GeneratorDocument4 pagesWays of Starting and Testing Emergency Generatornarendra_katdareNo ratings yet

- Mjis Operation Order For - # Turbine Hot Status StartingDocument4 pagesMjis Operation Order For - # Turbine Hot Status StartingEduardo GarridoNo ratings yet

- Optional Lincoln Lubricator: GeneralDocument3 pagesOptional Lincoln Lubricator: Generalferdy ramosNo ratings yet

- Testing Method StatementDocument9 pagesTesting Method StatementsardarmkhanNo ratings yet

- DX-ZB2 Hydraulic Jet Machine ManualDocument18 pagesDX-ZB2 Hydraulic Jet Machine ManualNguyễn ChungNo ratings yet

- York - Trouble Shooting Centrifugal Chiller PDFDocument6 pagesYork - Trouble Shooting Centrifugal Chiller PDFdanhtranHVAC67% (9)

- Graphic Organizer Answer Sample Shin SulDocument1 pageGraphic Organizer Answer Sample Shin Sulapi-302581865100% (2)

- Tesco: Multi-Grade Gear Oil 80W-90Document2 pagesTesco: Multi-Grade Gear Oil 80W-90lucas ronaldo coronel mendozaNo ratings yet

- Computer Code For Monte Carlo MarchingDocument78 pagesComputer Code For Monte Carlo MarchingJacob H. (Jack) LashoverNo ratings yet

- Chapter 2 (Mcmurry - 9th Edition)Document60 pagesChapter 2 (Mcmurry - 9th Edition)Paolo NaguitNo ratings yet

- Heat and Mass Transfer WorksheetDocument5 pagesHeat and Mass Transfer WorksheetBISRAT YIHUNNo ratings yet

- LabreportphysicdDocument4 pagesLabreportphysicdapi-263436863No ratings yet

- The Design of H2S Abatement System For Well Testing at Sorik Marapi Geothermal FieldDocument7 pagesThe Design of H2S Abatement System For Well Testing at Sorik Marapi Geothermal Field허준No ratings yet

- Fall14 - Lab 2 Phase RelationshipsDocument4 pagesFall14 - Lab 2 Phase RelationshipsMewnEProwtNo ratings yet

- D18a Under Keel Clearance Calculation r5Document6 pagesD18a Under Keel Clearance Calculation r5paul John castroverdeNo ratings yet

- Motion in A Straight Line Class 11 WorksheetDocument4 pagesMotion in A Straight Line Class 11 Worksheetmn m,n m, bm43% (7)

- Lesson Plan LightDocument12 pagesLesson Plan LightRhisia RaborNo ratings yet

- Fraunhofer Diffraction Through A Thin Wire and Babinet's PeincipleDocument19 pagesFraunhofer Diffraction Through A Thin Wire and Babinet's PeincipleShwetaNo ratings yet

- Breather Valves For Tank # 6907-08-09-010 Chakpirana Dia 3.8m Length 18mDocument2 pagesBreather Valves For Tank # 6907-08-09-010 Chakpirana Dia 3.8m Length 18mSohail AzharNo ratings yet

- Design of Welded Connections - AWSDocument43 pagesDesign of Welded Connections - AWSnunosobral100% (1)

- Ink Drop ExperimentDocument3 pagesInk Drop Experimentprash_hingeNo ratings yet

- DynaDocument27 pagesDynarammableNo ratings yet

- Atomic StructureDocument4 pagesAtomic StructureThea GermanNo ratings yet

- L90e - Manual HidraulicoDocument41 pagesL90e - Manual HidraulicoLuís Fernando Oliveira100% (1)

- Vdoc - Pub Microchip Fabrication A Practical Guide To Semiconductor ProcessingDocument979 pagesVdoc - Pub Microchip Fabrication A Practical Guide To Semiconductor Processingsaiganeah884No ratings yet

- Arduino and BH1750 SensorDocument4 pagesArduino and BH1750 SensorrealaffiliateNo ratings yet

- Physics 9 Icse Sample Paper 5Document5 pagesPhysics 9 Icse Sample Paper 5Study in an easy wayNo ratings yet

- ME6503-Design of Machine ElementsDocument15 pagesME6503-Design of Machine ElementsBas RamuNo ratings yet

- Design of ScaffoldingDocument9 pagesDesign of ScaffoldingdfdgggNo ratings yet

- Classical Mechanics (NETGATE) PDFDocument30 pagesClassical Mechanics (NETGATE) PDFSaley SaeedNo ratings yet

- Mechanics of Machines - at 6302 Question Bank: Unit - 1Document8 pagesMechanics of Machines - at 6302 Question Bank: Unit - 1Daniel DasNo ratings yet

- Chemical Engineering - Fluid Flow, Heat Transfer and Mass Transfer - Vol. 1 - J. M. Coulson, J. F. Richardson, J. R. Backhurst and J. H. HarkerDocument128 pagesChemical Engineering - Fluid Flow, Heat Transfer and Mass Transfer - Vol. 1 - J. M. Coulson, J. F. Richardson, J. R. Backhurst and J. H. HarkerFlyNarutoFly27100% (2)

- Wallap Part 2Document11 pagesWallap Part 2Nizar HalabiNo ratings yet

- ACI 318/350 P-M Interaction Diagram: US Customary UnitsDocument6 pagesACI 318/350 P-M Interaction Diagram: US Customary UnitsMohit VatsNo ratings yet

- Heat Exchangers Course Baher Part04Document32 pagesHeat Exchangers Course Baher Part04Baher ElsheikhNo ratings yet