Professional Documents

Culture Documents

Workplace Hazard Identification & Assessment Sheet: Residual Risk (With Controls) BASE RISK (Without Controls)

Uploaded by

Tawsif AhmedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Workplace Hazard Identification & Assessment Sheet: Residual Risk (With Controls) BASE RISK (Without Controls)

Uploaded by

Tawsif AhmedCopyright:

Available Formats

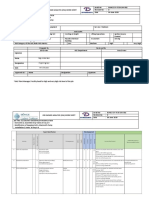

WHIS #: OHS /RA / 04

WORKPLACE HAZARD IDENTIFICATION Revision #:00

& ASSESSMENT SHEET Date Issued: 04.03.2020

Page:

Area: Black Start Facility Department: Operation & Maintenance of Emergency Diesel Generator

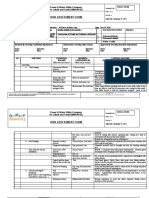

BASE RISK (without RESIDUAL RISK (with

Hazard

Examples of activities Cause List of Hazards Legal controls) Controls controls) Relevent procedure

Category Risk Risk

Severity Probability Assessment Severity Probability Assessment

Electrical Preventive & corrective All electrical protections. LOTO &

maintenace of motors, Generators, Permit Procedure. Insulated tools,

ELECTRICAL Electric Shock No 5 4 20 5 1 5 Electrical safety

LV panels, Contactors, breakers, PPE, competant staff to operate,

batteries etc.. Special PPE

Routine and non routine O&M work Entangle with Motor fan guards, Shafts and

on diesel engines, generators, ROTATING ENTITIES moving & rotating Yes 5 4 20 rotating parts are covered properly, 5 1 5 LOTO

pumps, fans & motors parts Special tools, LOTO procedure

STORED Expose to

Regular maintenance, Trained staff,

PHYSICAL HAZARDS

ENERGY(PRESSURIZED pressurized liquids/

Starting / Stopping of equipment Yes 5 4 20 protective enclousures, machine 5 1 5 EDG SOP

FLUID RELEASE/ SURGE/ Moving & rotating

guards, Remote operation, SOP

LEAKS) parts of equipment

Routine and non routine O&M work Fall from height & Safe working platforms, Guard rails,

on diesel engine radiator& exhaust WORK AT HEIGHT Material / tools Yes 4 4 16 Hand rails, safety harness, gloves, 4 1 4 Work at height

system falling from height Area barrication

Expose to high By design, Hot surfaces are

Work on or near diesel engine & HIGH TEMPERATURE Personal Protective

temperature liquids No 5 3 15 insulated. Trained staff, appropriate 5 1 5

exhaust piping POINTS Equipment

& surfaces gloves, coveralls & safe practices

Arrest oil & waterleakages quickly,

During the maintenace activities

LIQUIDS / SOLVENTS Use spill response kit to Clean and

and rugular housekeeping / floor Slipping / tripping No 3 4 12 3 1 3

SPILL ON THE FLOOR keep floor dry, appropriate safety

cleaning activities

shoes, Barricade slippery areas

Prolong exposure to

Operation & maintenance of Safe Design, Gloves, Coveralls &

diesel engines, diesel transfer

Diesel diesel / bodily No 3 3 9

Trained staff, adequate ventillation

3 1 3 Chemical Handling

contact

CHEMICAL HAZARDS

Gloves, Coveralls, Face sheilds,

Expose to Hazardous

Maintenance of batteries Acid chemicals

Yes 4 4 16 Ventillation & trained staff, MSDS, 5 1 4 Chemical Handling

periodic medical check ups

Fire monitioring and protection

system. Fire extinguishers, Fire

Hot work & electrical FLAMMABLE LIQUIDS detectors, PM on Fire detection &

Fire Yes 5 4 20 5 1 5 Fire Prevention / Hot work

maintenance work EXPOSED TO HEAT fighting system safety permit

system, safety procedures & Fire

prevention / fighting training

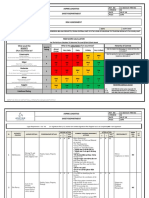

WHIS #: OHS /RA / 04

WORKPLACE HAZARD IDENTIFICATION Revision #:00

& ASSESSMENT SHEET Date Issued: 04.03.2020

Page:

Area: Black Start Facility Department: Operation & Maintenance of Emergency Diesel Generator

BASE RISK (without RESIDUAL RISK (with

Hazard

Examples of activities Cause List of Hazards Legal controls) Controls controls) Relevent procedure

Category Risk Risk

Severity Probability Assessment Severity Probability Assessment

BIOLOGICA

L HAZARDS

Dust & Exhaust gas during UNHYGEINIC Exposure to dusty Dust masks / respirators, gloves SOP

operation and maintenace

No 2 3 6 2 1 2 EDG SOP

CONDITION environment & trained staff

Restricted entry, Sign boards, Ear

NOISE EMISSION Exposure to protections, machnes in enclosed Personal Protective

Normal operation Yes 5 4 20 5 1 5

ERGONOMIC HAZARDS

FROM EQUIPMENT Excessive Noise building, annual audiometric tests & Equipment

trained staff

Hit Against Regular PM on lighting systems,

During the normal operation & stationory / moving Trained people, Illumination

INADEQUATE LIGHTING Yes 4 4 16 4 1 4

Maintenance objects measurements, Emergency lights,

Portable lamps

MANUAL HANDLING,

Preventive & Corrective Prone to injuries due Use safe lifting meathods, tool and

LIFTING OR SHIFTING No 2 3 6 2 1 2

maintenance activities to incorrect posture teckels, trained staff, gloves

Assessment done by: Kamal Peiris Assessment reviewed by: Thilina Ranasinghe Assessment approved by:

Date: 04.03.2020

You might also like

- Workplace Hazard Identification & Assessment SheetDocument3 pagesWorkplace Hazard Identification & Assessment SheetTawsif Ahmed100% (1)

- HSE Plan Ocon CommentsDocument4 pagesHSE Plan Ocon CommentsqaqqaqqNo ratings yet

- STARRT CardDocument2 pagesSTARRT Cardsanny100% (1)

- Job Risk Assessment Form: Vessel: M/V Gemini 2Document1 pageJob Risk Assessment Form: Vessel: M/V Gemini 2Danilo OralNo ratings yet

- Job Hazard Analysis: Format For JHA WorksheetDocument3 pagesJob Hazard Analysis: Format For JHA WorksheetWaseem AhmadNo ratings yet

- PTW GZR-304Document1 pagePTW GZR-304sasidharan syamNo ratings yet

- UntitledDocument8 pagesUntitledshamierrul shahliNo ratings yet

- F KG HSE RA Steel Doors Installation 2Document3 pagesF KG HSE RA Steel Doors Installation 2Alvin Badz50% (2)

- MS-DD-3000-HSE-FRM-0026 - Heavy Plant & Eqpt ChecklistDocument2 pagesMS-DD-3000-HSE-FRM-0026 - Heavy Plant & Eqpt ChecklistcrystinNo ratings yet

- 2 - JSA Hot WorkDocument9 pages2 - JSA Hot WorkAijaz AhmedNo ratings yet

- Lifting Operations RA LdwcnsDocument3 pagesLifting Operations RA LdwcnsUmair Khan100% (1)

- Scaffolding Erection and Dismantling CwhohsDocument3 pagesScaffolding Erection and Dismantling CwhohsmurasolimaranNo ratings yet

- Crane SafetyDocument9 pagesCrane SafetyAzadh MoosaNo ratings yet

- Job Safety Assessment Worksheet: Document No: 700-FOR-001 Revision: 0 Issue Date: 05-Jul-2013 Page 1 of 4Document4 pagesJob Safety Assessment Worksheet: Document No: 700-FOR-001 Revision: 0 Issue Date: 05-Jul-2013 Page 1 of 4Job MateusNo ratings yet

- Risk Assessment 53 Light TowerDocument18 pagesRisk Assessment 53 Light TowerAchmad ChusnadiNo ratings yet

- Risk Assessment For Testing & Commissioning of Electrical InstallationDocument14 pagesRisk Assessment For Testing & Commissioning of Electrical InstallationAnandu Ashokan100% (14)

- qf771-37 Electrical BedDocument3 pagesqf771-37 Electrical BedmohammedNo ratings yet

- ATRDocument3 pagesATRbalasubramaniamNo ratings yet

- Supplemental Inflatable Restraints (Sir)Document7 pagesSupplemental Inflatable Restraints (Sir)David Wise-MannNo ratings yet

- TSA-014 - Electrical Works - LOTODocument4 pagesTSA-014 - Electrical Works - LOTOMusadiq HussainNo ratings yet

- Check List AlimakDocument2 pagesCheck List Alimakmaria elena100% (4)

- HSE-F-NEOM-014 - General Risk AssessmentDocument32 pagesHSE-F-NEOM-014 - General Risk AssessmentAhmed Mohamed100% (1)

- Drilling and Milling Machine HIRARCDocument1 pageDrilling and Milling Machine HIRARCMahendren Jayapalan0% (1)

- Task Risk AssesmentDocument3 pagesTask Risk Assesmentafsalkareem100% (1)

- Hansvahini Auto Interior Pvt. LTD: Hazard Identification and Risk AssessmentDocument6 pagesHansvahini Auto Interior Pvt. LTD: Hazard Identification and Risk AssessmentAtul SharmaNo ratings yet

- JSA PRE-TEST Upload ContohDocument2 pagesJSA PRE-TEST Upload ContohDenny Kurniawan PrawiraNo ratings yet

- JSA Welding & GrindingDocument2 pagesJSA Welding & GrindingtaufikNo ratings yet

- HIRA-POND A Ext.Document4 pagesHIRA-POND A Ext.pravash883No ratings yet

- Construction of Masjid and CafeteriaDocument10 pagesConstruction of Masjid and CafeteriaFaisal RazaNo ratings yet

- Annex 2 HIRADEC FormatDocument9 pagesAnnex 2 HIRADEC Formatamit100% (1)

- AFA HIRA - Electrical Control PanelDocument30 pagesAFA HIRA - Electrical Control PaneljavedNo ratings yet

- Aspire Logistics Safetydepartment: Ref. No. AL-SSD-SAF-FRM-02 01 Date 18.07.19 1of6Document6 pagesAspire Logistics Safetydepartment: Ref. No. AL-SSD-SAF-FRM-02 01 Date 18.07.19 1of6Kevin ColmoNo ratings yet

- 038 - Working On Mobile Elevating Work PlatformDocument4 pages038 - Working On Mobile Elevating Work PlatformPrem ChristianNo ratings yet

- JRA No 11-195 Field Calibration For Valves & Transmitters at FEC AreaDocument5 pagesJRA No 11-195 Field Calibration For Valves & Transmitters at FEC AreaAijaz AhmedNo ratings yet

- Jsa Servicing of Rudder RoomDocument2 pagesJsa Servicing of Rudder RoomIlya BordonosovNo ratings yet

- 464 20081015 01 Major Form YAGDocument5 pages464 20081015 01 Major Form YAGChaphidzun NakMadridista SejaetieNo ratings yet

- Door Window and Roller ShutterDocument7 pagesDoor Window and Roller Shuttershamierrul shahliNo ratings yet

- JRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaDocument8 pagesJRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaAijaz AhmedNo ratings yet

- ABRA For E-HouseDocument10 pagesABRA For E-HouseSatish SharmaNo ratings yet

- Jsa 01 - Incoming ContohDocument2 pagesJsa 01 - Incoming ContohDenny Kurniawan PrawiraNo ratings yet

- JRA 10-005 Insttalation of New Dodo GateDocument9 pagesJRA 10-005 Insttalation of New Dodo GateAijaz AhmedNo ratings yet

- Apprvd. Foundation, Grade Beam Final For Isham 1Document7 pagesApprvd. Foundation, Grade Beam Final For Isham 1Faisal RazaNo ratings yet

- Risk Assessment For Testing & Commissioning of HVAC SystemDocument12 pagesRisk Assessment For Testing & Commissioning of HVAC SystemAnandu Ashokan73% (11)

- Eme-D-062 Underwater Diving OperationsDocument3 pagesEme-D-062 Underwater Diving Operationslatish salianNo ratings yet

- Risk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Document12 pagesRisk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Anandu Ashokan100% (1)

- Ims-L4l2-Pr02-F01 RM - 7 - Cutting - PlasmaDocument1 pageIms-L4l2-Pr02-F01 RM - 7 - Cutting - PlasmaMyusof MohamadNo ratings yet

- JHA For Pipe Scrap Loading and UnloadingDocument5 pagesJHA For Pipe Scrap Loading and Unloadingkunnar corrosionNo ratings yet

- RMDJV Pj74 Hiradc Subc 05a (Piling Work)Document1 pageRMDJV Pj74 Hiradc Subc 05a (Piling Work)myn maliQue100% (1)

- Work Instruction Template (Operational)Document5 pagesWork Instruction Template (Operational)haaNo ratings yet

- Risk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiDocument4 pagesRisk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiSamboy Dionisio0% (1)

- Peb New Jha - Hot WorkDocument2 pagesPeb New Jha - Hot WorkChe Wan ErliyasNo ratings yet

- Jsa For RadiographyDocument3 pagesJsa For Radiographyjithin shankarNo ratings yet

- Program Needs: Analysis By: Reviewed byDocument3 pagesProgram Needs: Analysis By: Reviewed bysajidkaleemNo ratings yet

- JHA Pressure Testing and PiggingR.1Document7 pagesJHA Pressure Testing and PiggingR.1Oliver SanvictoresNo ratings yet

- Risk Assesment @ro, WTP & STP PremDocument6 pagesRisk Assesment @ro, WTP & STP PremvarunthalariNo ratings yet

- Opertaing Window LimitsDocument6 pagesOpertaing Window LimitshejaNo ratings yet

- Methane (0 00014 4) Inbalanceair1710757295133Document7 pagesMethane (0 00014 4) Inbalanceair1710757295133carlosNo ratings yet

- PSJV Duqm Refinery Project Hsse Observations Tracking RegisterDocument3 pagesPSJV Duqm Refinery Project Hsse Observations Tracking RegisterbalasubramaniamNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- AafDocument4 pagesAafSyeda Fatima aliNo ratings yet

- Ims PolicyDocument1 pageIms PolicyTawsif AhmedNo ratings yet

- EMERGENCY RESPONSE PLAN - Operational Phase-Revision 00Document20 pagesEMERGENCY RESPONSE PLAN - Operational Phase-Revision 00Tawsif Ahmed100% (6)

- Abaqus Tutorial: Fracture Analysis Consultants, IncDocument200 pagesAbaqus Tutorial: Fracture Analysis Consultants, IncTawsif AhmedNo ratings yet

- Handover Report - 02 (Wartsila Maintenance Tool)Document34 pagesHandover Report - 02 (Wartsila Maintenance Tool)Tawsif AhmedNo ratings yet

- Elastic-Plastic Analysis of Simply Supported Rectangular Plates U PDFDocument178 pagesElastic-Plastic Analysis of Simply Supported Rectangular Plates U PDFTawsif AhmedNo ratings yet

- Decrease in Paco2 With Prone Position Is Predictive of Improved Outcome in Acute Respiratory Distress SyndromeDocument7 pagesDecrease in Paco2 With Prone Position Is Predictive of Improved Outcome in Acute Respiratory Distress SyndromedarwigNo ratings yet

- DHCS Handbook EnglishDocument33 pagesDHCS Handbook EnglishprabhaNo ratings yet

- Electrodeposited Coatings of Rhodium For Engineering UseDocument5 pagesElectrodeposited Coatings of Rhodium For Engineering UsesamehNo ratings yet

- Assessment of Groundwater Quality For Irrigation of Green Spaces in The Rourkela City of Odisha, IndiaDocument11 pagesAssessment of Groundwater Quality For Irrigation of Green Spaces in The Rourkela City of Odisha, Indiaghalit mohammadNo ratings yet

- 1 PDFDocument3 pages1 PDFSugiThanikaNo ratings yet

- Jay Dee Harp - RedactedDocument7 pagesJay Dee Harp - RedactedHeavyNo ratings yet

- Eocr-Pfz: Digital Over Current RelayDocument1 pageEocr-Pfz: Digital Over Current RelayFaris RasyadiNo ratings yet

- Nchem2 PosttestDocument4 pagesNchem2 PosttestJessa GuerraNo ratings yet

- CVA DVA Werkstuk Bekele - tcm39 91310Document40 pagesCVA DVA Werkstuk Bekele - tcm39 91310s_75No ratings yet

- Medication Errors PaperDocument6 pagesMedication Errors Paperapi-487459879No ratings yet

- The Non Invasive Assessment of VascularDocument39 pagesThe Non Invasive Assessment of VascularLilia RadjefNo ratings yet

- Class 9 Science Annual Paper 2 Prince Public SchoolDocument3 pagesClass 9 Science Annual Paper 2 Prince Public SchoolSHAURYA VARDHANNo ratings yet

- Jase's Lenormand MeaningsDocument3 pagesJase's Lenormand MeaningsXimena FariasNo ratings yet

- Grease Select Guide PDFDocument12 pagesGrease Select Guide PDFeng13No ratings yet

- AP SCERT 1-4 HighlightedDocument41 pagesAP SCERT 1-4 Highlightedyamuna0% (1)

- Pocket Dermatology Sara Hylwa, Elisabeth Hurliman, Jing Liu EtcDocument542 pagesPocket Dermatology Sara Hylwa, Elisabeth Hurliman, Jing Liu EtcMuhammad Ahmad bin makruf syammaku100% (1)

- Manual Osciloscopio GOM620FGDocument29 pagesManual Osciloscopio GOM620FGJesus PereiraNo ratings yet

- Revision 5Document4 pagesRevision 5Phương MinhNo ratings yet

- Covenant On Civil and Political RightsDocument3 pagesCovenant On Civil and Political RightsRainier Rhett ConchaNo ratings yet

- Classification of Engines & Its ComponentsDocument33 pagesClassification of Engines & Its ComponentsSunil DhankharNo ratings yet

- D FTP Payslip 00040502 04 2023 PDFDocument1 pageD FTP Payslip 00040502 04 2023 PDFmuhammed basil kmNo ratings yet

- Analysis of Oil in Water Using The Agilent Cary 630 FtirDocument4 pagesAnalysis of Oil in Water Using The Agilent Cary 630 FtirsalvaleuvenNo ratings yet

- Medi Claim Health InsuranceDocument3 pagesMedi Claim Health InsuranceRupesh VNo ratings yet

- Manual pp40 En-20180906-171652296Document28 pagesManual pp40 En-20180906-171652296mohamedNo ratings yet

- HU038 - Humes Oasis 2000 Series Owners Manual v6 WEBDocument22 pagesHU038 - Humes Oasis 2000 Series Owners Manual v6 WEBCodrut DavidNo ratings yet

- Visio SM12, RTC048200405UDocument1 pageVisio SM12, RTC048200405UMN Titas TitasNo ratings yet

- 2024self-Report of Medical ConditionsDocument3 pages2024self-Report of Medical Conditionsdiolanto5No ratings yet

- YakultDocument15 pagesYakultPRIYA KUMARINo ratings yet

- Metal Cutting Forming Module 3Document52 pagesMetal Cutting Forming Module 3Sathya DharanNo ratings yet

- Press Release: Semarang, 22 October 2017 - PT Kalbe Farma TBK (Kalbe) Through Kalbe EthicalDocument2 pagesPress Release: Semarang, 22 October 2017 - PT Kalbe Farma TBK (Kalbe) Through Kalbe EthicalYessy YasmaraldaNo ratings yet