Professional Documents

Culture Documents

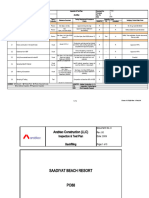

C851 3A MAT MAT CIV 013 Material Submittal

C851 3A MAT MAT CIV 013 Material Submittal

Uploaded by

sooraj0 ratings0% found this document useful (0 votes)

10 views464 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views464 pagesC851 3A MAT MAT CIV 013 Material Submittal

C851 3A MAT MAT CIV 013 Material Submittal

Uploaded by

soorajCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 464

ssn se ‘siNavino0a

SBUNSOTONS e ADYELINOO 3H 40 SuNarERANORY TIV Hut ZONYTIANOD 20

AUGISNOSSEU NORE HOLOVAIINOD BASIE LON $300 MEISE

Tea STS wen iueynsuog | “a Yo v s1 3000 NOLLOV NaHé A1NO 4330044 TIVES NOWWTWs

(asn sua3NION NOS) ZNOLLO3S

creel ee|ze zen es x peop susico wane SL e suzovnia 9010

are suorovanos | [on | ox :

2957045 SH 30s BOLDVRINGD SHI Aa OanOud

“OLON Sv 1043 'S1NNI900 OYINGD BL 40 SLNAMERUNIOSN HL HLM ZONW-NOD THAN SY ONY #SNOISO/00'OLOYAINGO BML ABNOHO NASH anv HuMsaN GaLmelis tau Tw Kull Sa

WONSUL N30 WO WANT

‘3dH HLIM ad 31349NO9 aaOWOANEEM ONY (via HOOT

GSHOVLLY Sy Asoyaes WeD0id YOR "8 VINOOOZ ‘WIN00%1 ‘WIN 0001) YVT109 7431S CW HUM MNT ‘

AM 1g 0 SdGH HLIM S3NIT NOLLVIS ONDOVE aLViGaMMLNI Yael

‘ONIHOWE 3LSUONOD G2DUOINE Hod TWAOMdAY TRISLYA

simeusig | smins 31409 "013 "ON aunHOONS: (913 "38N OlstOadS ‘ALIOAVD ‘azIS ‘34AL “SAVN) “ON

au | Soon | “on anoTvavs “on mvua soning) meen aus nowsiuoead wort

ee os

ZO00LS9Pb P16+ %E4 BL/GLEGSOPP yL6+ “TOL 00LSPPr 16+ “ON x03

J8}80 ‘240 ‘PEOY| Hodary LILISPbP pL6+ ON TO,

“Bpig zens YePIES ‘J0015 49 “109 UNS 42120 -2YOG 'Z9EL XO O'd

WHOHSW-WMd =°09 (23D mH FqHEUX :OL Auedwed 6uyeU0> YEH ‘WONS

Vo fb 0 Ao TVW jliviw ove 7b ee — yesh _

a a Sad0¢09 — eweunus vay syomioN

aoe “ON "bes suydiosig. Asobere) adh "ON 190 [01d WALD 610z We 10009 190/01 Jajempunoip y s2EENS

— a . sawp eyoa YEIISEO /oNWea109 40} stofoud seourpeoy vals O202"8O'30

NSQWANWVLUWGNE™ “NOUvoON ‘ON 1030 Ob SSWWN'193FOud BAVC

(SN S:OLOVULNOD YO4) | NOLLOZS:

ANSWLYVdad $194rOud JDVNIVUG JO YSOVNVW 3HL Ol TVLLINENS

WA yar

£40 T a8eq

O02 ELO-AI-LWW-LWW-VE/TS89 “ON jenIUgns

]

“vtoz (S90)

suoneoypads uonansasuo5 seve Jo

suonoas quenajau aya ydian Aldus0D Ajiny

TISIA UBnostp paylian aq ileys “Adwio> jm pue parON | sadig Oy ayLIeyY aunsua or 40;eRUCD | je!9Ua9 | po

: “uonjanpoud oy s0ud

auinbas jenoudde sjeuarew mey pue

enosdde Jo uBisag yy 31uqng “PAION | _95.Aq passauiim aq 03 SjeuR UBiseg x | Je1aU29 | ¢o

sin Hoes “asia uorey Uwondeysnes uewInsueD/ual

40} uonedynou jrewa yBnosy 240} ajnpayas aBuesse 04 19ps0 ut eau 01 siuausasinbas pue aaueydWwoD

ainpaups weis uoonposd aouo | Jo1vesnuo> ayp asinpe aseajd ‘paION | ays Ayenoriisin O;es aBUELIe aseajq | \e19Ua9 | 70

~ quouiasinbai/suoneaypads

peloid pue ptoz SD ad

se aoueydwo> 0} walang “youad, uado

40) 49UN7 3dGH UUM adig a1212U03

PeouqjuiaY pue (rsIeWeIP WUIQdZ

%B wuo9oz —“wUoOrT)

1221S PW Yam 49UN adGH uu

Peur] uoneIs Surper syerpaws9yUy)

B adig Buyper aaiouoy ariojujay «

spafosd ye dud 404 pasn + Bumeip, € uonsas -yenosdde

2g reys Yoiym sseawuelp jeusayut lu aas"wnpuappe se Bumesp-eip | ayHoHsy on walans Aor

se sazis sadid Ayoads aseaig WUIQ0OT 49}84 ApUry ‘osiy “PEIN | eYOGs/W pasedosd Jo} uonalg0 oN «| jexauay | To

ss - aaea/

asuodsay 54039220) qWeunwe) vay asuodsay 5103922309 quawwoy vex uon2as | -on

TOMY o07neu

AION se panoiddy (a) :smieys TO “ON uojsiaay €T0-AID-AVIW-LVWW-VE/TS89 FON jenmwuans

‘wouad] wado 40} 29UN) 3aGH Wim adi ayaz0u0 par10jujoy pue (iazaWeEIp

wwodrz °8 WiLUGOOZ ‘wUIDOHT) 4e1109 1999S PIN YalM JOU 3dGH YIM pour] uoReIS

Oz0z-#nv-80 :Panjsroy axeq Supper ayelpauuieyUy g adi BuIy2er a3210U09 a210yulay Joy ySanboy jenoUddy JeOIEW — :ORL4 SuyMesg/wuoWNsoG

vE/1S89 PON Walosd

PIBUINULL TW 38 HONIAN 4018/M Puno pue aDe}iNs YE alld SSaUIPeDY Wald 10} 39E:U0D pling pue Ud|saq sOweEN walOd

mumrernres Aueduiog 6un0B.1409, Pave cv]

824s asuodsay yuaWiWO?

Mar

£40 Z a8eg

TO "ROY ELO“N-LVIN-LWN-VE/TS8D “ON JeRIWIGNS

upduisug Suuuey,

us

~s99U)8U3 "WSW 2yses1 / 22e,:09U) peoy Is

‘sofenans AaRuen>

1g pamoinal @ paiDdaig

810 OOOT Sy) ‘iewWgns jevayew

“(pauonuaui you

yeas asuodsay yuawwoD

Mari

0} Bulpsoaze Bupeay ay) aBuey> 60

‘Ripe ujeyuiew

03 pamauas ag pinoys pue pljen

‘ue s9su29}) Je 1euy aunsud 01 103283309

"0202 ‘T 4aqo90,

“pamauad s! | auUO pap|roud ue 0202 ‘8 IsN3ny uo Buyidxa ale

PaION | 2 IIIMSasua91] parepdn pue pa}oN | paruasaid sasuaDy) ay ey a10U aseaig | Je1aua9 | go

i “03 pauiajas s} wiwi0OKz |

13 wiwiQ00z ‘wODrT Pasodoud ay st

£70477 asnep | DOg ay 40 Wed 40 LoRDas ay!Dads Yo1uM

‘suondas DOA YeNe aseaid 7’ uonras DOK 03 sajou aseaig Aue aseald ‘payzene si Dog IINy | jesaue9 | 70

“siuauoduio> jeunyonays |

Jenoudde 40 [eaoudde pue mainas 03 32aIqns 2q

|___ 40) sSuymesp ywigns aseajg PeION | les sBumesp paysene/paxiwans ay | jes2Ua9 | 90

‘Auep aseaig WOS ® WUIgp LL

GE J9A09 smoys Bulmesp payene

ay} “JaNaMOH “Bujmedg 0} paiajas

pue wugz wnwjU ag 09 parers

quawis2i0jure4 B43 04 4an09 qUa|DyyNsUI

quaurasndau so Aysnes (8 o'€'€ asnelp € weg g uonDas

01 papinoid sey wuawassojulo4 “Ainpeoy |

842 07 4409 Ua!Dy4NS “Buymerp | jeRUaIEY OT asNeID YAIM Y/N JO AIdWOD

aION Sdeumpejnuew oy aouasajoy | 31 wWsyuod 04 soDeNUOD-772BT'ZaiaeL | je12Ua | 50

e8ed/

asuodsoyssowenuey | quowwoD vey asuodsay 51032813109 quawwoy vy won2as | ‘on

TOAay _ - 00"A8y l

Ferereperen ‘Aueduiog Bugoesuog

A

£40 ¢ a8eq TO ‘AY ETO-AID-LWN-LVN-VE/TS80 ‘ON ieniwqns

ee 2 7 SN aia bgt

~ uaseuew mainay usisag

ugeur8u3 jemanaas is

okanng

cya9uu3 21INeIpAH 3S as

Pee | avwausog ounoanueo ]

yeays asuodsay yuaWWIOD iy

Meh A

Document Wo: | PWAAPO-CONFMASIO

IA |HBK Motel Ammonitenen ELLE

ee ee

taro

Document No: C851-3AMAT-MAT-CIV.013 Rev.No 01 Date: 08/08/2020

Project No: PA 2019 C 030 FPS. ‘Area: Al Thumama, Zone 47

Project Title: Design & Build (DB) for FIFA Readiness Project 3A (FRP 3A) for Surface and Ground Water

* “Network at Al Thumama Scheme

GEC Khatib & Alami Contractor: HBK Contracting Co.

Area of Appli

BoQ Ref:

Specification:

Reinforced Concrete Jacking Pipe & Intermediate Jacking Station Lined with HDPE

‘Type of Material Liner with Mild Steel Collar (1000mm, 1400mm, 2000mm & 2400mm Dia.) and

Reinforced Concrete Pipe with HDPE Liner for Open Trench

ication: SW Microtunneling and Open Trench Pipe Line

Section 7.2 Drawing Ref:

QCS 2014 Section-8 Part 9

Applicable Standards: QCS 2014

Country of ©

Availabilty:

rigin: Qatar

List and attach all relevant technical literature marked to identify relevant description, current test certificates,

samples as appropriate

a) As

»)

°

9)

attached

ey

Company Name: Doha Precast Factory (DPF)

Address 1 P.O. Box: 50311, Doha, State of Qatar

‘Address 2:

‘Address 3:

Address 4:

e-mail #974 4490 3836

Telephone No: mail@dohaprecast.com

"THE DOCUMENT IS UNCONTROLLED ONCE PRINTED Last pind T5OT/2070 57 Pave Tez

=i Tne [rere connie

=F A HBK Material Approval Request [_resmno |

sue Date: | 36/0n 2019

iculars of Local Agent (if app

Company Name: — Not applicable

Address 4

‘Address 2:

Address 3:

Address 4:

email:

Telephone No:

Ex-Works Total Latest Date for

Duration: Order: 30.03.2020

Date Material Estimated Date of

Required on Site: 24042020 Arrival on Site: 15042020

We certify that the above submitted items have been reviewed in detail and are correct and in strict

accordance with the contract drawings and specifications except as otherwise stated, and also that the

material sources indicated above have been reviewed in detall and that we will supply the submitted items in

full compliance with the schedule delivery plans

Name: Signature: om Date:

mmendation

ee

To Contractor:

‘Action Code A: [1] Approved as Submitted

Action Code B: C1 Revise and Re-submit

Action Codec: (]_ Rejected

Name Position:

Signature: Date:

en OR re

Name: Position:

Signature: Dat

Footnote:

Approval by the GEC shall not relieve the Contractor of its obligations and liabilities under the contract or constitute

authorization of any change to Contract Documents, and therefore, shall not imply any recognition whatsoever of edditional

time or cost tothe contract.

‘THIS DOGUWENT 6 UNCONTROLLED ONCE PRINTED Last prnied THUTROTO TeBT SSSR

HBK

Reocton tebe

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

Index

1 - Company Profile

Process Flow Chart

Organization Chart

* Location

% Contact List

Registration

% 180 Certificate

% Quality Certificate

@ Safety Certificate

3 - Catalogue / Brochure

Mix Design

% Drawing

% Jacking Force Calculation

> DPF Brochure

4 Inspection and Testing Plan (ITP)

5 ~Matorial Safety Data Sheet

6 - Warranty Lettor

7-Test Reports

* Aggregate

Cement

Admixture

Water

Stool

EPDM Rubber Gasket

HDPE Liner

eeseee

8 - List of Project & Approvals

% List of Project

% Previous Approvals

‘9 Compliance Statement

DOHA PRECAST FACTORY

Tek (974) 4490 3836 Fax: (974) 4490 3835 P.0. Box 50311, Doha, State of Qatar Email mailScohaprecast.com, Web: waw.dohaprecast.com

lA

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

Company Profile

—

Tel: (974) 4490 3836 Fax: (974) 4490 3835 P.0. Box: 60311, Doha, State of Qatar Emaikmall@donaprecast com, Web: www. dohaprecastcom

SARARAARARARARARRARARRARRRRRRARERARRARARRRR CORRS ERODE

x

DOHA PRECAST FACTORY

DOHA PRECAST FACTORY

Doha Precast Factory (DPF)

PO. Box 50311 = Doha, Gator

Messaeed Industiol Area

1: +974-4490-3836F: +974.4490-3835

E: mail@dohaprecast.comW/: wv.dohaprecast.com

RAARARARE RARER

BBP IPAPAR EREDAR AA APAPADASIS SANDALS ISAN REAP ALAND RAAAARAAANSANASAR AANA

PALI LABARALARAPSASAPPARRAAPABAAS PAPA SALAALADARAAARAAPPARA LIRR DB,

BABES,

Baeae,

RA ARRRAARRERARRERARSRERSERRERARRRARRK,

AARARKARARARAARALSARARSRARSARAARARRRARRARARARSARARAR

Company Profile ey

Introduction: Or \

DOHA PRECAST FACTORY

Doha Precast Factory (DPF) established in Qatar 2008

located in Mesaieed Industrial City about 30KM from

Doha. The Factory meant to produce reinforced

Concrete Pipes and fittings in low head and gravity flow

systems and Precast Manhole system. The present

concrete pipes and produce in the DPF design utilizing

EPDM gasket , and T- Locking system PVC, H.D.P.E.

and GRP lining and externally coated by coal tar epoxy

(optional). The production range is from 200mm to

3600mm Internal Diameter. The manhole system is

suitable for foul Sewerage, Storm water drainage and

Sewage with GRP lining and without lining. The Range

for the Manhole is ID900mm to 4000mm. All the

products are especially developed for drainage system

in the generally corrosive soils and ground water of

Qatar and G.C.C. coastal areas.

The RC Pipe and Manhole designed to be with stand

against external load and to suit client specifications

and requirements. Doha Precast Factory is

Producing Precast JRC 6, JRC 12, JRC 14, LOR Champers.

Standards and Quality Assurance:

All products are manufactured in accordance with relevant standard mainly ASTM C 76M and

related standard of ASTM pertain to reinforced concrete pipes and raw materials, BS 5911 P: 1

2000 and, BSEN 1916 and related standard of BS for reinforcement concrete pipe and raw

material, with considering 8S 5911 P: 100 and P:120, which are clearly defines all the

performance tests necessary to ensure that the product will perform satisfactorily in service

and be durable for long period.

The Doha Precast Factory is certified international Quality system as ISO 9001:2008 Quality

Management Systems, ISO 14001:2004 Environmental Management Systems and OHSAS

18001:2007 Occupational Health and Safety Management systems. Doha precast Factory

has the Laboratory accredited by IAS ISO IEC 17025 for most of the parameters (34)

related to Aggregate test, Concrete Test and Concrete Pipe test as per BS and ASTM Doha

Precast Ensure about not only quality of Product, but also it will ensure about the Safety and

Environmental aspects.

The Doha Precast Factory is certified for Storm Sewer and Culvert pipe and Manholes Plant

by American Concrete Pipe Association- Q-Cast and Certified by BSI for KITE Mark,

Concrete pipes and Fittings, unreinforced, steel fiber and reinforced and fiber-cement

products - pressure pipes and joints. While we believe that this certification scheme gives

added assurance that the products fully comply through third party scheme of supervision

administrated by the quality assurance services. In addition to monitoring all aspects of

quality contro! procedure from receipt of raw materials through the production, inspection

a

=

x

x

x

x

x

x

&

x

mn

®

=

=

=

x

x

x

g

x

&

®

&

a

&

<

x

g

5

5

x

a

x

x

g

x

5

x

x

x

S

x

x

x

&

s

a

g

x

a

x

x

5

s

5

=

& and testing stages to the efficient loading and transportation of products to site.

a

&

&

SAAR RAR RRR RR AR RARER RRARARRARRARARARRARRRRRRRR RARER RR,

&

®

®

x

=

a

&

&

x

&

a

&

x

S

x

&

5

5

x

8

e

&

S

x

x

x

x

x

x

&

®

x

x

x

=

g

~~

=

=

x

=

=

8

s

=

5

5

g

x

x

x

x

=

5

=

=

x

AHARAAAT ETA AF ARA TERRA RAS RERERAE RARER AR RRARARRERR RAR!

= sd

Technology: DOHA PRECAST FACTORY

Doha Precast Factory is equipped with latest modern technology to meet with our client’s satisfaction by

producing consistent and high quality products meeting the latest international standards.

ee ee

Following technology suppliers are utilized in Doha Precast Factory:

Pipe Casting Machine and Moulds (Forms)-M/s PEDERSHAAP - Denmark

3 Machine 2station each machine

EOT Crane-M/s DEMAG -Germany -3 NOs. 15,30,40 Ton

Gantry Crane -1 No. 25 Ton

Concrete Batching Plant- M/s IMER - Italy -1No. (1.5m3)

SKAKO-Denmark-2Nos.(1.0m?)

Steel Cage Machine -M/s MBK - Germany - 2 Nos. 4000mm

Fork Lifts -M/s KALMAR - Sweden -4Nos. 25, 25, 35, 35

Hyundai -1No. 16 Ton, Komatsu-7Ton

i Automatic Coating Machine -M/s GRACO - USA

Pipe Cutting & Milling Machine -M/s KOLB - Germany

Laboratory Equipments - M/s ELE - England

ARR RR RALAL PAIN AANA LAAA ARIANA AANA AAAARAAPAAAPPAAAAAAASAPARAPAARD

Hydrostatic Testing Machine -M/s MESSMANN - Germany

Pipe Crushing Machine- M/s PEDERSHAAP - Denmark

APBPARISSBRA BASSANI IS ASIPRIBAE ES SARA RAILS PASS PEPAAPAAAAAIIVAAAIAVABAR ARAN

APARSSIARA RADAR,

RAAPARRRARARARARERRERERRRRERRESERRERASRE REDRESS RODS

SSASSSESSASSARSSARSAARSRASS ASSESS ERERRRRARSRARRARSS,

Internal Lining: DOHA PRECAST FACTORY

Doha Precast Factory can produce reinforced concrete pipe lined with H.D.P.E., P.V.C. or G.R. P.

(optional)

The pipe will be 360° lined to protect the internal service and against chemical attack from

liquids conveyed. During the fabrication process of the pipe the sheet lining is placed around

the core, so the concrete is casted around the ribs or the anchor if we use G.R.P. liner once the

concrete is set, the lining is locked mechanically to the pipe interior and can tolerate large

movements at the joints without losing its physical integrity, while the continuity of the lining is

assured by welding or laminating each individual pipe joint to the next.

The quality control programme of Doha Precast Factory shows how we can test any welded joint

to ensure that the welding processes fulfilled the requirements,

Reinforcement:

Reinforcement cage required for the reinforced

concrete pipes are produced from cold drawn

steel wire to meet with BS and ASTM related

standards. On automatic welding machine (MBK-

Germany). As the cage revolves, steel wire is

wind in spiral around longitudinal bars and

automatically welded at each contacts point till

the required length of cage completed.

HANNS ASIA DARE ARADAARPSIPRSPPPRPRAPAPAP SAARI DS

Water Protection Coating

Doha Precast Factory has a facility to coat the service of

reinforced concrete pipe with coal tar epoxy coating

with normally applied to thickness of between 200 to

1000 micron by either Graco machine technology or

brush to protect the exterior of the pipe from attack by

potentially destructive soil chemicals. The coating can

tolerate soil stresses and pipe deflections without

cracking or disbanding. Also Doha Precast Factory's

laboratory is furnished with all required test

equipments to control thickness and bonding criteria of

coating.

WSR AR ER ARAAAARARARAIAAR ADDS

PSSBBAABSSBARIAB RARE SAARI ARRAN RPIRAARAD INARA ARANRAAP PRD IIIRPD RARER RP ARR ERED P.

RAR ARRRARAARRARRRAR REE E RRA REESE ERE RERRE REESE RHE R EER!

4,

BRIARASABAB AB ERRANDEPR ERA RARARRSARARAS ASSAD DS SLADDARAAA PAAR SP ASASAANAR AAR

APA,

ARRARRARRARARARARRARKARKARARRATRARARERRARRRRRARARRAS

DOHA PRECAST FACTORY

Product Dimension

Doha Precast Factory producing standard and

jacking pipe with 2m,2.5m,and 3m lengths and

from 200 to 3000 mm ID. All acceptable limits

as dimensions are mentioned in Quality

Manual of DPF and ASTM / BS Standards.

Moreover, Doha Precast Factory has very high

technology to produce any length to meet the

site requirements.

The KOLB cutting and milling machine is

sophisticated to do these activities with very

high performance and accuracy.

Materials:

Doha Precast Factory committed to use very high

quality materials such as cement, full crushed gabbro

aggregate, sweet water and additives in the

manufacturing product, which are constantly monitored

at each work to ensure compliance with relevant

standards the process of producing a dense high

strength concrete involves electronic monitoring to

control water content and patch weighing the mixing of

material.

Quality Control:

[Doha Precast Factory offer superior quality

concrete pipe products and services to our

customers. We established Quality Control and

Research Department staffed with qualified and

experienced personnel and equipped with

modern measuring and testing devices. The

function of Quality Control and Research

Department is to ensure that Doha Precast

Factory products are manufactured in full

compliances to the project specification,

specified national standard, approved project

quality assurance and Quality Control

Programme of Doha Precast Factory.

Doha Precast Factory Quality Control and

Research Departments are supported by Group

Engineering Department consisting _of

experienced and _—_ professional engineers

dedicated to support and upgrade the quality

standard, when required.

BARARAARRRARRGRERRARR ARERR TREE REA REREORERSERRERE RE

a!

S

x

x

&

x

e

x

x

g

x

e

x

:

5

x

x

a

a

x

£

5

S

a

z

8

x

x

5

5

x

a

&

x

S

=

x

q

x

x

x

x

x

g

s

x

x

5

a

g

x

a

5

s

x

5

*

x

x

x

8

TARARRARAALAAAATAAALAATAA STARA LARRASARARRRAARARARS AG!

SPE

DOHA PRECAST FACTORY

Besides our internal quality an audit, Doha

Precast Factory is audited annually by Bureau

Veritas and American Concrete Pipe Association

for Q-Cast and BSI for Kite mark, this will keep us

alert to maintain and improve our quality product

and to add more reinforcement to our strong

platform.

Doha precast Factory has the Laboratory accredited by IAS for ISO IEC 17025 for most of

the parameters (34) related to Aggregate test, Concrete Test and Concrete Pipe test as

per BS and ASTM as required by QCS 2014

Handling, Storage and Transportation :

Each shipment of pipes is loaded, should be

blocked and securely fasten to avoid damages

during transportation.

Unloading of the pipes should be controlled by the

customer representative at the site, following Doha

Precast Factory's instruction

Care should be taken to avoid damages especially

the spigots and sockets.

Use appropriate lifting equipments for the

offloading.

Nylon slings are recommended to be used for

offloading and should be used around the pipe and

never through it.

Stacks pipes on even ground on timber to protect

mainly their sockets and spigots. The pipe bottom

must be securely chocked at both ends using

suitable timber wedges.

Rubber gasket should be kept clean away from oil,

grease, excessive heat and out of the direct rays of

the sun.

Installation procedure could be found in the Doha

Precast Factory's technical submittal.

For the Technical and structure details and specification will be presented with Technical

submittal as per project specification or Clients requirements

REAR SAREE ARERR ERR REO OER EE RRO RERERRE RSE RSE RSRRERER RS

i

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

Process Flow Chart

DOHA PREGAST FACTORY

Tok: (974) 4490 3836 Fax: (974) 4490 2835 P.O. Box: 50311, Doha, State of Qatar E-mailalSdohaprecast.com, Web: ww.dohaprecast.com

SPF! DOWA PRECAST FACTORY

ila AD GE As jal gia SOT

Process Flow Chart

APPENDIX?

fev. N02

Date:01-082015,

[“ciStomertnuiey order

(Clere/custorer)

Verlistion Forder

(su

(Georanaton& Doainent Canal

{oocument controler & IT service)

"Ghent

fe “Satna

Messier

R

z

4

g

“Thi Party interested

-aicroe

(ent customer

Lega Requrements

SE Aspects

Health & Safety

s&- Environmental

Beoctonnenet

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

Organization Chart

DOHA PRECAST FACTORY

Tek (974) 4490 3836 Fax: (974) 4490 2895 P.0. Box: 50311, Doha, State of Qatar Emaltmail@dohaprecastcom, Web: wwn.dohgprecestcom

‘Rew 10 Dated: 0107-2018

Conractng Company

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

Location

DOHA PRECAST FACTORY

Tek (974) 4490:3836 Fx: (974) 4490 3835 P.O, Box 50311, Doha, State of Qatar Emalimaédoheprecastcom, Web: win dohaprecastcom

HBK A

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

Contact List

———

DOHA PRECAST FACTORY

Tel: (974) 4490:3896 Fax (974) 4490 3835 P.0. Box: 60311, Doha, State of Qatar E maitmall@doheprecast.com, Web: www. dohaprecastcom

—

POM. PRECAST FACTORY

Key Personnel Contact Details

Name Designation E-Mail ID Contact

Number

Mr. Nasser Kammar | General Mana: hasser.kammar@dohaprecast.com | 55574196

Mr. Rajarethinam —_| Factory Manager raja@dohaprecast.com 55852361

Mr. Rami Barhowm | Operation Manager arhowm@dohaprecast.com | 55828142

Mr. Wassim Ibrik —_| Maintenance Man: wassim.ibrik@dohaprecast.com | 55665958

Mr. Jebin De Rose | Production Engineer _| jebin@dohaprecast.com 70592403

Mr. Khaled Kammar | Production Engineer | Khaled.kammar@dohaprecast.com | 33742110

| Mr. Ahmad Masri | Maintenance Engineer | ahmad.misri@dohaprecast.com | 50191196

Mr. Al Gerry QA/QC Engineer gerry@dohaprecast.com 66866507

Mr. Nair AV Secretary mail@dohaprecast.com 66076783

Mr. Tawfik Administrator tawfik.amin@dohaprecast.com —_| 33400872

Mr. Emil Coordinator emil@dohaprecast.com 66611782

Mr, Sameeh Accountant sameeh@dohaprecast.com 55124469

Mr. Safeer ‘Store Keeper safeer@dohaprecast.com 30957936

Mr. Ram Kisun Delivery Clerk ram.kisun@dohaprecast.com 50040642

Te: (974) 4490 3836 Fax (974) 4490 3835 P.0. Box: 60311, Doha, State of Qatar E-mailmalSdohaprecastcom, Web: wnw.dohaprecast.com

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

Certification

Tek: (974) 4490 3896 Fax: (274) 4490 3835 P.O, Box 50311, Doha, State of Qatar E-mailmailBdohaprecast com, Web: wwn.dehaprecast com

SSSI

Sram HBK

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

Trade & Commercial Registration

DOHA PRECAST FACTORY

‘Tek (974) 4490 3836 Fex: (974) 4490 3835 P.0. Box: 50311, Doha, State of Qatar E-mailmail@dohaprecast.com, Web: www dohaprecast com

2019/08/29 cacllall aul (Be ~

Nol of1 18) aan \;

Registration and Commercial Leauuill Sylal

Licenses Department BJLAUig aLiS UI 6 jLig aylall yaayllg

Ministry of Economy and Commerce

TO

2013/09/12 :anayljlanl yt 69492 sail a5)

2020/08/29 :anyl claw ay sis

“(BISSUTUOSET MMM) aySGEM

SVI 843 UO punos aq UeD adovs ay, “uoRepa.00e Jo adors pancudde ayy u! payst] spoyyaLL 3593 B43 404 payIpe.00e udaq Sey

ue ‘savsoresoge; uonjeiques pue bunsaj Jo 22ua}adwo> ay) J0J SjuBUIa/NNbes [2/9U29 'S00Z:SZOLT PAePUEIS I3I/OSI WIM

soueliduio> payensuowap sey ‘(68d¥) SeHoIei0qe] GuNSA 404 eLaI119 VOReW"pa.ooy ST aU3 Jo SWSWSUINba! ayy Jw Sey

§29-1L Mioyesogey SunsaL

‘vv

vHOG

WRILSNGNI GIvssaW

TZ!ON Avid

AYOLIVA LSVIAUNd VHOG — ANOLVHOSV1 90

soy 1sayyo 01 1 sty,

NOILVLIGAYDOV 4O ALVIISILYSD

eA IAUIS Fay

NOLWIG3YOOV Fa 77 f

TWNOLLWNUAINI 2

P70 ACCREDITATION

INTERNATIONAL — <2».

SERVICE" aS

SCOPE OF ACCREDITATION

TAS Accreditation Number

1-675 ]

‘Company Name

‘QC Laboratory - Doha Precast Factory

‘Address

Plat No.:21 Messaid Industrial Doha Qatar

Contact Name

S. Rajarethinam QA & QC/Technical

Manager

Telephone

+974-55852361

Effective Date of Scope

November 16, 2016

‘Accreditation Standard

ISO/IEC 17025:2005

cur

ASTM C88,

ASTM C117

ASTM C123

ASTM C127

ASTM C128

ASTM C131

ASTM C136

ASTM C138/C136M

ASTM C142

ASTM C172/C172M

Standard test method for soundness of aggregates by

Use of sodium sulfate or magnesium sulfate

Standard test method for materials finer than 75-ym (no,

200) sieve in mineral aggregates by washing

Standard test method for light weight particles in

aggregate

Standard test method for relative density (specific

gravity) and absorption of coarse aggregate

Standard test method for relative density (specific

gravity) and absorption of fine aggregate

Standard test method for resistance to degradation of

‘small size coarse aggregate by abrasion and impact in

the Los Angeles machine

Standard test method for sieve analysis of fine and

coarse aggregate

Standard test method for density (unit weight), yield and

air content (gravimetric) of concrete

‘Standard test method for clay lumps and friable particles

in aggregates

Standard practice for sampling freshly mixed concrete

International Accreditation Service, Inc.

3060 Saturn Street, Suite 100, Brea, California 92821 U.S.A

Telephone +1 562-364-8201 — [ASInfo@iasonline.ora

ww. Jasonline,ora

Page 1 of 3

SCOPE OF ACCREDITATION

ASTM C231/C231M Standard test method for air content of freshly mixed

concrete by the pressure method

ASTM C535 Standard test method for resistance to degradation of

coarse aggregate by abrasion and impact in the Los

Angeles machine

ASTM D75/075M Standard practice for sampling aggregate

ASTM C702 Standard practice for reducing sample of aggregate to

testing size

Bs 1881-122 Testing concrete- method for determination of water

absorption

BS EN 932-1 Tests for general properties of aggregates- methods for

sampling

BS EN 932-2 Tests for general properties of aggregates- methods for

reducing laboratory samples

BS EN 933-1 Tests for geometrical properties of aggregates

determination of particle size distribution- test sieves,

nominal size of apertures,

BS EN 933-3 Tests for geometrical properties of aggregates-

determination of particle shape- flakiness index

BS EN 933-7 Tests for geometrical properties of _aggregates-

determination of shell content - percentage of shells in

coarse aggregates

BS EN 933 -8 Tests for geometrical properties of aggregates

assessment of fines- sand equivalent test

BS EN 1916 ‘Annex C: conerete pipes and fittings, unreinforced, steel

fiber and reinforced- test method for crushing strength

and annex E clause E-4, E5.1, and E5.2: test method for

water tightness

as 5911 Dimension Test (ennexure-D)

8S EN 12350-1 Testing fresh concrete- sampling

BS EN 12350-2 Testing fresh concrete- slump test

BS EN 12350-6 Testing fresh concrete- density

T6875 <>, Page 2 of 3

QC Laboratory - Doha Precast Factory cad)

BS EN 12350-7

BS EN 12390-1

BS EN 12390-2

BS EN 12390-3

BS EN 12390-7

BS EN 12390-8

BS EN 12504-1

TL-675

QC Laboratory - Doha Precast Factory

SCOPE OF ACCREDITATION

Testing fresh concrete- air content- pressure methods

Testing hardened concrete- shape, dimensions and other

requirements for specimens and moulds

Testing hardened concrete- making and curing specimens

for strength test

Testing hardened concrete- compressive strength of test

specimens

Testing hardened concrete- density of hardened concrete

Testing hardened concrete- depth of penetration of water

under pressure

Testing concrete in structure- cored specimens- taking,

examining and testing in compression

Page 3 of 3

Kitemark® Licence

No. KM 590202

The licence is granted to:

Doha Precast Factory

Plot No 21

Gabbro Area

Mesaieed Industrial City

PO Box 50311

Doha

Qatar

In respect of

BS EN 1916 & BS 5911-1

Concrete pipes fittings and ancillary products

This issues the right and licence to use the Kitemark in accordance with the Kitemark Licence Conditions of

Contract governing the use of the Kitemark, as may be updated from time to time by The British Standards

Institution, and as approved by the Registrar under the Trade Marks Act 1994 (the "Conditions". All defined terms

in this Licence shall have the same meaning as in the Conditions.

The use of the Kitemark is authorized in respect of the Product(s) detailed on this Licence provided at or from the

above address.

For and on behalf of BSI:

Gary Fenton, Global Assurance Director

First Issued: 19/10/2012 Latest Issue: 19/10/2012

raising standards worldwide™ age 1 of 2

‘eres me nao Th ii Sarr neon asa serena Rg eh ey er A A 8D

Intermain an contact BS, Koma Court, Davy ene, Knowl, itn Koynes HKG EPP To = B45 089 BOLO. BSI Assurance UK Lind oistod in

rfanunior nano 8021 a 389 Cnet gn oad, Lndon a SA, UR. men tw Eh Srp et Cons 7

Kitemark® Licence

No. KM 590202

BS EN 1916: 2002 Concrete pipes and fittings, unreinforced, steel fibre and reinforced.

BS 6911-1: 2002 Concrete pipes and ancillary concrete products. Specification for

unreinforced and reinforced concrete pipes (including jacking pipes)

and fittings with flexible joints (complementary to BS EN 1916:2002).

ular Concrete Trench Pipes

DN 200 to DN 3000

Circular Concrete Jacking Pipes

DN 200 to DN 3000

: : -_

First Issued: 19/10/2012 Latest Issue: 19/10/2012 ne eo

raising standards worldwide” page 2082 pon

‘Tis cance rr 0 poor The sh Starrs stun anshall be reer ney pen ret T ek ay phon (45 0809200

Informaton and contact 551, Kumi Cost. Day Avenue, Knowl Mion Koynes MKS BPP, Te 44 4S O80 200. BSI Assurance UK Lined, episred n

England under nonbor 780521, at 360 Chiswick igh ona, Landen, Vt AL, UR-A mamba’ of be BSI Gro. of Comriog.

M10JIDY JSVIAIg DYOT

‘smeT-Ag pue uonnjysuos oy} Aq popraoid so8optatid pue

SIYSII OY} [Te YIM SoUDT[9Ox9 SuLNjoR;NUEUI pue

sonovid ssoursng Jo sprepurys soysry oy 0} SuNQLUOD

Jaquia|y jeuoleuse}U]

uoje|loossy

did 9}0190u0D

UeoueWUYy

6

Certificate of Compliance

Awarded

Storm Sewer and Culvert

Pipe and Manholes Plant

By

O°

y

American Gonerete Pipe Association

5605 N MacArthur Blvd.

living, TX 75038

‘This Certificate represents that at the time of the audit,

Doha Precast Factory

Doha, State of Qatar

was manufacturing precast concrete pipe in accordance with ACPA QCast Manual,

Version 2020 guidelines and that sufficient and appropriate procedures and

‘documentation of the manufacturing process were in place as evidence of continued

manufacturing practice in accordance with those guidelines.

This Certificate of Compliance is awarded annually on the basis of successful

completion of a compliance audit performed by Wiss, Janney, Elstner Associates,

Inc. This Certificate is valid until:

October 1, 2020

Margarita Takou Jake Jyrkama

QCast Manager Chairman

‘American Concrete Pipe Association Quality/Safety Committee

INTERNATIONAL

: ACCREDITATION

SERVICES

Brea, California, United States of Ame:

Doha Precast Factory }

‘An IAS Accredited Testing Laboratory

P. comply with the ISO/IEC Standard 17

the laboratory,

CP. Ramani, P-E., C.B.0.

1AS President

fo7-N i

Outstanding Plant

Awarded To

Doha Precast Factory

beter Peer tee

Re ereceey oes Meee Pa ee

Nanhales of any O-Cast plant

2016

British Safety Council

— Member —

Vatid unti Sth March 2021

This is to certify that

Doha Precast Factory

as a member of the British Safety Council, is committed

to keeping people safe and healthy at work.

Yel i eae ome 4\60

oe

Lynda Armstrong OBE Mike Robinson feo f YEARS

Chair of The Board of Trustees Chief Executive 4 11957-2017

by Guranon) Rogier in Erland and Membership numbor

No 1097271 and OSCR No, SO27098,

soesnaes.

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

Safety Certificate

DOHA PRECAST FACTORY

Tok (974) 4490 3836 Fax: (974) 4490 3835.0. Box: 50311, Doha, State of Qatar Emaimall@dohaprecastcom, Web: wmv. dohaprecast.com

TINTS 01 a1Gedva Ajornjosqe aq or AYOLOVA LSVOTUd VH

| W-WANG PHE STI V-VALG “1-1 165 SA “9161 Na Se spo Surmoyjoy axp Buy

Auygendy ayejduioo ay jy) or ,0Ad UI aoUDIJaOx9 ZUNIqIYXa 405

4£1099kJ JS¥I9.1g YO

0} papreame St deOIIWOD sty],

SMR

+norpeisasddyy yo ageaizry sag +

SRE

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

Catalogue / Brochure

—

Te: (974) 4490 3836 Fax: (974) 4490 3835 P.O, Box: 50311, Doha, State of Qatar Emalmall@dohaprecast com, Web: wi dohaprecast.com

Convaciag Company —

aa

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

Mix Design

DOHA PRECAST FACTORY

Tok (974) 4490 3836 Fax (974) 4490 3835 P.O. Box: 50311, Doha, State of Qatar EmaitmallGdohaprecastcom, Web: www dohaprecast.com

Doha Precast Factory

Po.BoxiNo.90341, Tel: 00974 4490388, Fax: 40874 4490285, Dohs, Slate of Gatar, Emall: mali@dohaprecast.com

ee

Ayla JAN ul gill Ga pall inane

Concrete ClassiGrade

Required Strength

Concrete Mix Design

cr50

50

Dry Cast

Nimm?

carro

Rev. Datee1-042019,

2811212019

Date of Trail done

at 28 days

Use in Reinforced Concrete Pipes as per BS §911 P1 and BS EN 1916

Project Design & Build for FIFA Readiness Project 3A Surface Water and Ground Water Network at Al

‘hee Thumama Scheme

Client ASHGHAL Mix Referance : C-50-3.0-H-2

Consultant Khatib & Alami Contractor HBK Contracting Co, W.LL

ater Cement Ratio 025 Total Cementatious Material 440

[Target Strength at 28 Days Nimm? |Target Slump at 15 minutes -

rie pes [Absolute ‘$80 | Moisture | Corrected

Materials source | Gravity |A¥59"™!°") yojume | S484 | Weight | content | Weight

kgim? % m % | kgim® %

20mm Gabbro | PMC Cater 32 639

2

& | tommcaobro | apuc-cater | 2921 0.50 0.191 28 559

B [erates conc caar | 2512 os | os | 40 798

nd

a | a

g oPc AlKhalj- Qatar | 3120 0.064 45 198 : 198

2 ‘Al Jabor Cement

: SB} soes Industies Co, 2860 oo77 50 220 220

a ica AiStam Al

S| miostca | eer traing | 2200 : 010 5 2 22

S| adminture | MMREPCE | 4994 one : 22 22

€ 350

=

ZL}

| Potable [Katranmacetar] 1000 ; 4110 : 91

=

Air 2

Total Volume

Theoretical Density_ 2548 2548

Slump After 15 minutes Nil mm Strength at 7 days 548 Nimm?

Concrete Density 2540 kglm? [Strength at 28 days 65.6 Nimm®

19% [Concrete Temperature

Durability Target

10 mm

$1000 Coulombs

7 DOHA PRECAST FACTORY _|

Compressive strength of test specimens BS EN 12390 P 3

Date of Test /Report Date 31/12/2019

1

Test 1D/ Report No. 20191228-11-1-CS

‘Sample 1D /20191228-11-1

‘Sampled Date 28/12/2019

‘Material ||Mix Referance : C-50-3-D-H-2

In tab

{Dry Cast

_JAs Per BS EN 12350-1

thod Variation

Sample Temperature

Degree

4B

‘Doha Precast Factory

‘Trial Mix.

"Design & Build for FIFA Readiness Project 3A Surface Water and Ground Water

‘Network at Al Thumama Scheme

HBK Contracting Co. W.LL

|ASHGHAL

Khatib & Alami

Nit

ics

1As Per BS EN 12390-2

i 2 3 a] 5 | 6 |Remans

31/12/2018 31/12/2018 04/01/2020 04/01/2020] 25/01/2020] 25/01/2020

days | 3 3 7 7 28 28

mm | 1500 | 1499 | 1503 | 1507 | 1503 | 149.6

mm | 149.8 | 1501 | 1502 | 1500 | 1507 | 149.8

mm | 150.2 | 1497 | 1496 | 149.7 | 1498 | 150.2

ge | s490 | 2523 | 2523 | 8547 | 8529 | 8490

kg/m*| 2520 | 2540 | 2530 | 2530 | 2520 | 2530

kn_| 909 | 934 | 212 | 1262 | 1492 | i459

mpa| 405 | 414 | 537 | 559 | 660 | 65.1

SF SF SF SE SE Se

HBK wzA

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

DOHA PRECAST FACTORY

To: (874) 4490 3896 Fax: (974) 4490 9835 P.0. Bor: 50311, Doha, State of Qatar E maitmailcohaprecast.com, Webr wa cohaprecast cont

=a aoa

ins remo

or a a IT

TER Bg Teossor O's ey UNA pH] TT

10: BIg CUO SoC)

Gu

SCTE ny Ce BTML

TaD "BuO "TLEOSNON O'a ey lMNSRPUT PSSIESH

soem eee nae

=

aus) 400% Bune00 URI ages SY HOA

Tore ous] © 9 [Se Tor Deora [sei we] ore [a [ome

ow er Peter fea tt Paw fi pow eae ae oo]

eegrenee Te z z |R8), |. RE § | Heel

en smagpees || § gi) dip Poletgisfe i lr

som fet cra OE oe af wae | as) § | g [Fe eck' epee

22D “eyo "TEOS HO O'd KAY IRLASNPUT_POBeSAN | ye

Mowe. yeild eyog | == w eS

oz:t_aWos

dH PuneugM.g, 1FeI8q

oz

(Cons) one Sone ausug ICD RS a

‘did PAE yey 2 1 mwos

(peyinbau 9!) payersur oq of » NOLLD3S TWNIGNLISOT

2yon Suge2uam

Eas =——— ees

Om

HES

7

wae

(ssoupna Cunu) wawe'z asan

‘wu BUN 08 rT

2. 5 ‘oe wom Sea

8 aid 557 5UT ROL

Bier vase Ta Teese GIs Pe

‘RSD WBS HIST OZ-HED SI6T NI Se 5D Sd

rugs 99 wa.

BD Gupeds yada ack tao po pq way ups“

aupun ear as ox wee 0 am @ 305934

‘ew Gupeds poe soup 290 voeURUeS

‘yoy WouRDioueyio poe ULL -2

uu wave svostae Ye Pa eB Sea -T

3519 °PRL Ca) oo Geng eu

‘woRDaS JeU|pNy!EUOT

60 FS PIM

Ee

ee

= RE le 2 ile?

§ Ry 2 i aslgo elas ge

pieces pay np ump asevea in| 2 Eo Po cleo ge| eee

vaacactomenmtares| ys | # | OF ARE MIEGEy 2 A

capers

‘WUE Uy Gu SUORSUAWID Ife "PA}OU SS WUOND SSRIUN -T |NOLLYWYOANI| Va G3YOINTSY Sea 190. 59 wvo

= wee TWNKONLIDNOT ‘WLWO ANAWGOUOINTSE wena

UoRIsod PASOD woes Bunper ae)

(PSULISTUT UO SyISG

es

99, WORDES $501)

Senasetaniase ds me

“SSW SL eES 65

Pec sen Haney

Py 19 79090

Tepe aurea] Guo a a 2 wo any ane

iS pS ues 5

=a ‘tens sagen a ase

]0D PS SSIES Kay :

2411 40H LON BUPHET SPOIL“ OOF20 J O00 |

"Sane moe

spuee leg

remwon ada | E

pewo' eon aso pve] “iC

IA El sones

SUBIC SnaeIS PAIS Bjewa]

Wonisod pes0ID UoReis Duper S\eIpeULSTUT UO SEG)

WwEeE PH PL, ie

ue eins 100 3eGH

-SSHOPIL WUZT araa Bag feUy

sou fi som (a vlo)

PUN cH Od DUD POHOUTY "UL HLT / OOH —_y

SO 9 SEs SREP =

22 Wsca‘THEDEROGOY eV INSTT FRO

vz osse | 9 Ez ‘9 | et | ot loor| 9 |svzx| os | 9 | os | ov | ooor

wu 6y_|"@a_|on |"e1G | “ON ‘sau uu | vuaw run [ead Z “wu

‘ mn 3 LEE BEE) 2

ime SS Tora cee, pony aay il

cer tae e

WNDU wae |

Tha le

Zs

+

* JeTE apeIO(>MA WS)

eT FWoOS TLD SSowpL aqqmy Gupped 22109 (ORS SSBIUIEIS

9, NOLLAS SSOWD— “) "OOF wes rewoya ByseD qaTY WES

(Gouna s) 36a pan TE j= 5

BP Bag

ssouprus Coma) wwe

23zcH iw pour .o9¢ Arewiut

3F == =

% | 000 A] aARPaIE

witeed Sere W697 feo,

iam HBK ~A

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

Jacking Force Calculation

DOHA PRECAST FACTORY

Tel: (974) 4490 2896 Fax (974) 4490 3835 P.0. Box: 50311, Doha, State of Qatar &maitmail@dohaprecastcom, Web: wnw.dohaprecas.comt

DOHAPRECASTFACTORY OFF Gina mange

{Internal diameter of the Joint surface (bdi)

[Bearing Area (Ac)

Ac

Maximum theoretical

design Jacking Load Fimax= _fek x Ac/Factor of Safety

[Closed Joint Situation

[Maximum Jacking Load is Foj= 0.5Fmax MN] 9.6900]

Metric Force Ton, 988.105]

vou 600) 453)

Open Joint Situation

Load reduction Factor (from the Curve 8.3)

[Maximum Jacking Load is Foj-e x Foj Mn

Metric Force Ton

KN

Page Ot of 2

~ DOHAPRECASTFACTORY FF Sua uaa ge

As per BSEN 1916:2002(E) Appendix-B

Nominal!D 1400 _[Out Dia. 1720

Load reduction (eccentricity) Factor e=F,/I Fy as

function of the joint surface diameter - B.3

ad —ayjieros

oe —dites09

8s —ayjae=0839

comath

Factory Manager

Delia Precast Factory

Page 02 0f 02

Design & B Ne AlTThuman

‘ASHGHAL

J Alam

Maximum theoretical

design Jacking Load Fimax= _fek x AcfFactor of Safety 3000.99) 14125.41

[Closed Joint Situation

Maximum Jacking Load is Foj= 0.5Fmax MIN] 16.9500]

Metric Force Ton| _ 1728.419]

KN

Load reduction Factor (from the Curve B.3)

(Maximum Jacking Load is Foj=e x Foj wn

Metric Force Ton|

Kn

Page 0t of 2

“DOHAPRECASTFACTORY Fi Gui sidtiay aa

As per BS EN 1916:2002(E) Appendix-B

Nominal 1D

Load reduction (eccentricity) Factor e=F,,/I Fy as

function of the joint surface diameter - B.3

—si/ée-08

—di/de=09

——di/de=0.858

Sa

S.Rajarethinam

Factory Manager

Dobie Precast Factory

Page 02.0102

DOHAPRECASTFACTORY =F Alu Al isitl nal gia

: ASHGHAL

a

Internal diameter ofthe Joint surface (6)

[Bearing Area (Ac)

Acs (de*-dxm/4 mm] __ 1722600]

|Applying Factor of Safety

Maximum theoretical

dasign Jacking Load

Fimax= feck x AciFactor of Safety

[Closed Joint Situation

Maximum Jacking Load is Foj= —_0.5F max MIN] 25.8390] _ 10.7660)

Metric Force Ton

Ka

Joint Situation

dilde= 0.8510 | 0.8510

zide= 05 05

Load reduction Factor. = e= (ftom the Curve B.3) 0588 | 0.588

|Maximum Jacking Load is Fojze x Fo} wn

Metric Force Ton|

Kn

Page Ot of 02

DOHAPRECASTFACTORY = <2 FAS call 4a ll ghee

As per BS EN 1916:2002(E) Appendix-B

Load reduction (eccentricity) Factor e=F/Fy as

function of the joint surface diameter - B.3

—difde=0.9

—sivee=0.851

sama

Factory Manager

Delia Precast Factory

Page 020102

DOHAPRECASTFACTORY FF 9 Studi Wadia

‘As per BS EN 1916:2002(E) Appendix-B

Nominal 1D

External diameter of ofthe Joint Surface (jde)

Internal diameter of the Joint surface (él)

Bearing Area (Ac)

Ace (de*a?d

Maximum theoretical

design Jacking Load Fimax= _fek x AcfFactor of Safety KN] 66863.28) 27859.70|

|Ciosed Joint Situation

(Maximum Jacking Loadis Foj= 0.5Fimax mn| 33.4320] 43.9300]

Metric Force Ton|3409.115| _1420.464|

Kn

{Open Joint Situation

dilde= 0.8190 | 0.8190

zide= 05 05

Load reduction Factor. = 6= (from the Curve B.3) os7a | 0578

‘Maximum Jacking Load is Foj=e x Foj MN}

Metric Force Ton|

KN

Page 01 of 02

DOHA PRECAST FACTORY aa all al a

‘As per BS EN 1916:2002(E) Appendix-B

Nominal iD 2400 _[Out Dia. 3000 ]

| Load reduction (eccentricity) Factor e=F,,/F,; as

function of the joint surface diameter - B.3

1.

09

08

07

os

ao —tilde=08

04 ~di/de-0.9

03 —difde=0.819

02

oa |

0

S.Rajarethinamn

Factory Manager

Dota Frocass Factory

Page 02 of 2

(Contacting Company mss

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

DPF Brochure

DOHA PRECAST FACTORY

‘Tak (074) 4490 3896 Fax (974) 4490 3835 P.O. Box: 60311, Doha, Stat of Qatar EmaitmallSdoliaprecest.com, Web: www dohaorecast.com

Ca ote

rater

Manufacturer

of world class

Precast Concrete Drainage

and Sewerage System

oP

DOHA PRECAST FACTORY

LoCo ee TaTem Icey (=)

Doha Precast Factory (DPF) is unique: we are Qatar's first and only to design, Manufacture, and distribute

eS oe a Nae coke ace ee nt eee

Since 2008, we are the leader in supplying pipe and manhole systems specially designed for corrosive soils

and GCC ground conditions. Created with the latest manufacturing technologies from the USA and Europe,

DPF products are suited for long-term performance. Our products thrive in open trench and micro-tunneling

(pipe Jacking) requirements for surface water drainage, sewerage and storm-water networks. Our fittings are

‘deal for low head and gravity flow systems, Now we reached to the level of producing Precast Electrical

Scouse ee et eT

ce eee ee ete een eee

recognitions and reputation for high performance, quality and on-time delivery

Quality Control

DPF products were the first-ever products—and still the only—in Qatar to achieve certification in British

Standard Institute's prestigious Kite Mark License for superior quality. Our additional certifications of

10 9001:2008, ISO 14001:2008, and OHSAS 18001, Certificate of Compliance (Q-Cast) from esteemed

‘American Concrete Pipe Association's (ACPA) attest to our unrelenting commitment to top quality. The Quality

control Department achieved ISO IEC 17025 Accreditation From IAS for 34 Parameters of Testing Aggregate,

Concrete and Finished products of Precast.

DPF has a Quality Control & Research Department solely dedicated to ensure full compliance with specifications,

international and local standards, and the detailed Quality Control Program of Doha Precast Factory. The Group

Engineering department provides yet additional support with an experienced team of engineers devoted to

research & development and continuous quality improvement.

Our Design & Manufacturing Processes are according to internal standards of BS, ASTM, ACPA, DIN, ATV

and, of course, our client requirements. We use only superior processed and raw materials—cement, full

rushed gabbro aggregate, sweet water, and various additives—that are constantly tested by our quality

department to ensure rigid control standards. We guarantee the longest-lasting pipes, as our facilities undergo

3rd-party / Clients audits several times a year.

Hs

[\ ea?

» American Concrete Pipe Association Certified (Q-Cast)

» BSI KITEMARK Lic. No. KM 590202 (BSEN 1916 & BS 5911-1)

» ISO 9001:2008, ISO 14001:2004, OHSAS 18001

1SO IEC 17025:2005.

International Quality Crown Award - GOLD Category

Documented quality controlled system to ensure traceability

is (raw & finished product)

One-point access for inspection of all mat

o7

RC Advantages

Choosing DPF's Reinforces Concrete pipe and manhole products just makes sense. Technical Advantages

of controlled conditions and ultimate performance. Economic advantages of reduced project time and

supervision costs, Health and Safety advantages of minimize human activity and shortened construction

periods; Environmental advantages of the strongest resistance against chemical attacks and corrosive

agents, as well as controlled manufacturing processes and minimized construction waste.

‘Our RC concrete mixes out perform all other pipe materials and provide the longest most durable life

cycles compared to any industry alternative over aging 60 - 120 years.

Health and Safety Advantages

From its factory conditions tots products, DPF isabeacan ofhealth Tidy production environments «

land safety, For contractors, choosing DPF precast means: ci WP

No risk of contamination on

Shorter construction periods «

Less public disturbance «

Less dust emmission «

No form work or complicated «

Scaffolding required «

Sharer constructio

08

Environment Advantages Sustainable Concrete

DPF creates the environmentally: friendly solution that is the most sustainable option for infrastucture

development. Concrete out performs all other pipe-materials and is the most reliable choice for

extensive use:

» Withstands corrosive soll and abrasive ground Precast also requires shorter construction periods,

» water conditions (typical for GCC region) realting in:

Average service life of over 100 years

¥ Offers the lowest life cycle cost than any other

» Construction material

ger overtime

> Tolerates extreme temperature fuctr

» Gets st

» Prevents toxin leek into the environment

Product Details

Our technologies allow for any pipe or manhole lerigth. Different types of jacking pipes (ie. micro tunneling)

suitable for long drives- straight and curved with hydraulic joints.

Manhole shaft lenaths may reach and

even exceed 9 meters by incorporating a” landing slab’ technology that allows several pieces to connect.

To guarantee the integrity and life of our products while meeting special client needs, we offer made to

measure and custom dimensions within the acceptable limits of ASTM / BS / ATV guidelines and DPF policies.

‘These are described in detail in our Quality Manual and are addressed by our Client Services team ona

case per approval of clients.

» Alldimensions per approval of Clients

> Reinforcement arrangement per approved di

ings

» External Protection is Cool Tar Epoxy Coating minimum 400u to 1000u t

> Internal lining with GRP, HDPE or unlined per project requirement

> Internal Nominal Diameter range from 200mm to 3600mm for RC pipe

> Internal Nominal Diameter range from 900mm to 3200mm for RC manhole

> Pipe standard effective length 3000mm

> Shaft height maximum 310mm

> Joint type is Socket and Spigot (Rebated)

> Fixed collar joint type for RC jacking pipe

> Concrete minimum grade C50 width high durability suitable for any exposure condition

Handling, Storage/and Transportation

n of transporting the products themselves, ar requesting the service through DPF. We

partner with the nation’s experts in heavy transportation and take every precaution in handling. Loading and

fransporting our products safely and undamaged to project site.

* Each shipment must be blocked andsecurely fastened! to avoid damages during transportation.

» Unloading attsite must be controlled by client representative following DPF’ ingttuctions.

» Care should be given to avoid damages, especially toh spigots and sockets

» Offloading shoulld be executed using only appropri

fting equipment.

» Nylon slings are recortisiended and should be used

Detailed installation procedures and structure specifications may be found in the DPF technical stubmittal, as

per project specification and client requirements.

! Micro Tunneling

i DPF has the facility to produce for the microtunneling purpose like intermediate Jacking station with different

type of flanges and steel/Stainless steel drums and different type of liners.

‘@

DPF can produce from nominal diameter 900mm to 300Umm with different wall thickness and different length

as per project/ customer requirements.

DPF can supply different type of lead pipes which can suitable to any manufacturer of microtunneling

Machines

Dpf can supply different type jacking pipe which can suitable for long drive (Straight) and Curve drive with

hydraulic joint.

Intermediate Jacking Station

RC Jacking Pipe with Hydraulic Joint

13,

Precast Manholes - Technical Advantages

Controlled conitions onthe precast yard / Production Area

rmination risks Guacantees proper handing, storage and inspections

‘On-premises concrete batching ‘

Homageneous extemal & internal coating by specialized equipment F

RT Bs—Tor slab

]

Qualty-cortrelled unt the momentof delivery

rican Concrete Pipe Associatior

008, 14007-2008, OHSAS 18 .

50: certified in 80

tolled system to ensure traceability :

ished) .

ofall materials aw &

Reinforcement ensures the most durable manholes ‘

}-— Reduced Shaft “(especially compared to non-reinforced or cast in-situ .

| Higher Performing Manholes

|

Bonding between iner components and concrete isthe .

pe. ss

Resistance against chemical attacks and ¢

rosive agents A

Is strongest in precast

soit be

Shaft

Joint Detal-A

Base / Benching

Option:

Inner Di

ia Meter: Range from 900 to 3200 mm

Wall Thickness: Upon Approval

Reinforcement:Upon Approval

Joint Type: Socket/Spigot (Repeat)

Inner Liner: Unlined, coated with CTE, GRP 6mm to 12mm

ternal Coating: Uncoated CTE for 250 to 1000 micron

Economical Advantages

Almost 99% reduction of project time

» Construction time reduced from 2-3 weeks{full manhole

system construction! to hardly one hour for installation

of base, shaft and cover slab.

» Preparation activities executed in parallel: advanced

planning and fabrication at the plant premises along

4 with site preparation and build.

j Reduced Supervision Costs

Client and consultant carry inspections at a single

location (batching plant rather than inspectingindividual

stages for each manhole scattered across project site

» The need for inspection of raw materialsand concrete

at ready-mix companies premises is eliminated

Reduced Maintenance Costs

» Concretehasthelongest

» Minimal leakage

» Continuous performance without disruption to utilities

» Easy upgrades and additions to existing networks,

fe cyclethananyalternative

Health, Safety and Environment Advantages

Longest Life Cycle

Concrete provides the longest life cycles (average of 60-100 years) compared to any industry alternative

Tidy Production Environment

No risk contamination by trench collapses, building debris, underground water, etc.

Shorter Construction Periods

Less public disturbance Less dust emission less noise pollution Less (Long) traffic diversion

No form work or complicated scaffolding required

Reduces human activities Lesson risks of accidents and injuries

j Minimal construction waste No need for loose concrete and other raw

material on site Simple delivery from precast factory to site

ony JOINT DETAILS AND DIMENTIONS

ee)

}) OPTIONY BE ae

I art

Wall thickness : Vary depend upon the intent of use

i } Reinforcement ; Can vary depend upon intend of use

Collar : will be Mild Steel or Stainless Steel Collar as per Project Specification

} Effective Length ; From 500mm to 3000 for Short pipes

Reinforced Concrete Jacking Pipe 6 C Short Pipe Integrity : Socket /Plain End, Spigot / Plain End

+ . External Coating: Un-Coated, Coal ta Epoxy coating thickness from 400 micron to 1000 micron,

for Micro Tunneling Construction Internal Li : Unlined, PVC lining, HDPE lining thickness from 1.65 to2.3mm

"omPN 609mm f0 3000mm Dimension Reinforcement and ination details Conerete : Grade from C50 with OPC+GGBS-+MS cement, high durable suitable for

aggressive Exposure Condition

‘pint Detot Service Life span: Up to 120 years

DPF can supply special pipe with Lubricant nozzles to inject grout as per the requirements and specifications

| Reinforced Concrete Jacking Pipe {For Trenchless / Micro Tuncling Construction)

SESE] Se ne ee Ste canremerne eter

cowie

_ | wales

Joint Detail i =

Stainless Steel/ Mild Steet Collar @ @ can

ae EPDM Rubber Gasket

ihsaaeeatieiasitseunaancaienaene al

220 ate Boles Lor |e | oe Dn Ta Tse aa]

"20 | 3a | 300 | 3000 | 1037 | s0n0 3400 2527 | sas a peter

Sanaa SAE ERAS

[ee a ea oar

Pete Sees eared

pee en Daas aor so in do Piet ie]

i

_ — i

PVC End Cap Wooden / MDF Packer i:

19

Special Fittings

Fittings with GRP Joint

Bend with Fittings Model-1 Bend with Fittings Model-2,

Bend with Fittings Model-3 Bend with Fittings Model-4. Tee with Fittings Model-5

22

Tunnel and Vertical Shaft Solution

DPF has the range of Segment production meet requirement of the latest Industry It is designed with

onsideration to ease of construction and speed of installation and offering High Grade of Concrete with High

durability and Stability.

Sealing and Connection

All the segments are pre-ftted with EPDM Rubber gaskets on every segment of shaft or tunnel ining, Cross

Joints connection made using a spear bott passing a pocket on one segment and plastic socket in the

adjacent segment. Circle joints connection are made using bot system, Bots are designed to fully compress

the gaskets.

Concrete Mix and Reinforcement

Each segment is Wet-cast to achieve smooth internal and external finish. The concrete mix is provide the

grade C55 and above with OPC, GBBS and Micro silica blended cement giving high durable concrete for

any exposure Condition. The segments are reinforced with either a reinforcing Cage or Steel fibers to suit

specifications.

The Segments rings are suitable for Vertical shaft construction and Tunnel lining,

Prestigious Clients

Js jill bo4 &

Qatar Petroleum temas

y

fas

Ms

CERTIFICATE

QUALITY EXCELLENCE

DOHA PRECAST FACTORY

KK

are

+ KAHRA' MAA

Sentence Sh cies

Certificate of Compliance

we 4

RasGas)— RAIL 3.

e

AT

Leste ART OF REAL ESTATE anal clizallegsite

NEW PORT PROJECT

be Lesa, ah

Map Desilatsl

(qua cera Bey ae Coprton

<==

EqoHhb

ube Ug simi, bs

Qatar Deserves The Best

CERTIFICATE

QUALITY EXCELLENCE,

DONA PRECAST FACTORY

Certieate of Compliance

‘Storm Sewer and Culvert

Prestigious Clients

Jo full bad & GI

* owen oe oronusy ‘nd nmig| 9

womnnrsvoy | a ee ronis| sounder]

wewsosioy | a el ‘aronasy reed aR Pe st |

x =o SEE Towers ser wadionmangaminen| ¢

wmKioseoy 7 rawne | amen | MEEBO | cme | cron swuggoo mem sug emer]

loan oseo¥ a smo ARON a WawaHDOY 44d retencr sal ‘Supein) 1

pai aa eS a :

‘PUD TUNA Ty IP HLOMION IVER PUNDIT Pl ook

-BWwAL DEFINE VE Hoforg ssIMIPERY VATA 10) PLING UBISI Fefoad nasty > aneuy, aueyinsuo3)

TTA05 Sup2e2009 ER 0) “VAOHSV woo}

woumare | POUT DAd / Fal 2dig Supioep Qu wvia BUNS], paw uonsadsuy =e

Liowasiot | AWOL LSVDIRE VHOG SG

rezvtes

¥ ee ae)

¥ =D A copes smaR|

x some A wale

. ; wopemes eM) €

* : wopbosay Sen]

f ony [Sasa SCA) 1

10) Suamusmnboy Axzadoaq|

sant weno ne ey

* " 1) Bag 200 fa 207

x so mv wrwononnuss] 2.052 Amen agsads

S-4 $-S P107 S90 20d se soumrUpy|

x sma ¢ seven ounsens| ¢

* — sano] ¢

1 vm A “ie

7 wows vsionusy] — maueg mpeg mug] 1

TEL Ed $$ F107 S90 40d se sqesarE TN snoppusUIaD|

H Sm vere 9

4 a 1 Sapeclennaaery |<

‘sre ‘Sprout ‘uo pono

x “vgs ee sepmo unps wareanto neary]

x a “ees a

. ys pa srewogieg env]

x some am as 208%) swims]

sae vw cosh .e ses en

x sent en 2 11959) wen909 eM]!

seq aoepg Ye aloud SOMMER VALE 29} PNG 7 HDC

TTA "09 3un2enW09 YEH

ep Ld $-S $107 $90 0d sw aoye 4 Burry Jo uopeyy eonI949|

emery ane

VHOHSV

yeuyynsu0.3}

suo.)

POUYT DAd /daH WIA oid SuppUr Du - weld TupsaL, pue wonsadsuz Tannese

LO-M-SIAL

AYOIDVA ISVOAd VOT

aC

estoy

wereseos | wa | smemota |, “stone. l ‘yseoq amie ysl] ot

vomeresion | wa | ommmoae | ages en | amnodimmanaeg inn) 6

weuwsras | wm | smemmora | Ome, ents soni] wong ayamouey ysis)

vosuwsros | wim | ssemmeoeg | ERO eee rexcvas] —— damsaaanog geal

w9 sui sas mtey tung sts] wouMEDW N89 98:09) 9

9 sono a aac =s nee ere

= m2 toa anna ey mn sexu perma

aces

ae | mo ca =a

Taste sia ee

mason ane

‘19 sa] SupmE Aypoeq "mu mssayy|

sevaoy| eusmsey| ¢

fd 8S F107 SOO 0d se YSN Joqqmy)

sors 194 jonwon]

‘es nog ey m0 coms wone@uor|

osu versio) fer oor ma [sme He (com) somnoos as] gerrsw'y zav HS} eee

ass $102 $90 20d se 29920005 20 uomasi0ju5>4|

20844 20851ms VE HofoLg SSOUIPHOM VALE 05 PINAL? UHI — PAO rmeyy ane

TTA SupseqWeD we _—_:0I9E.IH0D “VHOHSY yuan]

manner peu] DAd / AdCH WM adid Buppe¢ Dy - weg Base], pus wosodsuy a

siowa-sit_| ‘ AYOLIVA LSVIAYd VHOT =2G

revateg

woyg go muaumboy| Jo se 2043055] 99 130 Kona paw HU ase “2

‘woganpoig 0 iis Aso pu sepa 98s Abas uo OW Hey ORRELNIWOD pF BUPSOHD FESLA-L

SUM FOUTS HOH ‘Sede ON,

Tm = waa mae Tama ~ Ra ar

som ee SET rca TT

sme IHD JO mr taoldy won | aia - -

face st i = re

MeiaiienauameL | eeeia | wim Sou seneaie Somat] noua y Koga)

“PRndnes ge spasdoper per au

| stscainn | | mm en rma)

era! wormaao | aD | mmm | ma TEL) a

wommmoenn | weuosiu | xa | omemoca [muRTCo! verpeotemuma)

voneses | xm | socumaia weLrora] 9

yet ser.

wera moseat ed senepeenss a) mo] S

romacoses | wn | someone reiomoni| +

omnes | wn | emmmoee |, (80NTT vs ano] summa]

peat romaseai30 wm orem |, row mony corres] jruanergaa daa ato) 2

orm

nat ade rMN gio 19st oH HEN ‘aoean03 smUNOS . i

evairaantney | “s susvorosc isa | Mearosseaey asec] 1

‘ad ge ror

[oats ean

Jo somerset

mo | smounysa [essere :

xo | mmo | wea CS] wtatentons 229]

wma | mio or tno ee oe

tone ears m9 ey sd 2 IER] gonenytods samoxseany| a

e813 nto ninetons een] eet Onaaaan eure

vowureaee | nro wn ato es ee

ery 3 aE jweyinsuo)

ATA" SupseWD Wa __:40)9631U05 ‘VHOHSV suom19

nennerete peur DAd / dd adid 8uppur Ju - Wid Supsa, pur uoHsadsuy ere

L10-Md-SINL AXOLIVA LSVITd VHOG at!G

AnwAA aoE}NS VE Jaforg ssMIPHIY VATA 10} PENG 7 UBIS9C

IA

Design & Build for FIFA Readiness Project 3A Surface Water and

Ground Water Network at Al Thumama Scheme

Material Safety Data Sheet

rc

Tek (974) 4490 3896 Fax: (974) 4490 3835 P.O. Box: 50311, Doha, State of Qatar E malt mailsdohaprecast.com, Web: www dohaprecastcom

—Z___

4 [SPEC

Specialities Construction

Chemicals Pectory

© Identification of the si

SAFETY DATA SHEET

KUT PLAST PCE 350

REF.: ADM-3964HC-0215,

© Description

‘A Superior High performance concrete Hyperplasticiser based on

polycarboxylate technology

© Company identification:

Manufacturer :

© Hazardous Constituents

Component

Polycarboxylic ether

Water

© First aid measures

HEALTH EFFECTS

Eyes:

May cause eye imitation by

‘mechanical abrasion

‘Specialities Construction Chemicals Factory

Doha Middle & small industries Area,

Road 340 Area 81

P.O. Box 7453,

Qatar.

Tel.: 974 40291992

Fax: 974 40290755

Gast ‘%Range Primary Hazard

27599-56-0 40-44% -

~ 56 -60% -

EMERGENCY & FIRST AID

PROCEDURES:

Ringo oye immediately with plenty of

Water for at least 15 minutes. Obtain

‘medical attetion

‘SPECIAL PROTECTION

Wear chemical safety goggles. If 2

respirator is required, use full face

mask to protect eyes from vapor or

mist.

‘Skin

Prolonged or repeated exposure

may cause skin irtaton or allergic

skin and respiratory reactions.

Wash hands with water as a

precaution

Page 1 of 3

‘Skin contact can be minimized by

wearing protective clothing and

impervious gloves, Launder clothes

balore use

Inhalation:

‘Vapors and aerosols can initale No special measures required Use in woll vontiated areas only.

respiratory passages. Severe Wear an OSHA approved type C air

overexposure may lead to supplied respirator if ventilation is

pulmonary edema, inadequate to keep vapors and mist

below the TLV,

Tageation: ~

Single dose toxicty is extremely Rinse mouth, ‘Avoid airborne mists which can be

low and not lkely to cause injury, inhaled or swallowed. Use protective

(Deo (rat) >5 mgikg, mask #f necessary. Provide general

ventilation or exhaust to control

airborne levels below exposure

‘guidelines

© Fire Protection

Flash Point: Not applicable

Auto ignition Temp.: Not applicable

Flammability Limits: No data available.

Extinguish Media: water spray, foam, carbon dioxide

Special fire fighting procedures: Fire fighters should wear self-contained breathing apparatus

and protective clothing,

Fire and Explosion Hazard: None.

© Physical Properties

Solubility: Soluble in water

Appearance (Color, Odor, etc.): Light brown liquid, odor - Mild

c

sity (Air = 1):

300 #100 eps

Percent Volatile (Volume) :

© Environmental Protection

Limit of tolerance concentration in fish inhabited

Water: 10 mg/l

LD50 for fish: >500 mail

BODS: about 300 gil

COD: about 1200 g/t

Total time of biological and chemical oxidation: 150 days

Page 2 of 3

© Stability & Reactivity Data

Product is stable for several years under dry storage conditions

© Conditions to avoid: Dusting

©. Materials to avoid: Not known

© Hazardous decomposition products: Not know, in normal conditions of use.

© LD50 oral (rats): > 2000 mafkg

© Dermal: Non iritant

‘©. Eyes: Non iritant

© Handling & Storage

© Handling: usual protection for handling of chemicals. Avoid dust generation. Ensure adequate

ventilation when handling. Dust mask recommended,

© Storage: Keep containers tightly closed, keep in a cool, well-ventilated place. Avoid contact with

strong oxidizing agents.

© Transport Information

(© The product is not classified as dangerous in the meaning of transport regulations

Page 3 of 3

O

OD

En

, Nl

SAFETY DATA SHEET aA.

4: IDENTIFICATION OF THE SUBSTANCE/PREPARATION OF THE

‘(COMPANY/UNDERTAKING

Product Name; NITOCOTE ET402 HARDENER

Application: Hardener component of high bull coal tar epoxy coating.

Company: Al Gurg Fosroc LLC

‘Address: P Box 857, Dubal, United Arab Emirates

Telephone: +871 4 868606 Fax: +971 4 959649

2: COMPOSITION/INFORMATION ON INGREDIENTS

Composition: coal tar pitch, alpnatic amine, plastioisers.

Hazardous Ingredients) Symbol_—_—=lsk Phrases ther information —_%6

coal tar pth T RAB 46/47 (cas No: — >50

dethylenetiamine c 21/22, 94, 43 CasNo: 111-400 >1025

‘Al constituents of this product ere listed in EINEOS (European Inventory of Exising Commercial Chemical

‘Substancee) or ELINCS (European List of New Chemical Substances) or are exempt

Fifer to Section 8 for Oocupational Exposure Limits

8: HAZARDS IDENTIFICATION

Hay one cot

somes sune, @] l=

May cause snaiiaton by sn contact. Se | |e

TOXIC _ CORROSIVE

4: FIRST AID MEASURES

Eyes: Irigate Irmediately with coplous quantities of water for several minutes. Obtain medica! attenton

urgenty

Skin: ‘Wash Immediately with soap and water or sultable skin cleanser. Obtain medical advice tf skin

disorders develop.

Inhalation: Remove from exposure. If feeng unwell obtain medical attention urgenty

Ingestion: DO NOTinduce vomiting. Obtain medical attention urgent, Beware of aspiration if vomiting occurs.

—_— eee

&: FIRE FIGHTING MEASURES

‘Carbon dioxide, powder, foam or water fog ~do NOT use water jets.

Suitable Extinguishing Media:

Iaeve No: Ot Date: 01.08.97 Preduct Name: NITOOOTE EP402 HARDENER Page of 4

D

‘Special Exposure Hazards: Toxic fumes, Nitrogen compounds.

‘Special Protective Equipmer ‘SeF-contained bresthing aoparatus.

@ ACCIDENTAL RELEASE MEASURES

Wear suitable protective clothing, gloves and eye/iace protection.

Personal Precautions:

Immediately issue NO SMOKING AND NO NAKED FLAMES warnings.

Environmental Precautions: rovont entry into drains, sewers and water courses.

Decontamination Procedures: Soak up with inert absorbent or contaln and remove by. best avatable

means. Gather into containers. Dispose off as waste.

7: HANDLING AND STORAGE

“To avoid the possibly of skin clsorders, repeated or prolonged contact with products ofthis type

Handling:

‘must be avoided. ft ls essential fo maintain a high standerd of insufficient ventlation, wear sultable

respiratory equipment.

Storage: _Storo away from sources of lgntion. Keep away from foodstuffs and food containers.

@ EXPOSURE CONTROLS/PERSONAL PROTECTION

(Ccoupational Exposure Limits:

‘Substance 8 Hour TWA Source/Other information

‘coal tar pitch volatiles 0.44 mgr EH«0 Table 4

22iminodietnyamine 4 mann? eo

(Gotnylenctriamine)

Engineering Control Measures: Use only in well ventiated aregs. Mechanical methods to minimise exposure

‘must take precedence over other personal protective measures.

Personal Protective Equipment: A high standard of personal hygiene Is essontal. Avold skin end eye

Contact. Safely glasses/goggles. Impervious gloves (e.g. PVC). Change

Contaminated clothing immediately and clean before re-use. In case of

Ineuffcient ventilation wear sultable respiratory equipment,

8: PHYSICAL AND CHEMICAL PROPERTIES

Physical State: Viscous quid.

Colour: Brack,

(Odour Pitch

Boling PoinRange (0: 200

Flash Point (closed, °C) 105

Autofiammabilty (C); ‘Autoignition temperature: }-400

Oxidising Properties: Not appicable,

‘Vapour Preseure (kPa at 20°C): 0.02

Relative Density (at 20°C}: 1aT

Water Solubility: Insoluble,

Iesue No 01 Date: 01.0887 Product Name: NITOCOTE EP402 HARDENER Page 2ot4

7

—_———

10: STABILITY AND REACTIVITY

‘Stabe fused as directed.

Stability:

Conditions to Avoid: Any source of ignition:

Materials to Avoid: Strong oxicising agents. Strong acids, Strong alkals.

Hazardous Decomposition Products: Thermal decorrposton: toxle furs. Oxides of carbon. Nitrogen

‘compounds.

——

11: TOXICOLOGICAL INFORMATION

‘Tho folowing toxcological assessment is based on a knowiodge ofthe toxiclty of the product's components

Health Effects

On Eyes: Severe irtation, Causes kroversible damage to eye tissve ifnot removed prompty.

(On Skin; Corrosve - causes burns, May cause sensitisation,

By Inhalation: Mey cause respiratory initation.

BBy Ingestion: Corrosive - cause sever damage to mouth, throat and digestive tract.

Chronic: Repeated and protonged contact ald to poor personal hygiene practioes may result In skin cancer.

esses

42: ECOLOGICAL INFORMATION

‘When used and disposed of as intended, no adverso environmental effects

Environmental Assessment:

sare forosoon.

Mobiity: Insoluble in water.

Persistence and Degradabilty: Not reedly biodegradable.

Bioaccumulative Potential Not determined,

Ecotoxio! Ecotoxic to fstvdaphnia/elgae.

—_—_———

48: DISPOSAL CONSIDERATIONS

‘Disposal must be F accordance with local and national legisation.

Dispose of through an authorised waste contractor toa foansed site.

Unused Produ

Used/Contaminated Product: As for Unused Product.

Packaging: “The method of dsposal must be acceptable tothe local authority.

ge

14: TRANSPORT INFORMATION

UN/SINumber. 1760

Imo: Chass: 8 Packing Group: Marine Pollutant: Yes

IATMICAO: Class: 8 Packing Group:

ADR: Cass 8 Item: CT)

‘Transport Name: Corrosive liquids, nos (clethylenetramine).

Hazchem/Kemler Code: 2x80

mane Waa ot poh REE OREN Pett]

15: REGULATORY INFORMATION

Hazard Label Data:

Named Ingredients: > al tar pitch

ethylenetriarine.

UN Number: 1780

symbol(s): ne

Fisk Phrases: ‘ay cause cancer. Causes burns. May cause sensitisation by skin contact.