Professional Documents

Culture Documents

تصنيع الزبد من الحليب

Uploaded by

yahyaalmoalmCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

تصنيع الزبد من الحليب

Uploaded by

yahyaalmoalmCopyright:

Available Formats

ﻤﺠﻠﺔ ﺍﻟﻬﻨﺩﺴﺔ ﻭﺍﻟﺘﻜﻨﻭﻟﻭﺠﻴﺎ،ﺍﻟﻤﺠﻠﺩ،28ﺍﻟﻌﺩﺩ 2010،14

ﺘﺼﻨﻴﻊ ﺍﻟﺯﺒﺩ ﻤﻥ ﺩﻫﻥ ﺍﻟﺤﻠﻴﺏ ﺍﻟﺠﺎﻑ ﻭ ﺍﻟﺤﻠﻴﺏ ﺍﻟﻔﺭﺯ ﺍﻟﻤﺠﻔﻑ ﺍﻟﻤﺴﺘﺭﺠﻊ

ﺩ.ﻋﻠـﻲ ﺭﺍﻀـﻲ ﻋـﻠﻲ*

ﺘﺎﺭﻴﺦ ﺍﻟﺘﺴﻠﻡ2010 /2/15:

ﺘﺎﺭﻴﺦ ﺍﻟﻘﺒﻭل2010/5/ 6:

ﺍﻟﺨﻼﺼﺔ

ﺘﻡ ﺘﺤﻀﻴﺭ ﺍﻟﻘﺸﻁﺔ ﻤﻥ ﺨﻠﻴﻁ ﺍﻟﺩﻫﻥ ﺍﻟﺤﺭ ﺍﻟﻤﺴﺨﻥ ﻭ ﺍﻟﺤﻠﻴﺏ ﺍﻟﻔﺭﺯ ﺍﻟﻤﺴﺘﺭﺠﻊ ﺒﻨﺴﺒﺔ 3:1ﻭ

ﺃﻀﻴﻑ ﻟﻠﺨﻠﻴﻁ ﻨﺴﺏ ﺘﺭﺍﻭﺤﺕ ﺒﻴﻥ ٪ 5-0ﻤﻥ ﺒﺎﺩﺉ ﺍﻟﺯﺒﺩ ﻭ ﺼﻨﻊ ﺍﻟﺯﺒﺩ ﻤـﻥ ﻫـﺫﻩ ﺍﻟﻘﺸـﻁﺔ

ﺒﺎﺴﺘﻌﻤﺎل ﺨﻀﺎﺽ ﻜﻬﺭﺒﺎﺌﻲ ﻭ ﺘﻤﺕ ﺩﺭﺍﺴﺔ ﺼﻔﺎﺕ ﺍﻟﺯﺒﺩ ﺍﻟﺘﺭﻜﻴﺒﻴﺔ ﻭ ﺍﻟﻔﻴﺯﻴﻭﻜﻴﻤﻴﺎﻭﻴـﺔ ﻭ ﺍﻋـﺩﺍﺩ

ﺍﻻﺤﻴﺎﺀ ﺍﻟﻤﺠﻬﺭﻴﺔ ﻓﻀﻼ ﻋﻥ ﺩﺭﺍﺴﺔ ﺘﺄﺜﻴﺭ ﺍﻟﺨﺯﻥ ﺒﺩﺭﺠﺔ ﺤﺭﺍﺭﺓ ﺍﻟﺜﻼﺠﺔ )8ﻡ( ﻓﻲ ﺍﻟﺼﻔﺎﺕ ﺃﻋﻼﻩ.

ﺘﻡ ﺍﻟﺤﺼﻭل ﻋﻠﻰ ﺯﺒﺩ ﻗﺭﻴﺏ ﻤﻥ ﺍﻟﺯﺒﺩ ﺍﻟﻁﺒﻴﻌﻲ ﻤﻥ ﺍﻟﻨﻭﺍﺤﻲ ﺍﻟﺘﺭﻜﻴﺒﻴﺔ ﻭ ﺒﻠﻐﺕ ﺍﻋﻠﻰ ﺩﺭﺠـﺔ

ﻟﻨﺘﺎﺌﺞ ﺍﻟﺘﻘﻴﻴﻡ ﺍﻟﺤﺴﻲ 92.5ﺩﺭﺠﺔ ﻟﻤﺠﻤﻭﻉ ﺍ ﻟﺨﻭﺍﺹ ﻭ ﻫﻲ ﺍﻟﻁﻌﻡ ﻭ ﺍﻟﻨﻜﻬﺔ ﻭ ﺍﻟﺸﻜل ﻭ ﺍﻟﺘﺭﻜﻴﺏ ﻭ

ﺍﻟﻠﻭﻥ ﻟﻠﺯﺒﺩ ﺍﻟﻤﻨﺘﺞ ﻤﻥ ﺍﺴﺘﺨﺩﺍﻡ ٪ 3ﺒﺎﺩﺉ ﻤﻘﺎﺭﻨﺔ ﺒﻨﻤﻭﺫﺝ ﺍﻟﻤﻘﺎﺭﻨﺔ ﻭﺍﻟﺫﻱ ﺤﺎﺯ ﻋﻠﻰ 97ﺩﺭﺠﺔ.

ﺃ ﺸﺎﺭﺕ ﺍﻟﻨﺘﺎﺌﺞ ﺍﻟﻰ ﺍﻨﺨﻔﺎﺽ ﺍﻟﺭﻗﻡ ﺍﻟﻬﻴﺩﺭﻭﺠﻴﻨﻲ ) (pHﻤﻥ 6.5ﺍﻟﻰ 4.5ﻋﻨﺩ ﺯﻴﺎﺩﺓ ﻨﺴﺒﺔ ﺍﻟﺒﺎﺩﺉ

ﻤﻥ 0ﺇﻟﻰ . ٪ 5ﺘﺭﺍﻭﺡ ﺭﻗﻡ ﺍﻟﺒﺭﻭﻜﺴﻴﺩ ﺒﻴﻥ 0.30 – 0.15ﻟﻜل ﺍﻟﻨﻤﺎﺫﺝ ﺒﻌﺩ ﺍﻟﺘﺼﻨﻴﻊ ﻤﺒﺎﺸﺭﺓ ﻭ

ﺍﺭﺘﻔﻊ ﺍﻟﺭﻗﻡ ﻨﺴﺒﻴﺎ ﺍﻟﻰ 0.45 – 0.25ﺒﻌﺩ ﺍﻟﺨﺯﻥ ﻟﻤﺩﺓ ﺍﺭﺒﻊ ﺍﺴﺎﺒﻴﻊ ﻓﻲ ﺍﻟﺘﺒﺭﻴﺩ .ﺍﻤﺎ ﺍﻋﺩﺍﺩ ﺍﻻﺤﻴﺎﺀ

ﺍﻟﻤﺠﻬﺭﻴﺔ ﺍﻟﻜﻠﻴﺔ ﻭ ﺒﻜﺘﺭﻴﺎ ﺍﻟﻘﻭﻟﻭﻥ ﻭ ﺍﻟﺨﻤﺎﺌﺭ ﻭ ﺍﻻﻋﻔﺎﻥ ﻓﻜﺎﻨﺕ ﻀﻤﻥ ﺍﻟﻤﻭﺍﺼﻔﺎﺕ ﺍﻟﻘﻴﺎﺴﻴﺔ ﺨﻼل

ﻤﺩﺓ ﺍﻟﺨﺯﻥ ﻭ ﻟﻠﻤﻌﺎﻤﻼﺕ ﺍﻟﻤﺨﺘﻠﻔﺔ .

Processing of Butter From Anhydrous Milk Fat and

Reconstituted Dried Skim Milk

Abstract

Butter was produced from a mixture of anhydrous milk fat and reconstituted

dried skim milk in a ratio of 1:3 and different percentages (0-5%) added to starter

mixture. Electrical butter churner was used for

butter production. Composition, physicochemical, microbiological, and

the effect of cold storage at 8ْ C of the resultant butter were studied. The

composition of the resultant butter was similar to natural butter and it was awarded

a total score of 92.5 for the organoleptic properties (taste, flavor, shape,

body(texture), color) as

compared to 97.0 for the natural butter. The pH of butter was reduced from 6.5 to

4.5

with increasing the added starter from 0 to 5%. Peroxide values of freshly prepared

butter were 0.15-0.30 and increased up to 0.25-0.45 after 4 weeks of cold storage.

The total bacterial counts, coliform counts, yeast and mold counts were within the

limits of the standards.

ﻗﺎﺒﻠﻴﺘﻪ ﺍﻟﺠﻴﺩﺓ ﻋﻠﻰ ﺍﻟﺨﺯﻥ ﻟﻤﺩﺓ ﻁﻭﻴﻠﺔ ﻨﺴﺒﻴﺎ، ﺍﻟﻤﻘﺩﻤﺔ

ﻭ ﻴﻌﺩ ﺍﻟﺯﺒﺩ ﻤﻥ ﻤﻨﺘﺠﺎﺕ ﺍﻟﺤﻠﻴﺏ ﺍﻟﺘﻘﻠﻴﺩﻴﺔ

ﻭ ﺍﻟﺘﻲ ﺍﺴﺘﻌﻤﻠﻬﺎ ﺍﻹﻨﺴﺎﻥ ﻤﺼـﺩﺭﺍﹰ ﻏـﺫﺍﺌﻴﺎﹰ

ﻷﻫﻤﻴﺘﻪ ﺍﻟﻐﺫﺍﺌﻴﺔ ﻭ ﻨﻜﻬﺘـﻪ ﺍﻟﻤﺴﺘﺴـﺎﻏﺔ ﻭ

* ﻜﻠﻴﺔ ﺍﻟﺯﺭﺍﻋﺔ ,ﺠﺎﻤﻌﺔ ﺒﻐﺩﺍﺩ /ﺒﻐﺩﺍﺩ

723

PDF created with pdfFactory Pro trial version www.pdffactory.com

ﺘﺼﻨﻴﻊ ﺍﻟﺯﺒﺩ ﻤﻥ ﺩﻫﻥ ﺍﻟﺤﻠﻴﺏ ﺍﻟﺠﺎﻑ ﻭ ﺍﻟﺤﻠﻴﺏ ﻤﺠﻠﺔ ﺍﻟﻬﻨﺩﺴﺔ ﻭﺍﻟﺘﻜﻨﻭﻟﻭﺠﻴﺎ،ﺍﻟﻤﺠﻠﺩ،28ﺍ ﻟﻌﺩﺩ2010،14

ﺍﻟﻔﺭﺯ ﺍﻟﻤﺠﻔﻑ ﺍﻟﻤﺴﺘﺭﺠﻊ

ﺍﻟﻐﺫﺍﺌﻴﺔ ﺍﻓﻀل ﻤﻥ ﺯﺒﺩ ﺍﻟﻤﻘﺎﺭﻨـﺔ) .(18ﺍﻥ ﻴﺴﺘﻭﺭﺩ ﺍﻟﻌﺭﺍﻕ ﺴﻨﻭﻴﺎ ﻜﻤﻴﺎﺕ ﻜﺒﻴـﺭﺓ ﻤـﻥ

ﺍﻟﺯﺒﺩ ﺍﻟﻤﻨﺘﺞ ﻤﻥ ﺤﻠﻴﺏ ﺍﻻﺒﻘﺎﺭ ﺍﻟﺘﻲ ﺘﺘﻐـﺫﻯ ﺍﻟﺯﺒﺩ ﻤﻥ ﺨﺎﺭﺝ ﺍﻟﻘﻁﺭ ﻭ ﻻﺤﺘﻭﺍﺀ ﻫﺫﻩ ﺍﻟﻤﺎﺩﺓ

ﻋﻠﻰ ﻨﺴﺒﺔ ﻋﺎﻟﻴﺔ ﻤﻥ ﺍﻻﻋﻼﻑ ﺍﻟﺨﻀﺭﺍﺀ ﻭ ﻋﻠﻰ ﻨﺴﺒﺔ ﻤﻥ ﺍﻟﺭﻁﻭﺒﺔ ﻻﺘﻘـل ﻋـﻥ ٪16

ﻨﺴﺒﺔ ﺍﻗل ﻤﻥ ﺍﻻﻋﻼﻑ ﺍﻟﻤﺭﻜﺯﺓ ﻴﺤﻭﻱ ﻨﺴﺒﺔ ﻓﺎﻥ ﻤﺎ ﻴﺼﺭﻑ ﻋﻠﻰ ﻨﻘل ﺭﻁﻭﺒـﺔ ﺍﻟﺯﺒـﺩ

ﻋﺎﻟﻴﺔ ﻤﻥ ﺍﻻﺤﻤﺎﺽ ﺍﻟﺩﻫﻨﻴﺔ ﻏﻴﺭ ﺍﻟﻤﺸﺒﻌﺔ ﻭ ﺍﻟﻤﺴــﺘﻭﺭﺩ ﺃﻤــﻭﺍل ﻜﺜﻴــﺭﺓ ﻭ ﻨﻅــﺭﺍ

ﻋﻠﻰ ﺍﻻﺨﺹ ﺤﺎﻤﺽ ﺃﻭﻟﻴـﻙ ﻤـﻥ ﻨـﻭﻉ ﻟﻠﺤﺎﺠـــــــــــــــــــﺔ

)(Trans-11ﻭ ﻨﺴﺒﺔ ﺍﻗل ﻤﻥ ﺤﺎﻤﺽ ﻟﻴﻨﻭﻟﻴﻙ ﺍﻟﻜﺒﻴﺭﺓ ﻟﻠﺯﺒﺩ ﻓﻲ ﺍﻟﺴﻭﻕ ﺍﻟﻤﺤﻠﻴﺔ ﺒﺴﺒﺏ ﺯﻴﺎﺩﺓ

ﻤﻥ ﻨﻭﻉ ) (Cis-9‘ trans-11ﻭ ﻫـﺫﺍ ﺍﺩﻯ ﺍﻟﻘﺩﺭﺓ ﺍﻟﺸﺭﺍﺌﻴﺔ ﻟﻠﻤﻭﺍﻁﻨﻴﻥ ﻓـﻲ ﺍﻟﻌـﺭﺍﻕ ﻭ

ﺍﻟﻰ ﺨﻔـﺽ ﺤـﺎﻤﺽ ﺍﻟﺒﺎﻟﻤﺘـﻙ Palmitic ﺍﺴﺘﻌﻤﺎل ﻫﺫﻩ ﺍﻟﻤﺎﺩﺓ ﻓﻲ ﺼﻨﺎﻋﺔ ﺍﻟﻜﺜﻴﺭ ﻤـﻥ

) (C16:0ﻭﻫﺫﻩ ﺍﻟﺯﻴـﺎﺩﺓ ﻓـﻲ ﺍﻻﺤﻤـﺎﺽ ﺃﻨﻭﺍﻉ ﺍﻟﺤﻠﻭﻴﺎﺕ ﺍﻟﺘﻘﻠﻴﺩﻴﺔ ﻭ ﺍﻟﻤﻌﺠﻨﺎﺕ ﻤﻤـﺎ

ﺍﻟﺩﻫﻨﻴﺔ ﻏﻴﺭ ﺍﻟﻤﺸﺒﻌﺔ ﺍﺩﺕ ﺍﻟﻰ ﺨﻔﺽ ﺩﺭﺠﺔ ﺃﺩﻯ ﺇﻟﻰ ﺯﻴﺎﺩﺓ ﺍﻟﻁﻠﺏ ﻋﻠﻰ ﻫﺫﻩ ﺍﻟﻤﺎﺩﺓ ﻓﺎﻥ

ﺍﻨﺼﻬﺎﺭ ﺍﻟﺯﺒﺩ ﻭﺒﻘﺎﺌﻪ ﻟﻤﺩﺓ ﺍﻗﺼﺭ ﻓﻲ ﺍﻟﻔـﻡ ﺍﺴﺘﻴﺭﺍﺩ ﺍﻟﺩﻫﻥ ﺍﻟﺤﺭ ﺍﻟﺠﺎﻑ ﻭ ﺍﻟﺤﻠﻴﺏ ﺍﻟﻔﺭﺯ

ﻟﻜﻭﻨﻪ ﺍﻗل ﺼﻼﺒﺔ ﻭ ﺍﻟـﺫﻱ ﻜـﺎﻥ ﺫﺍ ﻗﻴﻤـﺔ ﺍﻟﺠﺎﻑ ﺒﺄﺴﻌﺎﺭ ﻤﻨﺎﺴﺒﺔ ﻓﻴﻜﻭﻥ ﻤﻥ ﺍﻟﻤﻨﺎﺴـﺏ

ﻏﺫﺍﺌﻴﺔ ﺃﻓﻀل ﻟﺩﻯ ﺍﻟﻤﺴﺘﻬﻠﻙ) .(13ﻭﻗﺩ ﻭﺠﺩ ﺼﻨﺎﻋﺔ ﺍﻟﺯﺒﺩ ﻤﻥ ﻫﺎﺘﻴﻥ ﺍﻟﻤـﺎﺩﺘﻴﻥ ﺩﺍﺨـل

ﻓﻲ ﺒﻌﺽ ﻨﻤﺎﺫﺝ ﺍﻟﺯﺒﺩ ﻀـﺭﻭﺏ ﻟﺒﻜﺘﺭﻴـﺎ ﺍﻟﻌﺭﺍﻕ ﺨﺎﺼﺔ ﺃﺫﺍ ﺘﻤﺕ ﺃﻟﻤﺤﺎﻓﻅـﺔ ﻋﻠـﻰ

Esherichia coliﺍﻟﺴﺎﻤﺔ ﺍﻟﺘـﻲ ﺘﻌـﺭﺽ ﺍﻟﻤﻭﺍﺼﻔﺎﺕ ﻭ ﺍﻟﻘﻴﺎﺴﺎﺕ ﺍﻟﻤﻁﻠﻭﺒﺔ ﻟﻤﺜل ﻫﺫﻩ

ﺼﺤﺔ ﺍﻹﻨﺴﺎﻥ ﺍﻟـﻰ ﻤﺨـﺎﻁﺭ ﺍﻹﺴـﻬﺎل ﻭ ﺍﻟﻤﺎﺩﺓ .ﻭﺠـﺩ ﺃﻥ ﺍﻷﻜﺴـﺩﺓ ﻓـﻲ ﺍﻟﻁﺒﻘـﺔ

ﺍﻟﻤﻭﺕ) .(15ﻭ ﻤﻥ ﺍﻟﻤﻬـﻡ ﺫﻜـﺭ ﺩﺭﺍﺴـﺔ ﺍﻟﺴﻁﺤﻴﺔ ﻤﻥ ﺍﻟﺯﺒﺩ ﻜﺎﻨﺕ ﺃﺴﺭﻉ ﻤﻥ ﺍﻟﺠﺯﺀ

ﺃﺸﺎﺭﺕ ﺒﺎﻥ ﺍﻟﺯﺒﺩ ﺍﻟﺤﺎﻭﻱ ﻋﻠﻰ ﺍﻟﺒـﺎﺩﺉ ﻻ ﺍﻟﺩﺍﺨﻠﻲ ﻤﻨـﻪ ) .( 9ﻭ ﺇﻥ ﻨﻤـﺎﺫﺝ ﺍﻟﺯﺒـﺩ

ﻴﺼﻠﺢ ﻓﻲ ﺼﻨﺎﻋﺔ ﺍﻟﻜﻴﻙ) .(16ﻫﺩﻑ ﺍﻟﺒﺤﺙ ﺍﻟﻤﺨﺯﻥ ﻓﻲ ﺩﺭﺠﺘﻲ ﺍﻟﺤﺭﺍﺭﺓ 4ﻭ 12ﻡ ﻟﻤﺩﺓ

ﺍﻟﺤﺎﻟﻲ ﺇﻟﻰ ﺍﺴﺘﺨﺩﺍﻡ ﺩﻫﻥ ﺍﻟﺤﻠﻴﺏ ﺍﻟﺠﺎﻑ ﻭ 7ﺃﻴﺎﻡ ﻟﻡ ﺘﻅﻬﺭ ﻓﻴﻬﺎ ﺍﻷﻜﺴﺩﺓ ) .( 10ﻭ ﺍﻥ

ﺍﻟﺤﻠﻴﺏ ﺍﻟﻔﺭﺯ ﺍﻟﺠﺎﻑ ﻋﻨﺩ ﺘﻭﺍﻓﺭﻫـﺎ ﺩﺍﺨـل ﺍﻟﺤﻤﻭﻀﺔ ﻓﻲ ﺍﻟﺯﺒﺩ ﺘﺒﺩﺃ ﺒـﺎﻟﻅﻬﻭﺭ ﻋﻨـﺩﻤﺎ

ﺍﻟﻘﻁﺭ ﻟ ﺼﻨﺎﻋﺔ ﺯﺒﺩ ﺘﺘـﻭﻓﺭ ﺒـﻪ ﺍﻟﺼـﻔﺎﺕ ﺘ ﺼل ﻗﻴﻤﺔ ﺩﺭﺠﺔ ﺍﻟﺤﺎﻤﺽ Acid degree

ﺍﻟﻜﻴﻤﻴﺎﺌﻴﺔ ﻭ ﺍﻟﻔﻴﺯﻴﺎﺌﻴﺔ ﻭ ﺍﻟﺤﺴﻴﺔ ﻭ ﺍﻟﺼﺤﻴﺔ (ADV) valueﺍﻟﻰ ﻤﺎ ﺒـﻴﻥ 1.5 – 0.5

ﺍﻟﺘﻲ ﺘﻠﺒﻲ ﺤﺎﺠﺔ ﺍﻟﺴﻭﻕ. ) .(14ﺘﺯﺩﺍﺩ ﻫﺫﻩ ﺍﻟﻘﻴﻤﺔ ) (ADVﻓﻲ ﺍﻟﺯﺒﺩ

ﺍﻟﻤﻭﺍﺩ ﻭ ﻁﺭﻕ ﺍﻟﺒﺤﺙ ﺍﻟﻨﺎﺘﺞ ﻤﻥ ﺤﻠﻴﺏ ﻤﺘﺯﻨﺦ ) .(7ﺒﻴﻨﻤﺎ ﻴﻜـﻭﻥ

ﺘﺤﻀﻴﺭ ﺍﻟﻤﺴﺘﺤﻠﺏ ﺍﻟﺩﻫﻨﻲ -:ﺘـﻡ .1 ـﺔـل ﻋﺭﻀـ ـﺎﻑ ﺍﻗـ

ـﺏ ﺍﻟﺠـ ـﻥ ﺍﻟﺤﻠﻴـ

ﺩﻫـ

ﺘﺤﻀﻴﺭ ﻭﺠﺒﺎﺕ ﻤﺨﺘﻠﻔﺔ ﻤـﻥ ﺍﻟﻤﺴـﺘﺤﻠﺏ ﻟﻠﺘﺯﻨﺦ) .(22ﻟﻘـﺩ ﺍﺸـﺘﺭﻁﺕ ﺍﻟﻤﻘـﺎﻴﻴﺱ

ﺍﻟﺩﻫﻨﻲ ﺒﺎﺴﺘﺨﺩﺍﻡ ﺍﻟـﺩﻫﻥ ﺍﻟﺤـﺭ ﺍﻟﺠـﺎﻑ ﺍﻟﻤﺎﻴﻜﺭﻭﺒﻴﺔ ﻟﻠﺯﺒﺩ ﺒﺎﻥ ﻻ ﻴﺯﻴﺩ ﻋﺩﺩ ﺍﻻﻋﻔﺎﻥ

ﺍﻟﺤﺎﻭﻱ ﻋﻠﻰ ﻨﺴﺒﺔ ﻤﻥ ﺍﻟﺭﻁﻭﺒﺔ ﻻ ﺘﺘﺠﺎﻭﺯ

ﻭ ﺍﻟﺨﻤﺎﺌﺭ ﻋﻥ 20ﺨﻠﻴﺔ ﻓﻲ ﺍﻟﻐﺭﺍﻡ ﺍﻟﻭﺍﺤﺩ

ـﺭﺯـﺏ ﺍﻟﻔــﻊ ﺍﻟﺤﻠﻴـ

٪ 0.1ﻭ ﺨﻠﻁ ـﻪ ﻤـ ﻤﻥ ﺍﻟﺯﺒﺩ ﻭ ﺍﻥ ﻻ ﺘﺯﻴﺩ ﻋﺩﺩ ﺒﻜﺘﺭﻴﺎ ﺍﻟﻘﻭﻟﻭﻥ

ﺍﻟﻤﺴﺘﺭﺠﻊ ﺒﻨﺴﺒﺔ 1ﺤﻠﻴﺏ ﻓﺭﺯ ﻤﺠﻔﻑ ﺍﻟﻰ ﻋﻥ 10ﺨﻠﻴﺔ ﻓﻲ ﺍﻟﻐﺭﺍﻡ ﺍﻟﻭﺍﺤﺩ ﻤﻥ ﺍﻟﺯﺒﺩ

9ﻤﺎﺀ ﺤﻴﺙ ﺘﻤﺕ ﺍﻻﺫﺍﺒﺔ ﻓﻲ ﺩﺭﺠﺔ ﺤﺭﺍﺭﺓ ) .(21ﺍﻨﺘﺞ ﺯﺒـﺩ ﺫﻱ ﻤﺤﺘـﻭﻯ ﻤﺭﺘﻔـﻊ

55ﻡ ﻭ ﺍﻀﻴﻑ ﺩﻫﻥ ﺤﺭ ﺴﺎﺨﻥ ﺩﺭﺠـﺔ ﺒﺤﺎﻤﺽ ﻟﻴﻨﻭﻟﻴـﻙ (Cis- Linoleic acid

ﺤﺭﺍﺭﺘﻪ 65ﻡ ﺍﻟﻰ ﺍﻟﺤﻠﻴﺏ ﺍﻟﻤﺴـﺘﺭﺠﻊ ﻭ ) 9‘ trans-11ﻭ ﺒﺤﺎﻤﺽ ﺃﻭﻟﻴﻙ Oleicﻤﻥ

ﺒﻨﺴﺒﺔ 3:1ﻭ ﺨﻠﻁ ﺍﻟﻤﺯﻴﺞ ﺒﺨﻼﻁ ﻜﻬﺭﺒﺎﺌﻲ ﻨﻭﻉ ) (Trans-11ﻭ ﺫﻟﻙ ﻋﻥ ﻁﺭﻴﻕ ﺍﻀﺎﻓﺔ

ﻟﻤﺩﺓ ﺩﻗﻴﻘﺘﻴﻥ ﻭ ﻜﺎﻨﺕ ﻨﺴـﺒﺔ ﺍﻟـﺩﻫﻥ ﻓـﻲ ﺯﻴﺕ ﺍﻟﺴﻤﻙ ﺍﻟﻰ ﻋﻠﻴﻘﺔ ﺤﻴﻭﺍﻥ ﺍﻟﺤﻠﻴﺏ ﺍﻟﺫﻱ

ﺍﻟﻤﺯﻴﺞ ﺤـﻭﺍﻟﻲ ٪ 40 - 35ﻭﺃﺠﺭﻴـﺕ ﺍﻨﺘﺞ ﻤﻥ ﺤﻠﻴﺒﻪ ﺍﻟﺯﺒﺩ ﺍﻟﻤﺫﻜﻭﺭ ﻭ ﻜﺎﻨﺕ ﺍﺤﺩﻯ

ﻋﻤﻠﻴﺔ ﺒﺴﺘﺭﺓ ﻟﻠﻤﺯﻴﺞ ﺒﺩﺭﺠﺔ ﺤﺭﺍﺭﺓ 73ﻡ ﺍﻟﺼﻔﺎﺕ ﺍﻟﺤﺴﻴﺔ ﻟﻬﺫﺍ ﺍﻟﺯﺒﺩ ﻫﻭ ﺒﻘﺎﺌﻪ ﻟﻤـﺩﺓ

ﻟﻤﺩﺓ ﻨﺼﻑ ﺴﺎﻋﺔ ﻓﻲ ﻫﺫﻩ ﺍﻟﻤﺭﺤﻠـﺔ ﺘـﻡ ﺠﻴﺩﺓ ﺒﺎﻟﻔﻡ ﻭ ﻜﺎﻨﺕ ﻤـﺩﺓ ﺨﺯﻨـﻪ ﻭ ﻗﻴﻤﺘـﺔ

PDF created with pdfFactory Pro trial version www.pdffactory.com

ﺘﺼﻨﻴﻊ ﺍﻟﺯﺒﺩ ﻤﻥ ﺩﻫﻥ ﺍﻟﺤﻠﻴﺏ ﺍﻟﺠﺎﻑ ﻭ ﺍﻟﺤﻠﻴﺏ ﻤﺠﻠﺔ ﺍﻟﻬﻨﺩﺴﺔ ﻭﺍﻟﺘﻜﻨﻭﻟﻭﺠﻴﺎ،ﺍﻟﻤﺠﻠﺩ،28ﺍ ﻟﻌﺩﺩ2010،14

ﺍﻟﻔﺭﺯ ﺍﻟﻤﺠﻔﻑ ﺍﻟﻤﺴﺘﺭﺠﻊ

ﻁﺭﻴﻘﺔ ﺘﺤﻀﻴﺭ ﺍﻟﺒـﺎﺩﻯﺀ -:ﺃﺨﺫ ﺩﻭﺭﻗـﻴﻥ ﺍﻀﺎﻓﺔ ﻤﺎﺩﺓ ﻤﺴﺘﺤﻠﺒﺔ ﻤﻥ ﺍﻟﻠﺴﺜﻴﻥ ﺒﻨﺴـﺒﺔ

ﺯﺠﺎﺠﻴﻴﻥ ﻭ ﺃﻀﻴﻑ ﻟﻬﻤﺎ ﻨﺼﻑ ﻟﺘـﺭ ﻤـﻥ ٪ 0.3ﺜﻡ ﺒﺭﺩ ﺍﻟﻤﺯﻴﺞ ﻟﺩﺭﺠﺔ ﺤﺭﺍﺭﺓ 28

ﺍﻟﺤﻠﻴﺏ ﺍﻻﻋﺘﻴﺎﺩﻱ ﻭ ﺘﻡ ﺘﻌﻘﻴﻤﻬﻤﺎ ﺒﺎﻟﻤﺅﺼﺩﺓ ﻡ ﻭ ﺍﻀﻴﻑ ﺍﻟﺒﺎﺩﻱﺀ ﺒﻨﺴﺒﺔ 0ﻭ 1ﻭ 3ﻭ

. Autoclaveﻭ ﺒﻌﺩ ﺍﻟﺘﺒﺭﻴﺩ ﻟﺩﺭﺠﺔ ﺤﺭﺍﺭﺓ ٪ 5ﻭ ﺒﻌﺩﻫﺎ ﺤﻔﻅ ﺍﻟﻤﺴـﺘﺤﻠﺏ ﺒﺩﺭﺠـﺔ

24ﻡ ﺍﻀﻴﻑ ﺨﻠﻴﻁ ﺍﻟﺒﺎﺩﻱﺀ ﺍﻟﻤﺫﻜﻭﺭ ﺍﻋﻼﻩ ﺤﺭﺍﺭﺓ 15ﻡ ﻟﻤﺩﺓ 18ﺴﺎﻋﺔ.

ﺤﻀﻥ ﺍﻟﻤﺯﻴﺞ ﺒﺩﺭﺠﺔ ﺤﺭﺍﺭﺓ 22ﻡ ﻟﻤﺩﺓ ﻭ ﺘﺤﻀﻴﺭ ﺍﻟﺯﺒﺩ -:ﻭﻀﻌﺕ ﻗﻁﻌﺘﺎﻥ .2

14ﺴﺎﻋﺔ ﻭﻋﻨﺩﻤﺎ ﺤﺩﺙ ﺍﻟﺘﺨﺜﺭﺍﻟﺠﻴﺩ ﺍﺼﺒﺢ ﻤﻥ ﺍﻟﺜﻠﺞ )ﻴﺯﻥ ﻜل ﻤﻨﻬﻤﺎ ﻨﺼﻑ ﻜﻴﻠﻭ ﻏﺭﺍﻡ(

ﺼﺎﻟﺤﺎ ﻟﻼﺴﺘﻌﻤﺎل .ﺍﺠﺭﻴـﺕ ﻓﺤﻭﺼـﺎﺕ ﺍﻟﻤﺤﻀﺭ ﻤﻥ ﺍﻟﻤـﺎﺀ ﺍﻟﻤﻌﻘـﻡ ﻓـﻲ ﺠﻬـﺎﺯ

ﺍﻟﺘﻘﺩﻴﺭ ﺍﻻﺠﻤﺎﻟﻲ ﻟﻠﺯﺒﺩ ﻤﻥ ﺤﻴﺙ ﺍﻟﺭﻁﻭﺒﺔ ﻭ ﺍﻟﺨﻀﺎﺽ ﺍﻟﺨﺸﺒﻲ ﺍﻟﻜﻬﺭﺒﺎﺌﻲ ﺒﻌﺩ ﺘﻨﻅﻴﻔﻪ ﻭ

ﺍﻟﺩﻫﻥ ﻭ ﺍﻟﻤﻠﺢ ﻭ ﺍﻟﺨﺜﺭﺓ ) (Curedﺤﺴـﺏ ﺘﻌﻘﻴﻤﻪ ﺒﺎﻟﺒﺨﺎﺭ ،ﻭ ﺃ ﺴﺘﻌﻤل ﺍﻟﺨﻀﺎﺽ ﺒﻌـﺩ

ﻁﺭﻴﻘﺔ ).(11 ﺘﺒﺭﻴﺩﺓ ﻟﺒﻀﻊ ﺩﻗﺎﺌﻕ ﺤﻴﺙ ﺃﻀﻴﻑ ﺍﻟﻤﺴﺘﺤﻠﺏ

ﻗﻴﻤﺔ ﺍﻟﺤـﺎﻤﺽ -: Acid degree value ﺍﻟﺩﻫﻨﻲ ﺍﻟﻤﺒﺭﺩ ) 15ﻡ( ﺇﻟﻴﻪ ﻭ ﻏﻠﻕ ﺍﻟﺠﻬﺎﺯ ﺜﻡ

ﻗﺩﺭﺕ ﺒﺎﻟﻁﺭﻴﻘﺔ ﺍﻟﻤﺫﻜﻭﺭﺓ ﻓﻲ ).(21 ﺸﻐل ﻭ ﺘﻡ ﺘﺼﺭﻴﻑ ﺍﻟﻬﻭﺍﺀ ﺒﻌﺩ ﺨﻤﺱ ﺩﻗﺎﺌﻕ ﹸ

ﻗﻴﻤﺔ ﺍﻟﺒﻴﺭﻭﻜﺴـﻴﺩ -: Peroxide value ﻭ ﻓﺤﺼﺕ ﺩﺭﺠﺔ ﺤﺭﺍﺭﺓ ﺍﻟﻤـﺯﻴﺞ ﻭ ﺍﻟﺘـﻲ

ﻗﺩﺭﺕ ﺒﻁﺭﻴﻘﺔ ).(11 ﻭﺠﺏ ﺍﻥ ﺘﻜﻭﻥ ﺒﺤﺩﻭﺩ 12 – 10ﻡ ﺤﻴـﺙ

ﺍﻟﻔﺤﻭﺼﺎﺕ ﺍﻟﻤﻴﻜﺭﻭ ﺒﺎﻴﻭﻟﻭ ﺠﻴـﺔ -:ﺍﺠـﺭﻱ ﺍﻅﻬﺭﺕ ﺍﻟﺘﺠﺭﺒﺔ ﺒﺎﻨﻬﺎ ﺍﻓﻀل ﺩﺭﺠﺔ ﺤـﺭﺍﺭﺓ

ﻓﺤﺹ ﺒﻜﺘﺭﻴﺎ ﺍﻟﻘﻭﻟﻭﻥ ﻭ ﺍﻟﻌﺩﺩ ﺍﻟﻤﻴﻜﺭﻭﺒـﻲ ﻤﻼﺌﻤﺔ ﻟﻠﻘﺸﻁﺔ ﺍﻟﻤﺭﺍﺩ ﺘﺼﻨﻴﻊ ﺍﻟﺯﺒﺩ ﻤﻨﻬﺎ .ﺘﻡ

ﺍﻟﻜﻠﻲ ﻭ ﺍﻟﺨﻤﺎﺌﺭ ﻭ ﺍﻻﻋﻔﺎﻥ ﺤﺴﺏ ﻁﺭﻴﻘـﺔ ﺇﻀﺎﻓﺔ ﻗﻁﻌﺔ ﺜﻠﺞ ﺍﺨﺭﻯ ﻋﻨـﺩﻤﺎ ﺍﺭﺘﻔﻌـﺕ

).(21 ﺩﺭﺠﺔ ﺍﻟﺤﺭﺍﺭﺓ ﻋﻥ 12ﻡ ،ﻭ ﺍﻋﻴﺩ ﺍﻟﺨـﺽ

ـﻴﻡ

ـﺭﻱ ﺍﻟﺘﻘﻴـ ــﻲ -:ﺍﺠـ ـﻴﻡ ﺍﻟﺤﺴــ ﺍﻟﺘﻘﻴـ ﻟﻤﺩﺓ ﺨﻤﺴﺔ ﺩﻗﺎﺌﻕ ﺍﺨﺭﻯ ﻻﻜﻤﺎل ﺍﻟﻌﻤﻠﻴـﺔ ﻭ

ﺍﻟﺤﺴــﻲ ﻟﺨﻭﺍﺹ ﺍﻟﻁﻌـﻡ ﻭ ﺍﻟﻨﻜﻬـﺔ ﻭ ﺘﻜﻭﻴﻥ ﺍﻟﺯﺒﺩ.ﺘﻡ ﺘﺼﺭﻴﻑ ﺒﻌﺩﻫﺎ ﺤﻠﻴﺏ ﺍﻟﺨﺽ

ﺍﻟﺸﻜل ﻭ ﺍﻟﻨﺴﺠﺔ )ﺍﻟﻘﻭﺍﻡ( ﻭ ﺍﻟﻠﻭﻥ ﻭ ﺍﻟﻌﺒﻭﺓ ﺜﻡ ﺍﺠﺭﻴﺕ ﻋﻤﻠﻴﺔ ﺍﻟﻐﺴل ﺒﺎﻟﻤﺎﺀ ﺍﻟﺒﺎﺭﺩ ﻤﺭﺘﺎﻥ

ﻤﻥ ﻗﺒل ﺜﻼﺜﺔ ﻤﻥ ﺍﻟﻤﺤﻜﻤﻴﻥ ﻓﻲ ﻗﺴﻡ ﻋﻠـﻭﻡ ﻟﻠﺘﺨﻠﺹ ﻤﻥ ﺒﻘﺎﻴﺎ ﺤﻠﻴـﺏ ﺍﻟﺨـﺽ ﻭ ﺍﺨـﺫﹶ

ﺍﻻﻏﺫﻴﺔ /ﻜﻠﻴﺔ ﺍﻟﺯﺭﺍﻋﺔ ﻟﻠﻨﻤﺎﺫﺝ ﺍﻟﻤﺨﺘﻠﻔﺔ ﻓﻲ ﻨﻤﻭﺫﺝ ﻤﻥ ﺍﻟﺯﺒـﺩ ﻟﻐـﺭﺽ ﺘﻘـﺩﻴﺭ ﻨﺴـﺒﺔ

ﻨﺴﺏ ﺍﻟﺒﺎﺩﻱﺀ ﻭ ﺒﻤﻜﺭﺭﻴﻥ ﺒﻌﺩ ﺨﺯﻨﻬﺎ ﻓـﻲ ﺍﻟﺭﻁﻭﺒﺔ ﻭ ﺍﻀﻴﻑ ﻤﺎﺀ ﻤﻌﻘﻡ ﺒـﺎﺭﺩ ﻤـﺭﺓ

ﺩﺭﺠﺔ ﺤﺭﺍﺭﺓ ﺍﻟﺜﻼﺠﺔ ﻭﺘﻡ ﻓﺤﺼﻬﺎ ﻓﻲ ﺍﻟﻴﻭﻡ ﺍﺨﺭﻯ ﻭ ﺒﻜﻤﻴﺔ ﻤﻨﺎﺴﺒﺔ ﺍﻟـﻰ ﺍﻟﺯﺒـﺩ ﺤﺘـﻰ

ﺍﻟﺘﺎﻟﻲ. ﺍﺼﺒﺤﺕ ﺩﺭﺠﺔ ﺤﺭﺍﺭﺓ ﺍﻟﺯﺒﺩ ﺤـﻭﺍﻟﻲ -18

ﺍﻟﺤﻠﻴﺏ ﺍﻟﻤﺴـﺘﻌﻤل -:ﺍﺴﺘﻌﻤل ﺤﻠﻴﺏ ﻤﺠﻔﻑ

22ﻡ ﻭ ﻜﺎﻨﺕ ﻫﺫﻩ ﺍﻓﻀل ﺩﺭﺠـﺔ ﺤـﺭﺍﺭﺓ

ﻴﺤﺘﻭﻱ ﻋﻠﻰ ٪ 38ﺒﺭﻭﺘﻴﻥ ﻭ ٪ 48ﻻﻜﺘﻭﺯ ﻻﺩﺨﺎل ﺍﻟﻤﺎﺀ ﺍﻟﻰ ﺍﻟﺯﺒﺩ ﻓﻲ ﺤﺎﻟﺔ ﺍﻨﺨﻔـﺎﺽ

ﻭ ٪8ﺭﻤــﺎﺩ ﻭ ٪ 4ﺭﻁﻭﺒــﺔ ﻭ ﻫــﺫﻩ ﻨﺴﺒﺔ ﺍﻟﺭﻁﻭﺒﺔ ﻋﻥ ٪ 15ﺤﺩ ﺍﺩﻨﻰ ﻭﺍﻋﻴﺩﺕ

ﺍﻟﻤﻌﻠﻭﻤﺎﺕ ﺃﺨﺫﺕ ﻤـﻥ ﺒﻁﺎﻗـﺔ ﺍﻟﺘﻌﺭﻴـﻑ ﻋﻤﻠﻴﺔ ﺍﻟﺨﺽ ﻤﺭﺓ ﺍﺨﺭﻯ ﺜﻡ ﺍﻀﻴﻑ ﺍﻟﻤﻠـﺢ

ﺍﻟﻤﻠﺼﻘﺔ ﻋﻠﻰ ﺍﻟﻌﺒﻭﺓ.

ﺒﻨﺴﺒﺔ ٪ 2 - 0.5ﺤﺴﺏ ﺍﻟﺭﻏﺒﺔ ﻭ ﺤﻔـﻅ

ﺍﻟﻨﺘﺎﺌﺞ ﻭﺍﻟﻤﻨﺎﻗﺸﺔ

ﺍﻟﻤﻨﺘﺞ ﻓﻲ ﺍﻟﺜﻼﺠﺔ ﻟﻐﺭﺽ ﺇﺠﺭﺍﺀ ﻓﺤﻭﺼﺎﺕ

ﺍﻟﺘﺭﻜﻴﺏ ﺍﻟﻜﻠﻲ-:

ﺃﺴﺒﻭﻋﻴﺔ ﻭ ﻟﻤﺩﺓ ﺃﺭﺒﻊ ﺍﺴﺎﺒﻴﻊ.

ﻴﺒﻴﻥ ﺍﻟﺠﺩﻭل ) (1ﻤﻜﻭﻨﺎﺕ ﺍﻟﺯﺒﺩ ﺍﻟﻤﻌﺎﺩ ﺍﻟﺒﺎﺩﻯﺀ ﺍﻟﻤﺴﺘﻌﻤل -:

ﺘﺤﻀﻴﺭﻩ ﻤﻥ ﺍﺴﺘﻌﻤﺎل ﺍﻟﺩﻫﻥ ﺍﻟﺤﺭ ﺍﻟﺠﺎﻑ ﻭ Lactic culture

ﻨﺴﺏ ﻤﺨﺘﻠﻔﺔ ﻤـﻥ ﺍﻟﺒـﺎﺩﻯﺀ ) .( ٪ 5 - 0 DRI- VAC

ﺤﻴﺙ ﻴﻼﺤﻅ ﻤﻁﺎﺒﻘﺔ ﻤﻭﺍﺼﻔﺎﺘﻪ ﻟﺯﺒﺩ ﺍﻟﻤﻘﺎﺭﻨﺔ BD-culture- CH- A

ﻤﻥ ﺤﻴﺙ ﻨﺴﺏ ﺍﻟﺩﻫﻥ ﻭ ﺍﻟﺭﻁﻭﺒﺔ ﻭ ﺍﻟﻤﻠﺢ ﻭ Str .cremoris 70- 75

ﺍﻟﺨﺜﺭﺓ ﺤﻴﺙ ﺘﺭﺍﻭﺤﺕ ﺒﻴﻥ 80.3 – 79.9 Str .diacytyl lactis 15- 20٪

Str .lactis 1- 5 ٪

٪

PDF created with pdfFactory Pro trial version www.pdffactory.com

ﺘﺼﻨﻴﻊ ﺍﻟﺯﺒﺩ ﻤﻥ ﺩﻫﻥ ﺍﻟﺤﻠﻴﺏ ﺍﻟﺠﺎﻑ ﻭ ﺍﻟﺤﻠﻴﺏ ﻤﺠﻠﺔ ﺍﻟﻬﻨﺩﺴﺔ ﻭﺍﻟﺘﻜﻨﻭﻟﻭﺠﻴﺎ،ﺍﻟﻤﺠﻠﺩ،28ﺍ ﻟﻌﺩﺩ2010،14

ﺍﻟﻔﺭﺯ ﺍﻟﻤﺠﻔﻑ ﺍﻟﻤﺴﺘﺭﺠﻊ

ﻤﺒﺎﺸﺭﺓ ﻭ ﺘﺎﺜﻴﺭ ﺍﻟﺨﺯﻥ ﻭ ﻟﻤﺩﺓ ﺍﺭﺒﻊ ﺍﺴﺎﺒﻴﻊ ﻭ 17.9 – 17.3ﻭ 0.8 – 0.7ﻭ – 1.3

ﺒﺩﺭﺠﺔ ﺤﺭﺍﺭﺓ 8ﻡ .ﻭ ﺘﺸﻴﺭ ﺍﻟﻨﺘـﺎﺌﺞ ﺍﻟـﻰ ، ٪ 1.7ﻋﻠﻰ ﺍﻟﺘﻭﺍﻟﻲ .ﻭ ﻫﻲ ﺘﺘﻔﻕ ﺍﻭ ﻗﺭﻴﺒﺔ

ﺍﻨﺨﻔﺎﺽ ﺍﻟﺭﻗﻡ ﺍﻟﻬﻴﺩﺭﻭﺠﻴﻨﻲ ﺒﺯﻴـﺎﺩﺓ ﻤـﺩﺓ ﻤﻥ ﺍﻟﺘﺸﺭﻴﻌﺎﺕ ﺍﻟﻤﺫﻜﻭﺭﺓ ﺒﺎﻟﻤﻭﺍﺼـﻔﺎﺕ )2

ﺍﻟﺨﺯﻥ ﻭ ﺍﺭﺘﻔﺎﻉ ﻨﺴـﺏ ﺍﻟﺒـﺎﺩﻱﺀ ﺤﻴـﺙ ﻭ 4ﻭ 8ﻭ .(17ﻭ ﻜــﻭﻥ ﺍﻟﺭﻁﻭﺒــﺔ ﻓــﻲ

ﺍﻨﺨﻔﺽ ﺍﻟﺭﻗﻡ ﺍﻟﻬﻴﺩﺭﻭﺠﻴﻨﻲ pHﻤـﻥ 6.5 ﺍﻟﺘﺸﺭﻴﻌﺎﺕ ﺘﻘﻊ ﺒـﻴﻥ ٪ 18 – 16ﻭ ﺫﻟـﻙ

ﺍﻟﻰ 6.4ﻭ ﻤﻥ 5.78ﺍﻟـﻰ 5.46ﻭ ﻤـﻥ ﺒﺎﻻﻋﺘﻤﺎﺩ ﻋﻠﻰ ﺨﻠﻭﻫﺎ ﻤﻥ ﺍﻟﺒﺎﺩﺉ ﺃﻭ ﺍﺤﺘﻭﺍﺌﻬﺎ

5.46ﺍﻟﻰ 5.33ﻭ ﻤـﻥ 4.8ﺍﻟـﻰ 4.55 ﻋﻠﻴﻪ ﻭ ﺍﻟﻨﺘﺎﺌﺞ ﺘﺸﻴﺭ ﺇﻟﻰ ﺇﻨﻬﺎ ﺃ ﻋﻠﻰ ﻤﻥ ﻗﻴﻡ

ﻨﺘﻴﺠﺔ ﺍﻟﺨﺯﻥ ﻟﻤﺩﺓ ﺍﺭﺒﻊ ﺍﺴﺎﺒﻴﻊ ﻓﻲ ﺩﺭﺠـﺔ ﺍﻟﻤﻭﺍﺼﻔﺎﺕ ﺒﻘﻠﻴل ﻭﻫﺫﺍ ﻴﻌﺯﻯ ﺍﻟﻰ ﺍﻨﺨﻔﺎﺽ

ﺤﺭﺍﺭﺓ 8ﻡ ﻟﻠﻨﻤﺎﺫﺝ ﺍﻟﻤﺤﻀﺭﺓ ﻤﻥ ﺍﻀﺎﻓﺔ ﻜﻔﺎﺀﺓ ﻋﻤﻠﻴﺔ ﺍﻟﺨﺩﻤﺔ ﺍﻟﺘﻲ ﻜﺎﻨﺕ ﺘﺠﺭﻱ ﻟﻠﺯﺒﺩ

٪ 5 ، 3 ، 1 ، 0ﺒﺎﺩﻱﺀ ،ﻋﻠﻰ ﺍﻟﺘﻭﺍﻟﻲ ﻭ ﻟﻜﻭﻨﻬﺎ ﻴﺩﻭﻴﺔ ﻭ ﻟﻴﺴﺕ ﻤﻴﻜﺎﻨﻴﻜﻴﺔ ﺍﻻﻤﺭ ﺍﻟﺫﻱ

ﻫﺫﺍ ﻴﺘﻔﻕ ﻤﻊ ﺍﻟﻤﻭﺍﺼﻔﺔ ﺍﻟﻘﻴﺎﺴـﻴﺔ ﺍﻟﻌﺭﺍﻗﻴـﺔ ﻜﺎﻥ ﻟﻪ ﺘﺄﺜﻴﺭ ﻓﻲ ﺒﻘﻴﺔ ﺍﻟﻤﻜﻭﻨﺎﺕ.

ﻟﻠﺯﺒﺩ ﺒﺩﻭﻥ ﺒﺎﺩﻱﺀ ﻭ ﺍﻟﺫﻱ ﺘﺘﺭﺍﻭﺡ ﺒﻴﻥ 6.6 ﺍﻟﺘﻘﻴﻴﻡ ﺍﻟﺤﺴﻲ -:

– 7.0ﻭﻟﻡ ﺘﺫﻜﺭ ﺍﻟﻤﻭﺍﺼﻔﺔ ﺍﺭﻗـﺎﻡ ﻟﻠﺯﺒـﺩ ﻴﺒﻴﻥ ﺍﻟﺠﺩﻭل ) (2ﻨﺘﺎﺌﺞ ﺍﻟﺘﻘﻴﻴﻡ ﺍﻟﺤﺴﻲ

ﺍﻟﻤﻀﺎﻑ ﺍﻟﻴﻪ ﺒﺎﺩﻱﺀ) .(1ﻭ ﻫﺫﺍ ﻴﻌـﺩ ﺍﻤـﺭ ﻟﻨﻤﺎﺫﺝ ﺍﻟﺯﺒﺩ ﺍﻟﻤﻌﺎﺩ ﺘﺭﻜﻴﺒﻪ ﺒﺎﺴﺘﺨﺩﺍﻡ ﻨﺴـﺏ

ﻁﺒﻴﻌﻲ ﺤﻴﺙ ﺍﻥ ﺍﻻﺤﻴﺎﺀ ﺍﻟﻤﺠﻬﺭﻴﺔ ﺍﻟﻤﺴﺘﻌﻤﻠﺔ ﻤﺨﺘﻠﻔﺔ ﻤﻥ ﺍﻟﺒﺎﺩﻱﺀ ﻭ ﻤﻘﺎﺭﻨـﺔ ﺫﻟـﻙ ﻤـﻊ

ﻓﻲ ﺍﻟﺒﺎﺩﻱﺀ ﻭ ﺍﻟﺨـﺯﻥ ﺍﺩﺕ ﺍﻟـﻰ ﺘﻁـﻭﺭ ﺼﻔﺎﺕ ﺯﺒﺩ ﺍﻟﻤﻘﺎﺭﻨﺔ ،ﺤﻴﺙ ﺘﺭﺍﻭﺡ ﻤﻌـﺩل

ـﺭﻗﻡـﺽ ﺍﻟـ ـﺔ ﺍﻨﺨﻔـ ـﺔ ﻭ ﺒﺎﻟﻨﺘﻴﺠـ

ﺍﻟﺤﻤﻭﻀـ ﻤﺠﻤﻭﻉ ﺍﻟﺩﺭﺠﺔ ﻟﺼﻔﺔ ﺍﻟﻁﻌﻡ ﻭ ﺍﻟﻨﻜﻬـﺔ ﻭ

ـﺔـﺔ ﺩﺭﺠـ ـﺩﺀ ﻗﻴﻤــﺩﺭﻭﺠﻴﻨﻲ .pHﺘﺒـ ﺍﻟﻬﻴـ ﺍﻟﺸﻜل ﻭ ﺍﻟﻨﺴﺠﺔ )ﺍﻟﻘﻭﺍﻡ( ﻭ ﺍﻟﻠﻭﻥ ﻭ ﺍﻟﻤﻠﺢ ﻭ

ﺍﻟﺤـﺎﻤﺽ (ADV) Acid degree value ﺍﻟﻌﺒﻭﺓ ﺒﺎﻟﻨﺴﺒﺔ ﻟﻠﻨﻤﺎﺫﺝ ﺍﻟﻤﺤﻀﺭﺓ ﺒﺎﺴـﺘﺨﺩﺍﻡ

ﺒﺎﻟﻅﻬﻭﺭ ﻋﻨﺩﻤﺎ ﺘﺼـل ﻨﺴـﺏ ﺍﻷﺤﻤـﺎﺽ ﺍﻟﺒﺎﺩﻱﺀ ﺒﻨﺴﺏ 0ﺍﻟﻰ ٪ 5ﻤﻥ 88.7ﺍﻟـﻰ

ـﻰـﺔ (FFA) Free fatty acidﺍﻟـ ﺍﻟﺩﻫﻨﻴـ ـﺫﻱ ـﺔ ﺍﻟـ

ـﻭﺫﺝ ﺍﻟﻤﻘﺎﺭﻨــﺔ ﺒﻨﻤـ 92.5ﻤﻘﺎﺭﻨـ

٪ 1.5-0.5ﺍﺫﺍ ﺘﻡ ﺍﻟﺘﻌﺒﻴﺭ ﻋﻨﻬﺎ ﺒﺤﺎﻤﺽ ﺘﺭﺍﻭﺤﺕ ﺩﺭﺠﺘﻪ ﺒـﻴﻥ ، 97.6 – 96.0ﻭ

ﺍﻭﻟﻴﻙ ) (14ﻭ ﺍﻥ ﻻ ﺘﺯﻴﺩ ﻋﻥ ٪ 1ﻜﻤﺎ ﺠﺎﺀ ﻜﺎﻨﺕ ﺍﻋﻠﻰ ﺩﺭﺠﺔ ﻟﻠﺯﺒﺩ ﺍﻟﻤﻌﺎﺩ ﺘﺤﻀﻴﺭﻩ ﻤﻥ

ﻓــﻲ ﺩﻟﻴــل ﺍﻟﻨﻭﻋﻴــﺔ ﻟﻠﺸــﺭﻜﺔ ﺍﻟﻌﺎﻤــﺔ ﺍﺴﺘﺨﺩﺍﻡ ﺒﺎﺩﻱﺀ ﺘﺭﻜﻴﺯﻩ ٪ 3ﺤﻴـﺙ ﺒﻠﻐـﺕ

ﻟﻼﻟﺒﺎﻥ) (2005ﻭ ﺍﻟﻤﺎﺨﻭﺫ ﻋﻥ ) .(2ﻭ ﻜﺎﻨﺕ .92.5ﺍﻤﺎ ﺍﻟﻨﻤﻭﺫﺝ ﺍﻟﻤﺤﻀﺭ ﺒﺩﻭﻥ ﺍﺴﺘﺨﺩﺍﻡ

ﻨﺘﺎﺌﺞ ﻗﻴﻤﺔ ﺩﺭﺠﺔ ﺍﻟﺤـﺎﻤﺽ ) (ADVﺒـﻴﻥ ﺒﺎﺩﻱﺀ ﻓﻘﺩ ﻜﺎﻨﺕ ﺩﺭﺠﺘﻪ ﺍﺩﻨـﻰ ﺍﻟـﺩﺭﺠﺎﺕ

٪ 0.5-0.26ﻭ ﻫﺫﻩ ﺍﻟﺯﻴﺎﺩﺓ ﺒﺘﺎﺜﻴﺭ ﺯﻴـﺎﺩﺓ ) .(88.7ﻭ ﻗﺩ ﺍﺠﺭﻱ ﻫﺫﺍ ﺍﻟﺘﻘﻴﻴﻡ ﺒﺎﻻﻋﺘﻤـﺎﺩ

ﺍﻟﺒﺎ ﺩﻯﺀ ﺍﻭ ﺯﻴﺎﺩﺓ ﻤﺩﺓ ﺍﻟﺨﺯﻥ ﺍﻟﺘﻲ ﻜﺎﻨـﺕ ﻋﻠﻰ ﻤﺎ ﺠﺎﺀ ﻓـﻲ Nelsonﻭ .(20) Trout

ﺍﻭل ﻴﻭﻡ ﺍﻻﻨﺘﺎﺝ ﻭ ﺍﻻﺴﺒﻭﻉ ﺍﻟﺭﺍﺒﻊ ﻭ ﺒﻨﺴﺒﺔ ﺍﻤﺘﺎﺯ ﺍﻟﺯﺒﺩ ﺍﻟﻨﺎﺘﺞ ﺒﻨﻔﺱ ﺍﻟﺭﺍﺌﺤﺔ ﻭ ﺍﻟﻁﻌـﻡ

ﺒﺎﺩﻱﺀ ﻤﺨﺘﻠﻔﺔ ﺒﻴﻥ ) (٪ 5-0ﻭ ﻗـﺩ ﺘﻌـﻭﺩ ﺍﻟﻤﻤﻴﺯﻴﻥ ﻟﻠﺯﺒﺩ ﻭ ﻜﺎﻥ ﻤﺘﺠﺎﻨﺱ ﺍﻟﻤﻅﻬـﺭ ﻭ

ﺍﻻﺴﺒﺎﺏ ﺍﻟﻰ ﻭﺠﻭﺩ ﺍﻟﻔﻭﺴﻔﻭﻟﺒﻴﺩﺍﺕ ﻓﻲ ﺍﻟﺯﺒﺩ ﺍﻟﺘﺭﻜﻴﺏ ﻭ ﺍﻟﻘﻭﺍﻡ ﻭ ﻨﻅﻴﻔـﺎ ﻭ ﺨﺎﻟﻴـﺎ ﻤـﻥ

ﺍﻟﺘﻲ ﺘﻌﻤل ﻋﻠﻰ ﺘﻨﺸﻴﻁ ﺍﻨﺯﻴﻡ ﺍﻟﻼﻴﺒﻴﺯ )(19 ﺍﻟﺸﻭﺍﺌﺏ ﻭ ﺍﻱ ﺯﻴﻭﺕ ﻨﺒﺎﺘﻴـﺔ ﺍﻭ ﺤﻴﻭﺍﻨﻴـﺔ

ﺍﻭ ﻻﻨﺯﻴﻡ ﺍﻟﻼﻴﺒﻴﺯ ﺍﻟﺒﻜﺘﻴﺭﻱ ﺍﻟـﺫﻱ ﻴﻘـﺎﻭﻡ ﺍﺨﺭﻯ ﻭ ﻴﻤﻜﻥ ﻋـﺩﻩ ﻤﻁـﺎﺒﻕ ﻟﻠﻤﺘﻁﻠﺒـﺎﺕ

ﺍﻟﺤﺭﺍﺭﺓ ﻭﻻ ﻴﺘﺎﺜﺭ ﻜﺜﻴﺭﺍﹰ ﺒﺎﻟﺒﺴﺘﺭﺓ ﺍﻻﻋﺘﻴﺎﺩﻴﺔ ﺍﻟﺤﺴﻴﺔ ﺍﻟﻤﺫﻜﻭﺭﺓ ﻓﻲ ﺍﻟﻤﻭﺍﺼـﻔﺔ ﺍﻟﻘﻴﺎﺴـﻴﺔ

) .(6ﻜﻤﺎ ﺍﻥ ﻁﺭﻴﻘﺔ ﺍﻟﺨﻀﺎﺽ ﺘﻜﻭﻥ ﺍﻜﺜﺭ ﺍﻟﻌﺭﺍﻗﻴﺔ ).(2

ﻋﺭﻀﺔ ﻟﻠﺘﺤﻠل ﺍﻟﺩﻫﻨﻲ ﻭ ﺘﺯﺩﺍﺩ ﺒﻌﺩ ﺍﻟﺨﺯﻥ ﻭ ﺍﻟﺼﻔﺎﺕ ﺍﻟﻜﻴﻤﻴﺎﻭﻴﺔ ﻭ ﺍﻟﻤﻴﻜﺭﻭﺒﻴﺔ-:

ﻫﺫﺍ ﻴﻌﺘﻤﺩ ﻋﻠﻰ ﺍﻟﺤﺎﻟـﺔ ﺍﻟﻤﻴﻜﺭﻭﺒﺎﻴﻭﻟﻭﺠﻴـﺔ ﺘﻭﻀﺢ ﺍﻟﺠﺩﺍﻭل 3ﻭ 4ﻭ 5ﻭ 6ﺒﻌﺽ

ﺍﻟﻤﻭﺠﻭﺩﺓ ﺒﺎﻟﺯﺒﺩ .ﻭ ﻫﺫﻩ ﺍﻟﻨﺘﺎﺌﺞ ﺘﺘﻔـﻕ ﻤـﻊ ﺍﻟﺼﻔﺎﺕ ﺍﻟﻜﻴﻤﻴﺎﻭﻴـﺔ ﻭ ﺍﻟﻤﻴﻜﺭﻭﺒﺎﻴﻭﻟﻭﺠﻴـﺔ

ﺍﻟﻨﺘﺎﺌﺞ ﺍﻟﻤﺘﻌﻠﻘﻪ ﺒﺎﻟﺘﺤﻠل ﺍﻟﺩﻫﻨﻲ ﻓـﻲ ﺍﻟﺯﺒـﺩ ﻟﻠﺯﺒﺩ ﺍﻟﻤﺤﻀﺭ ﻤﻥ ﺍﺴﺘﺨﺩﺍﻡ 0ﻭ 1ﻭ 3ﻭ

) 22ﻭ .( 2ﺘﺸﻴﺭ ﺍﻟﻨﺘﺎﺌﺞ ﺍﻟﻰ ﻤﻨﺎﺴﺒﺔ ﻫـﺫﻩ ٪ 5ﺒﺎﺩﺉ ،ﻋﻠﻰ ﺍﻟﺘﻭﺍﻟﻲ ،ﺒﻌـﺩ ﺍﻟﺘﺤﻀـﻴﺭ

PDF created with pdfFactory Pro trial version www.pdffactory.com

ﺘﺼﻨﻴﻊ ﺍﻟﺯﺒﺩ ﻤﻥ ﺩﻫﻥ ﺍﻟﺤﻠﻴﺏ ﺍﻟﺠﺎﻑ ﻭ ﺍﻟﺤﻠﻴﺏ ﻤﺠﻠﺔ ﺍﻟﻬﻨﺩﺴﺔ ﻭﺍﻟﺘﻜﻨﻭﻟﻭﺠﻴﺎ،ﺍﻟﻤﺠﻠﺩ،28ﺍ ﻟﻌﺩﺩ2010،14

ﺍﻟﻔﺭﺯ ﺍﻟﻤﺠﻔﻑ ﺍﻟﻤﺴﺘﺭﺠﻊ

ﻤﻘﺎﻴﻴﺱ ﻤﻴﻜﺭﻭﺒﺎﻴﻭﻟﻭﺠﻴﺔ ﻓـﻲ ﺒﻌـﺽ ﺩﻭل ﺍﻟﻌﻤﻠﻴﺔ ﻻﻨﺘﺎﺝ ﺍﻟﺯﺒﺩ ﺨﺎﺼـﺔ ﻭ ﺍﻥ ﺍﻟﺘﻘـﻭﻴﻡ

ﺍﻟﻌﺎﻟﻡ ﻭ ﻤﻨﻬﺎ ﺍﻤﺭﻴﻜﺎ ﺤﻴﺙ ﺘﻘـﺭﺭ ﻓﻴﻬـﺎ ﺃﻻ ﺍﻟﺤﺴﻲ ﻟﻡ ﻴﺜﺒﺕ ﻅﻬﻭﺭ ﺍﻟﻁﻌـﻡ ﺍﻟﻤﺘـﺯﻨﺦ.

ﻴﺯﻴﺩ ﻋﺩﺩ ﺍﻻﻋﻔـﺎﻥ ﻭ ﺍﻟﺨﻤـﺎﺌﺭ ﻋـﻥ 20 ﻤﻤﺎﻴﺅﻜﺩ ﻤﻼﺌﻤﺔ ﺍﻟﻤﻨﺘﺠﺎﺕ ﻟﻼﺴﺘﻬﻼﻙ ﺒﻌـﺩ

/cfuﻏﻡ ﺯﺒﺩ ﻭ ﻋﺩﺩ ﺒﻜﺘﺭﻴﺎ ﺍﻟﻘﻭﻟﻭﻥ ﻋﻥ 10 ﺍﻻﻨﺘﺎﺝ ﻤﺒﺎﺸﺭﺓ ﺍﻭ ﻓﻲ ﺍﺜﻨﺎﺀ ﺍﻟﺨـﺯﻥ .ﺍﻤـﺎ

ـﻊـﻕ ﻤـ ـﻲ ﺘﺘﻔـ ـﺩ ) .(21ﻭﻫـ ـﻡ ﺯﺒـ /cfuﻏـ ﺒﺨﺼﻭﺹ ﻗﻴﻤـﺔ ﺍﻟﺒﻴﺭﻭﻜﺴـﻴﺩ Peroxide

ﺍﻟﻤﻭﺍﺼﻔﺔ ﺍﻟﻌﺭﺍﻗﻴﺔ ﺍﻟﺤﺩﻴﺜﺔ ﺍﻟﺘﻲ ﺘﺸﻴﺭ ﺍﻟـﻰ valueﻓﻘﺩ ﺍﺩﺕ ﻋﻤﻠﻴﺔ ﺍﻟﺨﺯﻥ ﻟﻤـﺩﺓ ﺍﺭﺒـﻊ

ﺍﻥ ﻻ ﺘﺯﻴﺩ ﺍﻟﺨﻤﺎﺌﺭ ﻭ ﺍﻻﻋﻔﺎﻥ ﻋـﻥ -10 ﺍﺴﺎﺒﻴﻊ ﺍﻟﻰ ﺭﻓﻌﻬﺎ ﻤﻥ 0.15ﺍﻟﻰ 0.43ﻤﻠﻠﻲ

/cfu 200ﻏﻡ ﺯﺒﺩ ﻭ ﺍﻥ ﺒﻜﺘﺭﻴﺎ ﺍﻟﻘﻭﻟـﻭﻥ ﻻ ﻤﻜﺎﻓﻲﺀ/ﻜﻐﻡ ﺯﺒﺩ ﺒﺎﻟﻨﺴﺒﺔ ﻟﻠﻨﻤﻭﺫﺝ ﺍﻟﻤﺤﻀﺭ

ﺘﺯﻴﺩ ﻋﻥ /cfu 10ﻏﻡ ﺯﺒﺩ) .(3ﻭﻫﻲ ﺍﻴﻀﺎ ﻤﻥ ﻏﻴﺭ ﺒﺎﺩﻱﺀ ﺍﺭﺘﻔﻌـﺕ ﺍﻴﻀـﺎﹰ ﺒﺎﻟﻨﺴـﺒﺔ

ﺘﺘﻔﻕ ﻤﻊ ﺍﻟﻤﻭﺍﺼﻔﺔ ﻟﻬﻴﺌﺔ ﺍﻟﺘﻘﻴـﻴﺱ ﻟـﺩﻭل ﻟﻠﻨﻤﺎﺫﺝ ﺍﻻﺨﺭﻯ ﻭ ﺒﺩﺭﺠﺎﺕ ﻤﺘﻔﺎﻭﺘﺔ ) 0.26

ﻤﺠﻠﺱ ﺍﻟﺘﻌﺎﻭﻥ ﻟﺩﻭل ﺍﻟﺨﻠﻴﺞ ﺍﻟﻌﺭﺒﻲ) .(8ﻭ ﺍﻟﻰ 0.43ﻤﻠﻠﻲ ﻤﻜﺎﻓﻲﺀ/ﻜﻐﻡ ﺯﺒﺩ ﺒﺎﻟﻨﺴـﺒﺔ

ﺍﺸﺎﺭ ﻜل ﻤـﻥ Bullockﻭ (12) Kenney ﻟﻠﻨﻤﻭﺫﺝ ﺍﻟﻤﺤﻀﺭ ﻤﻥ ٪ 1ﺒﺎﺩﻱﺀ ﻭ ﻤـﻥ

ﺇﻥ ﺍﻟﺘﻭﺯﻴﻊ ﺍﻟﺩﻗﻴﻕ ﻟﺤﺒﻴﺒﺎﺕ ﺍﻟﻤﺼل ﻓﻲ ﺍﻟﺯﺒﺩ 0.30ﺍ ﻟﻰ 0.45ﻤﻠﻠﻲ ﻤﻜﺎﻓﻲﺀ/ﻜﻐﻡ ﺯﺒـﺩ

ﻴﺴﺎﻫﻡ ﻓﻲ ﺇﻋﺎﻗﺔ ﺍﻭ ﺘﺜﺒﻴﻁ ﺍﻷﺤﻴﺎﺀ ﺍﻟﺩﻗﻴﻘﺔ ﻤﻤﺎ ﺒﺎﻟﻨﺴﺒﺔ ﻟﻠﻨﻤﻭﺫﺝ ﺍﻟﻤﺤﻀﺭ ﻤﻥ ٪ 3ﺒﺎﺩﻱﺀ ﻭ

ﻴﺯﻴـــﺩ ﻤـــﻥ ﻗﺎﺒﻠﻴـــﺔ ﺍﻟﺤﻔـــﻅ ﻜــﺫﻟﻙ ﻤــﻥ 0.15ﺍﻟــﻰ 0.25ﻤﻠﻠــﻲ

ﺍﻟﻤﻴﻜﺭﻭﺒﺎﻴﻭﻟﻭﺠﻴﺔ) .(12ﺍﻥ ﺍﻟﻨﺘـﺎﺌﺞ ﺍﻋـﻼﻩ ﻤﻜﺎﻓﻲﺀ/ﻜﻐﻡ ﺯﺒﺩ ﺒﺎﻟﻨﺴﺒﺔ ﻟﻠﻨﻤﻭﺫﺝ ﺍﻟﻤﺤﻀﺭ

ﺘﺅﻜﺩ ﺍﻤﻜﺎﻨﻴﺔ ﺘﺤﻀﻴﺭ ﺯﺒﺩ ﻭ ﺒﻨﻭﻋﻴﺔ ﺠﻴـﺩﺓ ﻤﻥ .( ٪ 5ﻭ ﺘﻌﺩ ﻫﺫﻩ ﺍﻟﻨﺘﺎﺌﺞ ﻀﻤﻥ ﺍﻟﺤـﺩ

ﻤــﻥ ﺍﻟﻨــﻭﺍﺤﻲ ﺍﻟﺘﺭﻜﻴﺒﻴــﺔ ﻭ ﺼــﻔﺎﺘﻪ ﺍﻟﻤﺴﻤﻭﺡ ﺒﻪ ﻜﻤﺎ ﺠﺎﺀ ﻓﻲ ﺩﻟﻴـل ﺍﻟﻨﻭﻋﻴـﺔ

ﺍﻟﻤﻴﻜﺭﻭﺒﺎﻴﻭﻟﻭﺠﻴﺔ ﻤﻥ ﺩﻫﻥ ﺍﻟﺤﻠﻴـﺏ ﺍﻟﺤـﺭ ﻟﻠﺸﺭﻜﺔ ﺍﻟﻌﺎﻤﺔ ﻟﻼﻟﺒﺎﻥ ) .(4ﻗﺩ

ﺍﻟﺠﺎﻑ. ﻴﻌﻭﺩ ﺍﺭﺘﻔﺎﻉ ﺭﻗﻡ ﺍﻟﺒﻴﺭﻭﻜﺴﻴﺩ ﺨـﻼل ﻤـﺩﺓ

ﺍﻟﻤﺼﺎﺩﺭ ﺍﻟﺨﺯﻥ ﻓﻲ ﻜل ﻨﻤﺎﺫﺝ ﺍﻟﺯﺒﺩ ﺍﻟـﻰ ﻋﻭﺍﻤـل

][1ﺍﻟﺠﻬﺎﺯ ﺍﻟﻤﺭﻜﺯﻱ ﻟﻠﺘﻘﻴـﻴﺱ ﻭﺍﻟﺴـﻴﻁﺭﺓ ﻤﺘﺩﺍﺨﻠﺔ ﺘﺸﺠﻊ ﺍﻻﻜﺴﺩﺓ ﻜﺎﻟﺭﻁﻭﺒﺔ ﻭ ﺍﻟﻤﻌﺎﺩﻥ

ﺍﻟﻨﻭﻋﻴﺔ (1987 ) ،ﺍﻟﺠﺯﺀ ﺍﻟﺨﺎﻤﺱ ﻟﻤﻨﺘﺠﺎﺕ ﻭ ﻓـﻲ ﻤـﺎ ﺍﻭ ﺍﻟﺘﻠﻭﺙ ﺍﻟﻤﻴﻜﺭﻭﺒﻲ).(5

ﺍﻷﻟﺒﺎﻥ ﻭﺒﻀﻤﻨﻬﺎ ﺍﻟﺯﺒﺩ ﺭﻗﻡ ﺍﻟﻤﻭﺍﺼﻔﺔ /607 ﻴﺨﺹ ﺍﻟﻌﺩﺩ ﺍﻟﻤﻴﻜﺭﻭﺒـﻲ ﺍﻟﻜﻠـﻲ ﻟﻠﻨﻤـﺎﺫﺝ

.1987ﺒﻐﺩﺍﺩ،ﺍﻟﻌﺭﺍﻕ ﺍﻟﻤﺨﺘﻠﻔﺔ ﻤﻥ ﺍﻟﺯﺒﺩ ﻓﺎﻨﻪ ﺘﺭﺍﻭﺡ ﺒـﻴﻥ ) -76

][2ﺍﻟﺠﻬﺎﺯ ﺍﻟﻤﺭﻜﺯﻱ ﻟﻠﺘﻘﻴـﻴﺱ ﻭﺍﻟﺴـﻴﻁﺭﺓ /cfu* ( 3096ﻏﻡ ﻤﻥ ﺍﻟﺯﺒﺩ ﻭ ﻓﻲ ﻅﺭﻭﻑ

ﺍﻟﻨﻭﻋﻴﺔ ،(2003 ) ،ﺍﻟﺯﺒﺩ ﺍﻟﻤﻭﺍﺼﻔﺔ ﺍﻟﻘﻴﺎﺴﻴﺔ ﺍﻟﺨﺯﻥ ﺍﻟﻤﺨﺘﻠﻔﺔ ﻤﻊ ﺍﻟﻌﻠﻡ ﺍﻥ ﻫﺫﻩ ﺍﻻﻋـﺩﺍﺩ

ﺭﻗﻡ 1987 /607ﻭﺍﻟﻤﻌﺩﻟـﺔ ﻓـﻲ ﺴـﻨﺔ ﺒﻀﻤﻨﻬﺎ ﺍﺤﻴﺎﺀ ﺍﻟﺒﺎﺩﻱﺀ ﺍﻟﺘﻲ ﺒﻘﻲ ﻗﺴﻡ ﻤﻨﻬـﺎ

) .(2003ﺒﻐﺩﺍﺩ،ﺍﻟﻌﺭﺍﻕ ﻤﻊ ﺍﻟﺯﺒﺩ ﻭ ﺍﻻﺨﺭﻯ ﻜﺎﻨﺕ ﻤﻊ ﺤﻠﻴﺏ ﺍﻟﺨﺽ

][3ﺍﻟﺠﻬﺎﺯ ﺍﻟﻤﺭﻜﺯﻱ ﻟﻠﺘﻘﻴـﻴﺱ ﻭﺍﻟﺴـﻴﻁﺭﺓ ﺍﻟﺫﻱ ﺘﻡ ﺘﺼﺭﻴﻔﻪ ﻓﻲ ﺍﺜﻨﺎﺀ ﺍﻟﺼﻨﺎﻋﺔ .ﻭ ﻫﺫﻩ

ﺍﻟﻨﻭﻋﻴﺔ ،(2006 ) ،ﺍﻟﺤـﺩﻭﺩ ﺍﻟﻤﺎﻴﻜﺭﻭﺒﻴـﺔ ﺍﻻﻋﺩﺍﺩ ﺍﻗل ﻤﻤﺎ ﺫﻜﺭ ﻓﻲ ﺩﻟﻴـل ﺍﻟﻨﻭﻋﻴـﺔ

ﻟﻠﺤﻠﻴــﺏ ﻭﻤﻨﺘﺠﺎﺘــﻪ.2006 /2270 /5 / ﻟﻠﺸﺭﻜﺔ ﺍﻟﻌﺎﻤـﺔ ﻟﻼﻟﺒـﺎﻥ ﻟﺴـﻨﺔ 2005ﻭ

ﺒﻐﺩﺍﺩ،ﺍﻟﻌﺭﺍﻕ ﺍﻟﻤﺎﺨﻭﺫ ﻤﻥ ﺍﻟﻤﻭﺍﺼﻔﺔ ﺍﻟﻘﻴﺎﺴـﻴﺔ ﺍﻟﻌﺭﺍﻗﻴـﺔ

][4ﺩﻟﻴل ﺍﻟﻨﻭﻋﻴﺔ ﺍﻟﺸﺭﻜﺔ ﺍﻟﻌﺎﻤﺔ ﻟﻤﻨﺘﻭﺠـﺎﺕ ) .(2ﻭ ﻜﺫﻟﻙ ﺍﻟﺤﺎل ﺒﺎﻟﻨﺴﺒﺔ ﻻﻋﺩﺍﺩ ﺒﻜﺘﺭﻴـﺎ

ﺍﻷﻟﺒﺎﻥ (2005 ) ،ﻭﺍﻟﻤﺄﺨﻭﺫﺓ ﻤﻥ ﺍﻟﻤﻭﺍﺼﻔﺔ ﺍﻟﻘﻭﻟﻭﻥ ﻭ ﺍﻟﺨﻤﺎﺌﺭ ﻭ ﺍﻻﻋﻔﺎﻥ ﻓـﺎﻥ ﺍﻋـﺩﺍﺩ

ﺍﻟﻘﻴﺎﺴﻴﺔ ﺍﻟﻌﺭﺍﻗﻴﺔ ﺭﻗﻡ /607ﺘﻌـﺩﻴل ﺭﻗـﻡ ﺒﻜﺘﺭﻴﺎ ﺍﻟﻘﻭﻟﻭﻥ ﻓﻲ ﻜل ﺍﻻﺤﻭﺍل ﻻ ﺘﺘﺠـﺎﻭﺯ

) .2003 /(1ﺒﻐﺩﺍﺩ،ﺍﻟﻌﺭﺍﻕ /cfu 12ﻏﻡ ﻤﻥ ﺍﻟﺯﺒﺩ ﻭ ﺍﻋﺩﺍﺩ ﺍﻟﺨﻤﺎﺌﺭ ﻟـﻡ

][5ﻋﺒﺩ ﺍﷲ ،ﺤﺎﻤـﺩ ) ،(1982ﺍﻟﺘﻐﻴـﺭﺍﺕ ﺘﺘﺠﺎﻭﺯ /cfu 23ﻏﻡ ﺯﺒﺩ ﺍﻤﺎ ﺍﻻﻋﻔﺎﻥ ﻓﻜﺎﻨﺕ

ﺍﻟﻜﻴﻤﻴﺎﻭﻴﺔ ﻭﺍﻟﻜﻴﻤﻴﻭﺤﻴﻭﻴـﺔ ﻓـﻲ ﺍﻟﺘﺼـﻨﻴﻊ ﺍﻋﺩﺍﺩﻫﺎ ﺼﻔﺭ ﻓﻲ ﻜل ﺍﻟﻨﻤﺎﺫﺝ ﺍﻟﻤﺤﻀﺭﺓ ﻤﻥ

ﺍﻟﺯﺒﺩ .ﻭ ﻫﺫﻩ ﺍﻟﻨﺘﺎﺌﺞ ﻀـﻤﻥ ﻤﻭﺍﺼـﻔﺎﺕ ﻭ

PDF created with pdfFactory Pro trial version www.pdffactory.com

ﺘﺼﻨﻴﻊ ﺍﻟﺯﺒﺩ ﻤﻥ ﺩﻫﻥ ﺍﻟﺤﻠﻴﺏ ﺍﻟﺠﺎﻑ ﻭ ﺍﻟﺤﻠﻴﺏ 2010،14ﺍ ﻟﻌﺩﺩ،28ﺍﻟﻤﺠﻠﺩ،ﻤﺠﻠﺔ ﺍﻟﻬﻨﺩﺴﺔ ﻭﺍﻟﺘﻜﻨﻭﻟﻭﺠﻴﺎ

ﺍﻟﻔﺭﺯ ﺍﻟﻤﺠﻔﻑ ﺍﻟﻤﺴﺘﺭﺠﻊ

chemical analysis of food, 8 th ed; ﻭﺯﺍﺭﺓ ﺍﻟﺘﻌﻠﻴﻡ ﺍﻟﻌـﺎﻟﻲ ﻭﺍﻟﺒﺤـﺙ،ﺍﻟﻐﺫﺍﺌﻲ

Churchill Livingstone, London. - ﺠﺎﻤﻌﺔ ﺒﻐﺩﺍﺩ – ﻜﻠﻴـﺔ ﺍﻟﺯﺭﺍﻋـﺔ،ﺍﻟﻌﻠﻤﻲ

[15]Hussein, H. S. and T., Sakuma .ﺍﻟﻌﺭﺍﻕ

(2006). Invited Review: prevalenc of

،(1983 ) ﺼﺎﻟﺢ ﻋﺒﺩ ﺍﻟﻬﺎﺩﻱ،[ﻋﺒﺩ ﻤﺤﻤﺩ6]

shiga Toxin-producing Escherichia

coli in dairy cattle and their products.

ﺩﺭﺍﺴﺔ ﺒﻌﺽ ﺍﻟﻌﻭﺍﻤل ﺍﻟﻤﺅﺜﺭﺓ ﻋﻠﻰ ﺍﻟﺘﺤﻠل

J. Dairy Sci, 88: 450-465. ﺍﻟﺩﻫﻨﻲ ﻓﻲ ﺍﻟﺤﻠﻴﺏ ﻭﺩﻭﺭ ﺍﻟﺒﻜﺘﺭﻴﺎ ﺍﻟﻤﺤﺒـﺔ

[16]Jinjarak, S.; A. Olabi; R., ﺭﺴﺎﻟﺔ ﻤﺎﺠﺴﺘﻴﺭ ﻤﻘﺩﻤـﺔ ﺇﻟـﻰ،ﻟﻠﺒﺭﻭﺩﺓ ﻓﻴﻪ

Jimenez – Flores and J. H., Walker . ﺠﺎﻤﻌﺔ ﺒﻐﺩﺍﺩ – ﺍﻟﻌﺭﺍﻕ،ﻜﻠﻴﺔ ﺍﻟﺯﺭﺍﻋﺔ

(2006). Sensory, functional, and ﻋﺎﻤﺭ ﻭﻤﺤﺴـﻥ ﺍﻟﺸـﺒﻴﺒﻲ،[ﻤﺤﻤﺩ ﻋﻠﻲ7]

analytical comparisons of whey (1984 ) .ﻭﻤﺤﻤﻭﺩ ﺍﻟﻌﻤﺭ ﻭﺼﺎﺩﻕ ﻁﻌﻤـﺔ

butter with other butters. J. Dairy ﻜﻴﻤﻴﺎﺀ ﺍﻷﻟﺒﺎﻥ ﻭﺯﺍﺭﺓ ﺍﻟﺘﻌﻠﻴﻡ ﺍﻟﻌﺎﻟﻲ ﻭﺍﻟﺒﺤﺙ

Sci. 89: 2428-2440.

. ﺍﻟﻌﺭﺍﻕ-ﺍﻟﻌﻠﻤﻲ – ﻤﻁﺒﻌﺔ ﺠﺎﻤﻌﺔ ﺍﻟﻤﻭﺼل

[17]Joint FAO/WHO food standards

programme codex alimentarius [ﻫﻴﺌﺔ ﺍﻟﺘﻘﻴﻴﺱ ﻟﻤﺠﻠﺱ ﺍﻟﺘﻌـﺎﻭﻥ ﻟـﺩﻭل8]

commission (2000). Milk and milk ﺍﻟﺴﻌﻭﺩﻴﺔ، ﺍﻟﺭﻴﺎﺽ.(2008 ) ،ﺍﻟﺨﻠﻴﺞ ﺍﻟﻌﺭﺒﻲ

products, Vol. Second edition 2000. [9]Amer M. A. and M. A., Myher

[18]Jones, E. L.; K. J. Shingfield; C. (1974). Oxidative stability to light

Kohen; A. K. Jones; B., Lupoli; and high temperature of butter

A.S., Grandison; D. E., Beever; C. product containing sunflower seed

M., Williams; P.C., Calder and P., oil. Can . Inst. Food Sci. Technol J.,

Yaqoob (2005). Chemical, physical, 7:59.

and sensory properties of dairy [10]Antila, V. and V. Kankare

products enriched with conjugated (1979). Experimental manufacture of

linoleic acid. J. Dairy Sci. 88: 2923 – butter – vegetable oil mixture,

2937. Karjantuote 62 (6/ 7) 44 – 48. (After

[19]Lurosa, J.C.; R. I., Levey; P., the Dairy Sci. Abs., 43:1018, 1981).

Herbert; S. E., Lux and D. S., [11]Association of Official analytical

Fredrickson (1970). Aspecific Chemists (A. O. A. C.) (1980).

apoprotein activator for L.B.L. Official Method of Analysis, 13th.

Biochem. Biophys. Res. Commun. ed, Washington, D. C., U.S.A.

41: 57. [12]Bullock, D. H. and A. R., Kenny

[20]Nelson, J. A. and C. M., Trout. (1969). Effect of emulsion

(1964). Judging dairy prducts. 4 th characteris of a low – fat spread on

ed. Olsen puplishing company. bacterial growth, J. Dairy Sc., 52:

Wisconsin, U.S.A. 625.

[21]Standard Method For the [13]Couverur, S., C., Hurtand; C.,

Examination Of Dairy Products. Lopez; Delaby and J. L., Peyrand ,

(1978). 14th. Ed. Amer. Pub. Health (2006). the linear relationship

Ass., Inc, Washington, D. C., U.S.A. between the proportion of fresh grass

[22]Woo, A, H. and R. C., Lindsay. in the cow diet, milk fatty acid

(1984). characterization of lipase composition and butter properties J.

activity in cold stored butter. J. Dairy Dairy Sci, 89:1956-1969.

Sci.; 67: 1194. [14]Egan, H.; R. S. Kirk and

R.Sawyer. (1981). Pearson's

PDF created with pdfFactory Pro trial version www.pdffactory.com

ﺘﺼﻨﻴﻊ ﺍﻟﺯﺒﺩ ﻤﻥ ﺩﻫﻥ ﺍﻟﺤﻠﻴﺏ ﺍﻟﺠﺎﻑ ﻭ ﺍﻟﺤﻠﻴﺏ ﻤﺠﻠﺔ ﺍﻟﻬﻨﺩﺴﺔ ﻭﺍﻟﺘﻜﻨﻭﻟﻭﺠﻴﺎ،ﺍﻟﻤﺠﻠﺩ،28ﺍ ﻟﻌﺩﺩ2010،14

ﺍﻟﻔﺭﺯ ﺍﻟﻤﺠﻔﻑ ﺍﻟﻤﺴﺘﺭﺠﻊ

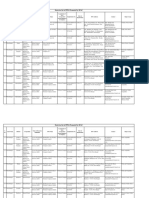

ﺠﺩﻭل) : (1ﺘﺄﺜﻴﺭ ﻨﺴﺒﺔ ﺍﻟﺒﺎﺩﺉ ﻓﻲ ﻨﺴﺏ ﻤﻜﻭﻨﺎﺕ ﺍﻟﺯﺒﺩ *

ﺍﻟﺨﺜﺭﺓ ﺍﻟﻤﻜﻭﻨﺎﺕ ٪

ﺍﻟﻤﻠﺢ ﺍﻟﺭﻁﻭﺒﺔ ﺍﻟﺩﻫﻥ

Curd ﻨﺴﺒﺔ ﺍﻟﺒﺎﺩﺉ٪

1.3 0.7 17.9 80.1 5

1.6 0.8 17.7 79.9 3

1.7 0.7 17.3 80.3 1

1.7 0.8 17.3 80.2 0

ﻤﻜﺭﺭﻴﻥ * ﻤﻌﺩل

ﺠﺩﻭل ) :(2ﺍﻟﺘﻘﻴﻴﻡ ﺍﻟﺤﺴﻲ ﻟﻨﻤﺎﺫﺝ ﺍﻟﺯﺒﺩ ﺍﻟﻤﺼﻨﻊ ﺒﺎﺴﺘﺨﺩﺍﻡ ﻨﺴﺏ ﻤﺨﺘﻠﻔﺔ ﻤﻥ ﺍﻟﺒﺎﺩﺉ *

ﺍﻟﺼﻔﺎﺕ

ﺍﻟﻤﺠﻤﻭﻉ ﺍﻟﻌﺒﻭﺓ ﺍﻟﻤﻠﺢ ﺍﻟﻠﻭﻥ ﺍﻟﺸﻜل ﻭ ﺍﻟﺘﺭﻜﻴﺏ ﺍﻟﻁﻌﻡ ﻭﺍﻟﻨﻜﻬﺔ

ﺍﻟﻨﻤﻭﺫﺝ ﺍﻟﻤﻘﺎﺭﻨﺔ ﺍﻟﻤﻘﺎﺭﻨﺔ ﺍﻟﻨﻤﻭﺫﺝ ﺍﻟﻨﻤﻭﺫﺝ ﺍﻟﻨﻤﻭﺫﺝ ﺍﻟﻤﻘﺎﺭﻨﺔ ﺍﻟﻤﻘﺎﺭﻨﺔ ﺍﻟﻤﻘﺎﺭﻨﺔ ﺍﻟﻨﻤﻭﺫﺝ ﺍﻟﻤﻘﺎﺭﻨﺔ ﺍﻟﻨﻤﻭﺫﺝ ﻨﺴﺒﺔ

ﺍﻟﺒﺎﺩﺉ٪

92.4 97.0 5.0 5.0 9.5 9.7 9.5 9.7 28.5 30.0 39.9 42.6 5

92.5 96.0 5.0 5.0 9.5 10.0 9.4 9.7 28.6 29.3 40.0 42.0 3

91.9 97.6 5.0 5.0 9.9 10.0 9.8 10.0 27.0 29.6 39.6 43.0 1

88.7 96.0 5.0 5.0 9.9 10.0 8.8 9.7 26.1 29.3 38.9 42.0 0

* ﻤﻌﺩل ﻤﻜﺭﺭﻴﻥ

PDF created with pdfFactory Pro trial version www.pdffactory.com

ﺘﺼﻨﻴﻊ ﺍﻟﺯﺒﺩ ﻤﻥ ﺩﻫﻥ ﺍﻟﺤﻠﻴﺏ ﺍﻟﺠﺎﻑ ﻭ ﺍﻟﺤﻠﻴﺏ ﻤﺠﻠﺔ ﺍﻟﻬﻨﺩﺴﺔ ﻭﺍﻟﺘﻜﻨﻭﻟﻭﺠﻴﺎ،ﺍﻟﻤﺠﻠﺩ،28ﺍ ﻟﻌﺩﺩ2010،14

ﺍﻟﻔﺭﺯ ﺍﻟﻤﺠﻔﻑ ﺍﻟﻤﺴﺘﺭﺠﻊ

ﺠﺩﻭل ) :(3ﺒﻌﺽ ﺍﻟﺼﻔﺎﺕ ﺍﻟﻜﻴﻤﻴﺎﻭﻴﺔ ﻭ ﺍﻟﻤﻴﻜﺭﻭﺒﻴﺔ ﺨﻼل ﺨﺯﻥ ﻨﻤﺎﺫﺝ ﺍﻟﺯﺒﺩ ﺒﺩﻭﻥ ﺒﺎﺩﻱﺀ ﻓﻲ

ﺍﻟﺜﻼﺠﺔ *

ﺭﻗــــــﻡ ﺍﻟﻌـــﺩﺩ ﻓﺘﺭﺓ

ﺒﻜﺘﺭﻴـــﺎ

ﺍﻻﻋﻔـــﺎﻥ ﺍﻟﺨﻤﺎﺌﺭ ﻗﻴﻤﺔ ﺩﺭﺠﺔ ﺍﻟﺒﻴﺭﻭﻜﺴــﻴﺩ ﺍﻟﻤﻴﻜﺭﻭﺒﻲ ﺍﻟﺨﺯﻥ

ﺍﻟﻘﻭﻟــﻭﻥ pH

/cfuﻏﻡ /cfuﻏﻡ ) ﻤﻠﻠـــــﻲ ﺍﻟﻜﻠـــﻲ ﺍﻟﺤﺎﻤﺽ٪

/cfuﻏﻡ

/cfuﻏﻡ ﻤﻜﺎﻓﺊ/ﻜﻐﻡ( )ﺃﺴﺒﻭﻉ(

0 23 8 3069 0.15 0.30 6.5 0

0 13 3 1466 0.20 0.30 6.5 1

0 10 2 966 0.40 0.32 6.43 2

0 8 2 566 0.40 0.35 6.41 3

0 7 1 76 0.43 0.41 6.40 4

* ﻤﻌﺩل ﻤﻜﺭﺭﻴﻥ.

) (0ﺍﻭل ﻴﻭﻡ ﺍﻻﻨﺘﺎﺝ (1) ،ﺍﻻﺴﺒﻭﻉ ﺍﻻﻭل ﻤﻥ ﺍﻟﺨﺯﻥ ﻓﻲ ﺍﻟﺜﻼﺠﺔ (2) ،ﺍﻻﺴﺒﻭﻉ ﺍﻟﺜﺎﻨﻲ ﻤﻥ ﺍﻟﺨﺯﻥ

ﻓﻲ ﺍﻟﺜﻼﺠﺔ (3) ،ﺍﻻﺴﺒﻭﻉ ﺍﻟﺜﺎﻟﺙ ﻤﻥ ﺍﻟﺨﺯﻥ ﻓﻲ ﺍﻟﺜﻼﺠﺔ (4) ،ﺍﻻﺴﺒﻭﻉ ﺍﻟﺭﺍﺒﻊ ﻤﻥ ﺍﻟﺨـﺯﻥ ﻓـﻲ

ﺍﻟﺜﻼﺠﺔ

ﺠﺩﻭل ) : (4ﺒﻌﺽ ﺍﻟﺼﻔﺎﺕ ﺍﻟﻜﻴﻤﻴﺎﻭﻴﺔ ﻭ ﺍﻟﻤﻴﻜﺭﻭﺒﻴﺔ ﺨﻼل ﺨﺯﻥ ﻨﻤﺎﺫﺝ ﺍﻟﺯﺒﺩ ﺍﻟﺤﺎﻭﻴﺔ ﻋﻠﻰ

ﺒﺎﺩﻱﺀ ﻭ ﺒﻨﺴﺒﺔ ٪ 1ﻓﻲ ﺍﻟﺜﻼﺠﺔ ) 8ﻡ ( *

ﺭﻗـــــﻡ ﺍﻟﻌـــﺩﺩ ﻓﺘﺭﺓ

ﺒﻜﺘﺭﻴــﺎ ﻗﻴﻤـــﺔ

ﺍﻻﻋﻔــﺎﻥ ﺍﻟﺨﻤﺎﺌﺭ ﺍﻟﺒﻴﺭﻭﻜﺴﻴﺩ ﺍﻟﻤﻴﻜﺭﻭﺒﻲ ﺍﻟﺨﺯﻥ

ﺍﻟﻘﻭﻟﻭﻥ ﺩﺭﺠـــﺔ pH

/cfuﻏﻡ /cfuﻏﻡ )ﻤﻠﻠــــﻲ ﺍﻟﻜﻠـــﻲ

/cfuﻏﻡ ﺍﻟﺤﺎﻤﺽ٪

ﻤﻜﺎﻓﺊ/ﻜﻐﻡ( /cfuﻏﻡ )ﺃﺴﺒﻭﻉ(

0 19 0 866 0.28 0.26 5.78 0

0 10 0 716 0.30 0.30 5.58 1

0 3 0 553 0.30 0.33 5.55 2

0 2 0 223 0.31 0.36 5.50 3

0 2 0 174 0.33 0.43 5.46 4

*ﻤﻌﺩل ﻤﻜﺭﺭﻴﻥ

PDF created with pdfFactory Pro trial version www.pdffactory.com

ﺘﺼﻨﻴﻊ ﺍﻟﺯﺒﺩ ﻤﻥ ﺩﻫﻥ ﺍﻟﺤﻠﻴﺏ ﺍﻟﺠﺎﻑ ﻭ ﺍﻟﺤﻠﻴﺏ ﻤﺠﻠﺔ ﺍﻟﻬﻨﺩﺴﺔ ﻭﺍﻟﺘﻜﻨﻭﻟﻭﺠﻴﺎ،ﺍﻟﻤﺠﻠﺩ،28ﺍ ﻟﻌﺩﺩ2010،14

ﺍﻟﻔﺭﺯ ﺍﻟﻤﺠﻔﻑ ﺍﻟﻤﺴﺘﺭﺠﻊ

ﺠﺩﻭل ) : (5ﺒﻌﺽ ﺍﻟﺼﻔﺎﺕ ﺍﻟﻜﻴﻤﻴﺎﻭﻴﺔ ﻭ ﺍﻟﻤﻴﻜﺭﻭﺒﻴﺔ ﺨﻼل ﺨﺯﻥ ﻨﻤﺎﺫﺝ ﺍﻟﺯﺒﺩ ﺍﻟﺤﺎﻭﻴﺔ ﻋﻠﻰ ﺒﺎﺩﻱﺀ ﻭ

ﺒﻨﺴﺒﺔ ٪ 3ﻓﻲ ﺍﻟﺜﻼﺠﺔ ) 8ﻡ* (

ﺭﻗـــــﻡ ﺍﻟﻌـــﺩﺩ ﻓﺘﺭﺓ

ﺒﻜﺘﺭﻴـــﺎ ﻗﻴﻤـــﺔ

ﺍﻟﺨﻤــﺎﺌﺭ ﺍﻻﻋﻔــﺎﻥ ﺍﻟﺒﻴﺭﻭﻜﺴﻴﺩ ﺍﻟﻤﻴﻜﺭﻭﺒﻲ ﺍﻟﺨﺯﻥ

ﺍﻟﻘﻭﻟــﻭﻥ ﺩﺭﺠـــﺔ pH

/cfuﻏﻡ /cfuﻏﻡ )ﻤﻠﻠــــﻲ ﺍﻟﻜﻠـــﻲ

/cfuﻏﻡ ﺍﻟﺤﺎﻤﺽ٪

ﻤﻜﺎﻓﺊ/ﻜﻐﻡ( /cfuﻏﻡ )ﺃﺴﺒﻭﻉ(

0 0 1 2130 0.30 0.30 5.46 0

0 0 0 996 0.36 0.31 5.36 1

0 2 0 633 0.41 0.33 5.36 2

0 4 0 967 0.43 0.33 5.33 3

0 1 0 710 0.45 0.35 5.33 4

*ﻤﻌﺩل ﻤﻜﺭﺭﻴﻥ

ﺠﺩﻭل ) : (6ﺒﻌﺽ ﺍﻟﺼﻔﺎﺕ ﺍﻟﻜﻴﻤﻴﺎﻭﻴﺔ ﻭ ﺍﻟﻤﻴﻜﺭﻭﺒﻴﺔ ﺨﻼل ﺨﺯﻥ ﻨﻤﺎﺫﺝ ﺍﻟﺯﺒﺩ ﺍﻟﺤﺎﻭﻴﺔ ﻋﻠﻰ

ﺒﺎﺩﻱﺀ ﻭ ﺒﻨﺴﺒﺔ ٪ 5ﻓﻲ ﺍﻟﺜﻼﺠﺔ ) 8ﻡ ( *

ﺭﻗـــــﻡ ﺍﻟﻌـــﺩﺩ ﻓﺘﺭﺓ

ﺒﻜﺘﺭﻴـــﺎ ﻗﻴﻤـــﺔ

ﺍﻟﺨﻤــﺎﺌﺭ ﺍﻻﻋﻔــﺎﻥ ﺍﻟﺒﻴﺭﻭﻜﺴﻴﺩ ﺍﻟﻤﻴﻜﺭﻭﺒﻲ ﺍﻟﺨﺯﻥ

ﺍﻟﻘﻭﻟــﻭﻥ ﺩﺭﺠـــﺔ pH

/cfuﻏﻡ /cfuﻏﻡ )ﻤﻠﻠــــﻲ ﺍﻟﻜﻠـــﻲ

/cfuﻏﻡ ﺍﻟﺤﺎﻤﺽ٪

ﻤﻜﺎﻓﺊ/ﻜﻐﻡ( /cfuﻏﻡ )ﺃﺴﺒﻭﻉ(

0 0 12 1920 0.15 0.25 4.8 0

0 0 0 2500 0.2 0.25 4.8 1

0 0 0 2000 0.25 0.30 4.65 2

0 0 0 1420 0.25 0.50 4.65 3

0 0 0 840 0.25 0.5 4.55 4

*ﻤﻌﺩل ﻤﻜﺭﺭﻴﻥ

Cfuﻭﺤﺩﺓ ﺘﻜﻭﻴﻥ ﺍﻟﻤﺴﺘﻌﻤﺭﺍﺕ

PDF created with pdfFactory Pro trial version www.pdffactory.com

You might also like

- Biological Sludge Minimization and Biomaterials/Bioenergy Recovery TechnologiesFrom EverandBiological Sludge Minimization and Biomaterials/Bioenergy Recovery TechnologiesEtienne PaulNo ratings yet

- Pleurotus OysteratusDocument7 pagesPleurotus Oysteratusسومر صيموعةNo ratings yet

- PDFDocument16 pagesPDFmuhanad100% (1)

- Al LahhamDocument13 pagesAl LahhamMohamed BakerNo ratings yet

- ﺭﻤﺘﻟﺍ لﻴﺨﻨ ﺩﻴﻤﺴﺘﻟ ﺔﻔﻴﻟﻭﺘ ﻡﻴﻴﻘﺘ ﻲﻓ ﺔﺴﺍﺭﺩ) dactylifeira .L (ﻑﻨﺼ ﻱﻭﺍﺭﻀﺨ ﻁﻴﻘﻨﺘﻟﺎﺒ ﻱﺭﻟﺍ ﻡﺎﻅﻨ ﺕﺤﺘDocument8 pagesﺭﻤﺘﻟﺍ لﻴﺨﻨ ﺩﻴﻤﺴﺘﻟ ﺔﻔﻴﻟﻭﺘ ﻡﻴﻴﻘﺘ ﻲﻓ ﺔﺴﺍﺭﺩ) dactylifeira .L (ﻑﻨﺼ ﻱﻭﺍﺭﻀﺨ ﻁﻴﻘﻨﺘﻟﺎﺒ ﻱﺭﻟﺍ ﻡﺎﻅﻨ ﺕﺤﺘdadaNo ratings yet

- تاااتتاااDocument14 pagesتاااتتاااMegdam Sameeh TarawnehNo ratings yet

- 40100029Document22 pages40100029watersoul.nNo ratings yet

- 201511231014162Document33 pages201511231014162saidNo ratings yet

- (HPLC) Performance Liquid Chromatography HighDocument16 pages(HPLC) Performance Liquid Chromatography HighYahia MasriNo ratings yet

- Pseudomonas E.coli SalmonellaDocument12 pagesPseudomonas E.coli SalmonellaAwatef FituriNo ratings yet

- 2 5348228160427133754Document18 pages2 5348228160427133754Muhammad HasanNo ratings yet

- Undp WB WRIDocument11 pagesUndp WB WRIAbdalteefNo ratings yet

- PDF Created With Pdffactory Pro Trial VersionDocument15 pagesPDF Created With Pdffactory Pro Trial Versionwatersoul.nNo ratings yet

- Poultry Product Technology (Part One) Egg Production and TechnologyDocument234 pagesPoultry Product Technology (Part One) Egg Production and TechnologyMohammed FattoumNo ratings yet

- Ash Ash AshDocument17 pagesAsh Ash AshAbdulrahman Tawfik SerorNo ratings yet

- YSMO Salt StandardsDocument8 pagesYSMO Salt StandardsYalimNo ratings yet

- A1 Form PDFDocument8 pagesA1 Form PDFAsim AqeelNo ratings yet

- Phoenix Dactylifera L Mauginiells Scaettae CavDocument17 pagesPhoenix Dactylifera L Mauginiells Scaettae CavAlaa Oudah100% (1)

- 54484Document11 pages54484watersoul.nNo ratings yet

- Adel Shareef XDocument22 pagesAdel Shareef XosamahNo ratings yet

- جبس 2 PDFDocument9 pagesجبس 2 PDFMuhanned AljeboryNo ratings yet

- 14166Document21 pages14166watersoul.nNo ratings yet

- مهم جدا في صناعة المطهراتDocument16 pagesمهم جدا في صناعة المطهراتSherif MagdyNo ratings yet

- Portland Cement ManuDocument13 pagesPortland Cement Manuابراهيم بدرNo ratings yet

- PDFDocument12 pagesPDFALINo ratings yet

- Bio FertilizersDocument12 pagesBio FertilizersSalam H AlhelaliNo ratings yet

- E 69 CC 2 A 7093 DC 133Document10 pagesE 69 CC 2 A 7093 DC 133Ammar AlaghbariNo ratings yet

- 35 48Document14 pages35 48Mohamed Saddek SalmiNo ratings yet

- 131 156Document26 pages131 156khalidNo ratings yet

- Liza Abu Pure Water FishesDocument6 pagesLiza Abu Pure Water FishesAlaa A. AbedNo ratings yet

- IbrahimDocument13 pagesIbrahimDrWeaam AlkhateebNo ratings yet

- ﺔﺴﺍﺭﺩ ﺨﻟﺍ ﻟ ﺔﻴﺤﻁﺴﻟﺍ ﺹﺍﻭ ﻠ لﻴﻟﺎﺤﻤ ﺔﻴﺌﺎﻤﻟﺍ ﺓﺩﺎﻤﻟ ﹰﺎﻴﺤﻁﺴ ﺔﻟﺎﻌﻓ ﺔﻴﻨﻭﻴﺃ ﺭﻴﻏ) C E (ﻭ ﺃ ﹰﺎﻴﺤﻁﺴ ﺔﻟﺎﻌﻓ ﺓﺩﺎﻤ ﺔﻴﻨﻭﻴﻨ) Sdbs (ﺎﻤﻬﺠﻴﺯﻤﻭ ﻻﻭ ﺔﻴﻭﻀﻋ ﺩﺍﻭﻤ ﺔﻓﺎﻀﺇ ﺭﻴﺜﺄﺘﻭ ﺔﻴﻭﻀﻋ ﻟ ﺎﻤﻬﻨﻤ لﻜ لﻴﻟﺎﺤﻤDocument23 pagesﺔﺴﺍﺭﺩ ﺨﻟﺍ ﻟ ﺔﻴﺤﻁﺴﻟﺍ ﺹﺍﻭ ﻠ لﻴﻟﺎﺤﻤ ﺔﻴﺌﺎﻤﻟﺍ ﺓﺩﺎﻤﻟ ﹰﺎﻴﺤﻁﺴ ﺔﻟﺎﻌﻓ ﺔﻴﻨﻭﻴﺃ ﺭﻴﻏ) C E (ﻭ ﺃ ﹰﺎﻴﺤﻁﺴ ﺔﻟﺎﻌﻓ ﺓﺩﺎﻤ ﺔﻴﻨﻭﻴﻨ) Sdbs (ﺎﻤﻬﺠﻴﺯﻤﻭ ﻻﻭ ﺔﻴﻭﻀﻋ ﺩﺍﻭﻤ ﺔﻓﺎﻀﺇ ﺭﻴﺜﺄﺘﻭ ﺔﻴﻭﻀﻋ ﻟ ﺎﻤﻬﻨﻤ لﻜ لﻴﻟﺎﺤﻤAmr KamelNo ratings yet

- ,488-510 4 National Journal of Chemistry, 2006, Volume 2Document23 pages,488-510 4 National Journal of Chemistry, 2006, Volume 2jamal shalabiNo ratings yet

- UntitledDocument15 pagesUntitledali nouariNo ratings yet

- 92411Document13 pages92411muhanadNo ratings yet

- تأثير اضافة سمادي البوتاسيوم والمغنيسيومDocument19 pagesتأثير اضافة سمادي البوتاسيوم والمغنيسيومalaaNo ratings yet

- January: Vol: 9 No:1, 2013 ISSN: 2222-8373Document9 pagesJanuary: Vol: 9 No:1, 2013 ISSN: 2222-8373watersoul.nNo ratings yet

- An Optimum Modern Spinning Methods Achieving Physiological Comfort in Circular Weft Knitting Fabrics.Document12 pagesAn Optimum Modern Spinning Methods Achieving Physiological Comfort in Circular Weft Knitting Fabrics.Hadir DeyabNo ratings yet

- YSMO Sugar StandardsDocument7 pagesYSMO Sugar StandardsYalimNo ratings yet

- Laboratory Experiments To Evaluate Samples of Iraqi Flint Clay and Kaolinitic Clay in The Production of RefractoriesDocument10 pagesLaboratory Experiments To Evaluate Samples of Iraqi Flint Clay and Kaolinitic Clay in The Production of RefractoriesZaid M. AliNo ratings yet

- Print ISSN: 2226-4086, Online ISSN: 2572-5149: K.k20082009@mu - Edu.iqDocument15 pagesPrint ISSN: 2226-4086, Online ISSN: 2572-5149: K.k20082009@mu - Edu.iqsarhang talebaniNo ratings yet

- GSO-ISO-685-1994-ADocument11 pagesGSO-ISO-685-1994-Aجبر البرحNo ratings yet

- Dokumen - Tips - Ead Technical Guidedance tg0003Document53 pagesDokumen - Tips - Ead Technical Guidedance tg0003Ismail SultanNo ratings yet

- النظرة الحديثة لحفظ المجموعات المتحفية المودوعة في المخازنThe modern view of preserving museum collections kept in reserveDocument18 pagesالنظرة الحديثة لحفظ المجموعات المتحفية المودوعة في المخازنThe modern view of preserving museum collections kept in reserveﺗﺴﻨﻴﻢ بن مهيديNo ratings yet

- 74 PDF Created With Pdffactory Pro Trial VersionDocument12 pages74 PDF Created With Pdffactory Pro Trial VersionSeashells Do ImpossibleNo ratings yet

- C 8 F 390 Dae 8790 EcbDocument13 pagesC 8 F 390 Dae 8790 Ecbjaafar abdullahNo ratings yet

- GCC Standardization Organization (Gso)Document13 pagesGCC Standardization Organization (Gso)mdkadryNo ratings yet

- Ôéñ) Ç ) Ê Ó×Ö " 'Jú÷) Æ ŠÓÖ) È ÃÚ Î×â Ôéñ) Ç ) Ru Œ ÏÚ M'iDocument10 pagesÔéñ) Ç ) Ê Ó×Ö " 'Jú÷) Æ ŠÓÖ) È ÃÚ Î×â Ôéñ) Ç ) Ru Œ ÏÚ M'iZaManiNo ratings yet

- 215 227Document13 pages215 227Sayed TawfeekNo ratings yet

- Khebrety MagazineDocument74 pagesKhebrety MagazineMohammed Hassan100% (2)

- YSMO Wheat Grain StandardsDocument9 pagesYSMO Wheat Grain StandardsYalimNo ratings yet

- 2008 A تأثیر ماء الري الممغنط والتسمید الفوسفاتي في نمو وحاصل الحنطةDocument12 pages2008 A تأثیر ماء الري الممغنط والتسمید الفوسفاتي في نمو وحاصل الحنطةMUHAMMED ALSUVAİDNo ratings yet

- The Industrial and Nutritional UtilizationDocument95 pagesThe Industrial and Nutritional UtilizationElioNo ratings yet

- حقائق عن الخرشوفDocument2 pagesحقائق عن الخرشوفAhmed Mohamed HassanNo ratings yet

- Finding of The Iraqi Natural Pozzolana in Injana Area, Hemrin South, Central IraqDocument13 pagesFinding of The Iraqi Natural Pozzolana in Injana Area, Hemrin South, Central IraqaliNo ratings yet

- Quality Scheme For RMC and Its Role in The Implementation of Saudi Building Code For Concrete StructuresDocument16 pagesQuality Scheme For RMC and Its Role in The Implementation of Saudi Building Code For Concrete StructuresMostafa MNo ratings yet

- Allium Cepa LDocument16 pagesAllium Cepa LMohammed FattoumNo ratings yet

- Energy and Environmental Performance of A Complementary Design For The Cover of The BuildingDocument16 pagesEnergy and Environmental Performance of A Complementary Design For The Cover of The BuildingAnas Khalid TahirNo ratings yet

- Domestic Air Conditioning UnitDocument14 pagesDomestic Air Conditioning UnitMedo HamedNo ratings yet

- E LEc TROnicsDocument19 pagesE LEc TROnicsLotfi MessaadiNo ratings yet

- International User 2022Document13 pagesInternational User 2022yahyaalmoalmNo ratings yet

- 1 Fire ExtinguishersDocument146 pages1 Fire ExtinguishersAhmed Hassan Shehata75% (4)

- Global Baby Bath Soap Industry 2016 Market Research Report - QDocument20 pagesGlobal Baby Bath Soap Industry 2016 Market Research Report - QyahyaalmoalmNo ratings yet

- Safe Formula PreparationDocument7 pagesSafe Formula PreparationyahyaalmoalmNo ratings yet

- SDB 209K Ie enDocument19 pagesSDB 209K Ie enyahyaalmoalmNo ratings yet

- Glycolic Acid Cert 50gDocument8 pagesGlycolic Acid Cert 50gyahyaalmoalmNo ratings yet

- Moonshine Pasta RecipeDocument2 pagesMoonshine Pasta RecipeAlex NeelyNo ratings yet

- Sbi Card Restaurant Week Delhi Dinner Menu: Choice of Any OneDocument4 pagesSbi Card Restaurant Week Delhi Dinner Menu: Choice of Any OneNovelaNo ratings yet

- Vegetables & Fruits From 01-04-2011Document10 pagesVegetables & Fruits From 01-04-2011perlanityanandNo ratings yet

- Laosbrochure 1Document6 pagesLaosbrochure 1api-302249336No ratings yet

- Cold CoffeeDocument11 pagesCold CoffeePrince Rener Velasco PeraNo ratings yet

- La Rosa Main Menu 042023Document2 pagesLa Rosa Main Menu 042023Kestell AppalsamyNo ratings yet

- EIU1 AIO UT7 Level1 PDFDocument4 pagesEIU1 AIO UT7 Level1 PDFminoro2583No ratings yet

- Microwave Recipes A Man, A Can, A Microwave PDFDocument24 pagesMicrowave Recipes A Man, A Can, A Microwave PDFErika100% (1)

- Gazette Notification Milk Products 24-10-2017Document136 pagesGazette Notification Milk Products 24-10-2017Easy ways2017No ratings yet

- Brewing Grain Substitution ChartDocument1 pageBrewing Grain Substitution ChartDavid EspínNo ratings yet

- The Meal Prep Manual - 60 Minute Meals V3 PDFDocument149 pagesThe Meal Prep Manual - 60 Minute Meals V3 PDFcasper russell100% (2)

- AFIELD - A Chef's Guide To Preparing and Cooking Wild Game and Fish - 1st Edition (2012)Document276 pagesAFIELD - A Chef's Guide To Preparing and Cooking Wild Game and Fish - 1st Edition (2012)mihokid100% (2)

- List of FPOs in The State of West BengalDocument8 pagesList of FPOs in The State of West BengaldebadityagNo ratings yet

- Rajsthani CuisineDocument25 pagesRajsthani Cuisineaman kumarNo ratings yet

- Complete The Chart With The Words Below. Use A / An or SomeDocument3 pagesComplete The Chart With The Words Below. Use A / An or SomeCristina Perez BaezaNo ratings yet

- Ibsdiets Fodmap ChartDocument3 pagesIbsdiets Fodmap ChartMuriloMatteiNo ratings yet

- Sensory Evaluation Tests1 PDFDocument3 pagesSensory Evaluation Tests1 PDFAnonymous OlU9bt3No ratings yet

- Polvoron RecipeDocument3 pagesPolvoron RecipeRj BengilNo ratings yet

- Atomic SushiDocument2 pagesAtomic Sushirallinc_raNo ratings yet

- BrunchDocument2 pagesBruncheatlocalmenusNo ratings yet

- Rumi Lounge: Lebanese WrapsDocument4 pagesRumi Lounge: Lebanese Wrapsapi-52123986No ratings yet

- DIA Light Color ChartDocument1 pageDIA Light Color ChartTessa M.No ratings yet

- Lawless Kalinga FoodDocument24 pagesLawless Kalinga FoodpopskyNo ratings yet

- Y3 SK Textbook Unit 02 Being HealthyDocument8 pagesY3 SK Textbook Unit 02 Being HealthyLingling NGNo ratings yet

- Final Concept PaperDocument13 pagesFinal Concept PaperVincent YambotNo ratings yet

- Msme Fish PickleDocument5 pagesMsme Fish PicklevivebajajNo ratings yet

- Japanese Cake+Document4 pagesJapanese Cake+marilenamariNo ratings yet

- Immersion Tables by Kirk (PHDND)Document4 pagesImmersion Tables by Kirk (PHDND)sasha.peudevinNo ratings yet

- Specialty Coffee Association of America Coffee Cupping Form: Name: DateDocument1 pageSpecialty Coffee Association of America Coffee Cupping Form: Name: DateFaradiba SafiraNo ratings yet

- Un-EAT-en Recipe BookDocument28 pagesUn-EAT-en Recipe BookvictorcpkNo ratings yet

- Summary: Fast Like a Girl: A Woman’s Guide to Using the Healing Power of Fasting to Burn Fat, Boost Energy, and Balance Hormones: Key Takeaways, Summary and AnalysisFrom EverandSummary: Fast Like a Girl: A Woman’s Guide to Using the Healing Power of Fasting to Burn Fat, Boost Energy, and Balance Hormones: Key Takeaways, Summary and AnalysisRating: 3 out of 5 stars3/5 (2)

- Instant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookFrom EverandInstant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookRating: 3.5 out of 5 stars3.5/5 (2)

- Forever Strong: A New, Science-Based Strategy for Aging WellFrom EverandForever Strong: A New, Science-Based Strategy for Aging WellNo ratings yet

- Gut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)From EverandGut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)Rating: 4 out of 5 stars4/5 (378)

- Summary of Mary Claire Haver's The Galveston DietFrom EverandSummary of Mary Claire Haver's The Galveston DietRating: 5 out of 5 stars5/5 (1)

- Metabolism Revolution: Lose 14 Pounds in 14 Days and Keep It Off for LifeFrom EverandMetabolism Revolution: Lose 14 Pounds in 14 Days and Keep It Off for LifeNo ratings yet

- The Body Book: The Law of Hunger, the Science of Strength, and Other Ways to Love Your Amazing BodyFrom EverandThe Body Book: The Law of Hunger, the Science of Strength, and Other Ways to Love Your Amazing BodyNo ratings yet

- How Not to Die by Michael Greger MD, Gene Stone - Book Summary: Discover the Foods Scientifically Proven to Prevent and Reverse DiseaseFrom EverandHow Not to Die by Michael Greger MD, Gene Stone - Book Summary: Discover the Foods Scientifically Proven to Prevent and Reverse DiseaseRating: 4.5 out of 5 stars4.5/5 (83)

- The Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingFrom EverandThe Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingRating: 4 out of 5 stars4/5 (3)

- Sugar Crush: How to Reduce Inflammation, Reverse Nerve Damage, and Reclaim Good HealthFrom EverandSugar Crush: How to Reduce Inflammation, Reverse Nerve Damage, and Reclaim Good HealthRating: 4 out of 5 stars4/5 (6)

- The Beck Diet Solution Weight Loss Workbook: The 6-Week Plan to Train Your Brain to Think Like a Thin PersonFrom EverandThe Beck Diet Solution Weight Loss Workbook: The 6-Week Plan to Train Your Brain to Think Like a Thin PersonRating: 3.5 out of 5 stars3.5/5 (33)

- The Diabetes Code: Prevent and Reverse Type 2 Diabetes NaturallyFrom EverandThe Diabetes Code: Prevent and Reverse Type 2 Diabetes NaturallyRating: 4.5 out of 5 stars4.5/5 (2)

- Keto Friendly Recipes: Easy Keto For Busy PeopleFrom EverandKeto Friendly Recipes: Easy Keto For Busy PeopleRating: 3.5 out of 5 stars3.5/5 (2)

- Body Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomFrom EverandBody Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomRating: 4 out of 5 stars4/5 (1)

- The Volumetrics Eating Plan: Techniques and Recipes for Feeling Full on Fewer CaloriesFrom EverandThe Volumetrics Eating Plan: Techniques and Recipes for Feeling Full on Fewer CaloriesNo ratings yet

- Secrets From the Eating Lab: The Science of Weight Loss, the Myth of Willpower, and Why You Should Never Diet AgainFrom EverandSecrets From the Eating Lab: The Science of Weight Loss, the Myth of Willpower, and Why You Should Never Diet AgainRating: 3.5 out of 5 stars3.5/5 (38)

- Find Your Path: Honor Your Body, Fuel Your Soul, and Get Strong with the Fit52 LifeFrom EverandFind Your Path: Honor Your Body, Fuel Your Soul, and Get Strong with the Fit52 LifeRating: 4 out of 5 stars4/5 (3)

- The Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsFrom EverandThe Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsRating: 4 out of 5 stars4/5 (49)

- Eat to Lose, Eat to Win: Your Grab-n-Go Action Plan for a Slimmer, Healthier YouFrom EverandEat to Lose, Eat to Win: Your Grab-n-Go Action Plan for a Slimmer, Healthier YouNo ratings yet

- Happy Gut: The Cleansing Program to Help You Lose Weight, Gain Energy, and Eliminate PainFrom EverandHappy Gut: The Cleansing Program to Help You Lose Weight, Gain Energy, and Eliminate PainRating: 3.5 out of 5 stars3.5/5 (6)

- The Diet Trap Solution: Train Your Brain to Lose Weight and Keep It Off for GoodFrom EverandThe Diet Trap Solution: Train Your Brain to Lose Weight and Keep It Off for GoodNo ratings yet

- The Candida Cure: The 90-Day Program to Balance Your Gut, Beat Candida, and Restore Vibrant HealthFrom EverandThe Candida Cure: The 90-Day Program to Balance Your Gut, Beat Candida, and Restore Vibrant HealthNo ratings yet

- How to Be Well: The 6 Keys to a Happy and Healthy LifeFrom EverandHow to Be Well: The 6 Keys to a Happy and Healthy LifeRating: 5 out of 5 stars5/5 (1)

- Hungry for Change: Ditch the Diets, Conquer the Cravings, and Eat Your Way to Lifelong HealthFrom EverandHungry for Change: Ditch the Diets, Conquer the Cravings, and Eat Your Way to Lifelong HealthRating: 4 out of 5 stars4/5 (7)

- Glucose Revolution: The Life-Changing Power of Balancing Your Blood SugarFrom EverandGlucose Revolution: The Life-Changing Power of Balancing Your Blood SugarRating: 5 out of 5 stars5/5 (351)

- The Complete Guide to Fasting: Heal Your Body Through Intermittent, Alternate-Day, and Extended FastingFrom EverandThe Complete Guide to Fasting: Heal Your Body Through Intermittent, Alternate-Day, and Extended FastingNo ratings yet

- Grit & Grace: Train the Mind, Train the Body, Own Your LifeFrom EverandGrit & Grace: Train the Mind, Train the Body, Own Your LifeRating: 4 out of 5 stars4/5 (3)