Professional Documents

Culture Documents

Heromotors Self Assessment2

Uploaded by

Rohit TripathiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heromotors Self Assessment2

Uploaded by

Rohit TripathiCopyright:

Available Formats

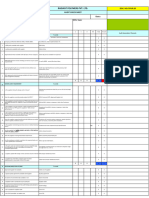

SUPPLIER ASSESSMENT REPORT

Type of assessment : Supplier Self-Assessment / Initial / Re-assessment Date of Visit :

Supplier Name: BONY POLYMERS (P) LTD. Supplier code:

Address: PLOT NO.132,SEC-24 ,FARIDABAD Auditors : ROHIT

Product (S): Auditee :

SUPPLIER

SUPPLIER SELF AUDIT ON SITE AUDIT

SURVEY ITEMS ITEMS TO BE CHECKED SELF AUDIT ON SITE AUDIT OBSERVATION COUNTERMEASURE TARGET DATE RESPONSIBILITY STATUS

OBSERVATION SCORE (0-3)

SCORE (0-3)

1-0

Do the Supplier implements / maintains the QMS

Yes maintains QMS as per

1-1 in accordance with ISO 9001,IATF 16949 or any 3

IATF 16949 .

other standard as applicable.

General Ref.

If the supplier is not certified to any standard, is

there a plan for certification available ? (Verify the

1-2 3 Certified bt tuv sud

adherence to plan during successive

assessments.)

Is the Quality Policy, Quality Objectives defined, Yes implimented and display

1-3 3

being implemented. on shoop floor.

Quality Manual

Is the Quality Manual & relevant Quality

1-4 Procedures, forms & other documents made & 3 Yes

implemented.

Has the supplier identified.

A) Document approval authority.

B) Document approval records.

C) Identification, storage disposal of obsolete

Document control /

1-5 documents. 3 Yes defined in procedure .

Control of records

D) System to ensure non-availability of obsolete /

Invalid documents all points of use.

E) System of record retention and disposal of

records.

Has the supplier defined a system to

a) Notify / distribute customer engineering

Engineering

1-6 standards changes. 3 yes defined inEG-03

Specifications

B) Process and records for the implementation of

the change.

2-0

Is the supplier management committed towards.

A) Ensuring the availability of resources including

human resources.

Management commitment 2-1 3 Yes available.

MANAGEMENT RESPONSIBILITY

B) Conducting timely Management Review.

C) Alignment of business plan with customer

objectives and stated Quality policy.

Do the suppliers management maintain the

QMS Planning 2-2 integrity of the management system when 3 Yes

changes to the QMS is planned.

Authority & Has the supplier management defined Authority

Responsibility/Quality 2-3 & Responsibility for Quality in case any Non- 3 Yes defined

Resp. conformance occur in all shifts.

Has the supplier identified

Management

2-4 1) MR (Management Representative) 3 Yes defined

Representative

2) CR (Customer Representative)

SUPPLIER

SUPPLIER SELF AUDIT ON SITE AUDIT

SURVEY ITEMS ITEMS TO BE CHECKED SELF AUDIT ON SITE AUDIT OBSERVATION COUNTERMEASURE TARGET DATE RESPONSIBILITY STATUS

OBSERVATION SCORE (0-3)

SCORE (0-3)

3-0

Do the supplier trains all the personnel

performing work affecting quality.

A) There training schedule, Training records are

available.

B) Qualification criteria defined.

RESOURCE MANAGEMENT

C) Records of training effectiveness.

D) Are trained for customer specific requirement i.

e. (Pass Through Characteristic i. e. PTC) and

any other requirement.

Human Resources / E) Training provided on the Job including to Yes available all records with

3-1 3

Training contract personnel. plan and defined in HR-02

F) Consequences to the

customer of non - conformity to quality

requirements (I. e. PTC)

G) Are the employee sufficiently empowered &

motivated ?

H) Contingency plan for man power.

I) Provide adequate work environment.

J) Maint 5'S.

K) Use of PPE (Personal Protective Equipments.)

4-0

Is the supplier capable to effectively

Customer Communication 4-1 communicate to customer in case of any 3 Yes

deviations occur in planned arrangements.

Is the supplier capable

A) To design and develop the product

Design Development 4-2 B) Use CFT approach N/A

C) An approach to develop the product equivalent

to APQP.

Do the supplier prepares as required.

A) Process specification (Control plan) &

drawings.

Mfg B) PFD Yes available all updated

4-3 3

output C) PFMEA documents.

D) Work Instruction

PRODUCT REALIZATION

E) Mistake proofing projects.

F) Product / Process verification plans.

Has the supplier identified a system

A) To submit PPAP as per latest AIAG standard

or as per check sheet given by customer. Yes available all records and

PPAP 4-4 3

B) To inform the changes & get approval from defined in EG-03.

customer before changing the process /

product/method on PPAP approved parts.

Do the supplier have system for

1. Incoming inspection of purchase products

including customer supplied product

2. Selection system & approved sub supplier Yes available all records

records. incoming inspection report as

3. Performance Rating method & information to per standard. Audit report as

Purchasing 4-5 sub supplier. 3 per plan.supplier rating

4. Sub - supplier audit results selection system of supplier

5. Compliance to governmental /regulatory also available as per procedure

requirements. all records available.

6. Development of sub supplier.

7. Sufficient purchasing information I. e. P. O.

Commercial Contract.

Do the supplier implements a system.

A) for existence of preventive maintenance.

B) taking corrective - Preventive action in case of Yes available as per plan

Preventive & Predicative any failure (i. e. contingency plan) C) An 3

4-6 contingency plan display on

maintenance effective break down maintenance system. shoop floor.

SUPPLIER

SUPPLIER SELF AUDIT ON SITE AUDIT

SURVEY ITEMS ITEMS TO BE CHECKED SELF AUDIT ON SITE AUDIT OBSERVATION COUNTERMEASURE TARGET DATE RESPONSIBILITY STATUS

OBSERVATION SCORE (0-3)

SCORE (0-3)

Has the supplier identified & planned the

processes required to produce products.

A) Availability of job instruction / Control plans / Yes available ab work

Product realization SOP / Drawing at shop floor. instruction on all areas cobtrol

Product & service 4-7 B) Adherence to documents. 3 plan drawing also available and

provision. C) Monitoring and control of suitable process other documents alao available

parameters and product charactristics. .

D) FOP approval.

E) Acceptance criteria.

Has the supplier identified process to protect the

Confidentiality 4-8 3 yes

confidently of customer information.

Is the supplier determines

A) Method to monitor 100% on time delivery.

Customer related process 4-9 3 Yes records available.

B) Corrective - preventive action in case delay in

achieving the compliance (I.e. 8D report)

Has the supplier identified significant

Customer related Sp. characteristic I. e. (Pass Through Characteristic

4-10 3 Yes defined

Characteristics I.e. PTC) in its documentation (I. e. Control Plan,

PFMEA etc.)

Do the supplier reviews the requirement related

Contract Review 4-11 3 yes

to product i.e. contract review with the customer.

Has the supplier identified a system for

PRODUCT REALIZATION

A) Tool & gauge design, manufacturing &

verification activities.

Tooling Management 4-12 B) Maintenance & repair facilities including 3 Yes records available.

providing trained personnel.

C) Tooling identification clearly defining their

status.

Is there a system for production scheduling to

Production scheduling 4-13 3 yes

meet customer requirements.

Has the supplier defined

A) A system to validate process where its output

cannot be measured.

Validation records available as

Validation of Production 4-14 B) Processes are capable to meet planned 3

per plan

results

C) Frequency of validation

D) Records of validation.

Has the supplier defined a method

A) Suitable product identification throughout the

Identification & facility I. e.tracebility from raw material to identification tag used for

4-15 3

Traceability delivered product. traceabilities

B) Method of traceability where required by

customer.

Is there a system for

1) Preservation of product.

Preservation of product / 2) Storage of incoming, WIP, finished product.

4-16 3 Records avaailable.

Storage & inventory 3) Providing adequate handling means

4) Inventory management

5) Evidence of FIFO.

SUPPLIER

SUPPLIER SELF AUDIT ON SITE AUDIT

SURVEY ITEMS ITEMS TO BE CHECKED SELF AUDIT ON SITE AUDIT OBSERVATION COUNTERMEASURE TARGET DATE RESPONSIBILITY STATUS

OBSERVATION SCORE (0-3)

SCORE (0-3)

Has supplier monitoring 4 M changes ?

A) List of planned unplanned change available.

B) What actions will be taken if 4M change yes records available of 4M

4 M Change management 4-17 3

occurs. change.

C) Part validation record.

D) Monthly 4 M change from supplier.

Has the supplier made

PRODUCT REALIZATION

A) List of equipment

B) Defined method for calibration

C) Calibration schedule

D) Records of calibration Report available as per plan

Control of MMD 4-18 E) Traceability of calibration 3 calibration done by external

F) Calibration status NABL approved lab.

G) MSA plan & implementation records

H) Lab scope for internal calibration

(I) Uses the calibration / testing / Inspection from

the NABL approved Lab for external calibration.

5-0

Measurement, analysis Has the supplier planned to demonstrate

5-1 3 Yes available as per plan .

improvement Conformity of the Product I. e. Product audit.

Do the supplier conducts the Manufacturing

process audit.

A) Review of production line to process flow

diagram and control plan.

Monitoring measurement B) Process capability results. Process and product audit

5-2 3

of manufacturing process C) Review of control charts. report available as per plan.

D) Process study reports.

E) Plan & Executed actions from process study.

F) Records of process change.

MEASUREMENT ANALYSIS & IMPROVEMENT

G) Corrective action (i. e. 8D) report.

Has the supplier

A) Defined the requirement of appropriate

Identification of statistical Spc records available as per

5-3 statistical tools in control plan. 3

tool plan.

B) Understand & implement basic SPC tools,

stability process capability etc. in the process.

Do the supplier monitors the customer

satisfaction in terms of delivery schedule, quality

Customer satisfaction 5-4 3 Yes

issues, customer line stoppages, incident of

premium freight paid etc.

Do the supplier maintains & implement

1) IQA schedule (Audit scope, criteria, frequency,

methods)

Audit records available as per

B) Records of performed audits.

IQA 5-5 3 plan qualified auditor list

C) Implementation of NC reports including follow

availble .

up audit records.

D) List of Qualified auditors.

E) Appropriate prioritization.

MEASUREMENT AN

SUPPLIER

SUPPLIER SELF AUDIT ON SITE AUDIT

SURVEY ITEMS ITEMS TO BE CHECKED SELF AUDIT ON SITE AUDIT OBSERVATION COUNTERMEASURE TARGET DATE RESPONSIBILITY STATUS

OBSERVATION SCORE (0-3)

SCORE (0-3)

Is the supplier audit at appropriate stage, of

Product audit, Monitoring

5-6 production and delivery to verify conformance to 3 yes

measurement of product

all specified requirements at defined frequency.

Layout inspection and Do the supplier perform layout inspection &

5-7 3 Yes available.

functional testing functional testing.

Has the supplier a defined method

A) To identify NC-product (Rework also)

Control of Non - Yes procedure available. QA-

5-8 B) Segregation from conformed material. 3

confirming product 01

C) Evaluation & Disposal

D) Information to customer.

A) Do you define clearly what is abnormal 3 Yes available and display on

situation and make operators know the definition? shop floor.

B) Do you

Handling abnormality in have criteria to estimate the scope of suspected

5-9

quality lot for abnormal situation? When abnormal

situation occurs, do you trace suspected lot

based upon the criteria?

Observe on site the Continuous improvement 3 Yes available.

objectives as defined Example :- A)

Process Efficiency Customer Complaints handling

measurables: targets and 5-10 B) In House PPM Trends

results C) Supply improvement

D) Other Requirement

MSA

Do the supplier determine collect & analyze

appropriate data to demonstrate the suitability

and effectiveness of defined system i. e. COPQ,

product inspection results, process capability

Analysis of data 5-11 data, Internal audit, CAPA & use the data for 3 All records available.

A) customer complaints resolution

B) Prioritization of action.

C) Continual improvement.

D) Manufacturing process improvement.

The supplier take action to eliminate the cause of

NC in order to prevent re occurrence (i. e. 8D

format)

A) Problem solving method used (why-why, 8D,

Corrective -Preventive 7step) All records availablre and poke

5-12 3

action B) Error proofing / Poka-yoke plan / yoke list also available.

implementation record.

C) Corrective action impact on similar process.

D) Preventive action

E) Reject product test / analysis records (8D)

6-0

Has supplier a defined system for following

A) Training of 5S and Safety to all

emplyoees

B) Proper identfication of required items

C) Signboard and location identification.

5S and Safety 6-1 3 Yes defined

D) Signboard and location

identification.

SUPPLIER CODE OF CONDUCT

E) Internal 5S and Safety audit with checksheet

F) Recognition and reward policy for 5S

champions

5S,SAFETY & SUPPLIER CODE OF CONDUCT

SUPPLIER

SUPPLIER SELF AUDIT ON SITE AUDIT

SURVEY ITEMS ITEMS TO BE CHECKED SELF AUDIT ON SITE AUDIT OBSERVATION COUNTERMEASURE TARGET DATE RESPONSIBILITY STATUS

OBSERVATION SCORE (0-3)

SCORE (0-3)

Has supplier a defined system for following

A) Does supplier have policy to ensure

that There is no child labour?

B) Do all workers have free safe access to toilets

which are in good condition and have running

water with soap?

C) Are Fire Extinguisher provided & is easily

accessible. D) Are

the emergency evacuation routes clearly

Supplier Code of Conduct 6-2 identified and free from obstacles? 3 Yes all records available.

E) Are there first aid kits containing products

suited to the risks? (At least 1 per 150

employees)

F) Is PPE distributed and replaced free of charge

to the personnel needing it? G) Is the

working hours policy displayed or known by the

workers? (Break time, factory operating hours,

days off, OT policy etc…) H) Do all

workers have access to free drinking water?

Has the supplier defined system for following.

A0 Are different type of wastes identified on shop

floor and standard procedure masde.

2) Is segeration done at source for different type

of waste.

Enviroment compliance 6-3 3) Storage and disposal being done as per 3 Yes available.

consent and periodic confirmation at disposal

stage.

4) Is a system in place to document/Register and

fulfill customer specific enviroment related

requirement.

7-0 Yescords available.

Has supplier following initial supply control during

ECN/PCN as per SLSPL supplier quality manual

Initial control

requirements ?

A) Initial production control period

Initial flow control 7-1 3 Yes available.

B) Stricker inspection during initial supply.

C) IFC announcement, Trend monitoring, Exit if

target achieved.

D) Analysis issue reported during IFC period.

8-0

Requirement of CQI Audit

A) Is CQI required for product

CQI

CQI Requirement 8-1 3 N/A

B) If yes, is audit check sheet available

C) What is the Audit status

9-0

Countermeasure Are all countemeasures implemented and

9-1 3 yes

verificetion effective submitted by supplier ?

NC

Are all countemeasures implemented and

Previous Audit NC

9-2 effective submitted by supplier against audit 3 yes

verification

NC's.

Rating is to be done on a scale of 0 to 3

0 System does not exist Score (Clause 1) 0%

1 Does not meet the requirement.

2 Marginally meets the requirement, needs improvement.

3 Fully compliant.

4 Minimum Score in Quality clause (Clause No.1) shall be 70% & score in each clause shall be Min 50% (Except Quality Clause) Overall Score

5 Over all rating shall be minimum 60%

(As a rule, when over all rating is less than 60 % and / or there is an itemized rating of 0 point, judgment is made as "Not Approved)

Overall remarks of the assessment team.

SUPPLIER

SUPPLIER SELF AUDIT ON SITE AUDIT

SURVEY ITEMS ITEMS TO BE CHECKED SELF AUDIT ON SITE AUDIT OBSERVATION COUNTERMEASURE TARGET DATE RESPONSIBILITY STATUS

OBSERVATION SCORE (0-3)

SCORE (0-3)

Signature of Auditors

Remarks of Approval Authority

Signature of HOD- Material

You might also like

- Ratio Analysis Formula Excel TemplateDocument5 pagesRatio Analysis Formula Excel Template023- TARANNUM SHIREEN GHAZINo ratings yet

- Master Sheet Process Audit Check SheetDocument11 pagesMaster Sheet Process Audit Check SheetRakesh S100% (1)

- 123Document30 pages123Pinkoo QualityNo ratings yet

- Supplier Audit Check SheetDocument19 pagesSupplier Audit Check SheetR.BALASUBRAMANI100% (1)

- Agency in International TradeDocument4 pagesAgency in International TradeAmita SinwarNo ratings yet

- Quality ToolDocument7 pagesQuality ToolAhmed M. HashimNo ratings yet

- Supplier Quality QuestionnaireDocument4 pagesSupplier Quality QuestionnairesutharitesshNo ratings yet

- Purchases Audit ProgramDocument3 pagesPurchases Audit Programvarghese200795% (22)

- Form - Supplier Quality Survey - Rev 0Document3 pagesForm - Supplier Quality Survey - Rev 0Selvaraj SimiyonNo ratings yet

- Alfred A. Marcus - Strategies For Managing Uncertainty - Booms and Busts in The Energy Industry (Organizations and The Natural Environment) (2019, Cambridge University Press)Document567 pagesAlfred A. Marcus - Strategies For Managing Uncertainty - Booms and Busts in The Energy Industry (Organizations and The Natural Environment) (2019, Cambridge University Press)Carlos100% (2)

- 103E. Supplier Evaluation Checklist For Externally Provided CalibrationDocument4 pages103E. Supplier Evaluation Checklist For Externally Provided CalibrationVikasNo ratings yet

- 13 Procedure For QADocument8 pages13 Procedure For QASasi Kss100% (1)

- Search and Seizure & Survey Under Income Tax Act 1961 - Taxguru - inDocument16 pagesSearch and Seizure & Survey Under Income Tax Act 1961 - Taxguru - insangeethaNo ratings yet

- Waterville TG Inc.: Purchasing GroupDocument35 pagesWaterville TG Inc.: Purchasing GroupShahnawaz PathanNo ratings yet

- SYS Procedure - Internal Quality Audit P1Document1 pageSYS Procedure - Internal Quality Audit P1sumanNo ratings yet

- CA Inter Audit SA Revision Book @CA - Study - NotesDocument62 pagesCA Inter Audit SA Revision Book @CA - Study - Notessantosh pandeyNo ratings yet

- NIAMM Maintenance Management StandardDocument36 pagesNIAMM Maintenance Management StandardSeenivasagam SeenuNo ratings yet

- FAB-QMF-60 (Outsources Process Audit Report)Document6 pagesFAB-QMF-60 (Outsources Process Audit Report)Ibrahim shaikNo ratings yet

- Estates and Trusts: Understanding Income TaxDocument9 pagesEstates and Trusts: Understanding Income TaxPawPaul Mccoy100% (1)

- QC Inspection and Test PlanDocument9 pagesQC Inspection and Test PlanAjaz MalikNo ratings yet

- Blockchain and Crypto in PaymentsDocument16 pagesBlockchain and Crypto in PaymentsforcetenNo ratings yet

- System Press Welding - Audit Check Sheet - 08062019Document23 pagesSystem Press Welding - Audit Check Sheet - 08062019dysonNo ratings yet

- 04) Supplier Audit Checksheet RevisedDocument2 pages04) Supplier Audit Checksheet RevisedShalin mishraNo ratings yet

- API Q1 Supplier Audit Check List - PurchaseDocument8 pagesAPI Q1 Supplier Audit Check List - PurchaseSandra SandersNo ratings yet

- API Q1 Supplier Audit Check List - StoresDocument8 pagesAPI Q1 Supplier Audit Check List - StoresSandra SandersNo ratings yet

- Inspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Document5 pagesInspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Daniel Martinez50% (2)

- QC Inspection and Test Plan ITPDocument9 pagesQC Inspection and Test Plan ITPArfanAli100% (1)

- Ashok Leyland SEA FORMATDocument68 pagesAshok Leyland SEA FORMATVi KraNo ratings yet

- SOP - Vendor Induction & Approval Procedure 062Document1 pageSOP - Vendor Induction & Approval Procedure 062ASIMNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- Jipl CL Pur 10 Testing Lab AuditDocument8 pagesJipl CL Pur 10 Testing Lab AuditMeghna SharmaNo ratings yet

- Test Bank For Supply Chain Management A Logistics Perspective 9th Edition CoyleDocument8 pagesTest Bank For Supply Chain Management A Logistics Perspective 9th Edition Coylea385904759No ratings yet

- Auditor Observation Form MASTERDocument7 pagesAuditor Observation Form MASTERGavin JordanNo ratings yet

- API Q1 Supplier Audit Check List - MRDocument8 pagesAPI Q1 Supplier Audit Check List - MRSandra SandersNo ratings yet

- Itp For Site Preparation & Earth WorksDocument17 pagesItp For Site Preparation & Earth WorksDaniel Martinez100% (1)

- Trai Qa R 45 Process Audit - FormatDocument5 pagesTrai Qa R 45 Process Audit - FormatRS MANIKANDANNo ratings yet

- Audit ManagementDocument21 pagesAudit ManagementeldhoisaacNo ratings yet

- Audit Report - Surveillance - Hayat IndustriesDocument9 pagesAudit Report - Surveillance - Hayat Industriessajid waqasNo ratings yet

- 58 - Supplier Assessment Report - R12 - 06 08 2021Document10 pages58 - Supplier Assessment Report - R12 - 06 08 2021Sanjay KumarNo ratings yet

- F-PUR-07, Supplier Audit Sheet 1Document5 pagesF-PUR-07, Supplier Audit Sheet 1Manish ChoudharyNo ratings yet

- New IATF 16949 Audit (MAQMSR SUPPLIER AUDIT)Document12 pagesNew IATF 16949 Audit (MAQMSR SUPPLIER AUDIT)dhuntNo ratings yet

- Lista de Documentos Auditoria Sistemas de Calidad YbDocument7 pagesLista de Documentos Auditoria Sistemas de Calidad YbJose DavilaNo ratings yet

- Supplier Initial Assesment Check Sheet 07.2.19Document13 pagesSupplier Initial Assesment Check Sheet 07.2.19Prathmesh BandNo ratings yet

- Materi QA 22 Nop 2023Document28 pagesMateri QA 22 Nop 2023Amira BaihaniNo ratings yet

- GM 1927-16b Bushing Press-In Process Audit - XLSX-GM ConfidentialDocument4 pagesGM 1927-16b Bushing Press-In Process Audit - XLSX-GM ConfidentialGabriel SánchezNo ratings yet

- SPTR Audit CSDocument3 pagesSPTR Audit CSRakesh SNo ratings yet

- BDT Internal Audit Check SheetDocument11 pagesBDT Internal Audit Check SheetlovableharryNo ratings yet

- Auditing and Assurance PrinciplesDocument10 pagesAuditing and Assurance PrinciplesJoannah maeNo ratings yet

- MAI 05 - Final Inspection and Testing - DJ - v1Document7 pagesMAI 05 - Final Inspection and Testing - DJ - v1IT Support - FernanNo ratings yet

- SGS GIS PCA Burundi Datasheet A4 EN 15 V5 PDFDocument4 pagesSGS GIS PCA Burundi Datasheet A4 EN 15 V5 PDFSkander HamadiNo ratings yet

- Reading MaterialDocument60 pagesReading MaterialsamikshaNo ratings yet

- Maruti Tier 2Document9 pagesMaruti Tier 2SahilBhallaNo ratings yet

- Manangement Audit Check SheetDocument8 pagesManangement Audit Check SheetlovableharryNo ratings yet

- Sa 230Document12 pagesSa 230meghanaNo ratings yet

- CA InfrastructureDocument9 pagesCA InfrastructureManoj SahNo ratings yet

- Subcon ItpDocument6 pagesSubcon ItpManu MohanNo ratings yet

- 08.03.04-Quality Assurance of Materials - Approval of Source-R2Document4 pages08.03.04-Quality Assurance of Materials - Approval of Source-R2tanmayascribdNo ratings yet

- (Food) Procedure For Food Facility InspectionDocument4 pages(Food) Procedure For Food Facility InspectionRakesh MishraNo ratings yet

- Cuestionario VdaDocument33 pagesCuestionario Vdaing1amm100% (1)

- R20.55IATF IATF 16949 Documentation ReviewDocument7 pagesR20.55IATF IATF 16949 Documentation ReviewPrakash kumarTripathiNo ratings yet

- SGS GIS PCA Cote Divoire Datasheet en 19 V19Document168 pagesSGS GIS PCA Cote Divoire Datasheet en 19 V19Budi IrawanNo ratings yet

- Summary NotesDocument2 pagesSummary NotesFar100% (1)

- Appendix 2 - Inspection & Test Plan, Forms and Check Lsit, and Method of StatementDocument37 pagesAppendix 2 - Inspection & Test Plan, Forms and Check Lsit, and Method of StatementMohammed AlbayatiNo ratings yet

- MAI 06 - Control of Inspection, Test & Submission Records - DJ - v1Document6 pagesMAI 06 - Control of Inspection, Test & Submission Records - DJ - v1IT Support - FernanNo ratings yet

- BRSM Form 009 Qms HRDocument12 pagesBRSM Form 009 Qms HRAnonymous q8lh3fldWMNo ratings yet

- Rediant-Supplier Audit Check Sheet RevisedDocument8 pagesRediant-Supplier Audit Check Sheet RevisedRohit TripathiNo ratings yet

- API Q1 Supplier Audit Check List-MarketingDocument8 pagesAPI Q1 Supplier Audit Check List-MarketingSandra SandersNo ratings yet

- API Q1 Supplier Audit Check List - PurchaseDocument8 pagesAPI Q1 Supplier Audit Check List - PurchaseSandra SandersNo ratings yet

- Rediant-Supplier Audit Check Sheet RevisedDocument8 pagesRediant-Supplier Audit Check Sheet RevisedRohit TripathiNo ratings yet

- Sae J 200Document62 pagesSae J 200Rohit TripathiNo ratings yet

- Machine Preventive Check SheetDocument1 pageMachine Preventive Check SheetRohit TripathiNo ratings yet

- Flow MFGDocument120 pagesFlow MFGRohit TripathiNo ratings yet

- CII - AVANTHA Centre For CompetitivenessDocument31 pagesCII - AVANTHA Centre For CompetitivenessRohit TripathiNo ratings yet

- Poka YokeDocument8 pagesPoka YokeRohit TripathiNo ratings yet

- Cost of Quality - TRG MatDocument36 pagesCost of Quality - TRG MatRohit Tripathi100% (1)

- Tax Alert Mining Royalty Income Tax TreatmentDocument6 pagesTax Alert Mining Royalty Income Tax Treatmentivan vivanoNo ratings yet

- Intermediate Financial Accounting Model DirDocument14 pagesIntermediate Financial Accounting Model Dirmelkamu tesfayNo ratings yet

- Key Test 14Document5 pagesKey Test 1424. Võ Nguyễn Ngọc NhiNo ratings yet

- BINUS University: Academic Career: Class ProgramDocument3 pagesBINUS University: Academic Career: Class ProgramJohan fetoNo ratings yet

- Class Test Accountancy 11 JanDocument2 pagesClass Test Accountancy 11 Jansara VermaNo ratings yet

- Principles of Taxation Mmu Jan-April 2022 AssignmentDocument4 pagesPrinciples of Taxation Mmu Jan-April 2022 AssignmentFlora WairimuNo ratings yet

- យុទ្ធសាស្ត្រការទូតសេដ្ឋកិច្ច ឆ្នាំ ២០២១-២០២៣ Economic Diplomancy Strategy 2021-2023Document26 pagesយុទ្ធសាស្ត្រការទូតសេដ្ឋកិច្ច ឆ្នាំ ២០២១-២០២៣ Economic Diplomancy Strategy 2021-2023Chan RithNo ratings yet

- Financial Accounting Fundamentals 6th Edition Wild Solutions ManualDocument6 pagesFinancial Accounting Fundamentals 6th Edition Wild Solutions ManualJeremyMitchellkgaxp100% (57)

- Midterm ExamDocument35 pagesMidterm ExamYane TimaNo ratings yet

- CreateWills Presentation+to+CustomersDocument13 pagesCreateWills Presentation+to+CustomersIhsan HakimNo ratings yet

- Sesa Goa Limited Vs Joint Commissioner of Income Tax Bombay High CourtDocument22 pagesSesa Goa Limited Vs Joint Commissioner of Income Tax Bombay High CourtPurnima ShekharNo ratings yet

- + Why Subsidy and Dumping Is Closedly Linked?Document2 pages+ Why Subsidy and Dumping Is Closedly Linked?ALù DũngNo ratings yet

- Adani Group's Response To Hindenburg ReportDocument19 pagesAdani Group's Response To Hindenburg Reportvijay srinivas KNo ratings yet

- Industrial Maids Service LTD Ims Is A Corporation Based inDocument1 pageIndustrial Maids Service LTD Ims Is A Corporation Based inCharlotteNo ratings yet

- Fundamentals of EntrepreneurshipDocument22 pagesFundamentals of EntrepreneurshipFarrukhNo ratings yet

- Loan-Agreement Citi MortgagesDocument80 pagesLoan-Agreement Citi Mortgagesmrinal lalNo ratings yet

- Cta 3D CV 09208 M 2021mar03 RefDocument5 pagesCta 3D CV 09208 M 2021mar03 RefFirenze PHNo ratings yet

- Livro Olericultura Teoria e PraticaDocument2 pagesLivro Olericultura Teoria e PraticaLohan de Souza SoaresNo ratings yet

- ENTR 420 MidtermDocument17 pagesENTR 420 MidtermCamillus Carillo AngelesNo ratings yet

- Develop and Understand TaxationDocument26 pagesDevelop and Understand TaxationNigussie BerhanuNo ratings yet

- Mwathi-Utility-Bill-1-Pdf-Free - 1 - 1Document1 pageMwathi-Utility-Bill-1-Pdf-Free - 1 - 1afrimall.storeNo ratings yet

- Chapter-11 Stock Return and ValuationDocument7 pagesChapter-11 Stock Return and ValuationAnushrut MNo ratings yet