0% found this document useful (0 votes)

725 views3 pagesValve Test Report

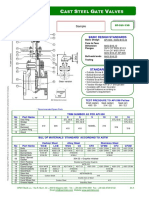

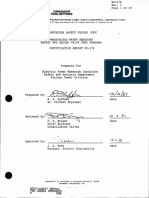

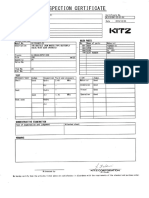

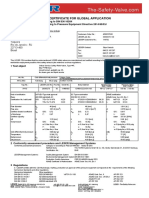

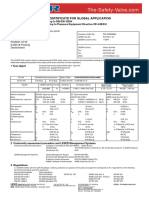

This document is a test sheet for a valve order from Valves.com Pte Ltd for a refinery project in Balikppan, referencing Hyundai. It includes testing and inspection instructions for 5 stainless steel process valves, noting they must open or close within 5 seconds and various parts will remain unpainted or be painted silver. The valves will undergo shell, seat, pressure switch, relief, regulator, and other tests to various pressures and temperatures per the listed standards and instructions.

Uploaded by

Hery MukhlisCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

725 views3 pagesValve Test Report

This document is a test sheet for a valve order from Valves.com Pte Ltd for a refinery project in Balikppan, referencing Hyundai. It includes testing and inspection instructions for 5 stainless steel process valves, noting they must open or close within 5 seconds and various parts will remain unpainted or be painted silver. The valves will undergo shell, seat, pressure switch, relief, regulator, and other tests to various pressures and temperatures per the listed standards and instructions.

Uploaded by

Hery MukhlisCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd