Professional Documents

Culture Documents

Ffu 0001047 01

Ffu 0001047 01

Uploaded by

Karunia LestariOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ffu 0001047 01

Ffu 0001047 01

Uploaded by

Karunia LestariCopyright:

Available Formats

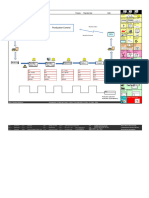

Standard for: Variant

SAU Long type trailer brake lines

Department / Group Position Takt time (s)

MZEPF 583861

Order of procedure

Issued by Date Reg.nr /

Issue

SNLVOJ 2018.01.1 1

Element nr.

Element time

Element time

Element time

Element time

Element time

Element time

Important / to remember / Safety

Acc. Time

Acc. Time

Acc. Time

Acc. Time

Acc. Time

Acc. Time

Activity / Element name

alternatively, Tool symbol

1 2477297 Dismantling

2 2477297 Dismantling

3 2477297 Fitting stickers and valves

4 2477297 Fitting spiral hoses

5 2477297 Fitting bracket and finishing

6 2477297 Platform preparation

7 2477297 Fitting bracket

8 2477297 Fitting spiral hoses on catwalk

9 2477297 Testing

10 2477297 Securing couplings

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

SV Approval TL Approval Sum. of Required Protective Equipment: Sum. Sum. Sum. Sum. Sum. Sum.

The variant proportion of the total volume (%):

Work that is incidentally done on the position

What: How: Why: When: Frequency:

Eng Approval

Purpose of Standard: Base for training and follow-up. The basis for improvement. How: Shows what happens at the position including variants, in what order and the right time

583861_2477297_SAU_Long_type_trailer_brake_lines_2018.01.1 TD - SPS Industrial Development 2012-11-14

Element name - task headline Dismantling MECO/Proj nr.

Variant/Type ECO nr. 583861

Task nr. 1 Issued by SNLVOJ Tools Global Elt nr. 2477297

Task location on product Element nr. 2477297 Date 12-12-17 Issuer SNLVOJ

Issue 1 Page 1/10 Protection equipments required:

Global eng. SNLVOJ

Element time 0,0 s Date 12-12-17

Picture Nr What How Why

1 Follow the correct standard for Use standard 3637 for tightening Quality Assurance

assembly torques and standard 4251 for line

marking unless otherwise stated

2 Check whether button A is Press it to check. It is located under No air pressure in the trailer

depressed. the parking brake lever. circuit

3 Dismantle the couplings Remove couplings (B) on the The plugs are needed to keep

bracket. Do not remove lines. Fit the trailer circuit airtight.

the plugs

4 Dismantle the couplings Dismantle couplings (C) on the Nuts and washers will be used

bracket. Save couplings, nuts and again

washers.

5 Disconnect connectors (D) Remove 4x M8 nut. Save nuts They will be used again

Approval by each shift, name & date

Legal

Supervisor requirement

s / Safety

TL

Equipment

Process engineer Product engineer

583861_2477297_SAU_Long_type_trailer_brake_lines_2018.01.1 TD - SPS Industrial Development 2012-08-31

Element name - task headline Dismantling MECO/Proj nr.

Variant/Type ECO nr. 583861

Task nr. 2 Issued by SNLVOJ Tools Global Elt nr. 2477297

Task location on product Element nr. 2477297 Date 12-12-17 Issuer SNLVOJ

Issue 1 Page 2/10 Protection equipments required:

Global eng. SNLVOJ

Element time 0,0 s Date 12-12-17

Picture Nr What How Why

1 Remove the heat shield (A), if Remove 2x M8 nut. Save nuts They will be used again

present.

2 Remove the bracket (B) Remove 4x M10 nut. Save nuts and Nuts and spacer bushes will

spacer bushes be used again

Approval by each shift, name & date

Legal

Supervisor requirement

s / Safety

TL

Equipment

Process engineer Product engineer

583861_2477297_SAU_Long_type_trailer_brake_lines_2018.01.1 TD - SPS Industrial Development 2012-08-31

Element name - task headline Fitting stickers and valves MECO/Proj nr.

Variant/Type ECO nr. 583861

Task nr. 3 Issued by SNLVOJ Tools Global Elt nr. 2477297

Task location on product Element nr. 2477297 Date 12-12-17 Issuer SNLVOJ

Issue 1 Page 3/10 Protection equipments required:

Global eng. SNLVOJ

Element time 0,0 s Date 12-12-17

Picture Nr What How Why

1 Affix the stickers to the See picture. First degrease surface To ensure good adhesion of

bracket the stickers

2 Fit the couplings in the shut-off Use the parts and order shown in

valves the picture.

3 Fit the shut-off valves to the Use the parts, sequence and

bracket. position shown in the picture.

4 Fit the plugs in the shut-off Fit the 45° couplings and the plugs

valves.

Approval by each shift, name & date

Legal

Supervisor requirement

s / Safety

TL

Equipment

Process engineer Product engineer

583861_2477297_SAU_Long_type_trailer_brake_lines_2018.01.1 TD - SPS Industrial Development 2012-08-31

Element name - task headline Fitting spiral hoses MECO/Proj nr.

Variant/Type ECO nr. 583861

Task nr. 4 Issued by SNLVOJ Tools Global Elt nr. 2477297

Task location on product Element nr. 2477297 Date 12-12-17 Issuer SNLVOJ

Issue 1 Page 4/10 Protection equipments required:

Global eng. SNLVOJ

Element time 0,0 s Date 12-12-17

Picture Nr What How Why

1 Fit the spiral hoses on the Place the adapter in a vice with Easy assembly without

adapters (A) protective jaws. Use Loctite 542. damage

Tighten to 30 Nm

2 Fit the spiral hoses to the See picture. Reuse washers and

bracket (B) nuts

3 Cut air lines Make a connection between the

shut-off valve and the spiral hose.

Cut lines to size during the work.

Apply marking according to

standard

4 Fit the air lines See picture

Approval by each shift, name & date

Legal

Supervisor requirement

s / Safety

TL

Equipment

Process engineer Product engineer

583861_2477297_SAU_Long_type_trailer_brake_lines_2018.01.1 TD - SPS Industrial Development 2012-08-31

Element name - task headline Fitting bracket and finishing MECO/Proj nr.

Variant/Type ECO nr. 583861

Task nr. 5 Issued by SNLVOJ Tools Global Elt nr. 2477297

Task location on product Element nr. 2477297 Date 12-12-17 Issuer SNLVOJ

Issue 1 Page 5/10 Protection equipments required:

Global eng. SNLVOJ

Element time 0,0 s Date 12-12-17

Picture Nr What How Why

1 Fit the bracket (A) Reuse 4x M10 nut and spacer

bushes

2 Fit connectors C and D Use 4x M8X20 and reuse 4x M8 nut

3 Strap the air lines Place the air lines along the cables

and strap them with heat-resistant

straps

4 Route the cables and lines at Where possible, use the original

your own discretion and strap positions and routing. Use heat

them in place resistant straps. Avoid sharp edges

5 Fit the heat shield (B) Reuse 4x M8 nut, if previously

removed

Approval by each shift, name & date

Legal

Supervisor requirement

s / Safety

TL

Equipment

Process engineer Product engineer

583861_2477297_SAU_Long_type_trailer_brake_lines_2018.01.1 TD - SPS Industrial Development 2012-08-31

Element name - task headline Platform preparation MECO/Proj nr.

Variant/Type ECO nr. 583861

Task nr. 6 Issued by SNLVOJ Tools Global Elt nr. 2477297

Task location on product Element nr. 2477297 Date 12-12-17 Issuer SNLVOJ

Issue 1 Page 6/10 Protection equipments required:

Global eng. SNLVOJ

Element time 0,0 s Date 12-12-17

Picture Nr What How Why

1 Fit the studs in the threaded 10 Nm. Short end into the threaded

sleeves. sleeve.

2 Dismantle the first catwalk Loosen 4x M8 bolt several turns to

release the clamps

3 Fit the threaded sleeves to the At the indicated positions (A) with

catwalk 6x M8 flange lock nut

4 Fit the plate (B) On the catwalk with 6x M8x14

flange screw

5 Drill a hole (C) Use 12 mm drill bit to drill through Finish to remove sharp edges

the plate in the catwalk. Finish with

a countersink bit

Approval by each shift, name & date

Legal

Supervisor requirement

s / Safety

TL

Equipment

Process engineer Product engineer

583861_2477297_SAU_Long_type_trailer_brake_lines_2018.01.1 TD - SPS Industrial Development 2012-08-31

Element name - task headline Fitting bracket MECO/Proj nr.

Variant/Type ECO nr. 583861

Task nr. 7 Issued by SNLVOJ Tools Global Elt nr. 2477297

Task location on product Element nr. 2477297 Date 12-12-17 Issuer SNLVOJ

Issue 1 Page 7/10 Protection equipments required:

Global eng. SNLVOJ

Element time 0,0 s Date 12-12-17

Picture Nr What How Why

1 Remove the plate (A).

2 Fit the bracket (B) on the plate 40 Nm. Note: the nut is an imperial

with the pipe clamp (C) turned size.

to the right (driver's side)

3 Fit the assembly on the 1st Reuse 6x M8x14 flange screw

catwalk.

4 Fit the catwalk on the chassis. In the original location

Approval by each shift, name & date

Legal

Supervisor requirement

s / Safety

TL

Equipment

Process engineer Product engineer

583861_2477297_SAU_Long_type_trailer_brake_lines_2018.01.1 TD - SPS Industrial Development 2012-08-31

Element name - task headline Fitting spiral hoses on catwalk MECO/Proj nr.

Variant/Type ECO nr. 583861

Task nr. 8 Issued by SNLVOJ Tools Global Elt nr. 2477297

Task location on product Element nr. 2477297 Date 12-12-17 Issuer SNLVOJ

Issue 1 Page 8/10 Protection equipments required:

Global eng. SNLVOJ

Element time 0,0 s Date 12-12-17

Picture Nr What How Why

1 Unscrew the bolt (1) from the

plastic clamp.

2 Fit the spiral hoses in the Place the clamp immediately after

clamp on the bracket the metal spring. Red right, blue

left. The spiral hoses must not cross

each other. Middle position remains

open.

3 Fit the bolt (1) back into the 3 Nm MAX.

clamp on the bracket

Approval by each shift, name & date

Legal

Supervisor requirement

s / Safety

TL

Equipment

Process engineer Product engineer

583861_2477297_SAU_Long_type_trailer_brake_lines_2018.01.1 TD - SPS Industrial Development 2012-08-31

Element name - task headline Testing MECO/Proj nr.

Variant/Type ECO nr. 583861

Task nr. 9 Issued by SNLVOJ Tools Global Elt nr. 2477297

Task location on product Element nr. 2477297 Date 12-12-17 Issuer SNLVOJ

Issue 1 Page 9/10 Protection equipments required:

Global eng. SNLVOJ

Element time 0,0 s Date 12-12-17

Picture Nr What How Why

1 Supply air pressure to the Pull out knob B on the dashboard To supply air pressure to the

trailer circuit trailer circuit.

2 Check that there are no air Spray leak detection spray on the In the event of air leakage,

leaks in the installation plugs (see page 1, point B) visible air bubbles are created

3 After checking for air leaks, The trailer circuit is now

push button A. pressure-free

Approval by each shift, name & date

Legal

Supervisor requirement

s / Safety

TL

Equipment

Process engineer Product engineer

583861_2477297_SAU_Long_type_trailer_brake_lines_2018.01.1 TD - SPS Industrial Development 2012-08-31

Element name - task headline Securing couplings MECO/Proj nr.

Variant/Type ECO nr. 583861

Task nr. 10 Issued by SNLVOJ Tools Global Elt nr. 2477297

Task location on product Element nr. 2477297 Date 12-12-17 Issuer SNLVOJ

Issue 1 Page 10/10 Protection equipments required: Global eng. SNLVOJ

Element time 0,0 s Date 12-12-17

Picture Nr What How Why

1 Strap the spiral hoses to the See picture. Place a protection To prevent damage

bracket rubber around the bracket

Approval by each shift, name & date

Legal

Supervisor requirement

s / Safety

TL

Equipment

Process engineer Product engineer

583861_2477297_SAU_Long_type_trailer_brake_lines_2018.01.1 TD - SPS Industrial Development 2012-08-31

ECO nr. / FPC code: 583861

Partlist Valid from p. period: 2018.01.1

Issue: 1

Description of adaptation: SAU Long type trailer brake lines

Date: 12-12-2017

Disc. parts Intro. parts

Part nr: QTY Part nr: QTY Description Conditions Remarks

2477297 Mounting instruction

2662757 1 LABEL "SERVICE"

2662758 1 LABEL "EMERGENCY"

2601258 1 TRAILER CONNECTION BRACKET ASS

1424404 2 SWITCH CONTROL VALVE

2058225 2 STRAIGHT JOINT UNION REG M22

1374839 2 SEAL

1762305 2 ADAPTER UNION 22-16

1349129 2 UNION

803007 4 WASHER 19X34

814577 2 HEXAGON NUT M18X1,5

1369865 2 INSERT CONNECTION

2058417 2 ELBOW JOINT UNION 45 DEG REG

2246502 2 PLUG

1765856 2 TRAILER COUPLING ASSY

2452475 1 COILED HOSE RED COLOURED

2452476 1 COILED HOSE BLUE COLOURED

2443494 450 PLASTIC PIPE 12X1,5

2443494 550 PLASTIC PIPE 12X1,5

805977 4 PAN HEAD SCREW M8X20

800045 6 STUD M8X35

1724974 6 NUT

377647 6 FLANGE LOCK NUT

812514 6 FLANGE SCREW M8X14

2333068 1 MOUNTING PLATE

2295557 1 TRAILER CONNECTION ARM

1314199 1 PROTECTION HOSE

2575051 1 HEAT SHIELD ASSY 142D or 142H

815132 4 HEXAGON NUT WITH FLANGE M8 142D or 142H

You might also like

- Ffu 0001115 01Document38 pagesFfu 0001115 01Karunia LestariNo ratings yet

- Ffu 0001108 01Document6 pagesFfu 0001108 01Karunia LestariNo ratings yet

- Ffu 0001117 01Document4 pagesFfu 0001117 01Karunia LestariNo ratings yet

- Ffu 0000966 01Document11 pagesFfu 0000966 01Karunia LestariNo ratings yet

- Ffu 0001109 01Document4 pagesFfu 0001109 01Karunia LestariNo ratings yet

- Ffu 0000911 01Document7 pagesFfu 0000911 01Omar ScaniaNo ratings yet

- Ffu 0001110 01Document9 pagesFfu 0001110 01Karunia LestariNo ratings yet

- Ffu 0001116 01Document9 pagesFfu 0001116 01Karunia LestariNo ratings yet

- Ffu 0001113 01Document11 pagesFfu 0001113 01Karunia LestariNo ratings yet

- Ffu 0001114 01Document27 pagesFfu 0001114 01Karunia LestariNo ratings yet

- Ffu 0001102 01Document12 pagesFfu 0001102 01Karunia LestariNo ratings yet

- Ffu 0000895 01Document4 pagesFfu 0000895 01Omar ScaniaNo ratings yet

- Ffu 0000879 01Document6 pagesFfu 0000879 01Omar ScaniaNo ratings yet

- RO082 - Cambridge Checkpoint, IGCSE, A Level Timetable - May June 2024Document20 pagesRO082 - Cambridge Checkpoint, IGCSE, A Level Timetable - May June 2024IOANA ISACNo ratings yet

- WC Timps PDFDocument1 pageWC Timps PDFAndrea FinettoNo ratings yet

- White Christmas: TimpaniDocument1 pageWhite Christmas: TimpaniAndrea FinettoNo ratings yet

- Lean Execution OEE Reporting TemplateDocument2 pagesLean Execution OEE Reporting TemplateVergence Business Associates100% (3)

- For-HO-CL-14 Value Stream VSM FormapackDocument1 pageFor-HO-CL-14 Value Stream VSM FormapackGRUPO ENSLEYNo ratings yet

- CPR CODE Flow SheetDocument2 pagesCPR CODE Flow Sheetfadhyl100% (1)

- T.Y B. Arch Cbcs-Sem. V and Vi 22.09.2021Document38 pagesT.Y B. Arch Cbcs-Sem. V and Vi 22.09.2021Shrenik SutarNo ratings yet

- UntitledDocument1 pageUntitledvenkateshNo ratings yet

- BC20 4thDocument8 pagesBC20 4thsami ullahNo ratings yet

- Rapidcast Pattern Plan: Advanced Manufacturing & Technology CentreDocument4 pagesRapidcast Pattern Plan: Advanced Manufacturing & Technology CentreDeepak DasNo ratings yet

- Plantilla VSMDocument4 pagesPlantilla VSMhejjiNo ratings yet

- Time Study SheetDocument1 pageTime Study SheetJahidul IslamNo ratings yet

- Value Stream MapTemplateDocument4 pagesValue Stream MapTemplatePercy Manuel Salazar PeñaNo ratings yet

- Value Stream Mapping: Production ControlDocument4 pagesValue Stream Mapping: Production ControlAbner I Choquevilca ChNo ratings yet

- Minisplit Inverter R-410a YJHJZCDocument3 pagesMinisplit Inverter R-410a YJHJZCjuanNo ratings yet

- Parametrizacion TECs 15031801Document1 pageParametrizacion TECs 15031801Ricardo QuijadaNo ratings yet

- T.Y. B Tech Mechnical Engg Final July 2020 With StructureDocument65 pagesT.Y. B Tech Mechnical Engg Final July 2020 With Structuresatyamchgl2010No ratings yet

- Dpti 002 37Document1 pageDpti 002 37Joshua CooperNo ratings yet

- Time Book and PayrollDocument1 pageTime Book and PayrollGilbertNo ratings yet

- B. Arch. CBCS Syllabus Part - IV 2022-23Document32 pagesB. Arch. CBCS Syllabus Part - IV 2022-23Amardeep PawarNo ratings yet

- Map Ament AsDocument1 pageMap Ament AsJesús VargasNo ratings yet

- Description Remark Actuator Sensor: Cycle Time: 135Document6 pagesDescription Remark Actuator Sensor: Cycle Time: 135Tanvi S PurohitNo ratings yet

- SES-QA-032 Man-Hour Plan (EBD & SSPC)Document4 pagesSES-QA-032 Man-Hour Plan (EBD & SSPC)BILAL FAROOQUINo ratings yet

- B Tech VIII SEM IBM CSE SchemeDocument9 pagesB Tech VIII SEM IBM CSE SchemePrakhar TiwariNo ratings yet

- Student Guide/Training Plan (Install and Configure Computer Systems) 40 HoursDocument5 pagesStudent Guide/Training Plan (Install and Configure Computer Systems) 40 HoursBunguiao NHS (Region IX - Zamboanga City)No ratings yet

- Strahinja Milosavljević - Time Sheet 202301 - Part2Document1 pageStrahinja Milosavljević - Time Sheet 202301 - Part2Strahinja MilosavljevićNo ratings yet

- Data Sheet of Actuator Valve & Control Valve - 27 05 2021Document1 pageData Sheet of Actuator Valve & Control Valve - 27 05 2021pt tabNo ratings yet

- 3-T.Y.B.Tech Chemical Engg SyllabusDocument45 pages3-T.Y.B.Tech Chemical Engg SyllabusVivek PatilNo ratings yet

- 4 OEE ExampleDocument8 pages4 OEE Examplevivek1312No ratings yet

- VSM Ladrillera LatesaDocument2 pagesVSM Ladrillera LatesaMeylin CaballeroNo ratings yet

- Tabela PeriodicaDocument1 pageTabela PeriodicaEdgarRafaelCardosoNo ratings yet

- Civil EngineeringDocument95 pagesCivil EngineeringBhikaji Bhairavnath ChougaleNo ratings yet

- HutjjuyjDocument15 pagesHutjjuyjRJ shotNo ratings yet

- M.Tech - Electornics Engg. 2018-19Document59 pagesM.Tech - Electornics Engg. 2018-19santoshNo ratings yet

- PM Calculate 22 November 2023Document1 pagePM Calculate 22 November 2023ririnkurniawan150No ratings yet

- 07 Daily BM JULI BRNADocument12 pages07 Daily BM JULI BRNAMas TeguhNo ratings yet

- B. Arch. CBCS Syllabus 2019 Minor Change PDFDocument40 pagesB. Arch. CBCS Syllabus 2019 Minor Change PDFAmruta PatilNo ratings yet

- Beethoven - 5 Pieces For Mechanical Organ WoO 33-2Document5 pagesBeethoven - 5 Pieces For Mechanical Organ WoO 33-2Peggy WangNo ratings yet

- M. Tech. Chemical 2018Document37 pagesM. Tech. Chemical 2018Shubham KumbharNo ratings yet

- Value Stream VSM TemplateDocument4 pagesValue Stream VSM TemplateChay NagNo ratings yet

- Value Stream VSM Template 2Document5 pagesValue Stream VSM Template 2EduardoSastreNo ratings yet

- Value Stream VSM TemplateDocument4 pagesValue Stream VSM TemplateGilberto Rojas CorderoNo ratings yet

- Value Stream VSM TemplateDocument6 pagesValue Stream VSM TemplateIng. Jhonny LópezNo ratings yet

- Value Stream Mapping: Production ControlDocument4 pagesValue Stream Mapping: Production Controlarelyta8123No ratings yet

- Minersheet: Operating Time Oriented Graph Time Usage GraphDocument1 pageMinersheet: Operating Time Oriented Graph Time Usage Grapharis_jrtNo ratings yet

- Ffu 0000922 01Document13 pagesFfu 0000922 01Karunia LestariNo ratings yet

- Ffu 0000423 01Document10 pagesFfu 0000423 01Karunia LestariNo ratings yet

- Ffu 0001062 01Document13 pagesFfu 0001062 01Karunia LestariNo ratings yet

- Ffu 0000574 01Document8 pagesFfu 0000574 01Karunia LestariNo ratings yet

- Ffu 0000678 01Document13 pagesFfu 0000678 01Karunia LestariNo ratings yet

- Ffu 0001102 01Document12 pagesFfu 0001102 01Karunia LestariNo ratings yet

- Ffu 0001110 01Document9 pagesFfu 0001110 01Karunia LestariNo ratings yet

- Ffu 0001108 01Document6 pagesFfu 0001108 01Karunia LestariNo ratings yet

- Ffu 0001115 01Document38 pagesFfu 0001115 01Karunia LestariNo ratings yet

- Ffu 0000034 01Document8 pagesFfu 0000034 01Karunia LestariNo ratings yet

- Ffu 0000046 01Document13 pagesFfu 0000046 01Karunia LestariNo ratings yet

- Ffu 0000053 01Document9 pagesFfu 0000053 01Karunia LestariNo ratings yet

- Ffu 0000061 01Document4 pagesFfu 0000061 01Karunia LestariNo ratings yet

- GRCDocument3 pagesGRCAristo OnanNo ratings yet

- RE4UHD EVD Tool TutorialDocument4 pagesRE4UHD EVD Tool TutorialMr. CuriousNo ratings yet

- Shayne Rebello ResumeDocument2 pagesShayne Rebello ResumeShayne RebelloNo ratings yet

- First Project Report Algorithmic Trading StrategyDocument7 pagesFirst Project Report Algorithmic Trading Strategyjuans_502No ratings yet

- Tecnam P2008 JCDocument54 pagesTecnam P2008 JCAshish Kumar verma100% (2)

- F1685 PDFDocument10 pagesF1685 PDFDaniel LodiNo ratings yet

- Cryogenic Tanks CatalogueDocument14 pagesCryogenic Tanks Cataloguejayakumar04985No ratings yet

- Control Charts - MBADocument30 pagesControl Charts - MBAShivangi Dhamija100% (1)

- Manual de Operacion PDFDocument306 pagesManual de Operacion PDFJhon Fabio Parra100% (1)

- Oracle EBS R12 Payables R2 - TRAINDocument575 pagesOracle EBS R12 Payables R2 - TRAINappsloaderNo ratings yet

- Jessica Ellis CVDocument8 pagesJessica Ellis CVapi-299779342No ratings yet

- Entrepreneur Guide To LeadershipDocument162 pagesEntrepreneur Guide To LeadershipMohit Anand100% (1)

- Ejemplo - CV STKDocument2 pagesEjemplo - CV STKOmar ChavezNo ratings yet

- Smart Specialisation Strategy of Montenegro 2019-2024Document65 pagesSmart Specialisation Strategy of Montenegro 2019-2024Portal Senat.meNo ratings yet

- Toledo CatalogueDocument26 pagesToledo CatalogueStevoIlicNo ratings yet

- Truflo-Tru2o - Line CardDocument2 pagesTruflo-Tru2o - Line CardPablo Martin Ruiz VirruetaNo ratings yet

- Digitech Df-7 Distortion Factory Oem ManualDocument24 pagesDigitech Df-7 Distortion Factory Oem ManualToMNo ratings yet

- Design Practices-ReboilerDocument7 pagesDesign Practices-Reboileragarwalashwin32100% (1)

- Operating Instructions: M-73 & M-88 CompassesDocument2 pagesOperating Instructions: M-73 & M-88 CompassesAdanNo ratings yet

- Zend Debugger Toolbar Installation GuideDocument11 pagesZend Debugger Toolbar Installation GuidePatricio Eduardo Cordero EspejoNo ratings yet

- AQUADA-DataDocument4 pagesAQUADA-DatajoseNo ratings yet

- 2017 Report - India's Rank On Various Index - WWW - Achieversrule.com..Document2 pages2017 Report - India's Rank On Various Index - WWW - Achieversrule.com..AnmolTiwariNo ratings yet

- Stage DirectionsDocument3 pagesStage Directionsapi-253387902No ratings yet

- AML & Compliance: Mandatory Guidelines (Based On MTSS and Other Country Specific Laws)Document20 pagesAML & Compliance: Mandatory Guidelines (Based On MTSS and Other Country Specific Laws)SitaramNo ratings yet

- Tn1224 Spi MarkingDocument28 pagesTn1224 Spi MarkingNnancy TorresNo ratings yet

- 1.3 Keyword Driven Automation Framework Model: 1.3.1 Project GuidelinesDocument24 pages1.3 Keyword Driven Automation Framework Model: 1.3.1 Project GuidelinesRaaju LenkaNo ratings yet

- Manual Servicio DWF 241pw Pwa (Edit)Document38 pagesManual Servicio DWF 241pw Pwa (Edit)Punchis Panchis100% (1)

- Cargador de AnfoDocument8 pagesCargador de AnfoJuan Diego Laura Flores100% (1)

- Sec 6030 Text Excercise W 2Document6 pagesSec 6030 Text Excercise W 2Meghana OrugantiNo ratings yet

- Zeta IiDocument2 pagesZeta IiRaghu NathNo ratings yet