Professional Documents

Culture Documents

Gate Valve Testing and Maintenance - AMARINE

Uploaded by

NovancyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gate Valve Testing and Maintenance - AMARINE

Uploaded by

NovancyCopyright:

Available Formats

!

GateValveComponent

GATEwhichOpenandClosefluidflowwithoutchangein

flowdirection

Handwheel

Yoke

Stem

Gland

Glandpacking(Seal)

Bonnet

Backseat

Body

083

WedDis

343

Seatring

Gate valve testing

and maintenance

1- Purpose of using Gate Valve on stream

Gate Valve is used to open and close the flow only. Not

commonly used in flow control with the following

components.

GateValveComponent

GATEwhichOpenandClosefluidflowwithoutchangein

flowdirection

Handwheel

Yoke

Stem

Gland

Glandpacking(Seal)

Bonnet

Backseat

Body

083

WedDis

343

Seatring

2- Operation (open-closed) of Gate Valve

3- The Hydrostatic Test for Gate Valve requires 3

parts, Shell, Seat, and Backseat

The hydro-testing according to API 598. The valve standard is

ASME B16.34

PressureTesting-GateValve

Pressure/HydrostaticTestperAPI598forGateValve

ASMEB16.34Standard;

1.BackseatTest

2.ShellTest

3.ClosureTests(SeatTests)-Bothside

Pressure Valve MaximumOperatingPressure(MOP)/

RatingClass Standard PressureRating

OP

ANSI 300

B16.341 740 @100°FMOP~410 @800°FM

BODYWCBST HF

EM 13CR DISC HF SEAT

FIG.NO 0312F-5 SERIALNO.

NameplateofAGateValve

Credit:ASME816.34,API598

!"#$%&'($)$*&(

REPORT THIS AD

***Gate Valve – Hydrotest Backseat;

The Hydrostatic Backseat Test must be tested at a

pressure of not less than 1.1 times the Maximum

Operating Pressure by fully opening the valve and

releasing the gland of the gate valve to check for leaks

through the Backseat.

PressureTesting-GateValve

HydrostaticBackseatTestperAPI598forGateValveASMEB16.34

Standard;

Fullyopen,andthepackingglandlooseorpackingnotinstalled

BackseatTestPressure≥1.1xPressureRating(MOP)at38°C

Novisualevidenceofleakagethroughthebackseat

Gandlos

BACKSE

ATTEST

Detectleakagethrough

TheBackseat

FullyOpen tredit.Aur363441338emadr.sos.com

***Gate Valve – Hydrotest Shell;

Hydrostatic Shell Test must be tested at a pressure not

less than 1.5 times the Maximum Operating Pressure

by opening the valve partially open and tightening the

gland to get the pressure. Then check for leaks through

Shell.

***Gate Valve – Hydrotest Seat;

Hydrostatic Closure Test or Seat Test, continue to test

from Shell Test at the pressure not less than 1.1 times of

Maximum Operating Pressure by closing the valve fully

closed and then checking the leak through Seat and

Disk. Both tests must be done on two (2) – Side of Gate

Valve.

***Valve – Pressure Test Duration;

Valve ‘s minimum hydrostatic/pneumatic pressure test,

according to the table in API 598, where the test duration

is the time we spend checking the valve leak after The

pressure can be maintained at Test pressure.

!"#$%&'($)$*&(

Line Blind

LINE BLIND

REPORT THIS AD

SHARE THIS:

! "

LIKE THIS:

Like

Be the first to like this.

Related

Flow direction of Valve – Part 3 ( Globe valve )

September 15, 2017

IN "PIPING"

Flow direction of Valve – Part 5 ( Butterfly valve )

September 18, 2017

IN "PIPING"

Globe Valve components and working

December 10, 2019

IN "API 570 - PI"

One thought on “Gate valve

testing and maintenance”

Afzalmeraj

OCTOBER 23, 2022 AT 2:40 PM

Dear friends.

I inform you that I need specification and testing of

valves like Ball valves and Gate valve, butterfly valve etc.

Note: it’s urgent please.

! Liked by 1 person

REPLY

Leave a Reply

Your email address will not be published. Required fields

are marked *

Comment *

Name *

Email *

Website

POST COMMENT

Notify me of new comments via email.

Notify me of new posts via email.

PREVIOUS

Erosion in Refinery,

Petrochemical Plant

NEXT

SMTS and Allowable Stress

!"#$%&'($)$*&(

Line Blind

LINE BLIND

REPORT THIS AD

Translation

Teua Lugha

Imedhaminiwa na Google Tafsiri

Subscribe to Blog via Email

Enter your email address to subscribe to this blog and

receive notifications of new posts by email.

Email Address

SUBSCRIBE

Join 313 other subscribers

Follow AMARINE

Followers

Blog Stats

1,463,659 hits

Start a Blog at WordPress.com. Follow

You might also like

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Actuator InformationDocument4 pagesActuator InformationFajar DwikurniaNo ratings yet

- AB01023.01-22en EroSolve-Flashing BrochureDocument8 pagesAB01023.01-22en EroSolve-Flashing BrochurebmlopeNo ratings yet

- Meritor Wabco Operación de La Válvula de Suspensión InglésDocument1 pageMeritor Wabco Operación de La Válvula de Suspensión InglésrichieNo ratings yet

- Valve Selection Guide D 35Document2 pagesValve Selection Guide D 35arrikanNo ratings yet

- Mts - 2013601 Carregador de NitrogenioDocument8 pagesMts - 2013601 Carregador de NitrogenioEduardo CramerNo ratings yet

- 800D SeriesDocument3 pages800D Seriesvkeie0206No ratings yet

- ASME Multivalves® For Vapor Withdrawal G8475RL Series Valves With Presto-Tap PG8475, PT7556 Series ValvesDocument1 pageASME Multivalves® For Vapor Withdrawal G8475RL Series Valves With Presto-Tap PG8475, PT7556 Series Valvesmohsen fatemiNo ratings yet

- Service Guide-Trampas Cubeta Armstrong-Manual Rapracion, Instalacion, Deteccion de FallasDocument36 pagesService Guide-Trampas Cubeta Armstrong-Manual Rapracion, Instalacion, Deteccion de FallasJORGE ALBERTO PEREZ RAMIREZNo ratings yet

- Flowact: High Performance ActuatorDocument16 pagesFlowact: High Performance ActuatorJAntonio De la CruzNo ratings yet

- Instruction Manual Fisher 377 TRDocument20 pagesInstruction Manual Fisher 377 TRGabrielA.MaffioldA.No ratings yet

- Mooney 1" Flowgrid Regulator: With Shutoff ValveDocument2 pagesMooney 1" Flowgrid Regulator: With Shutoff ValveLuis Alberto Portugal MariacalNo ratings yet

- ML - Repaw05j.marine - Cooling System DiagnosisDocument12 pagesML - Repaw05j.marine - Cooling System DiagnosisEdwin ArauzNo ratings yet

- DPV Flier-MAY2016-WPPTDocument2 pagesDPV Flier-MAY2016-WPPTPacoNo ratings yet

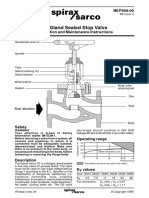

- Válvula Globo Tipo Placa - Spirax SarcoDocument2 pagesVálvula Globo Tipo Placa - Spirax SarcodgarciabNo ratings yet

- Ensemble Clapet Et VanneDocument4 pagesEnsemble Clapet Et VannegwinnruNo ratings yet

- Free Floating Lever Air/Gas Vents Installation and Operation ManualDocument7 pagesFree Floating Lever Air/Gas Vents Installation and Operation ManualhanshanantaNo ratings yet

- Instruction Manual Fisher 377 Trip Valve en 125040Document20 pagesInstruction Manual Fisher 377 Trip Valve en 125040Faisal AmarNo ratings yet

- Control Valves: Model C000 Globe Style Main Valve Model CA000 Angle Style Main ValveDocument4 pagesControl Valves: Model C000 Globe Style Main Valve Model CA000 Angle Style Main ValveAnderson SiqueiraNo ratings yet

- Apco Silent Check Valves CSC 640Document8 pagesApco Silent Check Valves CSC 640Julio MorenoNo ratings yet

- Control Valves User's Manual: Model ACP - /ACNDocument100 pagesControl Valves User's Manual: Model ACP - /ACNKahl YeongNo ratings yet

- 2way/2 - Part IIIDocument2 pages2way/2 - Part IIIYidel FloresNo ratings yet

- 008 DQDocument36 pages008 DQGabriela MotaNo ratings yet

- ITAPTECH AUTOMATIC-AIR-VENT EngDocument14 pagesITAPTECH AUTOMATIC-AIR-VENT EngCarlos EspNo ratings yet

- Waterleaks: Section 9IDocument6 pagesWaterleaks: Section 9IJarry PotterNo ratings yet

- Valve Selection Guide For MediumDocument3 pagesValve Selection Guide For MediumIbrahim Ahmed FarrukhNo ratings yet

- GS 15 Manual PDFDocument68 pagesGS 15 Manual PDFWalterNo ratings yet

- Catalog Functional Safety Solutions Asco en 5084612Document16 pagesCatalog Functional Safety Solutions Asco en 5084612alejomariana03No ratings yet

- Valv Diluvio Claval Diafragma TubularDocument29 pagesValv Diluvio Claval Diafragma TubularDaniel ReyNo ratings yet

- Original Equipmnet Surface - STCDocument64 pagesOriginal Equipmnet Surface - STCdilantha chandikaNo ratings yet

- Manual de Usuario Airvo2 PDFDocument150 pagesManual de Usuario Airvo2 PDFjhon edison rojas villada100% (1)

- TurboSmart Egate 45mm12Document1 pageTurboSmart Egate 45mm12fabio-ftzNo ratings yet

- Autoclave Full CatalogDocument481 pagesAutoclave Full CatalogGabriel Jamariqueli BueresNo ratings yet

- Gate Valve Installation InstructionsDocument20 pagesGate Valve Installation InstructionsRomi Kristanto100% (1)

- Datasheet Downhole-Fluid-Sampler en ScreenDocument8 pagesDatasheet Downhole-Fluid-Sampler en ScreenArash PourshoushtarNo ratings yet

- Catalog - GLT Gate ValveDocument9 pagesCatalog - GLT Gate Valveyudii.hidayatNo ratings yet

- Gate ValveDocument3 pagesGate Valveshashwath0904No ratings yet

- Valve Trip 377 InglesDocument20 pagesValve Trip 377 Ingleshades_x3No ratings yet

- Walworth Solid Wedge Slab Gate Valves Carbon Steel and Stainless Steel Class 150 To 900Document30 pagesWalworth Solid Wedge Slab Gate Valves Carbon Steel and Stainless Steel Class 150 To 900Ana LagunesNo ratings yet

- Jandy Check Valve Installation GuideDocument2 pagesJandy Check Valve Installation GuidejupodeNo ratings yet

- 181-1-2 Water Motor GongDocument2 pages181-1-2 Water Motor GongCkaal74No ratings yet

- Mooney Flowgrid Valve: Technical Specifications 12/2018Document2 pagesMooney Flowgrid Valve: Technical Specifications 12/2018Luis Yovany Aldana PonceNo ratings yet

- GLT Gate ValveDocument6 pagesGLT Gate Valveputra keluarga cipta bangunNo ratings yet

- Valve Test ReportDocument3 pagesValve Test ReportHery MukhlisNo ratings yet

- Related Products: Auto Drain Valve: PrecautionsDocument10 pagesRelated Products: Auto Drain Valve: Precautionsteknik otomotifNo ratings yet

- Seitz ES Datasheet PilotValveDocument2 pagesSeitz ES Datasheet PilotValveBayanaka Tehnik100% (2)

- Training of Hydraulic Power FailureDocument15 pagesTraining of Hydraulic Power Failureangelina oliverosNo ratings yet

- Operational Manualhcr-Fls Valve - 2 116 10K PDFDocument14 pagesOperational Manualhcr-Fls Valve - 2 116 10K PDFParag PadoleNo ratings yet

- 3 1.V83 Series Swing Out Ball Valves Aug.2017 1Document6 pages3 1.V83 Series Swing Out Ball Valves Aug.2017 1Tembre Rueda RaúlNo ratings yet

- Kidde Engineered Fire Suppression System: 3-Way Directional Ball Valve Data SheetDocument10 pagesKidde Engineered Fire Suppression System: 3-Way Directional Ball Valve Data SheetEmad SalamaNo ratings yet

- Av 05Document1 pageAv 05davidbejuNo ratings yet

- E BBOSYDocument48 pagesE BBOSYChima OsonduNo ratings yet

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 2 / Capacity: 30 GPM / Cavity: T-2ADocument2 pagesModel Pilot-To-Open Check Valve With Standard Pilot: Series 2 / Capacity: 30 GPM / Cavity: T-2AVEERAMANINo ratings yet

- Drill+Stem+Testing+Tools+-+DST SLBDocument13 pagesDrill+Stem+Testing+Tools+-+DST SLBMahrouz MadoNo ratings yet

- Drill+Stem+Testing+Tools+-+DST SLBDocument13 pagesDrill+Stem+Testing+Tools+-+DST SLBMahrouz MadoNo ratings yet

- Page 0170Document1 pagePage 0170cracoviamaszynaNo ratings yet

- Hydrostatic TestDocument2 pagesHydrostatic TestProduct EngineerNo ratings yet

- CKEB Full en Metric LetterDocument2 pagesCKEB Full en Metric LetterRafalNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Pump DesignDocument186 pagesPump DesignNovancyNo ratings yet

- National Foam Fire Fighting GuideDocument22 pagesNational Foam Fire Fighting Guidefloayzav5684100% (1)

- Guide On Stud Bolts & Practical ApplicationDocument2 pagesGuide On Stud Bolts & Practical ApplicationNovancyNo ratings yet

- EEMUA 159 Corrigendum Imprint 04 2015 PDFDocument22 pagesEEMUA 159 Corrigendum Imprint 04 2015 PDFAlfian Ibnu Pratama100% (1)

- International Paint Application GuidelineDocument3 pagesInternational Paint Application GuidelineNovancyNo ratings yet

- Foam Chamber Model FC PDFDocument6 pagesFoam Chamber Model FC PDFFadhila Ahmad AnindriaNo ratings yet

- Speak English FluentlyDocument240 pagesSpeak English Fluentlydevanadoctor95% (44)

- Maintenance Inspections: GAP.1.3.0.ADocument2 pagesMaintenance Inspections: GAP.1.3.0.ANovancyNo ratings yet

- 50 Business Ideas You Can Start in Africa With $300 (100, 000 Naira) or LessDocument27 pages50 Business Ideas You Can Start in Africa With $300 (100, 000 Naira) or LessNovancyNo ratings yet

- Hilti Fastening Chemical PDFDocument101 pagesHilti Fastening Chemical PDFNovancyNo ratings yet

- Procurement GuidelineDocument28 pagesProcurement GuidelinedvduronNo ratings yet

- Civil Design Basis - B PDFDocument45 pagesCivil Design Basis - B PDFhrol31060No ratings yet

- 50 Business Ideas You Can Start in Africa With $300 (100, 000 Naira) or LessDocument27 pages50 Business Ideas You Can Start in Africa With $300 (100, 000 Naira) or LessNovancyNo ratings yet

- GAPS Guidelines: Fire Protection Equipment InspectionDocument3 pagesGAPS Guidelines: Fire Protection Equipment Inspectionmakasad26No ratings yet

- A2 34+Transformer+maintenance+TutorialDocument64 pagesA2 34+Transformer+maintenance+TutorialJack DuffNo ratings yet

- 3 CFloatingroofandsealsby Andrew EastDocument49 pages3 CFloatingroofandsealsby Andrew Eastgion_ro401No ratings yet

- Oil Immersed Transformer MaintenanceDocument8 pagesOil Immersed Transformer MaintenanceNovancyNo ratings yet

- Elastomer, Fluid Compatibility Chart (Fluids Beginning With M)Document3 pagesElastomer, Fluid Compatibility Chart (Fluids Beginning With M)NovancyNo ratings yet

- Testing TransformerDocument83 pagesTesting Transformercharleselitb92100% (1)

- Condition Monitoring of Transformers SAILDocument17 pagesCondition Monitoring of Transformers SAILavadiraja100% (1)

- 591 0 PDFDocument6 pages591 0 PDFMohammed Jaffar AdnanNo ratings yet

- MFL Tank Bottom Scanner PDFDocument2 pagesMFL Tank Bottom Scanner PDFmarcelogf74No ratings yet

- Watermelon Fertilizer Schedule - Tips For Watermelon Feeding in The GardenDocument5 pagesWatermelon Fertilizer Schedule - Tips For Watermelon Feeding in The GardenNovancyNo ratings yet

- Civil Design Basis - B PDFDocument45 pagesCivil Design Basis - B PDFhrol31060No ratings yet

- Cummins Generator PDFDocument1 pageCummins Generator PDFNovancyNo ratings yet

- Painting B PDFDocument8 pagesPainting B PDFNovancyNo ratings yet

- PDF Catalogue Basket Duplex Simplex Type StrainersDocument8 pagesPDF Catalogue Basket Duplex Simplex Type StrainersNovancyNo ratings yet

- Document Version: 3.0: Hazardous Areas Across The Entire Defence Estate Must Be Checked To Verify ComplianceDocument24 pagesDocument Version: 3.0: Hazardous Areas Across The Entire Defence Estate Must Be Checked To Verify ComplianceramausNo ratings yet

- The Story of Lucifer - How Did He Fall and Become SatanDocument4 pagesThe Story of Lucifer - How Did He Fall and Become SatanNovancyNo ratings yet

- IFC FabStrainers - CatDocument40 pagesIFC FabStrainers - CatSpoonful BurnsideNo ratings yet

- ANSI/AWWA Standards: Std. Yr. Standard Name Keywords Committee Product No. Nonmemb Er Price Awwa Member PriceDocument10 pagesANSI/AWWA Standards: Std. Yr. Standard Name Keywords Committee Product No. Nonmemb Er Price Awwa Member PriceCalidad PellizzariNo ratings yet

- 03 - DOLE - Rule 1170 - Unfired Pressure VesselDocument17 pages03 - DOLE - Rule 1170 - Unfired Pressure Vesselronald s. rodrigo100% (1)

- AMINE OM Part-1 Rev.3Document64 pagesAMINE OM Part-1 Rev.3ShahzaibUsman100% (2)

- 32 Samss 036Document33 pages32 Samss 036naruto256No ratings yet

- Method Statement of Hydrostatic TestDocument28 pagesMethod Statement of Hydrostatic TestMassimo FumarolaNo ratings yet

- Mega Deal Power Plant Shat Al Basra 10 X Gt9E Natural Gas/Ldo Fired Open Cycle Power Plant 1250Mw: Installation of Hfo Heating System (Aux Boilers)Document2 pagesMega Deal Power Plant Shat Al Basra 10 X Gt9E Natural Gas/Ldo Fired Open Cycle Power Plant 1250Mw: Installation of Hfo Heating System (Aux Boilers)Gulzar AliNo ratings yet

- Katalog 2020 ENG Stand 2020 01 25 Optimierte ZeichnungenDocument289 pagesKatalog 2020 ENG Stand 2020 01 25 Optimierte ZeichnungenFábio GamaNo ratings yet

- Issues Causes and Safety Recommendations of NGV AccidentDocument7 pagesIssues Causes and Safety Recommendations of NGV AccidentAsim RiazNo ratings yet

- MALTA Requirements - Consolidated Version 20 October 2011Document85 pagesMALTA Requirements - Consolidated Version 20 October 2011swapneel_kulkarniNo ratings yet

- S-3000-3160-002 - A - 0010-Construction Procedure For Piping Pressure TestingDocument12 pagesS-3000-3160-002 - A - 0010-Construction Procedure For Piping Pressure TestingMessaoud Goutas100% (1)

- C&SU Dossier Eng PersonalDocument15 pagesC&SU Dossier Eng PersonalJosé Antonio Ferrer GutiérrezNo ratings yet

- Calculation Api 653Document23 pagesCalculation Api 653Anonymous YRyGcKPNo ratings yet

- KURD-SPC-PRJ-002 Flange Joint Integrity SpecificationDocument13 pagesKURD-SPC-PRJ-002 Flange Joint Integrity Specificationbmanojkumar16No ratings yet

- Review of Pipeline Integrity ManagementDocument8 pagesReview of Pipeline Integrity ManagementTaib Anwar100% (2)

- 00 ZA E 02018 Att2B Test Pack Contents 00ADocument36 pages00 ZA E 02018 Att2B Test Pack Contents 00AM.A.NNo ratings yet

- Leak - Testing Asme 31.3Document7 pagesLeak - Testing Asme 31.3Tran Trungtt100% (1)

- To-HQ-02-037 Rev 00 Philosophy For Piping Design - OnshoreDocument41 pagesTo-HQ-02-037 Rev 00 Philosophy For Piping Design - OnshoreHedi Ben MohamedNo ratings yet

- Hot Tap Procedure Checklist: Estlake VinylsDocument3 pagesHot Tap Procedure Checklist: Estlake VinylsNiraNo ratings yet

- Safety Valves For Power PlantDocument56 pagesSafety Valves For Power Planttek_surinder100% (1)

- Ras Markaz Crude Oil Park Project (Phase1)Document17 pagesRas Markaz Crude Oil Park Project (Phase1)anil pkNo ratings yet

- B. Specifications For FR TankDocument32 pagesB. Specifications For FR TankRoshin99No ratings yet

- Agenda Item: 650-2024: Coating Prior To Hydrostatic TestingDocument4 pagesAgenda Item: 650-2024: Coating Prior To Hydrostatic Testinggigiphi1No ratings yet

- RP - 76.0.01 Analyzer System Inspection and AceptanceDocument24 pagesRP - 76.0.01 Analyzer System Inspection and AceptancemilecsaNo ratings yet

- Guidelines For Hydrostatic Leak TeatingDocument4 pagesGuidelines For Hydrostatic Leak TeatingClyde CoopperNo ratings yet

- Tender Part-2 (SCC) - 20120621 - 114751Document80 pagesTender Part-2 (SCC) - 20120621 - 114751ThiruppathirajanNo ratings yet

- 2018proceedings Davis Food TruckDocument17 pages2018proceedings Davis Food TruckMohamad Iqbal HanfiNo ratings yet

- Sample Cylinders and Accessories enDocument13 pagesSample Cylinders and Accessories enmoh_ichwanuddinNo ratings yet

- Hydrostatic Testing of Fabricated Piping: 1. ScopeDocument2 pagesHydrostatic Testing of Fabricated Piping: 1. ScopeNicolae StanescuNo ratings yet

- Understanding API ICP653 Reading 12-Worksheet-8Document290 pagesUnderstanding API ICP653 Reading 12-Worksheet-8Charlie Chong100% (1)