Professional Documents

Culture Documents

MS-DD-3000-HSE-FRM-0026 - Heavy Plant & Eqpt Checklist

Uploaded by

crystin0 ratings0% found this document useful (0 votes)

3 views2 pagesOriginal Title

MS-DD-3000-HSE-FRM-0026_-_Heavy_Plant_&_Eqpt_Checklist

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pagesMS-DD-3000-HSE-FRM-0026 - Heavy Plant & Eqpt Checklist

Uploaded by

crystinCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

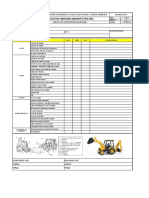

Heavy Plant and Equipment Inspection

Checklist

Doc Ref: MS-DD-3000-HSE-PRO-0003 Form No: MS-DD-3000-HSE-FRM-0026

Date: 28 March 2020 MANYAR SMELTER PROJECT Revision No: 00

Equipment No.: Log Book: Y /N Date:

Registration No.: Model Y / N Owner’s Manual: Y / N

Make: Classified Plant VIN:

Engine No.: Speedometer / Odometer Reading Checklist: Y / N

Noise Survey Report Attached Y N Plant does not exceed 85dB (a) Limit Y N Sound Insulation or Silencer/s fitted Y N

Where plant or equipment necessary for specific activities cannot meet the 85 dB(A) maximum noise limit. Subcontractor shall present a noise control plan to the Contractor Field SHES Manager and request written approval for the use of

that plant or equipment, prior to mobilizing plant or equipment.

() Inspected & Satisfactory (NA) Not Applicable (X) Requires and / or Repair

MANDATORY EQUIPMENT NA X OPERATIONAL CHECKS NA X ELECTRICAL CHECKS NA X

High beam Brakes Park / clearance lights

Low beam : auto activate Park brake Number plate light

Tail lights Steering Indicators

Brake lights Vibrations / rattles Dash lights

Driver Improvement Motor (Black Box) Clutch / gearbox operation Interior light

Safety Flag min 42 mtr above ground Acceleration / performance Gauges / warning lights

Window Tinting 80-90% BODY CHECKS NA X CABIN CHECKS NA X

Sleeper berth if fitted is restrained Panel damage / rust Upholstery

Uniquely identifiable front and sides Paint Pedal rubbers

Safe Access / Egress maintenance / emergency Door operation Window operation

Anti-slip access points Boot / tailgate operation Glass condition

Boarding / disembarking faculty Canopy / tonneau cond. Sun visors

Guards on moving parts and hazardous parts Tow bar Mirrors

Enclosed / sealed cabin (aircon) Bull bar

Speed Alerts UNDERBODY NA X

Isolation / Lockout point Exhaust condition / leaks WHEELS CHECKS NA X

Audible Reversing alarm Prop shaft / universals Hub bearings

Seat adjustments & Headrests Springs / shackles Tires / Rims incl. Spare

Chock blocks for rubber tired plant Ball-joints / tie-rod ends Rims internal external inspection

Rollover protection (ROPS) AS 2294.1 Fuel lines Wheel nuts

Fall object protection (FOPS) AS 2294.1 Brake pipes / hoses LUBRICATION CHECKS NA X

Communication (two way radio) ENGINE CHECKS NA X Engine oil

Seat Belts Oil leaks – nil Transmission oil

Horn Engine oil clean Differential oil

Revolving flashing light All fluid levels checked Grease points

First Aid Kit Fuel leaks Brake / Clutch fluid

Fire Extinguisher (9kg) (2 x for service / fuel trucks) or a fire

suppression system Moving parts guarded Inc. access to engine bay Air Filter

Jack & wheel brace Coolant leaks – nil Drip trays

Windscreen condition Hoses condition

Signage clear and legible Radiator condition

Windscreen wipers Belts condition List of approved fluids attached

Spill Kit Engine mounts condition

Battery condition

Comments:

Inspected By (competent person):

Subcontractor: Date:

CONTRACTOR USE ONLY

Mobilization of the equipment based on the information provided is approved Not approved

Contractor Representative (Print Name) ________________________________________________

Contractor Representative Signature ___________________________________________________

Date ____ / ____ / ____

Heavy Plant and Equipment Inspection

Checklist

Doc Ref: MS-DD-3000-HSE-PRO-0003 Form No: MS-DD-3000-HSE-FRM-0026

Date: 28 March 2020 MANYAR SMELTER PROJECT Revision No: 00

You might also like

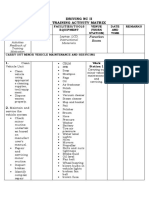

- MS DD 3000 HSE FRM 0060 Heavy Vehicle Inspection ChecklistDocument1 pageMS DD 3000 HSE FRM 0060 Heavy Vehicle Inspection ChecklistlukmanNo ratings yet

- MS DD 3000 HSE FRM 0028 Forklift Inspection ChecklistDocument1 pageMS DD 3000 HSE FRM 0028 Forklift Inspection ChecklistcrystinNo ratings yet

- Tractor Truck ChecklistDocument2 pagesTractor Truck ChecklistScribdTranslationsNo ratings yet

- Power Off Items Power On Items: Walk Around CabDocument1 pagePower Off Items Power On Items: Walk Around CabDoddy RakasiwiNo ratings yet

- Dump Truck General Daily Inspection Checklist PDFDocument1 pageDump Truck General Daily Inspection Checklist PDFJUCONS Construction100% (1)

- MS DD 3000 HSE FRM 0029 - MEWP - Inspection - ChecklistDocument1 pageMS DD 3000 HSE FRM 0029 - MEWP - Inspection - ChecklistcrystinNo ratings yet

- Walk Around Inspection Checklist For Service VehicleDocument1 pageWalk Around Inspection Checklist For Service VehicleRoland CullaNo ratings yet

- Vehicle Safety Inspection Form: Part 1Document2 pagesVehicle Safety Inspection Form: Part 1christologo manzanoNo ratings yet

- Excavator Check List 2Document1 pageExcavator Check List 2danielcudemezueNo ratings yet

- 307-Vehicle Inspection & Defect Report - Daily Rev 000Document1 page307-Vehicle Inspection & Defect Report - Daily Rev 000francisNo ratings yet

- Ak21 Eun: Dynamic Operation Engine Bay Engine RunningDocument1 pageAk21 Eun: Dynamic Operation Engine Bay Engine Runningashjam110077No ratings yet

- Excavator Daily Inspection ChecklistDocument1 pageExcavator Daily Inspection ChecklistDIBNESH PANDITA100% (8)

- AMVIC Mechanical Fitness Assessment Form Revised 09-15-2014 No LogoDocument1 pageAMVIC Mechanical Fitness Assessment Form Revised 09-15-2014 No Logojames bancescuNo ratings yet

- Pre-Use Inspection Checklist - Boom TruckDocument1 pagePre-Use Inspection Checklist - Boom TruckSAVIO100% (1)

- Checklist ExcavatorDocument2 pagesChecklist ExcavatorMahar Dika100% (1)

- Formulario de Mantenimiento 1Document2 pagesFormulario de Mantenimiento 1Marco Arias MartinezNo ratings yet

- Att 2Document1 pageAtt 2cina.mpegNo ratings yet

- Check List - RetroexcavadoraDocument1 pageCheck List - RetroexcavadoraRodrigo Eduardo Velazco AlvarezNo ratings yet

- Earth Moving EquipmentsDocument2 pagesEarth Moving EquipmentsSHARAFUDHEEN TKNo ratings yet

- Lamp 27 - Form Excavator - Backhoe InspectionDocument1 pageLamp 27 - Form Excavator - Backhoe InspectionSulhan PremixNo ratings yet

- Form A: Preventive Maintenance Service & InspectionDocument1 pageForm A: Preventive Maintenance Service & InspectionMarco Arias Martinez100% (2)

- Dot Vehicle Inspection FormsDocument3 pagesDot Vehicle Inspection FormsJohn Joseph WallsNo ratings yet

- Editable Driver's Vehicle Inspection ReportDocument2 pagesEditable Driver's Vehicle Inspection ReportzhelokhovNo ratings yet

- Excavator Daily Inspection ChecklistDocument2 pagesExcavator Daily Inspection ChecklistFira KurniatyNo ratings yet

- Bucket Truck Inspection ChecklistDocument2 pagesBucket Truck Inspection ChecklistRony Medina75% (4)

- Weekly Standard InspectionDocument3 pagesWeekly Standard InspectionFrancis Salonga100% (1)

- Tata Motors Bangladesh - Xenon Single Cab Pickup Truck22Document1 pageTata Motors Bangladesh - Xenon Single Cab Pickup Truck22ArîfNo ratings yet

- Liftking Forklift PDIDocument1 pageLiftking Forklift PDIManual ForkliftNo ratings yet

- Driver Pre-Trip/Post-Trip Inspection Checklist: Tires TrailersDocument1 pageDriver Pre-Trip/Post-Trip Inspection Checklist: Tires TrailersbasdNo ratings yet

- Annual Truck Inspection SheetDocument1 pageAnnual Truck Inspection Sheetw uNo ratings yet

- Komatsu D375a 6 Bulldozer Optional and Standard EquipmentDocument1 pageKomatsu D375a 6 Bulldozer Optional and Standard EquipmentDeni SaurusNo ratings yet

- MS-DD-3000-HSE-FRM-0027 - Crane Inspection ChecklistDocument7 pagesMS-DD-3000-HSE-FRM-0027 - Crane Inspection ChecklistlukmanNo ratings yet

- Vehicle Inspection Form 851Document1 pageVehicle Inspection Form 851arulananthan.pkNo ratings yet

- IS-HSE-R24 Safety Audit ChecklistDocument3 pagesIS-HSE-R24 Safety Audit ChecklistReds JomiNo ratings yet

- Abbreviation List: Vehicle SymbolsDocument1 pageAbbreviation List: Vehicle SymbolsNauj SaneraNo ratings yet

- Form Inspeksi Alat Berat (Compactor)Document1 pageForm Inspeksi Alat Berat (Compactor)HELMY RUSANDYNo ratings yet

- MD Super 80: Microsoft Flightsimulator 2002Document4 pagesMD Super 80: Microsoft Flightsimulator 2002andres ortizNo ratings yet

- TB 10 PDFDocument2 pagesTB 10 PDFalfaindiaNo ratings yet

- 2019 Mar Mobile Crane Inspection Checklist SAB-CR-001Document3 pages2019 Mar Mobile Crane Inspection Checklist SAB-CR-001aymenmoatazNo ratings yet

- qf771-17 Traction Unit-2Document3 pagesqf771-17 Traction Unit-2mohammedNo ratings yet

- Drill Rig Plant Pre Acceptance ChecklistDocument2 pagesDrill Rig Plant Pre Acceptance ChecklistRubén López Lema100% (1)

- Vehicle Inspection ReportDocument1 pageVehicle Inspection ReportVirna Lassiter100% (1)

- Double Drum Rollers 450dx Brochure India enDocument2 pagesDouble Drum Rollers 450dx Brochure India enRahul SharmaNo ratings yet

- Workplace Hazard Identification & Assessment Sheet: Residual Risk (With Controls) BASE RISK (Without Controls)Document2 pagesWorkplace Hazard Identification & Assessment Sheet: Residual Risk (With Controls) BASE RISK (Without Controls)Tawsif AhmedNo ratings yet

- Excavator Pre-Use Inspection ChecklistDocument1 pageExcavator Pre-Use Inspection ChecklistFyan SaputraNo ratings yet

- Majestic Dash8 Checklists PDFDocument13 pagesMajestic Dash8 Checklists PDFDanielNo ratings yet

- Mechanical ReportDocument1 pageMechanical ReportfxhhadNo ratings yet

- IsuzuDocument1 pageIsuzuFarhan Sheikh100% (1)

- DR401 Flight ManualDocument10 pagesDR401 Flight ManualNikiNo ratings yet

- LR35 Checklist ATI PDFDocument2 pagesLR35 Checklist ATI PDFBrendanRatchfordNo ratings yet

- Dozer Checklist: Y N Y NDocument1 pageDozer Checklist: Y N Y NEkaWulandariNo ratings yet

- Bolero Neo AmbulanceDocument4 pagesBolero Neo Ambulanceshashwatnandansharma0694No ratings yet

- JH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistAnwar DeenNo ratings yet

- Automotive BrochureDocument4 pagesAutomotive BrochureIngrid Garcia de JaureguiNo ratings yet

- Training Activity MatrixDocument6 pagesTraining Activity MatrixMaMerlinaJosue100% (2)

- Daily CraneDocument1 pageDaily CraneFrancisco José Meza ZepedaNo ratings yet

- (Australia) RG158-8193-1: 1BAAACDAP2310Document98 pages(Australia) RG158-8193-1: 1BAAACDAP2310PEGAZUS HUNGARY KFTNo ratings yet

- Car Inspection CheckList SampleDocument1 pageCar Inspection CheckList SampleghanavatyNo ratings yet

- Chapter 1: Investment Landscape: Financial GoalsDocument8 pagesChapter 1: Investment Landscape: Financial GoalsshubhamNo ratings yet

- Huawei Core Roadmap TRM10 Dec 14 2011 FinalDocument70 pagesHuawei Core Roadmap TRM10 Dec 14 2011 Finalfirasibraheem100% (1)

- Gis Tabels 2014 15Document24 pagesGis Tabels 2014 15seprwglNo ratings yet

- VP Construction Real Estate Development in NY NJ Resume Edward CondolonDocument4 pagesVP Construction Real Estate Development in NY NJ Resume Edward CondolonEdwardCondolonNo ratings yet

- 1.mukherjee - 2019 - SMM - Customers Passion For BrandsDocument14 pages1.mukherjee - 2019 - SMM - Customers Passion For BrandsnadimNo ratings yet

- Unit 13 - Business Hotels and Sales ConferencesDocument24 pagesUnit 13 - Business Hotels and Sales ConferencesMiguel Angel Escoto CanoNo ratings yet

- C Sharp Logical TestDocument6 pagesC Sharp Logical TestBogor0251No ratings yet

- Research Proposal IntroductionDocument8 pagesResearch Proposal IntroductionIsaac OmwengaNo ratings yet

- Staircase and Lintel As-03Document1 pageStaircase and Lintel As-03Divith B SannakkiNo ratings yet

- Ficha Tecnica 320D3 GCDocument12 pagesFicha Tecnica 320D3 GCanahdezj88No ratings yet

- Customer Satisfaction-ICICI Bank-Priyanka DhamijaDocument85 pagesCustomer Satisfaction-ICICI Bank-Priyanka DhamijaVarun GuptaNo ratings yet

- August 2015Document96 pagesAugust 2015Cleaner MagazineNo ratings yet

- Danube Coin LaundryDocument29 pagesDanube Coin LaundrymjgosslerNo ratings yet

- An Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)Document18 pagesAn Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)gurumurthy38No ratings yet

- Managerial Accounting-Fundamental Concepts and Costing Systems For Cost Analysis Module 1Document40 pagesManagerial Accounting-Fundamental Concepts and Costing Systems For Cost Analysis Module 1Uzma Khan100% (1)

- Durga Padma Sai SatishDocument1 pageDurga Padma Sai SatishBhaskar Siva KumarNo ratings yet

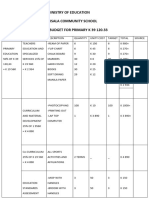

- Ministry of Education Musala SCHDocument5 pagesMinistry of Education Musala SCHlaonimosesNo ratings yet

- Home Guaranty Corp. v. Manlapaz - PunzalanDocument3 pagesHome Guaranty Corp. v. Manlapaz - PunzalanPrincess Aliyah Punzalan100% (1)

- Principles of SOADocument36 pagesPrinciples of SOANgoc LeNo ratings yet

- Different Software Life Cycle Models: Mini Project OnDocument11 pagesDifferent Software Life Cycle Models: Mini Project OnSagar MurtyNo ratings yet

- Sales Manager Latin AmericaDocument3 pagesSales Manager Latin Americaapi-76934736No ratings yet

- SettingsDocument3 pagesSettingsrusil.vershNo ratings yet

- List of People in Playboy 1953Document57 pagesList of People in Playboy 1953Paulo Prado De Medeiros100% (1)

- CBC Building Wiring Installation NC IIDocument72 pagesCBC Building Wiring Installation NC IIFaysbuk KotoNo ratings yet

- Scope: Provisional Method - 1994 © 1984 TAPPIDocument3 pagesScope: Provisional Method - 1994 © 1984 TAPPIМаркус СилваNo ratings yet

- Reference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsDocument43 pagesReference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsNisha JosephNo ratings yet

- ML7999A Universal Parallel-Positioning Actuator: FeaturesDocument8 pagesML7999A Universal Parallel-Positioning Actuator: Featuresfrank torresNo ratings yet

- Management in English Language Teaching SummaryDocument2 pagesManagement in English Language Teaching SummaryCarolina Lara50% (2)

- NX CAD CAM AutomationDocument12 pagesNX CAD CAM AutomationfalexgcNo ratings yet

- Intro S4HANA Using Global Bike Solutions EAM Fiori en v3.3Document5 pagesIntro S4HANA Using Global Bike Solutions EAM Fiori en v3.3Thăng Nguyễn BáNo ratings yet