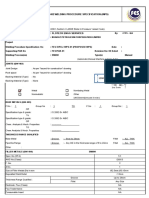

OFFSHORE INFRASTRUCTURES LIMITED

Format No. OIL/HPCL/EIL/ B016//3191-F- 02 - REV - 0

QW-482 WELDING PROCEDURE SPECIFICATIONS (ASME SEC.IX, BOILER &PRESSURE VESSEL CODE)

PROJECT NEW TANKAGES ASSOCIATED CIVIL AND PILING WORKS PART - A

CONSULTANT ENGINEERS INDIA LIMITED

CLIENT HINDUSTAN PETROLIUM CORPORATION LIMITED

LOCATION VISAKHA REFINARY MODERNISATION PROJECT(VRMP) VISAKHAPATNAM A.P

SUPPORTING PQR NO :

WPS NO :

WELDING PROCESS(ES) : TYPE :

JOINTS (QW-402)

JOINT DESIGN :

BACKING :

BACKING MATERIAL :

BASE METALS(QW(403)

P.NO. :

MATERIAL SPECIFICATION TYPE OR GRADE :

TO MATERIAL SPECIFICATION TYPE OR GRADE :

THICKNESS RANGE:

Base metal: Fillet:

Deposited weld metal: Fillet:

MAXIMUM PASS THICKNESS:

OTHERS:

FILLER METALS(QW-404)

PROCESS :

P L E

S AM

SFA SPEC. NO :

AWS CLASS. :

F-NO :

A-NO :

WELD THICKNESS RANGE

GROOVE :

FILLET :

ELECTRODE FLUX (CLASS) :

FLUX TRADE NAME :

SIZE OF FILLER METAL :

OTHERS :

M/s.Offshore infrastructures Ltd. M/s. TPIA / EIL

Page 1 of 4

�POSITION(QW-405) POST WELD HEAT TREATMENT (QW-407)

POSITION OF GROOVE : TEMPARATURE RANGE :

WELDING PROGRESSION : TIME RANGE :

POSITION OF FILLET :

PREHEAT(QW-406) GAS(QW-408)

: PERCENT COMPOSITION :

PREHEAT TEMP.(Min.)

SHIELDING GAS (ES) :

INTERPASS TEMP.(Max.) : FLOW RATE :

GAS BACKING : NA

ELECTRICAL CHARACTERISTICS (QW-409)

CURRENT : POLARITY :

AMPS (RANGE) : VOLTS (RANGE) :

TECHNIQUE (QW-410)

STRING OR WEAVE :

INITIAL & INTERPASS CLEANING :

OSCILLATION (max.) :

MULTI OR SINGLE PASS :

MULTIPLE OR SINGLE ELECTRODE :

CONTACT TUBE TO WORK DISTANCE :

GAS CUP SIZE :

METHOD OF BACK GOUGING :

PEENING :

TRAVEL SPEED (mm/min.) :

USE OF THERMAL PROCESS (QW-410.64)

FILLER METAL CURRENT

TRAVEL SPEED

WELD LAYER(S) PROCESS TYPE / VOLT RANGE

CLASS DIA AMP RANGE RANGE mm / mint.

POLARITY

OIL TPIA /EIL

SIGN SIGN

NAME NAME

DATE DATE

Page 2 of 4

� WPS-03

OFFSHORE INFRASTRUCTURES LIMITED

Tankage Works-IV for IREP Project of M/s.BPCL, Kochi Refinery.

QW-482 WELDING PROCEDURE SPECIFICATIONS

ASME SEC.IX, BOILER &PRESSURE VESSEL CODE

CLIENT : BHARAT PETROLEUM CORPORATION LIMITED

CONSULTANT : ENGINEERS INDIA LTD

MANUFACTURER'S NAME : OFFSHORE INFRASTRUCTURES LIMITED

SUPPORTING PQR NO : OIL/EIL/MRPL/PQR-07, REV-0, DT:30.07.10

WPS NO : OIL/EIL/BPCL/WPS-03Rev.0, DT: 26.10.14

WELDING PROCESS(ES) :SMAW TYPE : MANUAL

JOINTS (QW-402) 37.5°±2.5⁰

JOINT DESIGN : Single 'V' groove

7.62 mm

BACKING : NO

BACKING MATERIAL : N/A

2.5 mm 1.6 mm

BASE METALS(QW(403)

P.NO. :P1 TO P1

MATERIAL SPECIFICATION TYPE OR GRADE :A 106 Gr.B

TO MATERIAL SPECIFICATION TYPE OR GRADE :A 106 Gr.B

THICKNESS RANGE:

Base metal: groove 1.6 mm to 15.4 mm Fillet:All SIZE

Pipe dia Range : Upto 2 7/8'' and above Fillet:All SIZE

OTHERS: NA

FILLER METALS(QW-404)

Root Pass Filler Pass

PROCESS : SMAW SMAW

SFA SPEC. NO : 5.1 5.1

AWS CLASS. : E-6010 E-7018

F-NO : 3 4

A-NO : 1 1

WELD THICKNESS RANGE

GROOVE : 1.5 - 5 mm (max) 1.5-10.24 mm (max)

FILLET : ANY SIZE ANY SIZE

ELECTRODE FLUX (CLASS) : NA NA

FLUX TRADE NAME : NA NA

SIZE OF FILLER METAL : 2.5 mm 2.5 mm,3.15 mm

OTHERS : NA NA

� WPS-03

POSITION(QW-405) POST WELD HEAT TREATMENT (QW-407)

POSITION OF GROOVE :6G TEMPARATURE RANGE : NA

WELDING PROGRESSION : UPHILL TIME RANGE : NA

POSITION OF FILLET : ALL

PREHEAT(QW-406) GAS(QW-408)

: 10⁰ PERCENT COMPOSITION : NA

PREHEAT TEMP.(Min.)

SHIELDING GAS (ES) : NA

INTERPASS TEMP.(Max.) : 250 C. Max. FLOW RATE : NA

GAS BACKING : NA

ELECTRICAL CHARACTERISTICS (QW-409)

CURRENT :DC POLARITY :EP for SMAW

AMPS (RANGE) :100-132 VOLTS (RANGE) : 26-36

TECHNIQUE (QW-410)

STRING OR WEAVE : Root-String, Others-Weave

INITIAL & INTERPASS CLEANING : GRINDING/ BRUSHING / CHIPPING

OSCILLATION (max.) : Max 2.5 times the dia.of Electrode

MULTI OR SINGLE PASS : MULTIPASS

MULTIPLE OR SINGLE ELECTRODE : MULTIPLE

CONTACT TUBE TO WORK DISTANCE : NA

GAS CUP SIZE : NA

METHOD OF BACK GOUGING : GRINDING

PEENING : Nil

TRAVEL SPEED (mm/min.) : 73-79

USE OF THERMAL PROCESS (QW-410.64)

FILLER METAL CURRENT

TRAVEL SPEED

WELD LAYER(S) PROCESS TYPE / VOLT RANGE

CLASS DIA AMP RANGE RANGE mm / mint.

POLARITY

ROOT PASS SMAW E-6010 2.5MM DCEP 59-61 32-34 73-77

HOT PASS SMAW E-7018 3.15MM DCEP 75-80 36-40 70-78

FILUP SMAW E-7018 3.15MM DCEP 100-110 35-38 75-82

FINAL SMAW E-7018 3.15MM DCEP 126-132 32-36 69-79

OIL EIL

SIGN SIGN

NAME NAME

DATE DATE