Professional Documents

Culture Documents

Design Basis POL Terminal Rasayani

Uploaded by

pavanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Basis POL Terminal Rasayani

Uploaded by

pavanCopyright:

Available Formats

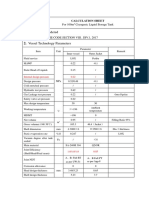

Tanks I/L ROSOV O/L ROSOV I/L MOV O/L MOV TLF O/L MOV TWF

Design Basis

Receipt thru Pipelines /TLD HSD 1 450 600 400 600 600

MS HSD ATF Ethanol Biodiesel HSD 2 450 600 400 600 600

Receipt Flow rate in KL/hr 1200 1200 1200 100 60 HSD 3 450 600 400 600 600

Design receipt velocity (max) in m/s 3 3 3 3 3 HSD 4 450 600 400 600 600

Size of the Receipt line required in mm 376 376 376 109 84 MS 1 450 600 400 450 600

Proposed line size in mm 400 400 400 150 100 MS 2 450 600 400 450 600

Type of tanks EFR EFR CR IFR CR MS 3 450 600 400 450 600

Proposed diameter of the tank in Mtrs 34 34 22 17 11 MS 4 450 600 400 450 600

Proposed Height of the tank in Mtrs 20 20 17.5 15 15 ATF 1 450 600 400 250 600

Roof movement rate (1.5m/hr) in KL/hr 1362 1362 NA 341 NA ATF 2 450 600 400 250 600

ATF 3 450 600 400 250 600

ATF 4 450 600 400 250 600

Despatch thru Tank lorry PCK 1 400 250 400 250 NA

MS HSD ATF PCK Ethanol Biodiesel SLOP 1 400 250 400 250 NA

No of loading points 10 14 4 4 10 14 SLOP 2 400 250 400 250 NA

Type of loading Bottom Bottom Top Top NA NA Ethanol 1 150 200 150 200 NA

Design flow rate in LPM 2000 2000 1200 1200 400 100 Ethanol 2 150 200 150 200 NA

Required flow rate in KL/hr 1200 1680 288 288 240 84 Biodiesel 1 100 100 100 100 NA

Bay Utilization factor 0.7 0.7 0.7 0.7 0.7 0.7 Biodiesel 2 100 100 100 100 NA

Proposed Design flow rate for TLF in KL/hr 840 1176 202 202 168 59

Required size for O/L or header in mm 450 600 250 250 200 100 *Note:- I/L nozzle size designed as per 1650KL/hr for HSD/MS/ATF tanks

Required size for TLF or header in mm 350 400 200 200 150 150

Capacity in Suction Delivery Delivery MOV

TLF Pumps

KL /hr sizein mm size in mm size in mm

Despatch thru Tank Wagon Gantry

MS HSD ATF MS1 300 300 200 200

No of wagons design 52 52 52 MS2 300 300 200 200

Capacity of wagon in KL 72 72 72 MS3 300 300 200 200

Total Quantity to be decanted 3744 3744 3744 HSD1 450 350 250 250

Time for decantation in hr 3.5 3.5 3.5 HSD2 450 350 250 250

Design flow rate in Kl/hr for TWF 1070 1070 1070 HSD3 450 350 250 250

Required size for O/L or header in mm 600 600 600 ATF1 150 200 150 150

ATF2 150 200 150 150

ATF3 150 200 150 150

TLF Pump design - TLF MS HSD ATF PCK Ethanol Biodiesel PCK 1 100 200 150 150

Throughput per day in KL 1315 2876 1000 263 144 PCK 2 100 200 150 150

No of tank lorries planned to fill ina shift 15 15 15 ETH 1 60 150 100 100

Design flow requirement in a shift 88 192 67 ETH 2 60 150 100 100

No of loading points 10 14 4 4 NA NA ETH 3 60 150 100 100

Pumping rates as optimized in KL/hr 600 900 300 100 120 45 BIODIESEL 1 75 150 100 100

Proposed capacity of Main pumps in KL/hr 300 450 150 100 60 75 BIODIESEL 2 75 150 100 100

No of Main pumps 2 2 2 1 2 1 SLOP TRNSFR 1 100 200 150 150

Proposed capacity of Standby pumps in KL/hr 300 450 150 100 60 75 SLOP TRNSFR 2 100 200 150 150

No of standby pumps 1 1 1 1 1 1

TLF Pump design - TLF MS HSD ATF

Total Quantity to be decanted 3744 3744 3744

Time for decantation in hr 3.5 3.5 3.5

Capacity in Suction Delivery Delivery MOV

TWF pumps

Design flow rate in Kl/hr for TWF 1070 1070 1070 KL /hr sizein mm size in mm size in mm

Pumping rates as optimized in KL/hr 1200 1200 1200 MS1 600 400 300 300

Proposed capacity of Main pumps in KL/hr 600 600 600 MS2 600 400 300 300

No of Main pumps 2 2 2 MS3 600 400 300 300

Proposed capacity of Standby pumps in KL/hr 600 600 600 HSD1 600 400 300 300

No of standby pumps 1 1 1 HSD2 600 400 300 300

Sick wagon / TT capacity max in KL 72 72 72 HSD3 600 400 300 300

Proposed capacity of Main pumps in KL/hr 75 75 75 ATF1 600 400 300 300

No of Main pumps 1 1 1 ATF2 600 400 300 300

ATF3 600 400 300 300

SICK WGN MS 75 150 100 100

SICK WGN HSD 75 150 100 100

SICK WGN ATF 75 150 100 100

MS HSD ATF PCK ETH BIODIESEL

TLF HEADER 350 400 200 200 150 150

TWF HEADER 400 400 400

Length Breadth Area in SQM

Tankage area 773.8 242.2 187414.36

TWG Area 794.3 78 61955.4

Spurline area from takeoff point 600 40 24000

Total area in SQM 273369.76

Total area in Acres 67.55

Area to land development 136684.88

Description 600MM 450MM 400MM 300MM 250MM 200MM 150MM 100MM 600MM

ROSOV 12 12 3 3 14 2 4

MOV 16

PUMPS 600KL/hr 450KL/hr 300KL/hr 100KL/hr 150KL/hr 75KL/hr 60KL/hr

MS 3 3

HSD 3 3

ATF 3 3

PCK 2

ETH 3

BIODIESEL 2

SICK WGN 3

Total 9 3 3 2 3 5 3

450MM 400MM 350MM 300MM 250MM 200MM 150MM 100MM Remarks

200NB re-circulation

nozzle considered.

4 19 1 9 10 7 19 12 Including U/G tank also

You might also like

- Temco International Limited: AlternatorDocument58 pagesTemco International Limited: AlternatorAlejandro XgNo ratings yet

- On-Highway Power: Series 60 EXPORT - Truck 14 L 525 BHP at 1800 R/min - 1850 LB FTDocument2 pagesOn-Highway Power: Series 60 EXPORT - Truck 14 L 525 BHP at 1800 R/min - 1850 LB FTRamonNo ratings yet

- Part Manual 4BT DGBB-BC-CA-CB 960-0291DDocument91 pagesPart Manual 4BT DGBB-BC-CA-CB 960-0291DJunior EspinalNo ratings yet

- D12D425 VHD PDFDocument2 pagesD12D425 VHD PDFMarco Antonio Esparza CastroNo ratings yet

- Mordec Deck Fittings CatalogueDocument32 pagesMordec Deck Fittings Catalogueseptian nurpratamaNo ratings yet

- Kawasaki Staffa HMB and HMC Hydraulic Motor 1Document15 pagesKawasaki Staffa HMB and HMC Hydraulic Motor 1titanwlx0% (1)

- 2012 A6 Self Study Program Part 1Document44 pages2012 A6 Self Study Program Part 1Soriteu Sorin100% (2)

- Denison Gold Cup PDFDocument64 pagesDenison Gold Cup PDFOleg080100% (3)

- Steam Coil SizingDocument2 pagesSteam Coil Sizingpavan100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- MIP Thickener DesignDocument3 pagesMIP Thickener DesignHatem SalahNo ratings yet

- Laborator Chimie DIYDocument11 pagesLaborator Chimie DIYotonel100% (1)

- Dust Collector DesignDocument3 pagesDust Collector DesignpavanNo ratings yet

- Nike Case StudyDocument6 pagesNike Case Studyapi-361156846100% (1)

- AAC BlocksDocument24 pagesAAC BlocksgururajNo ratings yet

- Completion Fluids Displacement and Cementing SpacersDocument18 pagesCompletion Fluids Displacement and Cementing SpacersAnonymous JMuM0E5YONo ratings yet

- Water Cooled Duct DesignDocument8 pagesWater Cooled Duct DesignpavanNo ratings yet

- Pump CalcDocument5 pagesPump CalcpavanNo ratings yet

- QSK 1 Cummins Inc.: Nox Ta-Luft Compliant. Refer To Emission Data Sheet For DetailsDocument3 pagesQSK 1 Cummins Inc.: Nox Ta-Luft Compliant. Refer To Emission Data Sheet For DetailsHernan Peñafiel Rea0% (1)

- 400HP LV Toshiba MotorDocument20 pages400HP LV Toshiba MotorEdil MartinezNo ratings yet

- Group5 PDFDocument11 pagesGroup5 PDFvzimak2355No ratings yet

- C&E Mini PlantDocument1 pageC&E Mini PlantpavanNo ratings yet

- Thermal Design of Water Cooled DuctDocument8 pagesThermal Design of Water Cooled Ductpavan100% (1)

- Cassette y Piso-Techo InverterDocument186 pagesCassette y Piso-Techo InverterDarwin Samir Silva Bautista0% (1)

- Hydraulic Specification: Service Manual Damcos Valve Remote Control: LPU Technical DataDocument1 pageHydraulic Specification: Service Manual Damcos Valve Remote Control: LPU Technical DataLanceal TanNo ratings yet

- 7S72-FF3-00-001-D Rev07 FNG CauseEffect MatrixDocument6 pages7S72-FF3-00-001-D Rev07 FNG CauseEffect MatrixpavanNo ratings yet

- PSV Sizing2Document3 pagesPSV Sizing2pavanNo ratings yet

- Diesel Engines 8V/12V/16V 4000 M60R: For Vessels With Unrestricted Continuous Operation (1A)Document2 pagesDiesel Engines 8V/12V/16V 4000 M60R: For Vessels With Unrestricted Continuous Operation (1A)Jorge Bellido100% (1)

- EPF FW Demand Calculation NoteDocument14 pagesEPF FW Demand Calculation NoteEmamokeNo ratings yet

- Cooling Water Line HydDocument7 pagesCooling Water Line HydpavanNo ratings yet

- Cooling Water Line HydDocument7 pagesCooling Water Line HydpavanNo ratings yet

- PSV SizingDocument3 pagesPSV SizingpavanNo ratings yet

- 7 5 Kva Escorts Silent Generator Set PDFDocument1 page7 5 Kva Escorts Silent Generator Set PDFmanoj_doshi_1No ratings yet

- 7 5 Kva Escorts Silent Generator Set PDFDocument1 page7 5 Kva Escorts Silent Generator Set PDFmanoj_doshi_1No ratings yet

- TCDS Trabajo Final Motores A ReaccionDocument11 pagesTCDS Trabajo Final Motores A ReaccionRICOYUDYNo ratings yet

- KTA38-M0 FR6219 - 850 at 1800Document4 pagesKTA38-M0 FR6219 - 850 at 1800javierdieselengineNo ratings yet

- 6 (1) .6KV SWGR Price CompDocument5 pages6 (1) .6KV SWGR Price Compmukesh_kht1No ratings yet

- Speck Pompa & Motor Area TurbineDocument46 pagesSpeck Pompa & Motor Area TurbineRelianus TandiNo ratings yet

- Configuration List Motor and Servo DriverDocument37 pagesConfiguration List Motor and Servo DriverJean GrimNo ratings yet

- GCDocument64 pagesGCEng-Mohammed SalemNo ratings yet

- D12D465 VNDocument2 pagesD12D465 VNGreg PulidoNo ratings yet

- 2008 Fork Oil Level ChartDocument1 page2008 Fork Oil Level ChartJoão RaimundoNo ratings yet

- To Order: For 1 ReplaceDocument6 pagesTo Order: For 1 ReplaceviktorNo ratings yet

- 0 280 158 279 Customer SheetDocument2 pages0 280 158 279 Customer Sheetarwid vasilevNo ratings yet

- Gear Box & Geared MotorDocument4 pagesGear Box & Geared MotorvinodsnNo ratings yet

- 40LM 120,150,200 - PRODUCT DATA DIGEST: The World Leading Air-Conditioning CompanyDocument14 pages40LM 120,150,200 - PRODUCT DATA DIGEST: The World Leading Air-Conditioning CompanyRalph Segundo SalvadorNo ratings yet

- Specification: Borewell Pump Discharge Chart: T0tal Depth in Feet Bore Well Pump Tower 1 HP 1.5 HP 2 HP 3 HP 5 HP 7.5 HP 10 HPDocument2 pagesSpecification: Borewell Pump Discharge Chart: T0tal Depth in Feet Bore Well Pump Tower 1 HP 1.5 HP 2 HP 3 HP 5 HP 7.5 HP 10 HPscbrajaNo ratings yet

- Data Sheet 750HPDocument11 pagesData Sheet 750HPHenry NinaNo ratings yet

- Borewell Compressor PumpDocument2 pagesBorewell Compressor PumpJagadish Gowda JagguNo ratings yet

- Lki HydDocument13 pagesLki HydcarlosibaNo ratings yet

- KV CVL: Cargo Oil, Tank Cleaning & Ballast PumpsDocument12 pagesKV CVL: Cargo Oil, Tank Cleaning & Ballast PumpsJohn100% (1)

- TC21Document2 pagesTC21Pierrat0% (1)

- 3C 3D 3B 3A: Power Rating 6R 1600Document3 pages3C 3D 3B 3A: Power Rating 6R 1600chris5depasqualeNo ratings yet

- At-Eng 7Document28 pagesAt-Eng 751980357396stwNo ratings yet

- Cat 3116 Propulsion PDFDocument6 pagesCat 3116 Propulsion PDFpaimeyNo ratings yet

- Heavy FV 51 MWB - 13sp Manual 12sp AMT Steel SuspensionDocument4 pagesHeavy FV 51 MWB - 13sp Manual 12sp AMT Steel Suspensionajay dattNo ratings yet

- EFI ResistanceDocument3 pagesEFI ResistanceMuni Muniyappan33% (3)

- Diapharam Ss Valve 1 4 3 8 1 2 3 4 All SizesDocument37 pagesDiapharam Ss Valve 1 4 3 8 1 2 3 4 All SizesSamarth DesaiNo ratings yet

- Bico Handbk 11-11 PDFDocument88 pagesBico Handbk 11-11 PDFSinghtoFCNo ratings yet

- Mixer VRPDocument4 pagesMixer VRPMelvin YapwhNo ratings yet

- Series: Horse Power Ratings As Per IS 10002/BS:5514/DIN 6271/ISO 3046Document4 pagesSeries: Horse Power Ratings As Per IS 10002/BS:5514/DIN 6271/ISO 3046Suresh KumarNo ratings yet

- Boq Sialkot Pak Army Panel B 1Document18 pagesBoq Sialkot Pak Army Panel B 1naqvikhizerNo ratings yet

- Marathon TEFC Slip Ring Motor Price List 2019Document1 pageMarathon TEFC Slip Ring Motor Price List 2019Akd DeshmukhNo ratings yet

- Cbi/A: High-Performance and Robust Backward-Curved ImpellerDocument2 pagesCbi/A: High-Performance and Robust Backward-Curved ImpellerVenu Gopal TallojuNo ratings yet

- Air Carbon Arc Gouging Data PDFDocument1 pageAir Carbon Arc Gouging Data PDFAgniva DuttaNo ratings yet

- A1000 - DBU-DBR For CraneDocument11 pagesA1000 - DBU-DBR For CranebdvraoNo ratings yet

- Atc Fire Panel - 2Document12 pagesAtc Fire Panel - 2Shubhajit ChakrabortyNo ratings yet

- PKW Passenger Cars Véhicules de Tourisme Turismos: Katalognachtrag Supplement Additif Catalogue Suplemento de CatálogoDocument15 pagesPKW Passenger Cars Véhicules de Tourisme Turismos: Katalognachtrag Supplement Additif Catalogue Suplemento de CatálogoddubokaNo ratings yet

- Ficha Tecnica MOTOR BALDORDocument11 pagesFicha Tecnica MOTOR BALDORcarlos.castillo.ing.1No ratings yet

- Pneumatic AC Spot Welding Machine-HWASHI 001Document8 pagesPneumatic AC Spot Welding Machine-HWASHI 001Juan OrtegaNo ratings yet

- LT3 00010 1 - P6 7 8 11 14 24 30 Piston PumpsDocument84 pagesLT3 00010 1 - P6 7 8 11 14 24 30 Piston PumpsNelson PaicoNo ratings yet

- Kudu Bro New Pump Models Int A4 WebDocument2 pagesKudu Bro New Pump Models Int A4 WebXXXXNo ratings yet

- MYK4600 HMB Datasheet A4 QshaftDocument96 pagesMYK4600 HMB Datasheet A4 QshaftDerek LeeNo ratings yet

- Truss DiagramDocument1 pageTruss DiagramJojo EstabilloNo ratings yet

- 6BT5.9-M120 Datasheet ENDocument4 pages6BT5.9-M120 Datasheet ENnarisNo ratings yet

- Hydraulic Breakers and Silent Demolition ToolsDocument24 pagesHydraulic Breakers and Silent Demolition ToolssinanNo ratings yet

- S. No Discription Type Qty U. Price T.PriceDocument1 pageS. No Discription Type Qty U. Price T.PriceOSAMANo ratings yet

- Falvent KS CatologueDocument5 pagesFalvent KS Catologuempe.mustafa.mansourNo ratings yet

- Deactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingFrom EverandDeactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingNo ratings yet

- Input Data RequiredDocument3 pagesInput Data RequiredpavanNo ratings yet

- Steam Consumption and Line SizingDocument3 pagesSteam Consumption and Line SizingpavanNo ratings yet

- Duct HydraulicsDocument2 pagesDuct HydraulicspavanNo ratings yet

- Duct Modification ScopeDocument6 pagesDuct Modification ScopepavanNo ratings yet

- PWOG HZL 6033 PR CAL 002 - Cooling Water Supply and Return ConfigurationDocument3 pagesPWOG HZL 6033 PR CAL 002 - Cooling Water Supply and Return ConfigurationpavanNo ratings yet

- Pwog HZL 6033 PR PFD 001 - Process Flow DiagramDocument1 pagePwog HZL 6033 PR PFD 001 - Process Flow DiagrampavanNo ratings yet

- Duct HydraulicsDocument2 pagesDuct HydraulicspavanNo ratings yet

- PWOG HZL 6033 PR CAL 001 - New Dust Collector Design and DatasheetDocument3 pagesPWOG HZL 6033 PR CAL 001 - New Dust Collector Design and DatasheetpavanNo ratings yet

- Att 2Document3 pagesAtt 2pavanNo ratings yet

- Att 2Document3 pagesAtt 2pavanNo ratings yet

- Att 2Document3 pagesAtt 2pavanNo ratings yet

- Att 2Document3 pagesAtt 2pavanNo ratings yet

- Att 2Document3 pagesAtt 2pavanNo ratings yet

- MailDocument3 pagesMailpavanNo ratings yet

- 21 13 25 High Expansion Expansion Foam Systemwith Surge Arrestor DetailsDocument50 pages21 13 25 High Expansion Expansion Foam Systemwith Surge Arrestor DetailspavanNo ratings yet

- 100 KL Old CalDocument8 pages100 KL Old CalpavanNo ratings yet

- C1112-GIP1A00003 (VP8 Building Ventilation Project Equipment and Piping Proposed Layout)Document2 pagesC1112-GIP1A00003 (VP8 Building Ventilation Project Equipment and Piping Proposed Layout)pavanNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- Syllabus Btech CeDocument15 pagesSyllabus Btech CePrasanna MuleyNo ratings yet

- s8q Pa PDFDocument2 pagess8q Pa PDFZulfi RahmanNo ratings yet

- Mahavir Swami Collage of Pollytechnic, Surat: "Automobile Carburettor"Document40 pagesMahavir Swami Collage of Pollytechnic, Surat: "Automobile Carburettor"Ayush BanerjeeNo ratings yet

- Design of Flywheel: Prepared By:-Mourya Sachin BabulalDocument16 pagesDesign of Flywheel: Prepared By:-Mourya Sachin BabulalSachin MouryaNo ratings yet

- Chapter8 PDFDocument54 pagesChapter8 PDFJoseph Constantino T. Fagel JrNo ratings yet

- English Assignment Class 5Document5 pagesEnglish Assignment Class 5vemuna katjiuanjoNo ratings yet

- (Page113-134) GCSE Physics Mark Scheme Paper 1 Nov 18Document12 pages(Page113-134) GCSE Physics Mark Scheme Paper 1 Nov 18ShaguNo ratings yet

- Rame ProfileDocument6 pagesRame Profiletri_purwadiNo ratings yet

- World Standard Sheet LinesDocument4 pagesWorld Standard Sheet LinesAlejandro RubianoNo ratings yet

- Catálogo VPADocument2 pagesCatálogo VPARafael LimaNo ratings yet

- CAT4-2 Complete ENDocument264 pagesCAT4-2 Complete ENalltheloveintheworldNo ratings yet

- CHE412 Process Dynamics Control BSC Engg 7th SemesterDocument17 pagesCHE412 Process Dynamics Control BSC Engg 7th SemesterwreckiebNo ratings yet

- An Experimental Study On Usage of Hollow Glass Spheres (HGS) For Reducing Mud Density in Geothermal DrillingDocument7 pagesAn Experimental Study On Usage of Hollow Glass Spheres (HGS) For Reducing Mud Density in Geothermal DrillingifebrianNo ratings yet

- Star Life Cycle Web Activity v2Document6 pagesStar Life Cycle Web Activity v2blackwellbertNo ratings yet

- Pulley Systems Printed Handout - HeilmanDocument46 pagesPulley Systems Printed Handout - HeilmanGerman ToledoNo ratings yet

- Wiring Digram For ACDocument3 pagesWiring Digram For ACahmed HOSNYNo ratings yet

- Seal of BushingDocument6 pagesSeal of BushingB.k. BirtiaNo ratings yet

- U.S. Energy Consumption by Source and Sector, 2019Document2 pagesU.S. Energy Consumption by Source and Sector, 2019rcmasterbNo ratings yet

- Pages From 0625 - s16 - QP - 43-10Document2 pagesPages From 0625 - s16 - QP - 43-10lelon ongNo ratings yet

- 1.1. Iso 11507-2007 (E)Document15 pages1.1. Iso 11507-2007 (E)Khin Khin ThawNo ratings yet

- Electricoutboard: Ep-50 Electric Outboard Features and BenefitsDocument1 pageElectricoutboard: Ep-50 Electric Outboard Features and Benefitsjuniono raharjoNo ratings yet