Professional Documents

Culture Documents

PPH Lec m5 7

Uploaded by

seecktskatrina03Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PPH Lec m5 7

Uploaded by

seecktskatrina03Copyright:

Available Formats

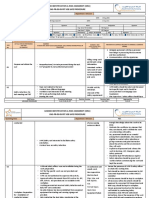

AUF CAMP – PHARMACY DEPARTMENT

PHYSICAL PHARMACY (LECTURE)

Module 5: Heterogenous Systems

Lecturer: Mairre Louie D. Punsalan

OUTLINE CLASSIFICATION OF DISPERSED SYSTEMS BASED ON

Colloidal Dispersions PARTICLE SIZE

Coarse Dispersions Molecular Dispersion

Interfacial Phenomena Particle size: less than 1nm

Characteristics of system

OBJECTIVES Invisible in electron microscope

Differentiate between different types of colloidal systems and Pass through ultrafilter and semipermeable

their main characteristics. membrane

Describe what pharmaceutical suspensions are and what roles Undergo rapid diffusion

they play in the pharmaceutical sciences. Examples: oxygen molecules, ordinary ions, glucose

Discuss the factors that affect the stability of suspensions and

explain flocculation. Colloidal Dispersion

Understand the terms surface tension and interfacial tension Particle size: from 1nm to 0.5um (micrometer)

and their application in pharmaceutical sciences. Characteristics of system

Not resolved by ordinary microscope (although may

be detected under ultramicroscope)

COLLOIDAL DISPERSIONS Visible in electron microscope

Pass through filter paper

Introduction Do not pass semipermeable membrane

Important to understand the theory and technology of dispersed Diffuse very slowly

systems Examples: colloidal silver sols, natural and synthetic polymers,

Understand the behavior of pharmaceutical dispersions cheese, butter, jelly, paint, milk, shaving cream, etc.

Difference in dispersed phase (based on size, not composition)

Coarse Dispersion

Molecular Dispersions – homogenous in character and form true solutions Particle size: greater than 0.5um (micrometer)

Characteristics of system

Visible under microscope

Do not pass through normal filter paper

Do not dialyze through semipermeable membrane

Do not diffuse

Examples: grains of sand, most pharmaceutical emulsions and

suspensions, red blood cells

*1nm (nanometer) = 10 -9m; 1um (micrometer) = 10 -6m

COLLOIDS

A system in which particles of colloidal size (1nm – 0.5um) are

dispersed in a continuous phase of a different composition

Types of Colloidal Systems

Lyophilic Colloids

Lyophobic Colloids

Association Colloids

Yellow Plasma: water (91.5%), proteins (7%), other solutes (1.5%)

White “Buffy coat” composed of white blood cells and platelets TYPES OF COLLOIDAL DISPERSIONS

White blood cells: lymphocytes, granulocytes, monocytes Dispersion Dispersed

Colloid Type Examples

Granulocytes: basophils, neutrophils, eosinophils Medium Phase

Red Red blood cells (coarse particles, coarse dispersion) Solid Solid Solid sol Pears, opals

RBCs carry oxygen to the cells and tissues Solid Liquid Solid emulsion Cheese, butter

Size: 6um (micrometer) in diameter, 2um in width Solid Gas Solid foam Pumice, marshmallow

Liquid Solid Sol, gel Jelly, paint

WBCs are also considered coarse dispersions

Liquid Liquid Emulsion Milk, mayonnaise

Liquid Gas Foam Whipped and shaving cream

Serum albumin, a component of blood, is considered also a colloidal Gas Solid Solid aerosols Smoke, dust

dispersion with particles having the size of greater than 1um (micrometer). Gas Liquid Liquid aerosols Clouds, mist, fog

Dispersed Systems LYOPHILIC COLLOIDS

Consists of:

Dispersed phase – particulate matter (e.g., nutrients Systems containing colloidal particles that interact to an

such as peptides, proteins, and glucose in the blood appreciable extend with the dispersion medium (e.g., colloidal

true solution); may range in different sizes from dispersions or sols)

the particles of atoms and molecules (millimeters or Sols are colloids made up of very small particles in

micrometer) a continuous liquid medium

Dispersion medium – or continuous phase, French or Latin: “lyo” – to loosely interact or to lose (solvent-

distributes the dispersed phase; can be vehicle or loving); “philia” – love

solvent (e.g., plasma in the human blood) Usually obtained by dissolving material in solvent

Classification of Dispersed Systems (based on particle size) Pharmaceutical Examples:

Molecular Dispersions Dissolution of acacia/gelatin in water

Colloidal Dispersions Celluloid in amyl acetate

Coarse Dispersions

Renhart M. Salas, fRPh 1|Pa ge

AUF CAMP – PHARMACY DEPARTMENT

PHYSICAL PHARMACY (LECTURE)

Module 5: Heterogenous Systems

Lecturer: Mairre Louie D. Punsalan

Solvation – attachment of solvent molecules to the molecules COMPARISON OF PROPERTIES OF COLLOIDAL SOLS

of dispersed phase Lyophilic

Hydration – water is the dispersion medium Dispersed phase consists generally of large organic molecules

Hydrophilic sols – gelatin, acacia, insulin, albumin lying within colloidal size range

(organic molecules in aqueous dispersion media) Molecules of dispersed phase are solvated, i.e., they are

Lyophilic colloids (specificity) associated with the molecules comprising the dispersion

Lipophilic colloids – rubber, polystyrene medium

Dissolved in non-aqueous organic Molecules disperse spontaneously to form colloidal solution

solvent Viscosity of the dispersion medium ordinarily is increased

greatly by the presence of the dispersed phase; at sufficiently

LYOPHOBIC COLLOIDS high concentrations, the sol may become a gel; viscosity and

gel formation are related to solvation effects and to the shape of

Have little attraction for the dispersion medium (solvent-hating) the molecules, which are usually highly asymmetric

Absence of a solvent sheath around the particle Dispersions are stable generally in the presence of electrolytes;

Examples: inorganic particles in water they may be salted out by high concentrations of very soluble

Gold, silver, sulfur, arsenous sulfide, silver iodide electrolytes; effect is due primarily to desolvation of lyophilic

Special Methods of Preparation molecules

Dispersion Methods – reducing particle size for

greater attraction to the solvent Association (Amphiphilic)

Condensation Methods – aggregate particles and in Dispersed phase consists of aggregates (micelles) of small

the colloidal size range organic molecules or ions whose size individually is below the

colloidal range

ASSOCIATION COLLOIDS Hydrophilic or lipophilic portion of the molecule is solvated,

depending on whether the dispersion medium is aqueous or

Also known as amphiphilic colloids nonaqueous

Amphiphiles or surface-active agents – have two distinct Colloidal aggregates are formed spontaneously when the

regions of opposing solution affinities can help in the concentration of amphiphile exceeds the critical micelle

solubility of the colloids and their dispersion concentration

Micelles Viscosity of the system increases as the concentration of the

Aggregates containing 50 or more monomer amphiphile increases, as micelles increase in number and

Example: detergents, cosmetic products become asymmetric

Critical micelle concentration (CMC) – In aqueous solutions, the critical micelle concentration is

concentration of the monomer in which the micelles reduced by the addition of electrolytes; salting out may occur at

are formed higher salt concentrations

Aggregation number – number of monomer units

aggregated to form a micelle Lyophobic

Dispersed phase ordinarily consists of inorganic particles

Little if any ineraction (solvation) occurs between particles and

dispersion medium

Material does not disperse spontaneously, and special

procedures therefore must be adopted to produce colloidal

dispersion

Viscosity of the dispersion medium is not greatly increased by

the presence of lyophobic colloidal particles, which tend to be

unsolvated and symmetric

Lyophobic dispersions are unstable in the presence of even

small concentrations of electrolytes; effect is due to

neutralization of the charge on the particles; lyophilic colloids

exert a protective effect

PROPERTIES OF COLLOIDS

Optical Kinetic Electrical

Brownian Motion

Faraday-Tyndall Effect

Diffusion Electrokinetic

Electron Microscope

Sedimentation Phenomena

Light Scattering

Viscosity

FARADAY-TYNDALL EFFECT

When a strong beam of light

is passed through a colloidal

sol, a visible cone, resulting

Traditional Cleansers The Micellar Difference from the scattering of light

The cleaning molecules in traditional The micelle molecules in micellar by the colloidal particles, is

cleansers work alone to dissolve cleansing water cluster together to lift formed.

makeup so you have to rub your face dirt, oil, makeup and impurities on

harshly and rinse with water to contact. No rinsing, no harsh rubbing – Can be observed also to examine the light points using an

completely clean your skin. it is an entirely different way to cleanse. ultramicroscope

Renhart M. Salas, fRPh 2|Pa ge

AUF CAMP – PHARMACY DEPARTMENT

PHYSICAL PHARMACY (LECTURE)

Module 5: Heterogenous Systems

Lecturer: Mairre Louie D. Punsalan

ELECTRON MICROSCOPE Zeta Potential

Also known as electrokinetic potential

Capable of yielding pictures of the actual particles, even those Difference in potential between the surface of the tightly-bound

approaching molecular dimensions layers and the electroneutral region of the dispersion

Widely used to observe the size, shape, and structure of Has more application in pharmacy (e.g., decreased zeta

colloidal particles potential results to flocculation)

High resolving powder allows observation of smaller particles

as compared to an ordinary microscope details, size, shape ELECTROKINETIC PHENOMENA

LIGHT SCATTERING The movement of a charged surface with respect to an adjacent

liquid phase is the basic principle underlying four electrokinetic

Depends on Faraday-Tyndall effect phenomena:

Widely used to determine MW (molecular weight) of colloids, Electrophoresis

size and shape of particles Electroosmosis

Can be described in terms of turbidity, which can be expressed Sedimentation potential

as the intensity of scattered light in all directions Streaming potential

At a given certain concentration of the dispersed phase, the

turbidity can be proportional to the molecular weight (MW) of Electrophoresis

the lyophilic colloid (T ~ MW) One of the mostly used biotechnology today

Movement of a charged particle through a liquid under the

BROWNIAN MOTION influence of an applied potential difference

An electrophoresis cell fitted with two electrodes contains the

Random movement of colloidal particles dispersion. When a potential is applied across the electrodes,

Erratic motion – observed with particles as large as about 5um the particles migrate to the oppositely charged electrode.

due to bombardment of the particles by the molecules of the Makes use of a gel and allow the charged particles to move

dispersion medium analyze certain DNA and RNA

Motion of molecules cannot be observed – too small

Velocity of particles increases with decreasing particle size;

increasing viscosity of medium, decreases and/or stops

Brownian movement (viscosity is the resistance to flow)

DIFFUSION

Particles diffuse spontaneously from a region of higher

concentration to one of lower concentration until the

concentration of the system is uniform throughout

Diffusion is a direct result of Brownian movement

Equation: Fick’s law

OSMOTIC PRESSURE

The osmotic pressure, π, of a dilute colloidal solution is

described by the van’t Hoff equation

π = cRT, where c is the molar concentration of the solute

SEDIMENTATION

The velocity, v, of sedimentation of spherical particles having

a density ρ in a medium of density ρ0 and a viscosity η0 is given

by Stokes’ law

v = [2r2(ρ - ρ0)g] / 9η0 Electroosmosis

Opposite in principle to electrophoresis

VISCOSITY

Liquid moves through a plug or a membrane across which a

potential is applied

Expression of resistance to flow of a system under an applied

Finding for the Zeta potential

stress

More viscous = greater force is applied to make it flow at a Sedimentation Potential

particular rate

Reverse of electrophoresis

Creation of potential when particles undergo sedimentation

ELECTRIC PROPERTIES

Streaming Potential

Nernst Potential

Differs from electroosmosis

Also known as electrothermodynamic potential

Forcing a liquid to flow through a plug or bed of particles which

Difference in potential between the actual surface of the particle

creates the potential

and the electroneutral region of the dispersion

Renhart M. Salas, fRPh 3|Pa ge

AUF CAMP – PHARMACY DEPARTMENT

PHYSICAL PHARMACY (LECTURE)

Module 5: Heterogenous Systems

Lecturer: Mairre Louie D. Punsalan

PHARMACEUTICAL APPLICATIONS OF COLLOIDS EMULSIONS

Hydrogels Dispersed system consisting of at least two immiscible liquid

Microparticles phases, one of which is dispersed as globules in another liquid

Emulsions / Microemulsions phase unstable systems

Liposomes Dispersed Liquid / Phase – Internal Phase (discontinuous)

Micelles Dispersion Vehicle / Phase – External Phase (continuous)

Nanoparticles Third Phase – emulsifier stabilizes emulsions

Nanocrystals

Types of Emulsions

COARSE DISPERSIONS Oil-in-Water Emulsion (O/W)

When an oil phase is dispersed into water

Suspensions Internal phase – oil

Insoluble solid particles are dispersed in a liquid medium External phase – water

Particles have diameters for the most part greater than 0.1um

Some of the particles can be observed under microscope Water-in-Oil Emulsion (W/O)

exhibits Brownian motion When the water phase is dispersed into oil

Examples Internal phase – water

Oral antibiotic formulations External phase – oil

Antacids and radiopaque suspensions

Parenteral suspensions – must not have 0.5-30% Preparation of Emulsions

solid particles In preparation of emulsions, a third phase should be use. This

Acceptable qualities third phase is known as emulsifier.

Suspended material should not settle rapidly Emulsifiers can interact with both oil and water phases, having

Particles settling at the bottom of container may be affinity with both oil and water.

readily redispersed (not hard cake) when shaken Emulsifiers are usually surfactants, which are surface-active

Must not be too viscous flow freely agents.

Important Considerations Surface Active Agents

Physical stability of suspensions – condition in which the Also known as surfactants

particles do not aggregate and in which they remain uniformly Used in preparation of emulsions in reducing the interfacial

distributed throughout the dispersion (or readily redispersed) tension between two immiscible liquids or particles and a

Thermodynamically unstable – particles are highly energetic vehicle

and tend to regroup in such a way as to decrease the total area

and reduce surface free energy (we do not want instability)

Theories of Emulsification

Reduce the solid to small particles dispersed

Surface Tension Theory – makes use of emulsifiers and

Large surface area will result to comminution,

stabilizers to lower down interfacial tension, especially of two

making the system thermodynamically unstable

immiscible liquids reduce repellent force between the liquids

Flocculate – light, fluffy conglomerates that are held together diminish attraction and break up globules into smaller ones

by weak van der Waals forces (good suspension) lesser tendency to reunite or coalescence

Flocculates will settle rapidly, but can easily be

redispersed (and not form cake) due to the weak

Oriented-Wedge Theory – a monomolecular layer of

bonds

emulsifying agent is curved around a droplet of the internal

Deflocculated – does not use flocculates, settle

phase of an emulsion; depending on the size, shape, solubility

slowly (which is good), but slow settling will form

characteristics, and orientation of the molecules, the wedge

sediments aggregation will occur hard cake

shape is envisioned for the molecules to either oil or water

Aggregates – particles that adhere to stronger forces globules to be surrounded

Interfacial Film Theory – thin film of emulsifying agent at the

interface, in between droplets and on their surface; tough and

pliable film is to prevent contact of the dispersed phase and

dispersion vehicle

Advantages of Emulsions

Enhanced solubility – especially for water-insoluble drugs

Suitability for consumption – oily solutions may not be

appropriate to directly consume

Settling in Suspensions Improved palatability

Theory of Sedimentation – Stoke’s Law Enhanced drug absorption

Effect of Brownian Movement

Brownian movement counteracts sedimentation to Instability in Emulsions

measurable extent at room temperature by keeping Flocculation – aggregation, conglomerates of small aggregates

the dispersed material in random motion Simple shaking can redisperse floccules

Coalescence – dispersed phase come together large droplets

Formulation of Suspensions Cannot be redispersed anymore into smaller ones

Use of structured vehicle – maintain deflocculated particles Phase Inversion – reversal of phase, may be due to usage of

Application of principles of flocculation – NO CAKING large amount of internal phase and/or misuse of emulsifier

Renhart M. Salas, fRPh 4|Pa ge

AUF CAMP – PHARMACY DEPARTMENT

PHYSICAL PHARMACY (LECTURE)

Module 5: Heterogenous Systems

Lecturer: Mairre Louie D. Punsalan

Creaming – upward movement of the internal phase Interfacial Tension

Sedimentation – downward movement of the internal phase Force per unit length existing at

Breaking – separation of internal and external phase, may be the interface between two

due to incorrect use of emulsifier immiscible liquid phases

Caking – kapag nagbuo ‘yung emulsion Similar in the case of emulsions

Phenomenon Interface Unit

Surface tension L-G, S-G dyne/cm, N/m

Interfacial tension S-S, L-L, S-L dyne/cm

MEASUREMENT OF TENSION

Capillary Rise Method

Liquid generally rises the capillary

tube a certain distance

The capillary tube can be placed in a

liquid contained in a beaker liquid

will rise

SEMISOLIDS

Force between the liquid molecules

and capillary wall, which is greater

Gels – solid or semisolid system of at least two (2) constituents

than those two molecules

consisting of a condensed mass enclosing and interpenetrated

by a liquid For surface tension of liquid

Jelly – when the coherent matrix is liquid

Xerogel – when the liquid is removed and only the DuNouy Tensiometer

framework remains (e.g., gelatin sheets, tragacanth) Depends on the fact that the force

necessary to detach a platinum-

iridium ring immersed at the surface

or interface is proportional to the

surface or interfacial tension

The wire provides the amount of

force needed to detach the ring in

dynes on a calibrated dial

SURFACE-ACTIVE AGENTS

Also known as surfactant

Alternative: amphiphile (amphiphilic or amphipathic)

Amphiphilic nature that causes surfactants to be adsorbed at

interfaces – L-G, L-L

Affinity for both polar and nonpolar solvents

Syneresis – gel structure shrinks due to pressing out of liquid Have both hydrophilic and lipophilic properties

(e.g., gelatin desserts), sometimes through time

Bleeding – liberation of liquid from the base deficient gel A scale showing surfactant function

structure rather than the contraction involved in syneresis on the basis of hydrophilic-

lipophilic balance (HLB) values.

Swelling – opposite of syneresis, takes up liquid, hence, volume

is increased

HLB – values on the basis of the

Imbibition – takes an amount of liquid, but in comparison to

surfactant function (higher value –

swelling, it does not take an appreciable amount of volume

hydrophilic; low value – lipophilic)

INTERFACIAL PHENOMENA

LIQUID INTERFACES

In the liquid state, the cohesive forces between adjacent molecules are well-

developed.

Surface Tension

A force pulls the molecules of the HLB Values

interface together and contracts the Utilities HLB Value Examples

surface Antifoaming agent 1-3 Mineral oil, fatty alcohol, wax

W/O emulsifying agent 4-6 Span 80, lanolin

Force per unit length that must be

Wetting agent 7-9 Brij 30, docusate sodium

applied parallel to the surface to O/W emulsifying agent 8-18 Tween 20, Cremophor A25

counterbalance the net inward pull Detergent 13-15 Alkyl benzene sulfonates

Solubilizing agent 15-20 Sodium lauryl sulfate

Renhart M. Salas, fRPh 5|Pa ge

AUF CAMP – PHARMACY DEPARTMENT

PHYSICAL PHARMACY (LECTURE)

Module 5: Heterogenous Systems

Lecturer: Mairre Louie D. Punsalan

Type Description Examples

Long chain molecules of

Sodium lauryl sulfate

Anionic carboxylates, sulfates, or

(solubilizer in surfactants)

sulfonates

Interactions with negatively

charged surfaces such as cell

Cationic Benzalkonium chloride

membranes; cytotoxic; used as

antimicrobial preservatives

Most of the naturally occurring Polypeptides, proteins,

Amphoteric surfactants in the biological alkyl betaines, lecithins,

system; are zwitterions cephalin

Fatty alcohols, steroid

Long but contain a small alcohol

alcohols, cholesterol,

base such as propylene glycol,

polyoxyethylene glyceryl

Nonionic sorbitan, or glycerol to which

esters, polyoxypropylene

fatty acids are attached to form

esters, polyoxyethylene-

the fatty acid esters

stearyl ether

Wetting Phenomena

Wetting is the process known to be the adsorption of pure liquid

by solid particle resulting in the formation of a liquid film over

the particle surface

Chemically, non-wetting may be due to failure of the liquid to

displace the film of air and/or other substances at the particle

surface (sometimes due to repellents)

Wetting Agent

A wetting agent is a surfactant that, when dissolved in water,

lowers the advancing contact angle (dictates if it is possible to

have wetting), aids in displacing an air phase at the surface, and

replaces it with a liquid phase

Examples:

Dispersion of powders in liquid vehicles

Displacement of air from matrix of cotton pads

Displacement of dirt using detergents

Application of medicinal lotions

Contact Angle

The most important action of a wetting agent is to lower the

contact angle between the surface and the wetting liquid

The lower the contact angle, the better wetting capacity

The contact angle is the angle between a liquid droplet and the

surface over which it spreads

Rule: ↑θ, ↓ wetting

The wetting tendency is larger, the smaller the contact angle or

the surface tension is

A wetting liquid is a liquid that forms a contact angle with the

solid which is smaller than 90º (0° - wetting)

A non-wetting liquid creates a contact angle between 90º and

180º with the solid (180° - completely non-wetting)

Renhart M. Salas, fRPh 6|Pa ge

AUF CAMP – PHARMACY DEPARTMENT

PHYSICAL PHARMACY (LECTURE)

Module 6: Rheology

Lecturer: Mairre Louie D. Punsalan

OUTLINE VISCOSITY

Rheology

Newtonian Systems Expression of the resistance of a fluid to flow

Non-Newtonian Systems The higher the viscosity, the greater is the resistance

Thixotropy Unit: poise

Determination of Rheologic Properties

n = F / G where

OBJECTIVES

Define rheology and provide examples of fluid Shearing stress (F) – amount of fore per unit area required to

pharmaceutical products exhibiting various rheologic cause a liquid to flow; expressed in dyne/cm2

behaviors, and describe the application of rheology in the Rate of shear (G) – velocity of the system that leads to the

pharmaceutical sciences and practice of pharmacy deformation of liquid; expressed in revolutions per minute

Understand various concepts involving rheology (rev/min)

Define and understand flow properties, Newton’s law of flow

and its application Fluidity

Reciprocal of viscosity: ø = 1 / n

RHEOLOGY Absolute viscosity – internal friction; resistance of fluid to flow

Unit: centipoise, poise

Greek words Shearing stress divided by rate of shear

“rheo” – to flow Kinematic viscosity – absolute viscosity to density

“logos” – science Unit: centistoke, stoke

Science of flow and deformation of matter Absolute viscosity divided by density

Describe the flow of liquids and deformation of solids Relative viscosity – absolute viscosity of liquid to water

Viscosity – resistance to flow (unitless)

Fundamentals of Rheology Kinematic Viscosity

Industrial application Absolute viscosity divided by the density of the liquid at a

Paints, inks, doughs, road-building materials, specified temperature

cosmetics, dairy products, and other materials

Pharmaceutical industry Kinematic viscosity = n / p

Formulation and analysis of products

Emulsions, pastes, suppositories – acceptable Example

consistency and produced with the same product An Ostwald viscometer was used to measure acetone, which was found to

properties have a viscosity of 0.313cp at 25℃. Its density at 25℃ is 0.788g/cm3. What

is the kinematic viscosity of acetone at 25℃?

NEWTONIAN SYSTEMS

Kinematic viscosity = n / p

Each lower layer will move with a velocity directly proportional Kinematic viscosity = 0.313cp / 0.788g/cm3

to its distance from stationary bottom layer Kinematic viscosity = 0.3972 centistoke

Direct relationship between shearing stress and rate of shear

increasing shearing stress, increasing rate of shear NON-NEWTONIAN SYSTEMS

Constant viscosity with increasing rate (linear)

Examples: water, ethanol, acetone, glycerine, benzene, and Major of products are not simple liquids more studied

most solvents Liquid and solid heterogenous dispersions such as colloids,

emulsions, ointments, liquid suspensions, and others

Newtonian flow

X axis – shearing stress Plastic Flow

Y axis – rate of shear Also known as Bingham bodies

Curves do not pass through the origin but rather intersect the

shearing stress axis at a particular point referred to as the yield

value

Does not begin to flow until a shearing stress corresponding to

the yield value is exceeded

Examples: flocculated suspensions, gels, ointments, pastes, and

Newton’s Law of Flow creams such as toothpaste

First to study flow properties of liquids in a quantitative way

High viscosity, greater force per unit area, high shearing stress U=

F−f

where

G

Block of liquid which may consist of parallel U – plastic viscosity

plates like a deck of card F – shearing stress

f – yield value

If the bottom layer is fixed in place and the G – rate of shear

top is being moved at a constant velocity (F),

each lower layer can move with a velocity

directly proportional to its distance from the

stationary, bottom layer

Renhart M. Salas, fRPh 1|Pa ge

AUF CAMP – PHARMACY DEPARTMENT

PHYSICAL PHARMACY (LECTURE)

Module 6: Rheology

Lecturer: Mairre Louie D. Punsalan

Example Rare property of a non-Newtonian fluid; time-dependent with

A plastic material was found to have a yield value of 5200 dynes/cm2. At increasing viscosity the longer the fluid undergoes a force,

shearing stresses above the yield value, F was found to increase linearly the higher its viscosity

with G. If the rate of shear was 150sec−1 when F was 8000 dynes/cm2, Sol-gel transformation

calculate U, the plastic viscosity of the sample. Examples: printer ink, gypsum paste, synovial fluid, serum

albumin, and hyaluronate

U = (F – f) / G

U = (8000 dynes/cm2 – 5200 dynes/cm2) / 150sec-1 Application of Thixotropy

U = 18.6667 poise Thixotropy is a very desirable property in liquid pharmaceutical

systems high consistency, pour/spread easily

Pseudoplastic Flow A well-formulated thixotropy such as a suspension will not

Also known as shear-thinning systems settle out readily , will become fluid upon shaking, regain

Consistency curve for a pseudoplastic material begins at the consistency

origin; no yield value Stability

Viscosity decreases with increasing rate of shear Sedimentation: higher thixotropy, lesser settling

Examples: dispersion of gums (tragacanth, sodium alginate, Parenteral formulations

carboxymethylcellulose [CMC], methylcellulose), paints, High inherent thixotropy, shear-thinning easier

ketchup flow of the drug when injected

DETERMINATION OF RHEOLOGIC PROPERTIES

Measurements

Capillary Tube Viscometers

Measure the time required for a given volume of

liquid to flow through a capillary

Examples

Ostwald Viscometer

Dilatant Flow Ubbelohde Viscometer

Also known as shear-thickening systems

Increase in resistance to flow with increasing rates of shear

Inverse of pseudoplastic flow

Viscosity increases with increasing rate of shear

Examples: zinc oxide (ZnO), barium sulfate (BaSO4), titanium

dioxide (TiO2), cornstarch in water, whipped cream, ink

(particularly cartridge-based)

Ostwald Viscometer Ubbelohde Viscometer

Poiseuille’s Law

Most useful method; for capillary tube viscometers

Usually used to determine relative or specific viscosity rather

than absolute viscosity

8nl(V/t) 1/4

r=( ) where

THIXOTROPY π△P

Similar to some non-Newtonian systems, except that they are time- r – radius of the capillary

dependent time related to thixotropy and rheopexy n – viscosity

l – length of capillary

V – volume

An isothermal and comparatively slow recovery, on standing of

t – time of flow

a material, of a consistency lost through shearing

π – 3.14 (value to be used all throughout)

Time-dependent, shear-thinning property

△P – pressure drop; pressure head in which the liquid flows;

Thixotropy can be applied only to shear-thinning systems

dynes/cm2

Resembles gel-sol transformation

n = (πr4t△P) / (8lV)

Negative Thixotropy

Antithixotropy; represents an increase rather than a decrease in Example

consistency on the down-curve Calculate the radius of an artery if the viscosity of blood at normal body

Increase in thickness or resistance to flow with increased time temperature is 0.04 dyne sec/cm2, with distances of 1cm along it. The

of shear average rate of blood flow (V/t), at rest, is 80cm3/sec, and the pressure drop,

Example: magnesia magma ΔP, is 3.8mmHg.

Use: 1 dyne/cm2 = 7.5x10-4mmHg

Rheopexy

A solid forms a gel more readily when gently shaken or △P = 3.8 mmHg 3.8mmHg / 7.5x10-4 mmHg = 5066.6667 dyne/cm2

otherwise sheared than when allowed to form the gel while the (8)(0.04 dyne sec/cm2)(1cm)(80cm3/sec) 1/4

r=[ ]

material is kept at rest (3.14)(5066.6667 dyne/cm2)

r = 0.2003cm

Renhart M. Salas, fRPh 2|Pa ge

AUF CAMP – PHARMACY DEPARTMENT

PHYSICAL PHARMACY (LECTURE)

Module 6: Rheology

Lecturer: Mairre Louie D. Punsalan

Falling-Sphere Viscometers

Glass or steel ball rolls down an almost vertical glass tube

containing the test liquid at a known constant temperature

The rate at which a ball of a particular density and diameter falls

is an inverse function of the viscosity of the sample

Cup-and-Bob Viscometers

Sample is sheared in the space between the outer wall of a bob

and the inner wall of a cup into which the bob fits

Make use of a bob or spindle which is immersed in the liquid

whose viscosity is to be determined

Drive shaft

Torque set proportional to shearing

stress in sample (loop-like)

Stationary cup (outer container)

Bob (container surrounded by sample;

spindle)

Sample undergoing shear (pink)

Bubble of entrapped air (middle box)

Rotating bob (Searle type)

Brookfield Synchro-Lectric

Rotovisco

Stormer

Rotating cup (Couette type)

MacMichael

Coaxial-cylinder

Cone-and-Plate Viscometers

The sample is placed at the center of the plate, which is then

raised into position under the cone

There is a variable speed motor, sample is being shared

(rev/min) compare to a certain reading or scale

Example: Ferranti-Shirley viscometer

Cone

Plate

Renhart M. Salas, fRPh 3|Pa ge

AUF CAMP – PHARMACY DEPARTMENT

PHYSICAL PHARMACY (LECTURE)

Module 7: Micromeritics

Lecturer: Mairre Louie D. Punsalan

OUTLINE SIEVING

Fundamental Properties of Particles

Methods of Determining Particle Size This method uses a series of standard sieves calibrated by the

Derived Properties of Powder National Bureau of Standards

Sieves are generally used for grading coarser particles

OBJECTIVES Involves size classification followed by the determination of the

Understand the concept of particle size as it applies to the weight of each fraction

pharmaceutical sciences

Discuss the common particle sizes of pharmaceutical Sieve/Mesh Number

preparations and their impact on pharmaceutical Number of opening per linear inch

processing/preparation Higher number, greater fineness

Describe the different methods of determining particle size, 20, 40, 60, 80, 100, 120

surface area, bulk density, angle of repose, compressibility,

and porosity of particles

Description Sieve Opening (um)

FUNDAMENTAL PROPERTIES OF PARTICLES Coarse 355-1000

Moderately fine 180-355

Micromeritics Fine 125-180

Very fine <125

Defined as the science and technology of small particles

Study of small properties solid dosage forms, powders

SEDIMENTATION

Description Particle Size (um) Use

Granulation 1000-3360 Tablet preparation Measured using Andreasen apparatus

Coarse powder 150-1000 Drug powders Employs the settling of particles in a liquid of a

Fine powder 50-100 Drug powders relatively low density under the influence of a

Emulsion & suspension 10-50

Coarse emulsions and gravitational or centrifugal field

flocculated suspensions Sedimentation rate is directly proportional to the

Dry powder 1-5 Inhalation particle size; follows Stoke’s Law

Nanoemulsion 0.01-0.5 Colloids

Nanoparticle 0.001-0.1 Novel drug delivery system

PARTICLE VOLUME MEASUREMENT

Description Particle Size Range

Coarse powder >1000um or 1mm Coulter Counter

Conventional 50-100um HIAC/Royco Instrument

Fine particle 1-50um Gelman Counter

Very fine 0.1-1um

Ultrafine <0.1um COULTER COUNTER

METHODS FOR DETERMINING PARTICLE SIZE When a particle suspended in a

OPTICAL MICROSCOPY conducting liquid passes through a

small orifice on either side of which

It should be possible to use the ordinary microscope for are electrodes, a change in electric

particle-size measurement in the range of 0.2-100um resistance occurs

Advantage: individual particles can be seen Count the voltage pulses and also

Disadvantage: only two-dimensional images can be seen; no involves the blockade or blocking of

estimation of depth (thickness) electrodes

Type Description HIAC/ROYCO INSTRUMENT

Measure of the distance between tangent (intersecting

Feret diameter

the circle once) parallel to some fixed direction More used, most cost-effective

Diameter of a circle with the same area as that of the

Projected area Involves a light blockade

particle observed perpendicular to the surface on

diameter

which the particle rest Use a laser light source for light

Martin diameter Taken as the length of a line that bisects the particle obscuration sensors

Light obscuration allows for a quick

and easy particle counting and

sizing in seconds

Fully automated method minimal

human error

Light obscuration is an analytical technique to which individual

particles in the liquid suspension are being placed between a

laser light source and a detector

Measured by the detector, which will also process

the signal and give the quantification of particles

determining its size

Laser light – illuminates the individual particles,

resulting in the shadow or blockage of light

Obscuration – shadow or blockade

Renhart M. Salas, fRPh 1|Pa ge

AUF CAMP – PHARMACY DEPARTMENT

PHYSICAL PHARMACY (LECTURE)

Module 7: Micromeritics

Lecturer: Mairre Louie D. Punsalan

DERIVED PROPERTIES OF POWDERS Hausner Ratio

It is a number that is correlated to the flowability of a powder

Void Volume or granular material

Void volume (v) – volume of the spaces Increase in Hausner ratio, decrease in flowability

Bulk volume (Vb) – volume occupied

Total volume of the material measured HR = TD/BD

with a graduated cylinder HR = BV/TV

For every bulk volume, there is a void

volume Compressibility / Carr’s Index

True volume (Vp) – true volume of particles (does It is a measure of the relative volume change of a fluid or solid

not contain internal pores) as a response to a pressure (or mean stress) change

Increase in Carr’s index, decrease in flowability

v = V b - Vp Indication of compressibility

Named after scientist Ralph J. Carr, Jr.

If the powder is considered nonporous where there is no internal pores or

capillary spaces, the bulk volume of the powder will then consist of the true CI = [(TD-BD) / TD] x 100

volume of the solid plus the volume of the spaces between the particles CI = [(BV-TV) / BV] x 100

actual volume, regardless (or outside/without) of the internal force or

capillary spaces Compressibility Index (%) Flow Character Hausner Ratio

<10 Excellent 1.00-1.11

Porosity or Voids (ƹ) 11-15 Good 1.12-1.18

Ratio of the void volume to the bulk volume 16-20 Fair 1.19-1.25

Measure of the void volume in a powder material 21-25 Passable 1.26-1.34

expressed as a fraction or percentage of the total 26-31 Poor 1.35-1.45

volume 32-37 Very poor 1.46-1.59

Porosity is frequently expressed in percent, ƹ x 100 >38 Very, very poor >1.60

Expressed as 0-1 or as percentage, 0-100

Example

ƹ = (Vb–Vp) / Vb = 1 – (Vp/Vb) = (v/Vb) x 100 A powder was poured into a graduated cylinder and was noted to have a

volume of 65mL. It was allowed to compressed by pounding the cylinder

Example on the table top. The final volume was reduced by 15mL. Determine the

A sample of calcium oxide powder with a true density of 3.203g/cm3 and compressibility index and Hausner ratio of the powder.

weighing 131.3g was found to have a bulk volume of 82.0cm3 when placed

in a 100mL graduated cylinder. Calculate the porosity. HR = BV / TV

TV = 65mL – 15mL = 50mL

Vp = mass / true density HR = 65mL / 50mL

Vp = 131.3g / 3.203g/cm3 HR = 1.3 (passable)

Vp = 41cm3

CI = [(BV-TV) / BV] x 100

ƹ = [(Vb–Vp) / Vb] x 100 CI = [(65mL – 50mL) / 65mL] x 100

ƹ = [(82cm3 – 41cm3) / 82cm3] x 100 CI = 23.0769% passable

ƹ = 0.5 or 50%

Angle of Repose

DENSITIES OF PARTICLES Measures the angle of pile of material at rest and give some

recognition of a powder’s ability to flow

True density – density of the actual solid material (mass/vol) The powder flows through a funnel and falls freely on a surface

Bulk density – mass of a powder divided by the bulk volume

Tapped density – refers to the bulk density of the powder after Ө = arc tan (h/r)

a specified compaction process, usually involving vibration of Ө = arc tan (2h/d)

the container

Angle of Repose Interpretation

25-30 Excellent

Bulkiness

31-35 Good

Specific bulk volume, the reciprocal of bulk density, is often 36-40 Fair

called bulkiness or bulk 41-45 Passable

It is an important consideration in the packaging of powders 46-55 Poor

Bulkiness increases with a decrease in particle size 56-65 Very poor

In a mixture of materials of different sizes, however, the smaller >65 Very, very poor

particles shift between the larger ones and tend to reduce the

bulkiness Examples

A 100g powder was dropped from a funnel suspended at a height of 20cm

FLOW PROPERTIES made an elevation of 12mm from the surface. The powder was noted to

have made a spread of 5cm. Determine the angle of repose.

Powder flowability – defined as the ease with which a powder

will flow under a set of conditions Ө = arc tan (2h/d)

Methods of evaluating flow properties h = 12mm 1.2cm

Carr’s Index (Compressibility) Ө = arc tan [2(1.2cm) / 5cm]

Hausner Ratio Ө = arc tan (2.4cm / 5cm)

Angle of Ratio Ө = 25.6410° excellent

Renhart M. Salas, fRPh 2|Pa ge

AUF CAMP – PHARMACY DEPARTMENT

PHYSICAL PHARMACY (LECTURE)

Module 7: Micromeritics

Lecturer: Mairre Louie D. Punsalan

A powder was known to produce an angle of 30º with a spread of 40cm.

What would be the expected height of the funnel?

Ө = arc tan (2h/d) tanӨ = 2h/d

2h = (tanӨ)(d) h = dtanӨ / 2

h = 40tan30° / 2

h = 11.5470cm

Renhart M. Salas, fRPh 3|Pa ge

You might also like

- Bicycle Engine Kit Installation Guide - Raw 80ccDocument9 pagesBicycle Engine Kit Installation Guide - Raw 80ccSokitome0% (1)

- Colloid Chemistry - Lectures 1 and 2Document55 pagesColloid Chemistry - Lectures 1 and 2dmitryigNo ratings yet

- Agriculturists 11-2023Document64 pagesAgriculturists 11-2023PRC Baguio100% (1)

- 07 Membrane SeparationDocument36 pages07 Membrane SeparationRalph EvidenteNo ratings yet

- Building Sustainability AnalysisDocument25 pagesBuilding Sustainability AnalysisvickersNo ratings yet

- Liposomes As Drug Carriers: Dr. Talib HussainDocument33 pagesLiposomes As Drug Carriers: Dr. Talib HussainbinteadamNo ratings yet

- CHM271 - Chapter 7 Colloid & Surface ChemistryDocument52 pagesCHM271 - Chapter 7 Colloid & Surface ChemistryNurfarhanah AsyknNo ratings yet

- S5Q2MOD5 WK5 Modes of Reproduction in Flowering and Non Flowering PlantsDocument26 pagesS5Q2MOD5 WK5 Modes of Reproduction in Flowering and Non Flowering PlantsShie PanteNo ratings yet

- As Level Biology Compact Notes PDFDocument49 pagesAs Level Biology Compact Notes PDFSaad AliNo ratings yet

- Water Treatment - Reverse OsmosisDocument217 pagesWater Treatment - Reverse OsmosisDangolNo ratings yet

- Laser / IPL Technology for Skin Care: A Comprehensive Technical and Informative TextbookFrom EverandLaser / IPL Technology for Skin Care: A Comprehensive Technical and Informative TextbookRating: 4 out of 5 stars4/5 (8)

- Study of Spray DryingDocument18 pagesStudy of Spray DryingMahe Rukh100% (2)

- Captopril (Drug Study)Document3 pagesCaptopril (Drug Study)Franz.thenurse6888100% (3)

- Bài tập thì Quá khứ đơn-Quá khứ tiếp diễnDocument8 pagesBài tập thì Quá khứ đơn-Quá khứ tiếp diễnÁnh Hồng100% (1)

- 17.0 Lec 8membran BioseprationDocument19 pages17.0 Lec 8membran BioseprationChan Chun ChenNo ratings yet

- Colloidal Dispersion MartinDocument24 pagesColloidal Dispersion Martinumesh chaudharyNo ratings yet

- Lecture 6 Colloidal Dispersed SystemDocument25 pagesLecture 6 Colloidal Dispersed SystemHassan mohamad Al-bayateNo ratings yet

- Colloid, Surface Chemistry and CatalysisDocument58 pagesColloid, Surface Chemistry and CatalysisViknish ArumugamNo ratings yet

- Unit 1 (Colloidal Dispersions)Document37 pagesUnit 1 (Colloidal Dispersions)Shiv Kumar VishwakarmaNo ratings yet

- Interfacial ScienceDocument54 pagesInterfacial ScienceShounak BiswasNo ratings yet

- 02 - Disperse SystemsDocument29 pages02 - Disperse SystemsamirNo ratings yet

- Colloids DR - RanaDocument87 pagesColloids DR - RanaAhmad Nouri100% (1)

- Ppar Lec Finals TransesDocument11 pagesPpar Lec Finals TransesJay JayNo ratings yet

- For Biology, Food & Cosmetics, Drug Discovery, Chemistry: Dolomite - A One-Stop Shop For Microfluidic SolutionsDocument11 pagesFor Biology, Food & Cosmetics, Drug Discovery, Chemistry: Dolomite - A One-Stop Shop For Microfluidic SolutionsWang CharlesNo ratings yet

- CHM271 - Chapter 7 Colloid & Surface Chemistry (Part 1)Document36 pagesCHM271 - Chapter 7 Colloid & Surface Chemistry (Part 1)happyflowerNo ratings yet

- Kuliah Likuida 7 - Dispersed System - ColloidalDocument63 pagesKuliah Likuida 7 - Dispersed System - Colloidalsalak smg11No ratings yet

- JACOBE - Experiment 2 - ColloidsDocument12 pagesJACOBE - Experiment 2 - ColloidsJoey Marie Mendoza JacobeNo ratings yet

- 6.sistem Dispersi PDFDocument6 pages6.sistem Dispersi PDFhi bbyNo ratings yet

- Biology: Topic 3 Cell Biology and Basic Tissue Histology (Part 1)Document65 pagesBiology: Topic 3 Cell Biology and Basic Tissue Histology (Part 1)EngNo ratings yet

- Structures and Functions of The CellDocument40 pagesStructures and Functions of The CellMark PinedaNo ratings yet

- CHE449 - MergedDocument246 pagesCHE449 - MergedmuffinNo ratings yet

- Disperse Systems: Tim Dosen Farmasi FisikaDocument73 pagesDisperse Systems: Tim Dosen Farmasi FisikairmaNo ratings yet

- Colloidal Dispersion: Md. Zahidul Islam Zahid LecturerDocument48 pagesColloidal Dispersion: Md. Zahidul Islam Zahid LecturerMahmuda Akter Marzia 2014151649No ratings yet

- Chapter 04Document61 pagesChapter 04이준성No ratings yet

- A Membrane Can Essentially Be Defined As A Barrier That Separates Two Phases and Selectively Restricts The Transport ofDocument4 pagesA Membrane Can Essentially Be Defined As A Barrier That Separates Two Phases and Selectively Restricts The Transport ofعبدالله البافاريNo ratings yet

- 200L Histology NotesDocument21 pages200L Histology Notesidokofavour2015100% (1)

- 1 Cell StructureDocument6 pages1 Cell Structuresofia zhouNo ratings yet

- 1 Cell StructureDocument6 pages1 Cell StructureMohammad WazirNo ratings yet

- Disperse SystemDocument22 pagesDisperse SystemZheng JoeyNo ratings yet

- Colloid, Cryatalloid & DialysisDocument15 pagesColloid, Cryatalloid & Dialysisiftiinishat2001No ratings yet

- Colloidal Sciences and EngineeringDocument38 pagesColloidal Sciences and EngineeringJane FrankNo ratings yet

- SY - PP II - Colloidal DipsersionDocument44 pagesSY - PP II - Colloidal DipsersionKevalNo ratings yet

- Module 1 Cells As The Basis of Life NotesDocument17 pagesModule 1 Cells As The Basis of Life NotesNicholas MichailouNo ratings yet

- CHM271 - Chapter 7 - Colloid - Surface ChemistryDocument45 pagesCHM271 - Chapter 7 - Colloid - Surface Chemistryhidayahtul adhaNo ratings yet

- As-Level Biology Notes: By: Bianca HimawanDocument65 pagesAs-Level Biology Notes: By: Bianca HimawanLauren ChikwehwaNo ratings yet

- Chapter 1 Cell StructureDocument37 pagesChapter 1 Cell StructureNawafNo ratings yet

- Gel ChromatographyDocument16 pagesGel ChromatographyDeepak shah100% (1)

- Chapter 2. Methodology of NanomaterialDocument55 pagesChapter 2. Methodology of NanomaterialHyun-Do JungNo ratings yet

- 1 Cell StructureDocument8 pages1 Cell Structureramloghun veerNo ratings yet

- Life Can Be Studied at Different Levels - From Molecules To The Entire Living Planet - Different Levels ofDocument13 pagesLife Can Be Studied at Different Levels - From Molecules To The Entire Living Planet - Different Levels ofBhavik KumarNo ratings yet

- Colloidal DispersionDocument27 pagesColloidal DispersionVISHNU RAJ VNo ratings yet

- Study Guide3 Learning Acts Sci123 2023 For MergeDocument2 pagesStudy Guide3 Learning Acts Sci123 2023 For MergeRovic GasmenNo ratings yet

- Membranes FactsDocument1 pageMembranes FactsLisbeth Roos RoosNo ratings yet

- Chem Academy: Assignment Home Work DPPDocument6 pagesChem Academy: Assignment Home Work DPPHamit RanaNo ratings yet

- Biology 6093 (Text) - Principles of Biology + Nutrition & Transport in HumansDocument31 pagesBiology 6093 (Text) - Principles of Biology + Nutrition & Transport in HumansmahimaloveswaterNo ratings yet

- Cee RevDocument11 pagesCee RevJorica Bren MinervaNo ratings yet

- Lecture 4Document41 pagesLecture 4Yasemin KaradağNo ratings yet

- Colloidal Dispersions PDFDocument6 pagesColloidal Dispersions PDFpharma princessNo ratings yet

- 5 A Tour of The CellDocument106 pages5 A Tour of The CellQuino AmarelaNo ratings yet

- Chap 1 Colloidal Dispersion 2017-2018Document24 pagesChap 1 Colloidal Dispersion 2017-2018Enzo BelliniNo ratings yet

- PHAR 305 Lecture 1 - ColloidsDocument34 pagesPHAR 305 Lecture 1 - ColloidsNuhu SibaNo ratings yet

- Lesson 2 - CellDocument4 pagesLesson 2 - CellA CNo ratings yet

- Techniques For Structure Determination of Proteins-X Ray CrystallographyDocument37 pagesTechniques For Structure Determination of Proteins-X Ray CrystallographyNasrullahNo ratings yet

- Facts at Your Fingertips-200803-MembranesDocument1 pageFacts at Your Fingertips-200803-Membranesonizuka-t2263No ratings yet

- Microemulsions Yuppieraj GaloreDocument20 pagesMicroemulsions Yuppieraj GaloreSairi Madhwika. 11No ratings yet

- Lecture 1 Life On EarthDocument30 pagesLecture 1 Life On Earthshanique thomasNo ratings yet

- Solid Waste Management PDFDocument3 pagesSolid Waste Management PDFGanga Dhar Chaudhary0% (1)

- Buffer PH 10Document7 pagesBuffer PH 10saiful2016No ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (19) Installation of Conductor JumperDocument14 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (19) Installation of Conductor Jumpermohammed tofiqNo ratings yet

- Fifa 11+Document7 pagesFifa 11+HeiYu TongNo ratings yet

- Kottak14e PPT ch03Document37 pagesKottak14e PPT ch03MMC BSEDNo ratings yet

- 3 - Vascualr DisordersDocument7 pages3 - Vascualr DisordersKatelinne DabucolNo ratings yet

- Reservoir Design and OperationDocument66 pagesReservoir Design and OperationUssamaLatifNo ratings yet

- Prasad 2017Document9 pagesPrasad 2017Dhruv MahajanNo ratings yet

- Vaccination List: Belyaletdinov, Ravil AbdulverovichDocument5 pagesVaccination List: Belyaletdinov, Ravil AbdulverovichCarlos MoriNo ratings yet

- Pnoz S2 24Vdc 3 N/O 1 N/C 750102: Pilz GMBH & Co. KG, Felix-Wankel-Strasse 2, 73760 Ostfildern, Germany Page 1/3Document3 pagesPnoz S2 24Vdc 3 N/O 1 N/C 750102: Pilz GMBH & Co. KG, Felix-Wankel-Strasse 2, 73760 Ostfildern, Germany Page 1/3Ibraheem AlfalahatNo ratings yet

- ArchDocument73 pagesArchRebin AliNo ratings yet

- Carbohydrate NotesDocument5 pagesCarbohydrate NotesdrewNo ratings yet

- HT 800 Medium Cellular SiliconeDocument2 pagesHT 800 Medium Cellular SiliconeDarwinPowChonLongNo ratings yet

- MBA 504 Ch3 SolutionsDocument22 pagesMBA 504 Ch3 SolutionsMohit Kumar GuptaNo ratings yet

- Reaction PaperDocument3 pagesReaction PaperMondejar KhriziaNo ratings yet

- Fatty AlcoholsDocument15 pagesFatty AlcoholsUtkarsh MankarNo ratings yet

- Optional 17 - DisplayDocument2 pagesOptional 17 - DisplayHà Ngọc ĐặngNo ratings yet

- OTC-26068-MS Wettability Alteration of Heavy-Oil/Bitumen Containing Carbonates Using Solvents, High PH Solutions and Nano/Ionic LiquidsDocument18 pagesOTC-26068-MS Wettability Alteration of Heavy-Oil/Bitumen Containing Carbonates Using Solvents, High PH Solutions and Nano/Ionic Liquidsjose floresNo ratings yet

- Unit I Health Literacy For StudentsDocument11 pagesUnit I Health Literacy For StudentsNilam Putri Defa100% (1)

- ScoliosisDocument3 pagesScoliosisTracy100% (1)

- Chemistry Mar 2009 EngDocument8 pagesChemistry Mar 2009 EngPrasad C M100% (1)

- IP Rating Chart - DSMTDocument18 pagesIP Rating Chart - DSMTAbi Putra100% (1)

- Notes Piping Symbols Pipe Components Cont. Pipe Components Pipe ComponentsDocument1 pageNotes Piping Symbols Pipe Components Cont. Pipe Components Pipe ComponentsMohd KhaidirNo ratings yet