Professional Documents

Culture Documents

Mitsubishi Fra 740 Catalog 193396 - A

Uploaded by

john solasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mitsubishi Fra 740 Catalog 193396 - A

Uploaded by

john solasCopyright:

Available Formats

MITSUBISHI

ELECTRIC

FACTORY AUTOMATION

Overload capacity SLD (super light duty) LD (light duty) ND (normal duty) HD (heavy duty)

60 s overload 100 % 120 % 150 % 200 %

3 s overload 120 % 150 % 200 % 250 %

Ambient temperature 40 ºC 50 ºC 50 ºC 50 ºC

Type Rated Rated motor Rated current Rated motor Rated current Rated motor Rated current Rated motor WxHxD

current [A] capacity [kW] [A] capacity [kW] [A] * capacity [kW] * [A] capacity [kW] (mm)

FR-A740-00023-EC 2.3 0.75 2.1 0.75 1.5 0.4 0.8 0.25

FR-A740-00038-EC 3.8 1.5 3.5 1.5 2.5 0.75 1.5 0.4

FR-A740-00052-EC 5.2 2.2 4.8 2.2 4 1.5 2.5 0.75 150x260x140

FR-A740-00083-EC

FR-A740-00126-EC

8.3

12.6

3.7

5.5

7.6

11.5

3.7

5.5

6

9

2.2

3.7

4

6

1.5

2.2

Frequency Inverter

FR-A740-00170-EC 17 7.5 16 7.5 12 5.5 9 3.7

220x260x170

FR-A740-00250-EC 25 11 23 11 17 7.5 12 5.5

FR-A740-00310-EC 31 15 29 15 23 11 17 7.5

220x300x190

FR-A740-00380-EC 38 18.5 35 18.5 31 15 23 11

FR-A740-00470-EC 47 22 43 22 38 18.5 31 15

220x550x195

FR-A740-00620-EC 62 30 57 30 44 22 38 18.5

FR-A740-00770-EC 77 37 70 37 57 30 44 22

325x550x195

FR-A740-00930-EC 93 45 85 45 71 37 57 30

FR-A740-01160-EC 116 55 106 55 86 45 71 37 435x550x250

FR-A740-01800-EC 180 90 144 75 110 55 86 45

FR-A740-02160-EC 216 110 180 90 144 75 110 55 465x620x300

FR-A740-02600-EC 260 132 216 110 180 90 144 75

FR-A740-03250-EC 325 160 260 132 216 110 180 90

465x740x360

FR-A740-03610-EC 361 185 325 160 260 132 216 110

FR-A740-04320-EC 432 220 361 185 325 160 260 132

498x1010x380

FR-A740-04810-EC 481 150 432 220 361 185 325 160

FR-A740-05470-EC 547 280 481 250 432 220 361 185

FR-A740-06100-EC 610 315 547 280 481 250 432 220 680x1010x380

FR-A740-06830-EC 683 355 610 315 547 280 481 250

FR-A740-07700-EC 770 400 683 355 610 315 547 280

790x1330x440

FR-A740-08660-EC 866 450 770 400 683 355 610 315

FR-A740-09620-EC 962 500 866 450 770 400 683 355

FR-A740-10940-EC 1094 560 962 500 866 450 770 400 995x1580x440

FR-A740-12120-EC 1212 630 1094 560 962 500 866 450

* Standard operation/initial value

Operating conditions Specifications Operating conditions Specifications

Voltage Three-phase, 380 – 480 or 500 V (-15 %/+10 %) Protection rating IP20 up to 22 kW, IP00 from 30 kW

Ambient temperature –10 ºC to +50 ºC (non-freezing) Shock resistance 10 G (for 00023 to 03610); 3 G (for ≤ 04320)

Storage temperature –20 ºC to +65 ºC Vibration resistance Maximum 0.6 G

Ambient humidity Maximum 90 % relative humidity (non-condensing) Certifications CE/UL/cUL/GOST

Altitude Maximum 1000 m above sea level

EUROPEAN BRANCHES EUROPEAN REPRESENTATIVES

MITSUBISHI ELECTRIC EUROPE B.V. FRANCE GEVA GmbH AUSTRIA louis poulsen DENMARK BEIJER ELECTRONICS UAB LITHUANIA CONSYS RUSSIA INEA SR D.O.O. SERBIA CSC Automation Ltd UKRAINE

25,Boulevard des Bouvets Wiener Straße 89 Geminivej 32 Savanoriu Pr.187 Promyshlennaya St.42 Karadjordjeva 12/260 15,M.Raskova St.,Fl.10,Off.1010

F-92741 Nanterre Cedex AT-2500 Baden DK-2670 Greve LT-02300 Vilnius RU-198099 St Petersburg SER-113000 Smederevo UA-02002 Kiev

Phone +33 (0)1 / 55 68 55 68 Phone +43 (0)2252 / 85 55 20 Phone +45 (0)70 / 10 15 35 Phone +370 (0)5 / 232 3101 Phone +7 812 / 325 3653 Phone +381 (0)26 / 617 163 Phone +380 (0)44 / 494 33 55

MITSUBISHI ELECTRIC EUROPE B.V. GERMANY TEHNIKON BELARUS BEIJER ELECTRONICS ESTONIA INTEHSIS SRL MOLDOVA Electrotechnical Sys.Siberia RUSSIA AutoCont Control SLOVAKIA SHERF MOTION TECHN.LTD ISRAEL

Gothaer Straße 8 Oktjabrskaya 16/5,Off.704 Pärnu mnt.160i Bld.Traian 23/1 Partizanskaya st.27,Office 14 Radlinského 47 Rehov Hamerkava 19

D-40880 Ratingen BY-220030 Minsk EE-11317 Tallinn MD-2060 Kishinev RU-121355 Moscow SK-02601 Dolný Kubín IL-58851 Holon

Phone +49 (0)21 02 / 4 86-0 Phone +375 (0)17 / 2104626 Phone +372 (0)6 / 51 81 40 Phone +373 (0)22 / 66 4242 Phone +7 495 / 744 55 54 Phone +421 43 / 5868 210 Phone +972 (0)3 / 559 54 62

MITSUBISHI ELECTRIC EUROPE B.V. IRELAND Koning & Hartman b.v. BELGIUM UTECO A.B.E.E. GREECE Koning&Hartmanb.v. NETHERLANDS ELEKTROSTYLE RUSSIA INEA d.o.o. SLOVENIA

Westgate Business Park,Ballymount Woluwelaan 31 5,Mavrogenous Str. Haarlerbergweg 21-23 Poslannikov Per.,9,Str.1 Stegne 11

IRL-Dublin 24 BE-1800 Vilvoorde GR-18542 Piraeus NL-1101 CH Amsterdam RU-105005 Moscow SI-1000 Ljubljana

Phone +353 (0)1 / 419 88 00 Phone +32 (0)2 / 257 02 40 Phone +30 211 / 1206 900 Phone +31 (0)20 / 587 76 00 Phone +7 495 / 542 43 23 Phone +386 (0)1 / 513 8100

MITSUBISHI ELECTRIC EUROPE B.V. ITALY AKHNATON BULGARIA MeltradeLTD HUNGARY Beijer Electronics A/S NORWAY RPS-AUTOMATIKA RUSSIA Beijer Electronics AB SWEDEN

Viale Colleoni 7 4,A.Ljapchev Blvd. Fertõ utca 14. Teglverksveien 1 Pr.Budenovsky,97,Office 311 Krangatan 4A

I-20041 Agrate Brianza (MI) BG-1756 Sofia HU-1107 Budapest NO-3002 Drammen RU-344065 Rostov on Don S-20124 Malmö

Phone +39 039 / 60 53 1 Phone +359 (0)2 / 97 44 058 Phone +36 (0) 1 / 431-9726 Phone +47 (0) 32 / 24 30 00 Phone +7 8632 / 22 63 72 Phone +46 (0)40 / 35 86 00

MITSUBISHI ELECTRIC EUROPE B.V. SPAIN INEA CR D.O.O. CROATIA KAZPROMAUTMATICSLTD. KAZAHSTAN MPL Technology SP Z.O.O. POLAND STC Drive Technique RUSSIA ECONOTEC AG SWITZERLAND

Carretera de Rubi,76-80 Losinjska 4 a 2,Scladskaya str. Ul.Krakowska 50 Poslannikov Per.9,str.1 Postfach 282

E-08190 Sant Cugat del Vallés HR-10000 Zagreb KAZ-470046 Karaganda PL-32-083 Balice Kraków RU-105005 Moscow CH-8309 Nürensdorf

Phone +34 93 / 565 31 31 Phone +385 (0)1 / 36 940 01 Phone +7 3212 / 50 11 50 Phone +48 (0) 12 / 630 47 00 Phone +7 495 / 790 72 10 Phone +41 (0)44 / 838 48 11

MITSUBISHI ELECTRIC EUROPE B.V.

Travellers Lane

UK AutoCont

Jelinkova 59/3

CZECH REPUBLIC BEIJER ELECTRONICS SIA

Lienes iela 28

LATVIA Sirius Trad.& Serv.SRL

Str.Biharia Nr.67-77

ROMANIA CRAFT D.O.O.

Toplicina str.4 lok 6

SERBIA GTS

Darülaceze Cad.No.43A KAT:2

TURKEY CBI Ltd

Private Bag 2016

SOUTH AFRICA Comprehensive functions to guarantee faster production cycles with

Hatfield Herts. AL10 8 XB

Phone +44 (0)1707 / 27 61 00

CZ-72100 Ostrava Svinov

Phone +420 (0)59 / 5691 150

LV-1009 Riga

Phone +371 (0)784 / 2280

RO-013981 Bucuresti 1

Phone +40 (0) 21 / 2 01 1147

SER-1800 Nis

Phone +381 (0)18 / 292-24-4/5

TR-34384 Okmeydani-Istanbul

Phone +90 (0)212 / 320 16 40

ZA-1600 Isando

Phone +27 (0) 11 / 9 28 20 00

outstanding speed constancy and dynamic performance

Many key components with 10-year design guarantee a long service life

MITSUBISHI

ELECTRIC Mitsubishi Electric Europe B.V. /// FA - European Business Group /// Gothaer Straße 8 /// D-40880 Ratingen /// Germany

FACTORY AUTOMATION Tel.: +49(0)2102-4860 /// Fax: +49(0)2102-486112 /// info@mitsubishi-automation.com /// www.mitsubishi-automation.com

Four overload ranges for easier product selection and greater flexibility

Specifications subject to change /// Art. no. 193396-A /// 11.2006

All trademarks are copyright acknowledged.

쐽 User-friendly operation

The New Drive 쐽 Network capabilities

The FR-A700 has very extensive network-

These new inverters have ample reserve

capacity. For example, even at high fre-

Configuration and operation of the fre-

quency inverter is simple. Setup is per-

formed with the FR Configurator program,

which can also download, store and docu-

For More Success

ing capabilities. It comes with both a USB quencies and the high nominal tempera-

port and a connection for Modbus-RTU as ture of 50 °C (in the ND and HD overload ment application data. Oscilloscope and

standard equipment. Support is also avail- ranges) you still don’t have to reduce the machine analysis functions help the user to

able for Profibus, CC-Link, CANopen and output of the FR-A700. This is made possi- optimise the drive system. Data and set-

the SSCNET III motion control network. ble by the use of high-quality power stage tings from the predecessor series can be

modules. imported directly and converted for use in

쐽 Cost effective positioning 쐽 Service-friendly the new models.

In combination with closed-loop vector The service-friendly design keeps mainte- An EMC filter is included as standard equip-

control the FR-A700 inverters can also be nance times short. Even replacing the ment for full compliance with the EN

used for positioning, with the control being entire inverter is a quick and simple opera- 61800-3 standard. The FR-A700 models for

realised via pulse train, digital inputs or net- tion, the terminal block is removable and the range up to 22 kW have an integrated

work. can be plugged directly into the replace- brake transistor and the models up to 7.5 kW

ment unit. have an internal brake resistor.

쐽 Autotuning

The optimum performance achieved in The FR-A700 series has the same installa- 쐽 Long service life guaranteed

encoderless vector operation depends on tion footprint as its predecessors. Mitsubishi Electric frequency inverter

precise motor data. This new generation of drives are known for their long service life,

inverters has an autotuning function that however the FR-A700 sets even higher

can obtain all the necessary specifications standards in this area. Its key components

from the motor in less than a minute, even are designed for a life of over 10 years.

when the motor is not running. You can Among other things, this is achieved with

store the data records for up to two motors. heat-resistant high-performance capaci- The FR-A700’s oscilloscope and machine analysis

functions in operation.

In addition to this, the online autotuning tors and cooling fans with sealed bearings

function automatically registers and com- and special lubricants. The PCBs are also

pensates changes in the data during opera- protected against aggressive environ- The FR-DU07 configuration terminal with

tion – for example, changes caused by ments with one or two layers of varnish. one-touch Digital Dial and 7-segment LED

temperature fluctuations. display provides manual access to all

쐽 Comprehensive PLC expertise parameters and operating modes and is

FR-A700: A comprehensive, high power line from 0.4 to 630 kW

The integrated PLC functions of the included as standard equipment. The

Service-friendly details: Accessible fans that are easy to FR-A700 series enable precise configura- optional FR-PU07 control terminal features

1200 replace.

The new FR-A700 frequency inverters com- tion for individual application needs. In a numeric keypad, plain text display in up

쐽 Precision without encoders

Speed (r/min)

1000

bine innovative functions and reliable tech- 800

addition to this, the inverter can even con- to eight languages and enhanced features

Even without encoders the FR-A700 contin- trol simple applications itself without any for storing up to three sets of data and

nology with maximum power, economy 600 쐽 Self-diagnostics prevent downtime

uously calculates the optimum magnetic support from other controllers. The PLC transferring them to other frequency

and flexibility. The FR-A700 is particularly 400

This inverter actively monitors its own

flux for every operating state. A complex 200 functions also provide access to the inverters. Getting started or upgrading to

well suited for demanding applications like 1 2 3

functions. For example, a pre-alarm is trig-

motor model and the specifications of the Time (s)

FR-A700’s internal data registers and the the new generation of frequency inverter

cranes and lifting gear, high-bay warehous- gered automatically if the fan performance

connected standard asynchronous motor Without Autotuning (blue graph) there are deviations states of its digital and analog I/Os. All the drives could hardly be easier.

ing systems, extruders, centrifuges and drops to 40 %. An internal program moni-

are used to improve torque constancy from the set speed. Autotuning (green graph) signifi- results of math calculations can be stored

winding machines. cantly reduces any overshoot. tors the ageing of the main circuit capaci-

across an extended speed range. For example, in the inverter’s own EPROM memory, 쐽 Four overload ranges

the system can generate torque of up to tors and an operating hours counter makes

ensuring that the data is safeguarded Many manufacturers of frequency inverter

200 % from a very low starting frequency of Another tuning system known as easy gain it easy to plan the best time for servicing.

against power failures. The internal PLC can drives design their products for different

just 0.3 Hz. Known as real sensorless vector tuning simplifies the optimisation of the System protection and overload functions

be programmed with Mitsubishi Electric’s overload modes, but seldom for more than

control (RSV), this new Mitsubishi Electric speed control. This system monitors the like phase failure monitoring for both the

user-friendly GX Developer programming two. The FR-A700 fully supports four over-

technology can even be used to regulate motor’s speed response and automatically input and output circuits help to ensure

software package. load ranges, which makes it very easy to

the torque. This now makes it possible to optimises the control parameters, eliminat- trouble-free operation.

select the right inverter for every applica-

use inverters for many applications that ing the need for time-consuming manual tion. For full details see the table overleaf.

were previously the exclusive domain of adjustment and calibration.

DC or closed-loop vector drives.

쐽 Ultra-precise speed and torque

When operated with an encoder, the

FR-A700 drives impress with ultra-precise

speeds across the entire control range (pre-

cision ±0.01 %) and extremely exact torque

control (±10 % precision and ±5 % repeat-

ability). This outstanding performance

makes it possible to switch from simple ser-

vos to inexpensive frequency inverter sys-

tems.

쐽 User-friendly operation

The New Drive 쐽 Network capabilities

The FR-A700 has very extensive network-

These new inverters have ample reserve

capacity. For example, even at high fre-

Configuration and operation of the fre-

quency inverter is simple. Setup is per-

formed with the FR Configurator program,

which can also download, store and docu-

For More Success

ing capabilities. It comes with both a USB quencies and the high nominal tempera-

port and a connection for Modbus-RTU as ture of 50 °C (in the ND and HD overload ment application data. Oscilloscope and

standard equipment. Support is also avail- ranges) you still don’t have to reduce the machine analysis functions help the user to

able for Profibus, CC-Link, CANopen and output of the FR-A700. This is made possi- optimise the drive system. Data and set-

the SSCNET III motion control network. ble by the use of high-quality power stage tings from the predecessor series can be

modules. imported directly and converted for use in

쐽 Cost effective positioning 쐽 Service-friendly the new models.

In combination with closed-loop vector The service-friendly design keeps mainte- An EMC filter is included as standard equip-

control the FR-A700 inverters can also be nance times short. Even replacing the ment for full compliance with the EN

used for positioning, with the control being entire inverter is a quick and simple opera- 61800-3 standard. The FR-A700 models for

realised via pulse train, digital inputs or net- tion, the terminal block is removable and the range up to 22 kW have an integrated

work. can be plugged directly into the replace- brake transistor and the models up to 7.5 kW

ment unit. have an internal brake resistor.

쐽 Autotuning

The optimum performance achieved in The FR-A700 series has the same installa- 쐽 Long service life guaranteed

encoderless vector operation depends on tion footprint as its predecessors. Mitsubishi Electric frequency inverter

precise motor data. This new generation of drives are known for their long service life,

inverters has an autotuning function that however the FR-A700 sets even higher

can obtain all the necessary specifications standards in this area. Its key components

from the motor in less than a minute, even are designed for a life of over 10 years.

when the motor is not running. You can Among other things, this is achieved with

store the data records for up to two motors. heat-resistant high-performance capaci- The FR-A700’s oscilloscope and machine analysis

functions in operation.

In addition to this, the online autotuning tors and cooling fans with sealed bearings

function automatically registers and com- and special lubricants. The PCBs are also

pensates changes in the data during opera- protected against aggressive environ- The FR-DU07 configuration terminal with

tion – for example, changes caused by ments with one or two layers of varnish. one-touch Digital Dial and 7-segment LED

temperature fluctuations. display provides manual access to all

쐽 Comprehensive PLC expertise parameters and operating modes and is

FR-A700: A comprehensive, high power line from 0.4 to 630 kW

The integrated PLC functions of the included as standard equipment. The

Service-friendly details: Accessible fans that are easy to FR-A700 series enable precise configura- optional FR-PU07 control terminal features

1200 replace.

The new FR-A700 frequency inverters com- tion for individual application needs. In a numeric keypad, plain text display in up

쐽 Precision without encoders

Speed (r/min)

1000

bine innovative functions and reliable tech- 800

addition to this, the inverter can even con- to eight languages and enhanced features

Even without encoders the FR-A700 contin- trol simple applications itself without any for storing up to three sets of data and

nology with maximum power, economy 600 쐽 Self-diagnostics prevent downtime

uously calculates the optimum magnetic support from other controllers. The PLC transferring them to other frequency

and flexibility. The FR-A700 is particularly 400

This inverter actively monitors its own

flux for every operating state. A complex 200 functions also provide access to the inverters. Getting started or upgrading to

well suited for demanding applications like 1 2 3

functions. For example, a pre-alarm is trig-

motor model and the specifications of the Time (s)

FR-A700’s internal data registers and the the new generation of frequency inverter

cranes and lifting gear, high-bay warehous- gered automatically if the fan performance

connected standard asynchronous motor Without Autotuning (blue graph) there are deviations states of its digital and analog I/Os. All the drives could hardly be easier.

ing systems, extruders, centrifuges and drops to 40 %. An internal program moni-

are used to improve torque constancy from the set speed. Autotuning (green graph) signifi- results of math calculations can be stored

winding machines. cantly reduces any overshoot. tors the ageing of the main circuit capaci-

across an extended speed range. For example, in the inverter’s own EPROM memory, 쐽 Four overload ranges

the system can generate torque of up to tors and an operating hours counter makes

ensuring that the data is safeguarded Many manufacturers of frequency inverter

200 % from a very low starting frequency of Another tuning system known as easy gain it easy to plan the best time for servicing.

against power failures. The internal PLC can drives design their products for different

just 0.3 Hz. Known as real sensorless vector tuning simplifies the optimisation of the System protection and overload functions

be programmed with Mitsubishi Electric’s overload modes, but seldom for more than

control (RSV), this new Mitsubishi Electric speed control. This system monitors the like phase failure monitoring for both the

user-friendly GX Developer programming two. The FR-A700 fully supports four over-

technology can even be used to regulate motor’s speed response and automatically input and output circuits help to ensure

software package. load ranges, which makes it very easy to

the torque. This now makes it possible to optimises the control parameters, eliminat- trouble-free operation.

select the right inverter for every applica-

use inverters for many applications that ing the need for time-consuming manual tion. For full details see the table overleaf.

were previously the exclusive domain of adjustment and calibration.

DC or closed-loop vector drives.

쐽 Ultra-precise speed and torque

When operated with an encoder, the

FR-A700 drives impress with ultra-precise

speeds across the entire control range (pre-

cision ±0.01 %) and extremely exact torque

control (±10 % precision and ±5 % repeat-

ability). This outstanding performance

makes it possible to switch from simple ser-

vos to inexpensive frequency inverter sys-

tems.

Specifications /// Product Information MITSUBISHI

EBG 172-EN ELECTRIC

FACTORY AUTOMATION

Overload capacity SLD (super light duty) LD (light duty) ND (normal duty) HD (heavy duty)

60 s overload 110 % 120 % 150 % 200 %

3 s overload 120 % 150 % 200 % 250 %

FR-A700

Ambient temperature 40 ºC 50 ºC 50 ºC 50 ºC

Type Rated Rated motor Rated current Rated motor Rated current Rated motor Rated current Rated motor WxHxD

current [A] capacity [kW] [A] capacity [kW] [A] * capacity [kW] * [A] capacity [kW] (mm)

FR-A740-00023-EC 2.3 0.75 2.1 0.75 1.5 0.4 0.8 0.25

FR-A740-00038-EC 3.8 1.5 3.5 1.5 2.5 0.75 1.5 0.4

FR-A740-00052-EC 5.2 2.2 4.8 2.2 4 1.5 2.5 0.75 150 x 260 x 140

FR-A740-00083-EC

FR-A740-00126-EC

8.3

12.6

3.7

5.5

7.6

11.5

3.7

5.5

6

9

2.2

3.7

4

6

1.5

2.2

Frequency Inverter

FR-A740-00170-EC 17 7.5 16 7.5 12 5.5 9 3.7

220 x 260 x 170

FR-A740-00250-EC 25 11 23 11 17 7.5 12 5.5

FR-A740-00310-EC 31 15 29 15 23 11 17 7.5

220 x 300 x 190

FR-A740-00380-EC 38 18.5 35 18.5 31 15 23 11

FR-A740-00470-EC

FR-A740-00620-EC

FR-A740-00770-EC

47

62

77

22

30

37

43

57

70

22

30

37

38

44

57

18.5

22

30

31

38

44

15

18.5

22

220 x 400 x 195

Top-class Drive Technology

325 x 550 x 195

FR-A740-00930-EC

FR-A740-01160-EC

93

116

45

55

85

106

45

55

71

86

37

45

57

71

30

37 435 x 550 x 250

Intelligent, flexible, powerful

FR-A740-01800-EC 180 90 144 75 110 55 86 45

FR-A740-02160-EC 216 110 180 90 144 75 110 55 465 x 620 x 300

FR-A740-02600-EC 260 132 216 110 180 90 144 75

FR-A740-03250-EC 325 160 260 132 216 110 180 90

465 x 740 x 360

FR-A740-03610-EC 361 185 325 160 260 132 216 110

FR-A740-04320-EC 432 220 361 185 325 160 260 132

498 x 1010 x 380

FR-A740-04810-EC 481 150 432 220 361 185 325 160

FR-A740-05470-EC 547 280 481 250 432 220 361 185

FR-A740-06100-EC 610 315 547 280 481 250 432 220 680 x 1010 x 380

FR-A740-06830-EC 683 355 610 315 547 280 481 250

FR-A740-07700-EC 770 400 683 355 610 315 547 280

790 x 1330 x 440

FR-A740-08660-EC 866 450 770 400 683 355 610 315

FR-A740-09620-EC 962 500 866 450 770 400 683 355

FR-A740-10940-EC 1094 560 962 500 866 450 770 400 995 x 1580 x 440

FR-A740-12120-EC 1212 630 1094 560 962 500 866 450

* Standard operation/initial value

Operating conditions Specifications Operating conditions Specifications

Voltage Three-phase, 380 – 480 or 500 V (-15 %/+10 %) Protection rating IP20 up to 22 kW, IP00 from 30 kW

Ambient temperature –10 ºC to +50 ºC (non-freezing) Shock resistance 10 G (for 00023 to 03610); 3 G (for £ 04320)

Storage temperature –20 ºC to +65 ºC Vibration resistance Maximum 0.6 G

Ambient humidity Maximum 90 % relative humidity (non-condensing) Certifications CE/UL/cUL/GOST

Altitude Maximum 1000 m above sea level

EUROPEAN BRANCHES EUROPEAN REPRESENTATIVES

MITSUBISHI ELECTRIC EUROPE B.V. FRANCE GEVA AUSTRIA B:TECH, a.s. CZECH REPUBLIC Kazpromautomatics Ltd. KAZAKHSTAN MPL Technology Sp. z o.o. POLAND SIRIUS Trading & Services srl ROMANIA Beijer Electronics AB SWEDEN

25, Boulevard des Bouvets Wiener Straße 89 U Borove 69 2, Scladskaya str. Ul. Krakowska 50 Aleea Lacul Morii Nr. 3 Box 426

F-92741 Nanterre Cedex AT-2500 Baden CZ - 58001 Havlickuv Brod KAZ-470046 Karaganda PL-32-083 Balice RO-060841 Bucuresti, Sector 6 SE-20124 Malmö

Phone: +33 (0)1 / 55 68 55 68 Phone: +43 (0)2252 / 85 55 20 Phone: +420 (0)569 777 777 Phone: +7 3212 / 50 11 50 Phone: +48 (0)12 / 630 47 00 Phone: +40 (0)21 / 430 40 06 Phone: +46 (0)40 / 35 86 00

MITSUBISHI ELECTRIC EUROPE B.V. GERMANY TEHNIKON BELARUS Beijer Electronics A/S DENMARK Beijer Electronics SIA LATVIA CONSYS RUSSIA CRAFT C. & E. d.o.o. SERBIA ECONOTEC AG SWITZERLAND

Gothaer Straße 8 Oktyabrskaya 16/5, Off. 703-711 LYKKEGARDSVEJ 17, 1. Vestienas iela 2 Promyshlennaya st. 42 Bulevar Svetog Cara Konstantina 80-86 Hinterdorfstr. 12

D-40880 Ratingen BY-220030 Minsk DK-4000 ROSKILDE LV-1035 Riga RU-198099 St. Petersburg SER-18106 Nis CH-8309 Nürensdorf

Phone: +49 (0)2102 / 486-0 Phone: +375 (0)17 / 210 46 26 Phone: +45 (0)46/ 75 56 26 Phone: +371 (0)784 / 2280 Phone: +7 812 / 325 36 53 Phone:+381(0)18/292-24-4/5,523962 Phone: +41 (0)44 / 838 48 11

MITSUBISHI ELECTRIC EUROPE B.V. IRELAND Koning & Hartman B.V. BELGIUM Beijer Electronics EESTI OÜ ESTONIA Beijer Electronics UAB LITHUANIA ELECTROTECHNICAL SYSTEMS RUSSIA INEA SR D.O.O. SERBIA GTS TURKEY

Westgate Business Park, Ballymount Woluwelaan 31 Pärnu mnt.160i Savanoriu Pr. 187 Derbenevskaya st. 11A, Office 69 Karadjordjeva 12/260 Darulaceze Cad. No. 43 KAT. 2

IRL-Dublin 24 BE-1800 Vilvoorde EE-11317 Tallinn LT-02300 Vilnius RU-115114 Moscow SER-113000 Smederevo TR-34384 Okmeydani-Istanbul

Phone: +353 (0)1 419 88 00 Phone: +32 (0)2 / 257 02 40 Phone: +372 (0)6 / 51 81 40 Phone: +370 (0)5 / 232 3101 Phone: +7 495 / 744 55 54 Phone: +381 (0)26 / 617 163 Phone: +90 (0)212 / 320 1640

MITSUBISHI ELECTRIC EUROPE B.V. ITALY AKHNATON BULGARIA Beijer Electronics OY FINLAND INTEHSIS srl MOLDOVA ELEKTROSTILY RUSSIA AutoCont Control s.r.o. SLOVAKIA CSC AUTOMATION Ltd. UKRAINE

Viale Colleoni 7 4 Andrej Ljapchev Blvd. Pb 21 Jaakonkatu 2 bld. Traian 23/1 Rubzowskaja nab. 4-3, No. 8 Radlinského 47 15, M. Raskova St., Fl. 10, Office 1010

I-20041 Agrate Brianza (MI) BG-1756 Sofia FIN-01620 Vantaa MD-2060 Kishinev RU-105082 Moscow SK - 02601 Dolny Kubin UA-02002 Kiev

Phone: +39 039 / 60 53 1 Phone: +359 (0)2 / 817 6004 Phone: +358 (0)207 / 463 500 Phone: +373 (0)22 / 66 4242 Phone: +7 495 / 545 3419 Phone: +421 (0)43 / 5868210 Phone: +380 (0)44 / 494 33 55

MITSUBISHI ELECTRIC EUROPE B.V. SPAIN INEA CR d.o.o. CROATIA UTECO A.B.E.E. GREECE Koning & Hartman B.V. NETHERLANDS RPS-AUTOMATIKA RUSSIA CS MTrade Slovensko, s.r.o. SLOVAKIA SHERF MOTION TECHN. Ltd. ISRAEL

Carretera de Rubí 76-80 Losinjska 4 a 5, Mavrogenous Str. Haarlerbergweg 21-23 BUDENNOVSKY 97, OFFICE 311 Vajanskeho 58 Rehov Hamerkava 19

E-08190 Sant Cugat del Vallés (Barcelona) HR-10000 Zagreb GR-18542 Piraeus NL-1101 CH Amsterdam RU-344007 Rostov on Don SK - 92101 Piestany IL-58851 Holon

Phone: +34 93 / 565 3131 Phone: +385 (0)1 / 36 940 - 01/ -02/ -03 Phone: +30 211 / 1206 900 Phone: +31 (0)20 / 587 76 00 Phone: +7 8632 / 22 63 72 Phone: +421 (0)33 / 7742 760 Phone: +972 (0)3 / 559 54 62

MITSUBISHI ELECTRIC EUROPE B.V.

Travellers Lane

UK AUTOCONT C.S., s.r.o. CZECH REPUBLIC

Technologicka 374/6

MELTRADE Ltd.

Fertő utca 14.

HUNGARY Beijer Electronics AS

Postboks 487

NORWAY STC DRIVE TECHNIQUE

Poslannikov per. 9, str 1

RUSSIA INEA d.o.o.

Stegne 11

SLOVENIA CBI Ltd.

Private Bag 2016

SOUTH AFRICA Comprehensive functions to guarantee faster production cycles with

UK-Hatfield, Herts. AL10 8XB

Phone: +44 (0)1707 / 27 61 00

CZ-708 00 Ostrava Pustkovec

Phone: +420 (0)59 / 5691 150

HU-1107 Budapest

Phone: +36 (0)1 / 431-9726

NO-3002 Drammen

Phone: +47 (0)32 / 24 30 00

RU-105005 Moscow

Phone: +7 495 / 790 72 10

SI-1000 Ljubljana

Phone: +386 (0)1 / 513 8100

ZA-1600 Isando

Phone: + 27 (0)11 / 928 2000

outstanding speed constancy and dynamic performance

Many key components with 10-year design guarantee a long service life

MITSUBISHI

ELECTRIC Mitsubishi Electric Europe B.V. /// FA - European Business Group /// Gothaer Straße 8 /// D-40880 Ratingen /// Germany

FACTORY AUTOMATION Tel.: +49(0)2102-4860 /// Fax: +49(0)2102-4861120 /// info@mitsubishi-automation.com /// www.mitsubishi-automation.com

Four overload ranges for easier product selection and greater flexibility

Specifications subject to change /// Art. no. 193396-A /// 06.2008

All trademarks and copyrights acknowledged.

You might also like

- NU3000 NU6000 Service ManualDocument35 pagesNU3000 NU6000 Service Manualoscarm311875% (16)

- Customer Project Name Drawing No Revision No Order No Kontrol Panosu-TJ509-T-DOOSAN-DP126 E3-191010459 - StandartDocument11 pagesCustomer Project Name Drawing No Revision No Order No Kontrol Panosu-TJ509-T-DOOSAN-DP126 E3-191010459 - StandartАлександр ЩеблыкинNo ratings yet

- ACS880-04 (315kW VFD)Document316 pagesACS880-04 (315kW VFD)Sudipon DasNo ratings yet

- EMCP II Testing & AdjustingDocument71 pagesEMCP II Testing & AdjustingHarish De Silva100% (2)

- 131197.BSC 01.HW - Piazza.dessie - Ner Eno PPT 20200107 2232Document29 pages131197.BSC 01.HW - Piazza.dessie - Ner Eno PPT 20200107 2232MikatechNo ratings yet

- Caracteristicas de Motor ff030pk PDFDocument1 pageCaracteristicas de Motor ff030pk PDFMelanie EstefaniaNo ratings yet

- Inovance Monarch Nice3000 Elevator User Manual 7 enDocument184 pagesInovance Monarch Nice3000 Elevator User Manual 7 enMehedi HasanNo ratings yet

- 303AC1204AC SE2006GK C DatasheetDocument6 pages303AC1204AC SE2006GK C DatasheetJoao LoboNo ratings yet

- Blue Print Hotel DliraDocument58 pagesBlue Print Hotel DliraMulbariqpas FamilNo ratings yet

- Valmet Rotary Installation and OperatingDocument72 pagesValmet Rotary Installation and OperatingNolan100% (2)

- A02 41 (Highlighted)Document1 pageA02 41 (Highlighted)HasmukhNo ratings yet

- Carbon-brush DC motor specs and performance dataDocument1 pageCarbon-brush DC motor specs and performance dataJordi MarsàNo ratings yet

- UPE Secpropsdimsprops Eurocode3 UK 16-11-2023Document8 pagesUPE Secpropsdimsprops Eurocode3 UK 16-11-2023Zack DaveNo ratings yet

- A105 - Section Views-Manufacturing PlantDocument1 pageA105 - Section Views-Manufacturing PlantAxiv The GreatNo ratings yet

- Ju202as-202 Facade Structure Submittal 051200-3aDocument1 pageJu202as-202 Facade Structure Submittal 051200-3aMoises GaytanNo ratings yet

- 35 Earned Value ReportDocument1 page35 Earned Value Reportmanolito cresencioNo ratings yet

- Bucket Elevator: Feed and BiofuelDocument4 pagesBucket Elevator: Feed and BiofuelOcta IrawanNo ratings yet

- Mono P-Type 490-510W 1500VDocument2 pagesMono P-Type 490-510W 1500Vfernando fernandezNo ratings yet

- Stability Test Curves and GraphDocument3 pagesStability Test Curves and GraphTALHA SHAHIDNo ratings yet

- ChartsDocument4 pagesChartsDaniela Alvarado GarcíaNo ratings yet

- Daikin VRV FXMQ Medium Static Concealed Ducted Indoor Unit BrochureDocument1 pageDaikin VRV FXMQ Medium Static Concealed Ducted Indoor Unit BrochureChuy Cantú100% (1)

- A105 - Podium 5 Floor PlanDocument1 pageA105 - Podium 5 Floor PlanDee-ar Inducil TrinidadNo ratings yet

- Medical Records: Ground Level Floor PlanDocument1 pageMedical Records: Ground Level Floor PlanBerlin Andrew SionNo ratings yet

- Notes: JGSK CFP Project Reviewed by Field EngineerDocument1 pageNotes: JGSK CFP Project Reviewed by Field EngineervssabinNo ratings yet

- Efr63 SpecDocument2 pagesEfr63 Specmike00No ratings yet

- Pareto Chart: Contributor # of Defects % CumDocument4 pagesPareto Chart: Contributor # of Defects % CumpraveenNo ratings yet

- Outdoor unit specifications tableDocument2 pagesOutdoor unit specifications tableAhmed NajjarNo ratings yet

- Valbia Actuator SetupDocument1 pageValbia Actuator SetupkikinNo ratings yet

- Wire Size - Area To Diameter ConverterDocument1 pageWire Size - Area To Diameter ConverterrahmatNo ratings yet

- Daily BDR, Dec-2015Document68 pagesDaily BDR, Dec-2015Yossy NugrahaNo ratings yet

- 1 Denah Lantai 1Document1 page1 Denah Lantai 1Ghiyats MaulanaNo ratings yet

- Spe 2322 Geophysics Lectures 4&5Document96 pagesSpe 2322 Geophysics Lectures 4&5Martinez MutaiNo ratings yet

- Plan DemisolDocument1 pagePlan Demisolade vitanNo ratings yet

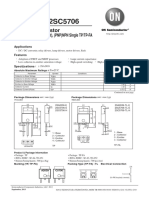

- Silicon NPN Triple Diffused Planar Transistor (High Voltage Switchihg Transistor)Document1 pageSilicon NPN Triple Diffused Planar Transistor (High Voltage Switchihg Transistor)miloud1911No ratings yet

- Duty Master Alternating Current Motors: Product Information Packet: EM4407TR-4 - 200HP, 1785RPM, 3PH, 60HZ, 447T, A44120M, TEFCDocument1 pageDuty Master Alternating Current Motors: Product Information Packet: EM4407TR-4 - 200HP, 1785RPM, 3PH, 60HZ, 447T, A44120M, TEFCIsaias de la CruzNo ratings yet

- Body PlanDocument84 pagesBody PlanGomgom SianturiNo ratings yet

- Denyo Dca Specifications-6128914Document1 pageDenyo Dca Specifications-6128914siva ramakrishnanNo ratings yet

- Denyo - DCADocument1 pageDenyo - DCAvicky beastNo ratings yet

- ChartsDocument4 pagesChartsDeepan KumarNo ratings yet

- Perf PDFDocument1 pagePerf PDFMGPHNo ratings yet

- Eh Ad 2.eheh Aoc 03 21Document1 pageEh Ad 2.eheh Aoc 03 21patrouilledeafranceNo ratings yet

- Utility deck and canopy dimensionsDocument1 pageUtility deck and canopy dimensionsBerlin Andrew SionNo ratings yet

- Typical Plunged Column Detail: General ConsultantDocument1 pageTypical Plunged Column Detail: General ConsultantghansaNo ratings yet

- Guide To Choosing Generator To Motor SizeDocument2 pagesGuide To Choosing Generator To Motor SizeMarlone RodriguezNo ratings yet

- Document analysis of 15 variablesDocument1 pageDocument analysis of 15 variablesMulti- FacetedNo ratings yet

- 03 PDFDocument1 page03 PDFMulti- FacetedNo ratings yet

- MTK-01 - 1-Model BNDocument1 pageMTK-01 - 1-Model BNUbaldo CruzNo ratings yet

- DatasheetDocument1 pageDatasheetmixespirit73No ratings yet

- 029 00065 0 2sa1746Document1 page029 00065 0 2sa1746karimNo ratings yet

- Multipurpose WarehouseDocument1 pageMultipurpose Warehousemark asistoresNo ratings yet

- MCC 2610-MC-501 load dataDocument3 pagesMCC 2610-MC-501 load dataRodrigo Pedraza GalazNo ratings yet

- Policy-Report-Overview-SlidesDocument20 pagesPolicy-Report-Overview-SlidesAFRICA GREEN AGENo ratings yet

- Powerflex 525 Adjustable Frequency Ac Drive: Product InformationDocument2 pagesPowerflex 525 Adjustable Frequency Ac Drive: Product InformationOmarAlirioSuarezCañareteNo ratings yet

- Bassstation: Owner'S Manual Owner'S ManualDocument20 pagesBassstation: Owner'S Manual Owner'S ManualDi RojasNo ratings yet

- DOCUMENTHydraulic BREAKERS Tools that make people move Turning your job into more value! ADVANCED TECHNOLOGY Breaker Selection Guide (applicable carrier range and minimum required hydraulic powerDocument5 pagesDOCUMENTHydraulic BREAKERS Tools that make people move Turning your job into more value! ADVANCED TECHNOLOGY Breaker Selection Guide (applicable carrier range and minimum required hydraulic powerJorge CarvajalNo ratings yet

- Bateria PLC B&R Diane CR277N RenataDocument1 pageBateria PLC B&R Diane CR277N RenataPedro AlvarengaNo ratings yet

- Axiata Iar-Our PerformanceDocument20 pagesAxiata Iar-Our PerformanceYour CrushNo ratings yet

- Events PlanelevDocument1 pageEvents Planelevmxp.phangNo ratings yet

- Guide To Choosing Generator To Motor Size - National Pump & EnergyDocument2 pagesGuide To Choosing Generator To Motor Size - National Pump & EnergyNiranjan JainNo ratings yet

- Materiale:: H/L 420 / 594 (0.25m2) Allplan 2017Document1 pageMateriale:: H/L 420 / 594 (0.25m2) Allplan 2017Victor RîndunicaNo ratings yet

- Remote Reading1Document2 pagesRemote Reading1joseph chungNo ratings yet

- 2 SC 5287Document1 page2 SC 5287Angelos AnagnostouNo ratings yet

- 2SC5706 e PDFDocument10 pages2SC5706 e PDFGudiño OrteganojfNo ratings yet

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- Professional Windows Phone 7 Application Development: Building Applications and Games Using Visual Studio, Silverlight, and XNAFrom EverandProfessional Windows Phone 7 Application Development: Building Applications and Games Using Visual Studio, Silverlight, and XNANo ratings yet

- Metkon Digiprep Accura PDFDocument4 pagesMetkon Digiprep Accura PDFRepresentaciones y Distribuciones FALNo ratings yet

- Carrier 58MXA-10SMDocument16 pagesCarrier 58MXA-10SMMichael MartinNo ratings yet

- PCRVN1447Baprv LineupDocument17 pagesPCRVN1447Baprv LineupTân NguyễnNo ratings yet

- Ebm Papst S4E315AC0807-1879477Document6 pagesEbm Papst S4E315AC0807-1879477npNo ratings yet

- Ades Pump Data Sheet K126Document4 pagesAdes Pump Data Sheet K126engnazmy10yahoo.comNo ratings yet

- Design of Machine ElementsDocument12 pagesDesign of Machine ElementsSai ThotaNo ratings yet

- Floor Cleaning Machine ReportDocument26 pagesFloor Cleaning Machine ReportMayur Madhukar MankarNo ratings yet

- Prof. Bhosale V.B. CONTROL SYSTEMS Question Bank 2021-22Document32 pagesProf. Bhosale V.B. CONTROL SYSTEMS Question Bank 2021-22BhNo ratings yet

- Type Series Booklet: Submersible Borehole PumpDocument104 pagesType Series Booklet: Submersible Borehole PumpJosko SanticNo ratings yet

- Iecex Certificate of ConformityDocument10 pagesIecex Certificate of ConformityFrancesco_CNo ratings yet

- PJ Umrichter 611 A1014 Englisch PDFDocument492 pagesPJ Umrichter 611 A1014 Englisch PDFSergeyNo ratings yet

- ATV6000 Product Data SheetDocument3 pagesATV6000 Product Data SheetHendrik BastiwNo ratings yet

- Md380 SeriesDocument298 pagesMd380 SeriesRulo Hdez LazoNo ratings yet

- Rotordynamicslinkedin 180418103729Document30 pagesRotordynamicslinkedin 180418103729Mahendra PrabhuNo ratings yet

- Report NTPC PDocument29 pagesReport NTPC PKarthick KumaresanNo ratings yet

- Cascadia Motion Catalog WebDocument29 pagesCascadia Motion Catalog WebEagle RyanNo ratings yet

- Specification: Specification Guide Horizontal TITAN Frame Motors Totally Enclosed Fan Cooled - TEFCDocument9 pagesSpecification: Specification Guide Horizontal TITAN Frame Motors Totally Enclosed Fan Cooled - TEFCManuel Simonds VegaNo ratings yet

- L03058engh j4 PDFDocument444 pagesL03058engh j4 PDFĐinh TiếnNo ratings yet

- ATV320D15N4C Variable Speed Drive DatasheetDocument10 pagesATV320D15N4C Variable Speed Drive DatasheetPhaniNo ratings yet

- IRB 660 Product Specifications 3HAC023932-001 - ReDocument48 pagesIRB 660 Product Specifications 3HAC023932-001 - ReAsim PedicNo ratings yet

- ManualOperacionMesa CorteDocument56 pagesManualOperacionMesa CorteFernando RomeroNo ratings yet

- BLV Series: Operating ManualDocument8 pagesBLV Series: Operating ManualGiovaniAricettiNo ratings yet

- Gujarat Technological University: Bachelor of EngineeringDocument3 pagesGujarat Technological University: Bachelor of EngineeringJigneshkumar PatelNo ratings yet

- General Departmental Competitive Examination For Northern Railway 24th July 2021 S2Document26 pagesGeneral Departmental Competitive Examination For Northern Railway 24th July 2021 S2AjaySaraswatiNo ratings yet

- Induction MotorDocument11 pagesInduction MotorMsKarolyNo ratings yet