Professional Documents

Culture Documents

3) Abu Dhabi Municipality Central Laboratory Reports

3) Abu Dhabi Municipality Central Laboratory Reports

Uploaded by

sooraj0 ratings0% found this document useful (0 votes)

5 views9 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views9 pages3) Abu Dhabi Municipality Central Laboratory Reports

3) Abu Dhabi Municipality Central Laboratory Reports

Uploaded by

soorajCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

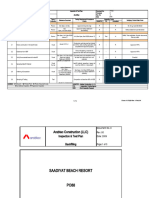

Emirate of: Lou Dhabi

Department of Municipal Affairs

Municipality of Abu Dhabi City

DYED

Bats! os} 4510

byt

_ Central Laboratories Section BAN yk pel

TEST REPORT ON CERAMIC/ STONEWARE/ KLINKER TILES i

[cone xo. : sera)

CLIENT nee iad ate

LETTER REP. ena S|

PROJECT coals ii ni Lapel

LOCATION : ae

parE oF Test_: 31-10-2009

|Sample Detail:

‘Fest Variation: Ne Shape Rectangle Finish Glossy

.d BUnglazed BPolished Use Floor BWall Shaping Bextruded (A) BDry-pressed (B) Basti) |

Texture Smooth

Colour fle yelon/aroun Cat Ref. Cat. Not furnished |

fot esrecived moisture)

Deviation from Average

Factory Mark: @IMuulded Binseribed Sticker _JY with Logo MAD |

rae ail

Gal: efijualndroaadie eeane ||heapemea| tare [= jes [ee es

eae ‘Ten whole tle specimen 6126 622.3 616.6

ft |iasm BS 6491: PL-10 =

-0.65

Ten whole tile specimen

Length

Araneae of side

Deviation from Average

n whole tile spe

Major Thickness

(atest pit)

from Average

Minor Thickness

(atthinest pins)

Ten whole tile specimen

Deviation from Average

S 6431: PELL

| Deleterious Defects

Water Absorption | 2H boiling & 4H cooling_| oe ome

7 [aupture Moduts [Rod-20Rubberstap-o [as ossi:r12| wow’ | ies

8 | Scratch Hardness _| Lowest value of Tile Face | BS 6431: Pt-13 |_Mohs _4 (Ref. Mineral - Fluorspar)

9. | Crazing Resistance | 1H at SO0kPa & 157°C __| BS.6431: P17 | Visual es

Intentional Effects None

10 | Surface Quality fo a a

yeseuation of theresa stp

No Obvious Defects Detectec

port pertains only othe samplts td and docs no imply approve quay ander performance ofthe atl protaction

2 Ths report must not be reproduced m part ur used any Way a5 Wad

Date of Reporting:

November 01, 2009

Tested by:

Checked by

Head of Construction Materials Labs:

> Laboratories Technical Support:

pp Ce ia

<>

Gaels Lecold Ls pene Std ly ee Sah lad

Pagal

www.dma.gov.ae: is, dst!

TR-FOMh | Plate tof 2 Rev. Mar 2000

EVERY Sth “YWAAAAA la da eat pall Lah alg RT ie

P.O. Box: 263. Abu Dhabi. United Arab Emirates. Tel: 02 6788888 . Fax: 02 6774919, Website: www.dma.gov.ae

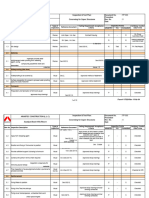

Emirate of Abn Dhabi On “le

Department of Municipal Affairs dtl agi Sls

Municipality of Abu Dhabi City tbls

_ Central Laboratories Section _ Soe ee:

TEST REPORT ON CERAMIC/ STONEWARE/ KLINKER TILES e

cope No. __: R-2506 [zs03 i a Gus ob |

cum: Ace |ntemnationer [wet : aad gata

LETTERREF. i parece 2 aay $i |

PROJECT ee = Eapaal |

LOCATION 5 oc se ia co sy

DATE OF Test: 31-10-2009 SY fs |

Glared DWnglazed BPolished Use WFIer Wall Shaping BExtruded (A) ADry-pressed (B) Bast (C)

Glossy Texture Smooth Colour Beige/pletroer Cat Ref. Cat, Not furnished

Factory Mark: [Moulded inscribed Sticker _J¥ with Logo Map -

ee ey ee ee |

T 1

hi | Ten whole tile specimen £ 610.9 624.5 t

| Mee BS 6431: Pr-10 = 1

|__| etasrescived moiture)_| Deviation from Average % 71.36 10.84 | |

} i

Ten whole tile specimen L_omm 298.8 299.8

> | Length ts BS 6451: P10 al —

© | Hoe squaeavs of 4 si5)| Deviation from Average % 0.20 | +013 a

‘Ten whole tile specimen mm 1997 | 2004 i

3 | Widen BS 6431: Pr-10 - i 4

{applicable oblongs) | Deviation from Average sa % | 025 | oo | - |

Ten whole tile specimen mm 6.08 6.36 6.21

4 | Major Tales eee he : ia

* | eacamctesponts) | Deviation from Average | % 209 | eae ||

‘Ten whole tile specimen mm 5.18 5.48 }

5 | Minor Thickness ca BS 6431: Pr-10 f — eal

{et thinnest pons) | Deviation from Average % 281 s2e1 |

6 | Water Absorption |2H boiling & ai coling | BS6ASI: PIN | oe : os |

7_| Rupture Modulus | Rod-20/Rubber-S/Lap-10 | BS 6431: Pt-12 |_Némm* it send

8 | Scratch Hardness | Lowest value of Tile Face | BS 6431: Pt-13 | _Mohs 4 (Ref. Mineral - Fluorspar) |

9 | Crazing Resistance | 1H at S00kPa& 159°C | BS 6431: P17] Visual ae |

Intentional Efgcts None j

BS 64.1: PIO el

Deleterious Defects oe | Visual No Obvious Defects Detected _|

port pertains only tothe smplts) tested nid doesnt imply approval ofthe quality and or performance ofthe bath production

2 This report must nt be reproduced in part nor sc anyway aso ea we ivepresentation of the esas o hie implication

Checked by:

wg: November 01,2009 Tested bys

Head of Construction Materials Labs: Laboratories Technical Support

7 a

ian oe ee eet

La ot ee bess ee Ley os TR-E08b | Plate 1 of 2 Rev. Mar 2000

www.dma gov. ae —Sn259 yl PWVENNN: Sb, WARM sala da al gall LAM gail MF ge

P.O. Box: 263. Abu Dhabi. United Arab Emirates. Tel: 02 6788888 . Fax: 02 6774919, Website: www.dma,gov.ae

mirae of Sou Dhabi On) Y WS

Department of Municipal Affairs Atl tia tls

Municipality of Abu Dhabi City tb iat

Central Laboratories Section

| LOCATION __ mee RTS ae Akg

DATE oF TEST_: 31-10-2009 ae Aas]

Sample Detail: Glazed WUnglazed WPolished Use WFlow DWall Shaping Wextruded (A) BDry-pressed (B) WCast (C)

Test Variation: No Shape Rectargle Finish Semi-Mat Texture Smooth Colour Pinkish Brown Cat Ref, Cat. Not furnished

Factory Mark: @Moulded inscribed Sticker JY with Logo MAD.

No| Physical and Performance Properties | Test Methods | Unit ies WPM aamrise

Head of Construction Materials Labs:

7

Fel Lelad Ly pac Lao Dyaholas

Pass of TREAD | Plate 1 of 2) Rev. Mar 2000

wrww.dma.gov ae 9 Bal TAWVENYG: Slbs STARA sila Bul all ag AF ge

P.O. Box: 263. Abu Dhabi. United Arab Emirates. Tol: 0 A7RARRR Faw: 09 774010 Waheita: wn ams a

Emirate yf: You Dhabi ery y We

Department of Municipal Affairs Apa Ll og att ls

Municipality of Abu Dhabi City eo a

Central Laboratories Section —Ashlay p pad

TEST REPORT ON CERAMIC/ STONEWARE/ KLINKER TILES

CODE NO. 2R es a -_ see aie! ab |

CLIENT ace [wTenvationan [nec Hilal ale

LETTER REF ca io eat ieee Aan 5 jet

| progecr 1 S- 200 a ape

LOCATION it a ey abyt|

DATE oF test: 31-10-2009 a |

Sample Detail: ZGlazed WUnglazed BPolished Use Floor BWall Shaping

‘Test Variation: No Shape Square Finish Mat_ Texture Gritty Colour Light brown Cat Ref. Cat. Not furnished

xtruded (A) Dry-pressed (B) BCast (C)

Factory Mark: EIMoukded Bnseibed Sucker 12 4 34 6 with Lage MID

wal Taps narceeeasieerns nancies | Ga ce

M: Ten whole tile specimen & 501.2 507.7,

1 ae BS 6431: Pt-10_ a

_(avreccived moisture) | Deviation from Average ert

Ten whole tile specimen 1982

| Length BS 6421: P-10

(Gesture ne. ten] Deviation fom Average

| Ten whole tile specimen

‘Width BS o451: PE-10 -

(eppicbetwoblnes) | Deviation from Avera % =

| a am

| Ten whole tile specimen Lmm 7.05

| steer Tbiciness BS 6431: PL-1O

(artickes pons) | Deviation from Average | {| % | 070

“Ten whole tle specimen mm 6.36

5 | Minor Thickness = BS 6431° PL-10

| 5 [tcttians poms) | Deviation from Average % | -230 rd

Water Absorption [211 boting& AH cooting [seat ret |__e Z |

Rupture Modulus | Rod-20/Rubber-si/Lap-10

6

7

8 | Scratch Hardness _| Lowest value of Tile Face

9 | crazing Resistance | 1H at SOOKPa & 159°C _

| totamtiowia toc

7 BS 6431: Pt-10 [~ ae

Deleterious Defects L_ Visual No Obvious Defects Detected

i Surface Quality

‘Remar

Tre eport pertains only to he samples) ested and doesnot imply approval ofthe quality and/or perirmance ofthe Bate production

2 This report must not be Yeprodced in part no sed in any wa aso Ted 0“ wsrepresentan oF the sults or heir implication,

s) AZ)

Date of Reporting: November 01,2009 Tested by: ae ! Checked by: a

Head of Construction Materials Labs: = Z —D Laboratories Technical Support: ze

Barely Lecolal Ls pure Las jee yah ole

as z iy Base aly TR.EORD| Plate of 2 Rew Mar 2009

wovwidma,gov.ae: gia all -YTWEAIN lbs “YVAN ila ba atl gyal Lath gig TT ie

P.O. Box: 263. Abu Dhabi. United Arab Fmiratec Tal: 0 ATRRARA Fay: 09 774010 Waco: wna Ames

coffey > projects ain

[SPECIALIST LEADERS ANO MANAGERS a ———

(074392 50.01-0-610nt Caml Tests -211008

21 October 2009

‘Nagaruna Contracting Company (LLC)

P.O. Box 117333,

Dubai

United Arab Emirates

Attention: Eng, Sanjay Joshi

Doar Sir,

Project: 200 AL SALAMAT RESIDENTIAL COMPLEX (Villas)

‘Subjact: Ceramic Tests

Aeleence; 1) NCC ero CA dtd 4-08.09 Ret (NCIOCICE 3028

1) CAV ier to NCE dees 16-Oet OB Re (07. e33e-00-001 408m)

oO Referring to the above mentioned subject. please find attached the consultant's recommendation

(Sherr crams out hed teen prod Ouba ena s,

Furthermore, CAJ remind NCC to expedite the tests in Abu Dhabi Central lab. and to approach the

(Gut Regioncounties for tne unavalable tests in UAE for he benef of the project

“This ie fr your information and action.

Yours sincerely

For CPME/AIN.N

fasan Hasan Al

5. Project Manager

tachment stor merione ate vom ACE

ce ACE Matera ng Monarned Rdhan Dynan

E

G

Til Gonaiatton Managemen TE

ewanne 03 AlMazu' Sara 113

PO Borers Oo Unie a Etta, ‘Aaa Sat (opoute we vy ga} PO Bee 128002

‘Teej sana F879) 0) 02 ‘ou ab Unie At Ere

‘Tlaars yeaa 2262 F070) @) 8449885,

ven een

ACA COTRACTISC0,LC.

| 26 ocr 7008

‘ater Prope (ade Eno HE

hen 905 tae Bang

pt

ota geapn tS !

ACE International — Consulting Engineers

Date: 20 OCT"2000

Ref: 30/07 ei S-200,

Coffey Projects (Middle East) Lid

‘Office 305 Al Barsha Building

P.O Box 34751

Dubai, United Arab Emirates

Anention Mr Hassan Hassan Ali

Sr. Project manager

Project: AL SALAMAT RESIDENTIAL COMPLEX (villas)

Suijest: Cormmic tes report by: Dubai exntral lab

Ref CA) letter DCL Ceramic Tost Reports -041009, Dated 14/10/09

Dear Sir,

Reference is made above; please be informed that we have completed our review of

“Ceramic test results” duly attzin by Central Lab., Dubai and we hereby enclosed our

detailed recommendation which is self explanatory.

“This is for your information and necessary action

“Thank you CPMETAIM IT

‘Yours faithfully, Tairhaet [rl wo ZB |

ie Fie te

ae [Ra ie

=

Enel. ACE report -copy

CC: MrAnis El sayed - Area Manager

Mr. Fadi Nakad _ Abu Dhabi Manager

Bhp At La AA 7302 0 GATING SH 6447764

‘A: Comments:

1, Breaking strength, Modulus of rupture & Water absorption only has been carried out by Dubai

Municipality, Dubai Cental Laboratory {0.C.L). ii pata

2. The submited tests resus vide DM Report No. 2000146725.37 & 2009146746 dated October 11,

2009 for ceramic tles have been checked & found okay which do comply with BS EN ISO 10545 for

Breaking stength, Modulus of rupture & Water absorption only.

B. Conclusions:

“The Length, width, thickness, staighiness of sides, Rectangular, surface quality & surface flatness,

Abrasion resistance, Moisture expansion, Crazing Resistance, Resistance to chemicals, Resistance to

~O Staining has not been cared oul by D.C. as required for standards compliance. Detals are given

an Tost

* Propertios Test Mathod Conelictad_|compiy

Yes [No

| Lang wih RERRESS,

straghiness of sides, a

Recianguanty, sulace | Test Method BS EN ISO 10546-2

qualty& surface faness a

2 T water absorption Test Method BS EN ISO 105453 | Yes Yes

5 | Breaking strength & 4

Breaking stonath & | Testathod 8S ENISO 10545-4 | Yes ve |

“| abrasion resistance | Test Method BS EN ISO 10545-7 No |

%}® | moisture expansion | Test Method BS EN 'SO 10545-10 Ne

a ® | crazing Resistance Test Method BS EN ISO 10545-11 No

C

— 7 | Resistance to chemicals | Test Method 8S EN ISO 10545-13 No |

5 | Resistance to staining | Test Method BS EN ISO 10545-14 No |

C- Recommendations:

1. To ensure ful compliance withthe requirements of BS EN ISO 10545 & BS EN ISO 13006 al! the

remaining tests, as mentioned inthe table above ae required and to be carried out together If

possible Oj, an.independent material testing taboratory:n the United Arab Emitate or abroad’on the

{oontractor expenses:

2. Adequate numbers of specimens in accordance with BS EN ISO 10548 requirements for each type &

{gr0up of ceramic es are to be selected randomly by the consultant representative from site Stock to

do testing for standard compliance,

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- DN001-P02-HYD-HBK-LET-A11567Document6 pagesDN001-P02-HYD-HBK-LET-A11567soorajNo ratings yet

- DN001-P02-HYD-HBK-LET-A11724Document4 pagesDN001-P02-HYD-HBK-LET-A11724soorajNo ratings yet

- DN001-P02-HYD-HBK-LET-A12145 Wrapping tape, primerDocument2 pagesDN001-P02-HYD-HBK-LET-A12145 Wrapping tape, primersoorajNo ratings yet

- DN001-P02-HYD-HBK-LET-A11550 Duker pipeDocument3 pagesDN001-P02-HYD-HBK-LET-A11550 Duker pipesoorajNo ratings yet

- C851 3A MAT MAT CIV 013 Material SubmittalDocument464 pagesC851 3A MAT MAT CIV 013 Material SubmittalsoorajNo ratings yet

- 1) Geoscience Testing Laboratory ReportsDocument83 pages1) Geoscience Testing Laboratory ReportssoorajNo ratings yet

- MAT-CIV-024 - Grout Material Submittal - fullDocument129 pagesMAT-CIV-024 - Grout Material Submittal - fullsoorajNo ratings yet

- BRE Digest 326Document8 pagesBRE Digest 326soorajNo ratings yet

- 2) Dubai Central Laboratory ReportsDocument14 pages2) Dubai Central Laboratory ReportssoorajNo ratings yet

- 4) CERAM UK Physical Testing ReportsDocument40 pages4) CERAM UK Physical Testing ReportssoorajNo ratings yet

- DN001-P02-HYD-HBK-LET-A11528 warnuing tapeDocument7 pagesDN001-P02-HYD-HBK-LET-A11528 warnuing tapesoorajNo ratings yet

- C851-3A-MAT-MAT-CIV-013Document463 pagesC851-3A-MAT-MAT-CIV-013soorajNo ratings yet

- Geotechnical Interpretative ReportDocument1,353 pagesGeotechnical Interpretative ReportsoorajNo ratings yet

- IJS 2400-2888-HDPE-SSC Model (1)Document1 pageIJS 2400-2888-HDPE-SSC Model (1)soorajNo ratings yet

- C851-3A-MAT-MAT-CIV-013-REPLYDocument5 pagesC851-3A-MAT-MAT-CIV-013-REPLYsoorajNo ratings yet

- IJS 2000-2400-HDPE-SSC Model (1)Document1 pageIJS 2000-2400-HDPE-SSC Model (1)soorajNo ratings yet

- BCS StairDocument3 pagesBCS StairsoorajNo ratings yet

- Scd. A Project Brief Part 2ADocument1 pageScd. A Project Brief Part 2AsoorajNo ratings yet

- IJS 2400-3000-HDPE-SSC - 2Document1 pageIJS 2400-3000-HDPE-SSC - 2soorajNo ratings yet

- SAADIYAT ITP (THERMAL Block Works) NEWDocument5 pagesSAADIYAT ITP (THERMAL Block Works) NEWsoorajNo ratings yet

- MAT-CIV-024 - Grout Mix design & Raw material test reportsDocument18 pagesMAT-CIV-024 - Grout Mix design & Raw material test reportssoorajNo ratings yet

- BCS FootingDocument10 pagesBCS FootingsoorajNo ratings yet

- 05-Saadiyat Itp (Backfilling) VillaDocument4 pages05-Saadiyat Itp (Backfilling) VillasoorajNo ratings yet

- Itsupport@apbava - Com 20100208 142407Document7 pagesItsupport@apbava - Com 20100208 142407soorajNo ratings yet

- BBS Compound WallDocument4 pagesBBS Compound WallsoorajNo ratings yet

- Itsupport@apbava - Com 20100208 143105Document42 pagesItsupport@apbava - Com 20100208 143105soorajNo ratings yet

- 01-SAADIYAT ITP (Concreting For Super Structure)Document12 pages01-SAADIYAT ITP (Concreting For Super Structure)soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142544Document63 pagesItsupport@apbava - Com 20100208 142544soorajNo ratings yet

- Itsupport@apbava - Com 20100208 143325Document1 pageItsupport@apbava - Com 20100208 143325soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142829Document22 pagesItsupport@apbava - Com 20100208 142829soorajNo ratings yet