Professional Documents

Culture Documents

Itsupport@apbava - Com 20100208 142407

Itsupport@apbava - Com 20100208 142407

Uploaded by

sooraj0 ratings0% found this document useful (0 votes)

7 views7 pagesOriginal Title

itsupport@apbava.com_20100208_142407

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views7 pagesItsupport@apbava - Com 20100208 142407

Itsupport@apbava - Com 20100208 142407

Uploaded by

soorajCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

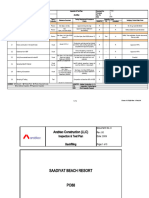

| Seadymix Abu'Bhabi Ltd.

Bagaaall gibodl us

pet digits YVAK ue

RO, Box: 7289, Abu Daabi, UAE. /

Fond Offer 2 = 329488 © Freee sioses FTN VA GSU T= TTA BAAS asl i ial

Aine) meme Fectgcaee 7 IWant ag or or WA Seale

jis Nanak = LS sto state: pha a Sat

» SB, nso-/ eae tee ceo mente pees

Sma’ ID AMAY CONVEYANCE NOTE

oo. ina slr 5198

PLANT NAME: “De pal] ORDER REFERENCE ‘oh | DRIVER, put

MADINAT ZAYED 198 11102799

503

eustowen cies [sre aboness tien

DHABI TRAIL MIX FOR HILALCO ove

PLANT

ok DESCRIPTION se

SON sMME SRC CLASS A Zorn

Saas | ae a OC

Serccwe | onvtans | meio rmecke —| toronerae | TimeovSre se Reror

4.00 4,00 4,00 069 | L

|

Ec i

ADOTIONAL INFORMATION centage | ga th meth

Brom She Bink WiveR RODEO are REQUEST OF CUSTOMER

Sum! So "

etn . 6 Coles Maso

| da

| d

[na dua Arey O AEGENED AND ACCEPTED Gann]

iC Bway |

‘ , |

Ha Hureitig — thlates |

; !

OR: READ ABU CHAE! ioe guvce | ron cusTOMER

{TERIAL | REQ'D BAT! MIX TOL ACHAT PEADYMTY DHABY

pesi20c BOBO 7790 0.0 Oo DATE & TIME 11/02/99

piaioc 2400 350. 0.7 ° PLANT

huNnosnis 2160 540 -0.5 ° BATCH Nor 61981 i

BcNFsanD 880 zo 1118 TRUCK 589 Deru

Ro 1680 420 0.2 ° GUAN 4,00M3 MIXy #egREe

99000 2250 0.0 ° fe

142 6.0 # SaB stun 75 an ff

“RECYCLED og"

WAT ADJUST Ee

AGG ST

ass 4

o :

‘OL OK

HANUAL 12248 = 9 WaT

i) MANUAL TRIM = 568 wat *

4IXED 15 OF 15 8 HI ST ADX “

Taye

a —

"TERMS AND CONDITIONS OVER LEA

oy

TRSSS Materials in reducing water permeao"-

ity was determined in three ways.

METHOD 1

otal absorption: Measures the amount of

‘ater absorbed, after total immersion of the

Specimen, at measured time intervals. Th

srrount of absorbed water being expressed

gs 2 percentage of the total weight.

METHOD 2

{nitia! Surface Absorption: A measure of

water penetration under set pressure 2s

described in BS 1881: Part 5.

METHOD 3

Penetration under pressure: Test

immersed in water and subjected to pr

equivalent to a free water head of 70 ft. Sawn

Sections of the cubes were taken and the

depth of water penetration measured.

MIX DESIGN 3:

Sulphate Resisting Cement

Crushed Sand (Zone 1)

Beach Sand

20-5mm Crushed Aggregate

‘Aggregate/Cement Ratio

Free Water/Cement Ratios

Control3

Mix3A

Mix38 08

Levels of Addition:

Control 3 Nil

Mix 34 210 ml CORMIX P.4per

50 kg cement

Mix 38 1500 ml Stearate Based

Waterproofer per 50 kg

cement

METHOD OF USE

CORMIX ?.4 is supplied ready for use. It

should be added to concrete mixes during the

mixing proce <--2t the same time as the water

or the aggregates. It should not be added

Girectly to the cement. No extension of

normal mixing time is necessery.

Cormix Mi

ddle Eest, P.O. Box 8006, Disbai, UAE. Tel

it is preferable that liquid admixtures for

conerete should be introduced into 3 mixerby

means of automatic dispensing equipment.

Such equipment is available from Cormix

Middle East or local Cormix agents

For details see our leaflet ‘Cormix Autornatic

Dispensing Equipment for Liquid Concrete

Aamixtures’, or consult Cormix Middle Ezst.

EFFECTS OF OVER-DOSING

Overdosing of CORMIX P:4 will geneslly

produce a considerable increase in workabir

Ry and. in certain circumstances, 2 sight

increase in air entrainment. This, particulerly

in cold weather, will be accompanied by @

retardation of the initial and final set of the

conarete. in such cases, however, provided

the concrete is properly cured, the ultimate

Strength will generally be higher than for

normal concrete. The effects of over-dosing

Will iso be exaggerated when sulphate

Msisting cement is used in place of ordinary

Portland cement. oe

PACKAGING

CORMIX P.4 is supplied in 210 litre free

Forretumable containers. Alternatively, bulk

deliveries can be arranged.

STORAGE

CORMIX P.4 requires no special st

facilities.

AVAILABILITY

Prompt. deliveries can, be. arrang

contacting Cormix Middle East, P.

5006, Dubai, UAE, Telephon:

432388, Telex 48709 CORMX EM,

local agent/stockist. |

ogmixTectinical S

lat fe to assistypu int!

ects and its/_resbufaes are at your

jodgal entirely without

‘he Ynformation given ih this lea

iy on work ja our laboratgnems

Afactical field “experienc FS

thoy guarantee a

urbe

a BRITISH STANDARD _gpsacess Kama C,,|BS 882! We

Specification for

Aggregates from natural |

sources for concrete

Contents

Committees responsible

Foreword

Specification

Introduction

Scope

Definitions

Sampling and testing

Quality requirements

Grading

Information to be provided by the supplier

Special considerations

Guidance on the chloride content of aggregates

Limits on shell concent

Limiting values on mechanical properties for different types of

Coarse aggregate

Allin aggregate

Appendices

A

B

c

Tables

1

concrete

3

4 Sand

6 Fines

Limi

chloride content of aggregates

Page

Inside front cover

phe ea co oo oo

3S 882

1992

a

Foreword

‘This British Standard has been prepared under the direction of Technical

Committee B/502 Aggregates. This edition introduces technical changes but it

does not reflect a full review or revision of the standard which will be

undertaken in due course. This standard supersedes BS 882 : 1983, which is

withdrawn.

‘Terminology included in this edition reflects the preliminary work being

undertaken on a European Standard, under the auspices of the European

Committee for Standardization (CEN), by CEN’TC 154, Aggregates, which will

supersede this edition in due course. ‘Fine aggregate’ is replaced by ‘sand’

Srhich now refers to natural uncrushed, partially crushed and crushed rock

material, ‘Fines’ replaces ‘clay, silt and fine dust’ and refers to any solid material

passing # 75 um sieve.

ew grading requirements are introduced for coarse aggregates containing 2 mm )

to 10mm fractions with the inclusion of limits for material passing a 14 mm

Sieve. This ensures a reasonable fraction of the aggregate will be retained

petween the 20 mm and 14 mm sieves and eliminates the anomaly that some

nominal 14 mm aggregates previously complied with the 20 mm grading

requirements.

Changes in test methods since the 1983 edition are reflected. The difference in

results for mechanical properties dependent on the moisture condition of the

by linking limits to tests on oven-dry maxerials.

ageregate is eliminate’

Another example reflects the change in the test for fines content to the washing

ane sieving method and limits have been correspondingly increased. Attention is

diso drawn to the importance of performance characteristics where doubt exists

in place of fixing particular limits for fines contents,

The appendices give furcher consideration to provision of information by the

supplier and advice on user concerns. Appendix A is expanded to include

provision of information on request from tests in accordance with BS 812 for acid

Soluble sulphate contents and drying shrinkage. Additionally in several cases the

time period is reduced from which test results are to be provided. Appendix 5

identifies the potential damaging effect of mundic mine waste specifically in

Cornwall and Devon. Finally appendix C includes tighter guideline limits on

chloride content in the total combined aggregate whilst stressing the need to

Caleulare the chloride content of the concrete mix from the total of the measured

values for each of the constituents

Compliance with a British Standard does not of itself confgsimmynity from

legal obligations. a

we

~~.

Specification

0 Introduction

When specifying aggregates in compliance with this

standard, there may be a need to specify or

approve certain additional quality requirements or

narrower grading limits within one of those in

table 4 for sands, to suit special applications, for

example, the production of concrete having an

especially fine finish or suitable for very severe

conditions of exposure. Certain machine-formed

concrete or precast products may also require

aggregate gradings outside those given in tables 3,

4-and 5, In these cases appropriate grading should

be agreed between the purchaser and the supplier

When narrower grading limits are required, sands

_should be obtained from sources which

demonstrate from test data no more variability

than a grading width (see appendix A), Guidance is

given in appendix B on special factors to be

considered in the selection of aggregates for which

limits cannot be specified and determined bs

testing the aggregate itself in accordance with an

accepted method of test. Guidance on chloride

content is given in appendix C.

In general it will not be necessary to test each

aggregate for all of the requirements specified in

this standard, Consideration of the nature of the

aggregate and its source will normally indicate

which characteristics will need periodic.

examination, particularly in respect of those

properties for which different regiirements are

given for specific uses. The suitability of an

aggregate for che required use can be assessed

intially by reference to data provided by the

supplier in accordance with appendix

Some variation in the measured quality of material

from any source can be expected due to sampling

and testing in addition to the variability of the

material itself. Data provided in accordance with

appendix A may not be strictly applicable to the

material in 2 single sample or consignment.

1 Scope

‘This British Standard specifies the quality and

grading requirements for aggregates obtained by

processing natural materials for use in concrete.

(For lightweight aggregates, see BS 3797.)

NOTE. The titles ofthe publications refered to inthis standard

axe listed on the inside back cover

BS 882 : 1992

2 Definitions

For the purposes of this British Standard the

following definitions apply.

2.1 aggregate

A granular material obtained by processing natural

materials.

2.2 coarse aggregate

Aggregate mainly retained on 2 5.0 mm BS 410 test

sieve and containing no more finer material than is

permitted for the various sizes in this specification.

NOTE. Coarse agaregate may be described as gravel (uncrushed,

rushed oF partially crushed) as defined in 2.2.3, or as crushed

rock as defined in 2.2.2, or as blended coarse aggregate as

defined in 2.2.3,

2.2.1 gravel

(a) unerushed gravel

Coarse ageregate resulting from the natural

disintegration of rock.

(b) crushed gravel

Coarse aggregate produced by crushing gravel

(c) partially crushed gravel

Coarse aggregate produced from a mixture of

crushed and uncrushed gravel

2.2.2 erushed rock

Coarse aggregate produced by crushing rock.

2.2.9 blended coarse aggregate

Coarse aggregate produced by the controlled

blending of gravel and crushed rock.

2.8 sand

Aggregate mainly passing 2 5:0 mm BS 410 test

sieve and containing no More coarser material thar

is permitted for the vazious gradings in this \?

specification.

NOTE. Sand may be described as uncrushed or paral crushed

as defined in 2.9.1, a8 crushed gravel sand as defined in

fs crushes rock sand as cefined jy 2.8.0 ora blended sane as

defines in 2.34 ON

a

2.3.1 uncrushed op/partially crnsi and

(a) uncrushed

Sand resulting’from the natural disintegration of

rock.

(0) partiallyferushed

Sand produded from a mixture of uncrushed sand

and crushed/sand resulting from the crushing of

associated particles during product processing,

2.8.2 crushed gravel sand

‘Sand produced by crushing gravel.

2,8.8 erushed rock sand

Sand produced by crushing rock,

2,84 blended sand

‘Sand produced by the controlled blending of two or

jnore of the types of sand defined in 2.8.1, 2.8.2

or 2.

2.8.5 fines

“Any solid material passing a 75 wm BS 410 sieve.

2.4 all-in aggregate

“Aggregate consisting nf a mbrure of coarse

aggregate and sand. It may’ be produced without

separating into coarse and fine fractions, or it may’

_be produced byy combining coarse aggrezate and

and.

5 heavy duty concrete floor finishes

Concrete made with specially selected aggregate of

a hardness, surface texture and particle shape

Suitable for use as a wearing finish, for floors.

2.6 pavement wearing surfaces

Concrete made with specially selected aggrecan

a hardness. surface texture and particle shape

Suitable for use in concrete pavements and similar

surfaces.

of

3 Sampling and testing

Sampling and testing of ageregates shall be carried

out in accordance with the requirements of the

appropriate Parts of BS 812.

4 Quality requirements

4.1 General

_ggregate for concreve shall consist of any types of

Coarse agaregate andor any types of sand oF of

all-in ageregave, as defined in clause 2

“Agaregate supplied as a mixture of different sizes

es shall be proportioned and mixed in such a

sway as to ensure reasonable consistency

OTE. Lever lading of loses with different sizes or 178 of

Jratrils ie unlkely u pve the required conssenc

4.2 Flakiness index

When determined in accordance with BS 812

Section 105.1, the flakiness index of the combined

Coarse agaregate shall not exceed 50 for uncrushed

rave] and 40 for crushed rock or crushed gravel

[NOTE |, For special cieumsances, e.g. for pavement wearing

Ferfaces,# lower fakines index may be eed

NOTE 2, Information onthe general facto affecting rab

Mfemerete be pven In BS Baan Fart 1 ad 1S 120

4.8 Shell content

When determined in accordance with BS

Pant 106, the shell content sill not exceed the

values given in table 1

Table 1, Limits on shell content

Limite on shell

content (%)

Size

Fractions of 10 mm single size, | 20

or of graded or all-in aggregate

that are finer than 10 mm and

| coarser than 5 mn |

Fractions of single sizes or of | 8

graded or all-in aggregate that

are coarser than 10 mm

“Aggregates finer than 5mm __| No requirement

4.4 Mechanical properties

When determined in accordance with 6.4 and 7.4

of BS 612 : Part 111 : 1990, the oven-dry 10 %

fines value shall not be less than the appropriate

value in table 2, As an alternative to the 10 %

Fines test, the ageregate impact value may be

carried out in accordance with BS 812 : Part 112.

wen-dry aggregate impact value shall not

exceed the appropriate value given in table 2

)

Table 2, Limiting values on mechanical

properties for different types of concrete

$0 fines:

value (min)

| Alternatively.

‘geregate irapact

ale tax.)

“Tepe of concrete

ene ene

ww 3

Beary dury 150

concrete floor

finishes '

Pavement wearing | 100 ‘30

surfaces | \

Others 30 45

4.5 Acid soluble sulphate content

When requested, the producer shall provide the )

acid soluble sulphate content of the ageresat

devermined in accordance with BS 612 : Part 116.

NOTE. BS S238: Pan J and BS 6110 a eulanee on

NOTE, BS FSGS content ple covet Satya ms

- Bie

ents 4 i

5 Grading §

3.1 Coarse aggresse!

When determined in fecordance with BS 812 :

Section 103.1 using tft sieves of the sizes given in

table 9. complying wfth BS 410, full tolerance, the

trading of the coarsefageregate shall be within the

¢ limits given in table 8

3.2.1 General 7

When determined in actefdam.ce With BS'612

Section 1113.1, using tes Sievetwfothe'sizes elven in

table 3 complying with BS 430. fill tolerance, the

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- DN001-P02-HYD-HBK-LET-A11567Document6 pagesDN001-P02-HYD-HBK-LET-A11567soorajNo ratings yet

- DN001-P02-HYD-HBK-LET-A11724Document4 pagesDN001-P02-HYD-HBK-LET-A11724soorajNo ratings yet

- DN001-P02-HYD-HBK-LET-A12145 Wrapping tape, primerDocument2 pagesDN001-P02-HYD-HBK-LET-A12145 Wrapping tape, primersoorajNo ratings yet

- DN001-P02-HYD-HBK-LET-A11550 Duker pipeDocument3 pagesDN001-P02-HYD-HBK-LET-A11550 Duker pipesoorajNo ratings yet

- C851-3A-MAT-MAT-CIV-013-REPLYDocument5 pagesC851-3A-MAT-MAT-CIV-013-REPLYsoorajNo ratings yet

- 1) Geoscience Testing Laboratory ReportsDocument83 pages1) Geoscience Testing Laboratory ReportssoorajNo ratings yet

- Scd. A Project Brief Part 2ADocument1 pageScd. A Project Brief Part 2AsoorajNo ratings yet

- 4) CERAM UK Physical Testing ReportsDocument40 pages4) CERAM UK Physical Testing ReportssoorajNo ratings yet

- 3) Abu Dhabi Municipality Central Laboratory ReportsDocument9 pages3) Abu Dhabi Municipality Central Laboratory ReportssoorajNo ratings yet

- 2) Dubai Central Laboratory ReportsDocument14 pages2) Dubai Central Laboratory ReportssoorajNo ratings yet

- DN001-P02-HYD-HBK-LET-A11528 warnuing tapeDocument7 pagesDN001-P02-HYD-HBK-LET-A11528 warnuing tapesoorajNo ratings yet

- Geotechnical Interpretative ReportDocument1,353 pagesGeotechnical Interpretative ReportsoorajNo ratings yet

- BRE Digest 326Document8 pagesBRE Digest 326soorajNo ratings yet

- IJS 2400-3000-HDPE-SSC - 2Document1 pageIJS 2400-3000-HDPE-SSC - 2soorajNo ratings yet

- C851-3A-MAT-MAT-CIV-013Document463 pagesC851-3A-MAT-MAT-CIV-013soorajNo ratings yet

- IJS 2400-2888-HDPE-SSC Model (1)Document1 pageIJS 2400-2888-HDPE-SSC Model (1)soorajNo ratings yet

- MAT-CIV-024 - Grout Mix design & Raw material test reportsDocument18 pagesMAT-CIV-024 - Grout Mix design & Raw material test reportssoorajNo ratings yet

- IJS 2000-2400-HDPE-SSC Model (1)Document1 pageIJS 2000-2400-HDPE-SSC Model (1)soorajNo ratings yet

- C851 3A MAT MAT CIV 013 Material SubmittalDocument464 pagesC851 3A MAT MAT CIV 013 Material SubmittalsoorajNo ratings yet

- BBS Compound WallDocument4 pagesBBS Compound WallsoorajNo ratings yet

- MAT-CIV-024 - Grout Material Submittal - fullDocument129 pagesMAT-CIV-024 - Grout Material Submittal - fullsoorajNo ratings yet

- BCS StairDocument3 pagesBCS StairsoorajNo ratings yet

- SAADIYAT ITP (THERMAL Block Works) NEWDocument5 pagesSAADIYAT ITP (THERMAL Block Works) NEWsoorajNo ratings yet

- Itsupport@apbava - Com 20100208 142829Document22 pagesItsupport@apbava - Com 20100208 142829soorajNo ratings yet

- BCS FootingDocument10 pagesBCS FootingsoorajNo ratings yet

- 01-SAADIYAT ITP (Concreting For Super Structure)Document12 pages01-SAADIYAT ITP (Concreting For Super Structure)soorajNo ratings yet

- 05-Saadiyat Itp (Backfilling) VillaDocument4 pages05-Saadiyat Itp (Backfilling) VillasoorajNo ratings yet

- Itsupport@apbava - Com 20100208 143325Document1 pageItsupport@apbava - Com 20100208 143325soorajNo ratings yet

- Itsupport@apbava - Com 20100208 143105Document42 pagesItsupport@apbava - Com 20100208 143105soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142544Document63 pagesItsupport@apbava - Com 20100208 142544soorajNo ratings yet