Professional Documents

Culture Documents

TP DATA 5 - Mode Fourière Correction

TP DATA 5 - Mode Fourière Correction

Uploaded by

Márton ŐriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TP DATA 5 - Mode Fourière Correction

TP DATA 5 - Mode Fourière Correction

Uploaded by

Márton ŐriCopyright:

Available Formats

TRAINING WORKSHEET

HEADLAND 2017

H2 16 MF8700 Dyna-VT

Allocated time : 2h00

Tractor model: ………………………

CAUTION:

Before starting to use and drive the tractor you must respect the

following instructions because of Health and Safety requirements at

Beauvais Training Centre:

- Put on the rotary beacons, if the tractor is without beacon use the

hazard lights

- 2 people inside the cab, nobody on linkage or footsteps, it is

recommended to use the seat belts whilst driving on road, track and

in the field

- Max speed on the test track 15 kph.

- Drive anticlockwise on the test track.

- When you don’t drive, stay Park in the centre of the test track.

Thank you.

International Technical Training Beauvais 1

TRAINING WORKSHEET

DATATRONIC 5 CCD

1. Which software version is fitted on the Datatronic 5?

2. Create a new profile, enter you name for the profile name and create a new rear

implement named « PLOUGH ».

You are working with a plough 8 bodies and 18 inch furrow width.

Select “rear linkage lowered” as trigger

Reset memory data to zero

Operator cost: 12 €/h.

Fuel cost: 0.8 €/l.

Start the implement record

3. Activate the DTM and in the DTM menu:

Set the engine speed lower limit to 1400 rpm and engine speed upper

limit to 1800 rpm

Select “linkage lowering” as trigger.

4. Set rear linkage flow rate priority to 70%

Rear linkage in position control.

Rear linkage lowering speed : maximum

Rear linkage maximum height : 80%

Depth potentiometer : between 3 and 4

5. In rear hydraulic screen :

Activate rear spoolvalve n°3 and set it to 50 % flow/ operating time 4 s.

6. Activate the auto brightness mode, and select metric units.

7. Activate Neutral brake pedal function.

International Technical Training Beauvais 2

TRAINING WORKSHEET

8. Record a Headland sequence followed next description (manual record) :

Rear linkage lowering position

2s

Quick soil engagement

3m

Rear linkage lowering position (deactivation of quick soil engagement)

1s

C1 activation (set to 8 kph)

Pause

Rear linkage lifting position

1s

C2 activation (set to 5 kph)

3m

Rear spoolvalve n° 3 (cylinder rod extension)

Pause

9. You can now try the Auto PTO mode set activation point at 50% of the linkage

stroke.

10. Now try the automatic position restore function of front linkage :

Lower position = 10%

Lift position = 90 %

11. List and count all the function you can set on H3 an H4 buttons :

- front linkage = 4

- diff = 1

- +12V = 1

- rear linkage = 3

International Technical Training Beauvais 3

TRAINING WORKSHEET

-engine = 3

- guidance = 2

-PTO = 1

- Gearbox = 2

- Hydro (rear) = 12

- 4WD = 1

- Headland = 1

- Hydro (front) = 8

-

-Total = 39

-

12. Try to use travel direction switch on the multipad (forward and reverse).

Clutch+press the trigger+direction switch

13. Try to engage rear PTO by get up from the seat

Rear PTO Switch ON-OFF-ON less than 3 s

14. Add some widgets in the left side bar :

15. To finish go in rear implement screen and note time and length you spend to

do this practice :

International Technical Training Beauvais 4

You might also like

- Viper 4806v Install GuideDocument2 pagesViper 4806v Install Guidejllaredo0% (3)

- Pasquali Service ManualDocument65 pagesPasquali Service Manualj100% (3)

- Parking Brake - TestDocument2 pagesParking Brake - Testyan100% (2)

- Fill Time For The Transmision Clutch - CalibrateDocument8 pagesFill Time For The Transmision Clutch - CalibrateTarwedi Tartor100% (1)

- Alert Indicators: Operation and Maintenance ManualDocument6 pagesAlert Indicators: Operation and Maintenance ManualSanath Jayanetti100% (5)

- Driving A Class 158Document4 pagesDriving A Class 158Frank NelsonNo ratings yet

- NT921G Operating ManualDocument50 pagesNT921G Operating Manualwendy100% (2)

- Gilera Runner 200 Runner 200 VXR 4T Race E3 2006Document71 pagesGilera Runner 200 Runner 200 VXR 4T Race E3 2006Dimis KaliviotisNo ratings yet

- Challenger7 Fly by Wire - V100Document21 pagesChallenger7 Fly by Wire - V100GustavoNo ratings yet

- Turnigy Quadcopter Mini ManualDocument7 pagesTurnigy Quadcopter Mini ManualAdrian RudinNo ratings yet

- Breaking System TestingDocument6 pagesBreaking System TestingAgungNo ratings yet

- DP Operator Manual 1. Procedure To Set Up The Alstom NutcrackerDocument10 pagesDP Operator Manual 1. Procedure To Set Up The Alstom NutcrackerKunal SinghNo ratings yet

- Nissan X Trail Idle Air Volume Relearn Procedure1Document10 pagesNissan X Trail Idle Air Volume Relearn Procedure1Mohammed Kamel0% (1)

- Ajuste RPM FanDocument9 pagesAjuste RPM Fandj danielilloNo ratings yet

- GPX UsersGuide enDocument4 pagesGPX UsersGuide enKreszan MihaiNo ratings yet

- Losi 130A ESC ManualDocument4 pagesLosi 130A ESC ManualvayaveNo ratings yet

- Breaking System Testing2Document4 pagesBreaking System Testing2AgungNo ratings yet

- Cargador 924GDocument14 pagesCargador 924GRonaldo GaleanoNo ratings yet

- Guia Moovi ScooterDocument18 pagesGuia Moovi ScooterLuis Felipe Espinosa GomezNo ratings yet

- Desmi TerminatorDocument26 pagesDesmi Terminatoralvaro yepes oviedoNo ratings yet

- Start & Taxi ProceduresDocument12 pagesStart & Taxi ProceduresJoao Vitor RojasNo ratings yet

- 950H WHEEL LOADER J5J00001-UP (MACHINE) POWERED BY C7 ENGINE (XEBP8563 - 00) - DocumentationDocument12 pages950H WHEEL LOADER J5J00001-UP (MACHINE) POWERED BY C7 ENGINE (XEBP8563 - 00) - DocumentationMohamed ZohierNo ratings yet

- Kami Export - Activity 3.1.6 Open & Closed Loop Systems (VEX V5) - Principles ofDocument7 pagesKami Export - Activity 3.1.6 Open & Closed Loop Systems (VEX V5) - Principles ofKidus FissehaNo ratings yet

- D PwrView 001NHNA ENU SBData SB2 2392Document3 pagesD PwrView 001NHNA ENU SBData SB2 2392Alex CummingsNo ratings yet

- PTO Configuration TESTDocument34 pagesPTO Configuration TESTEdwin Motta PiambaNo ratings yet

- Ride Control Accumulator - Test and ChargeDocument9 pagesRide Control Accumulator - Test and Chargeالبراق للتوريدات وصيانة المعداتNo ratings yet

- Throttle Learning 2Document2 pagesThrottle Learning 2Indy RufSanNo ratings yet

- A330 Rec TRNG 1-C Apr.2013Document16 pagesA330 Rec TRNG 1-C Apr.2013Rocky2488100% (4)

- A320 ResumeDocument18 pagesA320 ResumeDaniel Montero100% (1)

- Pacotes 12GDocument13 pagesPacotes 12GTatiano BrolloNo ratings yet

- Autohelm 6000 Power Pilot Installation and Operating Handbook PDFDocument18 pagesAutohelm 6000 Power Pilot Installation and Operating Handbook PDFМилен НанковNo ratings yet

- My Tweaks - 2Document7 pagesMy Tweaks - 2Samy MoustafaNo ratings yet

- Pruebas y Ajustes Servo 14GDocument15 pagesPruebas y Ajustes Servo 14Gyeison100% (1)

- Healtech Rapport EngagéDocument4 pagesHealtech Rapport EngagéFoggy211No ratings yet

- Air Volume Learn NissanDocument4 pagesAir Volume Learn NissanNuwan NishanthaNo ratings yet

- Nissan IAVL1Document7 pagesNissan IAVL1Motor House GarageNo ratings yet

- OPM AutopilotDocument50 pagesOPM AutopilotJohnNo ratings yet

- FS060 9.8hp Parsun Outboard MotorDocument3 pagesFS060 9.8hp Parsun Outboard MotorAndrew MacDonaldNo ratings yet

- Notices Original 920eDocument260 pagesNotices Original 920ex672cx9cxhNo ratings yet

- Fs Ct6b RemoteDocument22 pagesFs Ct6b RemoteNeilNo ratings yet

- 09 TowingDocument10 pages09 TowingBianco YepNo ratings yet

- Pump Performance (Steering) - TestDocument2 pagesPump Performance (Steering) - Testbangaly amadouNo ratings yet

- Syllabus For ARTO 400Document7 pagesSyllabus For ARTO 400Benedict CarandangNo ratings yet

- Lexus LFA 2012 Inseide The LFADocument128 pagesLexus LFA 2012 Inseide The LFAFloyd PriceNo ratings yet

- Special Project ReportDocument9 pagesSpecial Project ReportSangam PatariNo ratings yet

- SEBU6965-06 B StartingDocument7 pagesSEBU6965-06 B StartingLUIZ GUSTAVONo ratings yet

- On-Vehicle InspectionDocument5 pagesOn-Vehicle InspectionEdson CRNo ratings yet

- Bae 146 Technical Training Manual Mechanical & Avionics Course - B1+B2 (LVL 2&3) Towing & Taxiing $7$09Document14 pagesBae 146 Technical Training Manual Mechanical & Avionics Course - B1+B2 (LVL 2&3) Towing & Taxiing $7$09stiveNo ratings yet

- R1600G Load Haul Dump Operator Familiarization Student MaterialsDocument14 pagesR1600G Load Haul Dump Operator Familiarization Student Materialspaul heberth areche conovilcaNo ratings yet

- Nimbus VTOL Manual 180306Document11 pagesNimbus VTOL Manual 180306Efrain Rodriguez RamirezNo ratings yet

- Falke Flight ManualDocument26 pagesFalke Flight ManualDanielC SpiesNo ratings yet

- GM Vehicles - Crankshaft Variation Relearn (Case Learn)Document2 pagesGM Vehicles - Crankshaft Variation Relearn (Case Learn)John Jeshurun Samonte100% (1)

- 793FDocument26 pages793FHelar W. Cutipa MachacaNo ratings yet

- Moto Guzzi Euro 5 (All Models)Document2 pagesMoto Guzzi Euro 5 (All Models)motolabNo ratings yet

- 189 .777D Opearion and Maintenance Manual - RetardingDocument7 pages189 .777D Opearion and Maintenance Manual - Retardingzawmoe aungNo ratings yet

- Nissan Throttle Body Relearn ProcedureDocument2 pagesNissan Throttle Body Relearn ProcedureWilliam DroolNo ratings yet

- These Instructions Must Be Followed Exactly!: "Flatshift" Quick Setup Guide - Using Barrel TriggeringDocument2 pagesThese Instructions Must Be Followed Exactly!: "Flatshift" Quick Setup Guide - Using Barrel Triggeringandres castilloNo ratings yet

- 988h Implement Cylele Time Checktechdoc - Print - PageDocument3 pages988h Implement Cylele Time Checktechdoc - Print - Pagerao abdul bariNo ratings yet

- 572 TroubleshootingDocument3 pages572 TroubleshootingSunil KumarNo ratings yet

- tr5619 Engine Hood Sealing Improvement - 8700 8700SDocument2 pagestr5619 Engine Hood Sealing Improvement - 8700 8700SMárton ŐriNo ratings yet

- EN - Task Doc Prescription Maps Rev1.3Document12 pagesEN - Task Doc Prescription Maps Rev1.3Márton ŐriNo ratings yet

- DIAG07 19 Cylinder Head Top Surface Mark - Measure - 8600 8700Document7 pagesDIAG07 19 Cylinder Head Top Surface Mark - Measure - 8600 8700Márton ŐriNo ratings yet

- Co0220 New AgritronicPlus - Unicontrol4 - On Economy Combines 7344Document3 pagesCo0220 New AgritronicPlus - Unicontrol4 - On Economy Combines 7344Márton ŐriNo ratings yet

- 8S Einstellung (Differenciálmű)Document1 page8S Einstellung (Differenciálmű)Márton ŐriNo ratings yet

- User S Guide KDDocument22 pagesUser S Guide KDEmil KochanekNo ratings yet

- PRS Out Gas Line: Outlet HeaderDocument2 pagesPRS Out Gas Line: Outlet HeaderEslam MouhamedNo ratings yet

- St350 ManualDocument28 pagesSt350 ManualRicardo Cubillos PeñaNo ratings yet

- Dokumen - Tips Rooftop Unit Introduction Rooftop Unit Tica Frimec Product Range ComponentsDocument15 pagesDokumen - Tips Rooftop Unit Introduction Rooftop Unit Tica Frimec Product Range ComponentsFatimah ShNo ratings yet

- Lathe Preventative Maintenance ProcedureDocument2 pagesLathe Preventative Maintenance ProcedureVaishaliYadavNo ratings yet

- 7UM512x Catalog SIP2004 enDocument3 pages7UM512x Catalog SIP2004 enbuianhtuan1980No ratings yet

- Intercooler - WikipediaDocument6 pagesIntercooler - Wikipediashapoor_pouladiNo ratings yet

- Basic Informations-Clg856 Dcec IiDocument49 pagesBasic Informations-Clg856 Dcec IiNezar AminNo ratings yet

- AOC Manual de Servicio TV y Monitor LCD A 20E221Document75 pagesAOC Manual de Servicio TV y Monitor LCD A 20E221supermango007100% (1)

- VGIC307Document13 pagesVGIC307ravinderpal2007No ratings yet

- DCT 3D Welding Table CatalogDocument90 pagesDCT 3D Welding Table CatalogSusan ChenNo ratings yet

- RME Past BoardDocument100 pagesRME Past Boardglenn100% (2)

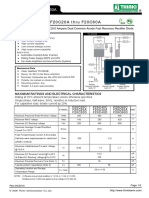

- F20C20C RectificadorDocument2 pagesF20C20C Rectificadoralexjcc10No ratings yet

- AmanoNet Manual April 2012 PDFDocument595 pagesAmanoNet Manual April 2012 PDFThe UserNo ratings yet

- VLSI QuestionsDocument1 pageVLSI QuestionsHemant SaraswatNo ratings yet

- The Roman Workbench - FineWoodworkingDocument14 pagesThe Roman Workbench - FineWoodworkingChris SpragueNo ratings yet

- Control Valve Specification Sheet: Fisher 2 Inches, Fisher 2 Inches, None,, Globe NPS 1/2 CL150 Fisher/24000SBDocument2 pagesControl Valve Specification Sheet: Fisher 2 Inches, Fisher 2 Inches, None,, Globe NPS 1/2 CL150 Fisher/24000SBJavier LopezNo ratings yet

- Từ Vựng Anh Việt: Chuyên Ngành Thủy ĐiệnDocument26 pagesTừ Vựng Anh Việt: Chuyên Ngành Thủy ĐiệnHà ChiếnNo ratings yet

- 3de e (Bocr) ManualDocument6 pages3de e (Bocr) ManualNaveen Gupta100% (1)

- CatalogoDocument20 pagesCatalogosanizam79No ratings yet

- Surge Arrestor - 10 Ka CL 1 - IDDocument1 pageSurge Arrestor - 10 Ka CL 1 - IDkapilNo ratings yet

- Analysis Design and Performance EvaluatiDocument6 pagesAnalysis Design and Performance EvaluatiHaijun GuNo ratings yet

- Tmux 7212Document45 pagesTmux 7212Kishore KumarNo ratings yet

- Transmision 10Document2 pagesTransmision 10Juan Carlos Moncada PáezNo ratings yet

- 17122-03 B11R D11C CHN 143748-144107 PDFDocument174 pages17122-03 B11R D11C CHN 143748-144107 PDFAnonymous EDNsviNo ratings yet

- Pneumatic PLCDocument109 pagesPneumatic PLCragdapattice100% (1)

- Moeller Datasheet IZMB2-A2500 229980Document6 pagesMoeller Datasheet IZMB2-A2500 229980Igor SilvaNo ratings yet

- Kawasaki B-Series Spot Welding RobotsDocument6 pagesKawasaki B-Series Spot Welding RobotsCrrobots SimulateNo ratings yet