Professional Documents

Culture Documents

Slurry Pumps MCU Introduction (English)

Uploaded by

Jose Antonio RojasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slurry Pumps MCU Introduction (English)

Uploaded by

Jose Antonio RojasCopyright:

Available Formats

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Mill Circuit University

Centrifugal Slurry Pump Introduction

Version 2.0

Developed by

Centrifugal Pump Technology Group

Presented by

Learning and Development

Weir Minerals Division

Outline

1. Product Information

2. Product Terminology

3. Product Types or Variations

4. Product Selection Methodology

5. Product Performance

6. Competition

Version 2.0 20 September, 2018 IP Category: Confidential Page 1

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Weir Minerals Division

Warman® MCR®, MCR-M®, MCU®

For the most severe services

SAG, ball, rod mill discharge service

MCR® - rubber lined

MCR-M® - metal lined

MCU® - metal unlined

Product Overview:

Flow

Up to 10,220 m3/hr (45,000 USGPM)

Pressure

Up to 55 m (180 ft) of Head 900 kPa

(~130 Psi)

Size

125 -760 mm discharge

Power

Up to 4,025 KW (5,400 HP)

Weir Minerals Division

Warman® AH®

Suitable for most applications

Product Overview:

Flow

Up to 5,000 m3/hr (22,000 USGPM)

Pressure

Up to 73 m (240 ft) of Head 2,070 kPa

(~300 Psi)

Size

Up to 18 inch discharge

Power

Up to 2,015 KW (2,700 HP)

Version 2.0 20 September, 2018 IP Category: Confidential Page 2

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Weir Minerals Division

WRT® – Wear Reduction Technology

Discharge guide vanes from

WBH® development

Born from the WBH development

program, this new technology was

retrofitted into the most popular

Warman AH, L and M models to

give your existing installations a

face lift in performance! Matching

throatbush

Weir Minerals Division

Warman® AHP / AHPP

Suitable for tailings or staged applications

Product Overview:

Flow

Up to 5,000 m3/hr (22,000

USGPM)

Pressure

Up to 73 m (240 ft) of Head

AHP 3,450 kPa (~500 Psi)

Some high pressure sizes AHPP

6,900 kPa (~1000Psi)

Size

4-18 inch discharge

Version 2.0 20 September, 2018 IP Category: Confidential Page 3

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Weir Minerals Division

Warman® WBH® Slurry Pumps

The next generation of the AH

Suitable for most applications

Product Overview:

Flow

Up to 2,725 m3/hr (12,000 USGPM)

Pressure

Up to 76 m (250 ft) of Head 2,070 kPa

(~300 Psi)

Size

50 – 300 mm discharge

Power

Up to 1,045 KW (1,400 HP)

Weir Minerals Division

Warman® Froth Pumps: AHF, LF, MF

Froth Slurry, Flotation, Chemical, Pulp &

Paper

Product Overview:

Flow

Up to 4,525 m3/hr (20,000 USGPM)

Pressure

Up to 37 m (120 ft) of Head 3,450 kPa

(~500 Psi)

Size

Up to 22 inch discharge

Power

Up to 1,420 KW (1,900 HP)

Version 2.0 20 September, 2018 IP Category: Confidential Page 4

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Weir Minerals Division

Warman® Froth Pumps: AHF, LF, MF

Warman® Froth Pumps: AHF, LF, MF

Easily retrofits existing AH®, L orM

installations by replacing:

Cover plate

Throatbush

Impeller

Intake joint ring

Weir Minerals Division

Warman® XU

Suitable for most applications, generally sold into

Coal and Aggregate

Metal unlined configuration

Product Overview:

Flow

Up to 2,270 m3/hr (10,000 USGPM)

Pressure

Up to 73 m (240 ft) of Head 1,035 kPa

(~150 Psi)

Size

Up to 12 inch discharge

Power

Up to 560 KW (750 HP)

Version 2.0 20 September, 2018 IP Category: Confidential Page 5

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Weir Minerals Division

Warman® HTP

High pressure Hydrotransport and

tailings

Only available with metal liners and

impeller

Product Overview:

Flow

Up to 9,085 m3/hr (40,000

USGPM)

Pressure

Up to 67 m (220 ft) of Head

4,400 kPa(~580 Psi)

Size

• 500, 600, 650 mm discharge

Power

Up to 4,025 KW (5,400 HP)

Warman Bearing Assemblies

Weir Minerals Division

Warman® Bearing Assemblies Terminology;

Defined by letter designation A (smallest)

through V (largest)

Grease lubricated as a standard

Includes grease purged labyrinth type shaft

seals

Inpro-Seals available upon request

U, V

Version 2.0 20 September, 2018 IP Category: Confidential Page 6

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Warman Bearing Assemblies

Weir Minerals Division

Warman® Bearing Assemblies

Bearing assemblies supplied with grease zerk fittings for the

labyrinth shaft seals

Recommended greasing intervals in IOM

Bearing assemblies supplied with pipe plugs in the bearing grease

holes

Greasing frequency/amount requirements in IOM manual

Provided with plugs vs. grease zerks in order to minimize

possibility of site over greasing the bearings when greasing the

shaft seals daily.

Warman® Horizontal Slurry Pumps

Weir Minerals Division

Standard Design Features

Heavy duty construction

Cast/ductile iron outer casing

Interchangeable thick elastomer or metal

liners and impellers

Large diameter impeller

Large internal passages

Cartridge style bearing assembly

Shaft sealing options: gland, low flow

gland, dry running centrifugal seals and

mechanical seals

Warman® pattern flanges

We have come a long way from the

original design…

Version 2.0 20 September, 2018 IP Category: Confidential Page 7

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Product Terminology

Weir Minerals Division

Bearing Assembly Volute Liner Seal Frame Plate Liner Rubber Lined

Metal Lined

Frame Plate Liner Seal

Impeller Cover Plate Liner

Unlined

One-Piece Frame Volute Liner seal Casing

OH0 – Unlined Pump

Volute Liner Impeller Throatbush Intake Joint Ring

Weir Minerals Division

Warman® Liner Interchangeability

Version 2.0 20 September, 2018 IP Category: Confidential Page 8

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Product Core Part numbers

Part Description Basic Part # Material Code Basic Part Number

Cover Plate Liner 018 Abrasion or Erosion/Corrosion Resistant Alloys A

Expeller 028 Corrosion Resistant Alloys C

Expeller Ring 029 SG Cast Irons D

Frame Plate Liner 036/043 Engineering Alloys E

Frame Plate Liner Insert 041 Grey Irons G

Gland / Bolts 044/045/126 Heat Resistant Alloys H

Impeller 056/058/145/147 Coper Base Alloys K

Intake Joint Ring 060 Aluminum Base Alloys L

Lantern Ring 063 Special Alloys M

Impeller Sealing O Ring 064 Nickel Base Alloys N

Neck Ring 067 Coatings

Shaft Sleeve 075/076 Spray / Cladding J

Stuffing Box 078 Polymers

Throatbush 083 Plastics P

Shaft O Ring 109 Gland Packings Q

Volute liner 110 Natural Rubbers R

Shaft Spacer / Sleeve Spacer 117/179 Synthetic Bushings T

Lantern Restrictor 118 Synthetic Elastomers S

Expeller Ring Seal 122 Polyurethanes U

Volute Seals 124/125 Combinations

Discharge Joint Ring 132 Multi-material Combinations Z

Warman® Materials

Weir Minerals Division

A05 – 27% Hi Chrome

The standard metal offering for

Warman® pump product

A61 – 30% HyperChrome®

Utilized when a greater level of wear

resistance vs A05 is required

A68 – 36% HyperChrome®

Utilized when a greater level of wear

resistance vs A61 is required

R55 – 47 ShoreA

The standard elastomer offering for

Warman® pump product

Version 2.0 20 September, 2018 IP Category: Confidential Page 9

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Types of Slurry Pumps – MCU, MCR-M, MCR 19

Courtesy of ANSI/HI 12.1-12.6 - 2016

Rubber

Unlined

Metal

Unlined

OH0 – Unlined Pump

Unlined

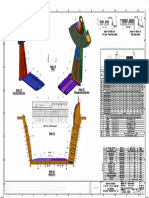

Weir Minerals MC Pumps: MCU Unlined Metal Design 20

Available 125, 150, 200, 250, 350, 450, 550, 650

Option for very course particles > 10 mm and ball scats

Same piping locations as MCR

Interchangeable throatbush, impeller, FPLI with the MCR

Ability to increase casing wall thickness on pattern

Version 2.0 20 September, 2018 IP Category: Confidential Page 10

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Weir Minerals MC Pumps: MCR-M, Metal Lined Design

Option to convert MCR to a High Chrome Iron Volute Liner

Available 400, 450, 550, 650, 750, 760

Ability to mix rubber and metal side liners

Weir Minerals MCR Pumps: 2 Piece Design

A 2-piece design Cover plate – size 300 and larger

Allows access to replace the impeller or throatbush without disconnecting the

discharge piping or splitting the casings

Version 2.0 20 September, 2018 IP Category: Confidential Page 11

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Two Piece Cover Plate

Remove Suction Cover and Throatbush subassembly

Two Piece Cover Plate

Suction Cover lifting beam has pick points for rubber or metal

Throatbush

Version 2.0 20 September, 2018 IP Category: Confidential Page 12

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Two Piece Cover Plate

Impeller lifting beam has moveable lower jaw for new vs worn

impeller

Two Piece Cover Plate

Provides ability to replace Throatbush or Impeller without

removing discharge piping or removing the Cover Plate

Version 2.0 20 September, 2018 IP Category: Confidential Page 13

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Pump Maintenance

Lifting Beam for 4 & 5 vane Impellers

Beams can safely lift both new and worn parts

Bottom hook (blue piece) is unbolted and rotated as needed

Preswirl

Localised wear of vane under front shroud (550MC)

Boddington

Ernest Henry

Cadia

Version 2.0 20 September, 2018 IP Category: Confidential Page 14

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Preswirl

Hypothesis for wear pattern

Recirculating flow across wear ring interacts

with gross flow onto leading edge of vane

causing vortex at inside of front shroud and

behind leading edge

Difficult to change amount of recirculation, so change angle of flow

onto leading edge by using pre-swirl vanes in inlet of throatbush

Pre-swirl vanes

Pre-swirl vanes developed

to give slurry a rotational

velocity ahead of the

impeller leading edge to;

a)Reduce the relative

velocity of the slurry onto

the vane, and

b) Lower the angle of

incidence to ensure the

flow is close to the

“shockless” entry angle

Version 2.0 20 September, 2018 IP Category: Confidential Page 15

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Conventional Centrifugal Pumps 31

Centrifugal, or radial flow pumps comprise a part of very wide class of rotodynamic pumps in

which pumping of liquids or generation of pressure is effected by a rotary motion of one or

several impellers, or blade cascades.

Predominantly radial direction of pumped liquid creates conditions of some centrifugal force

action.

Most rotodynamic slurry pumps are of centrifugal type.

Centrifugal Pump Impeller – Characteristic Dimensions

Note that vane angles are measured from

radial (meridional) direction. Another

convention is to measure vane angles from

tangential direction.

Centrifugal Pump Function 32

The main function of a pump intake is to provide for a uniform liquid velocity distribution at the

impeller eye.

The main function of a pump impeller is to transfer mechanical energy of a driver to the hydraulic

energy of liquid.

The function of a discharge collector (volute and diffusion chamber) is to convert the kinetic energy

imparted to the liquid by the impeller into pressure. The discharge collector takes no part in the

generation of head and therefore deals only with minimizing losses.

Conventional End-suction Pump Schematic

1 - Intake

2 - Impeller

3 - Volute

4 – Diffusion

chamber

5 - Cutwater

6 - Vane

Version 2.0 20 September, 2018 IP Category: Confidential Page 16

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Centrifugal Pumps of Conventional Design – Specific Speed

33

The physical meaning of specific speed (in US units):

revolutions per minute to deliver 1 gpm at 1-foot head with an impeller

similar to one under consideration but reduced in size.

Ns n Q 3/ 4

H

The specific speed as a type number is constant for all similar pumps and

does not change with speed for the same pump.

US units to metric units conversion for specific speed:

Ns 51.6n s

Centrifugal Slurry Pumps

Variety of Pump Types for Different Applications

ANSI/HI 1.3 (2009). American National Standard for Centrifugal Pumps For Design and Application.

Version 2.0 20 September, 2018 IP Category: Confidential Page 17

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Centrifugal Pumps of Conventional Design 35

Pump Efficiency versus Specific Speed and Pump Size

Centrifugal Pumps of Conventional Design

Conventional Pump Design – Performance Curves for Various Ns

Version 2.0 20 September, 2018 IP Category: Confidential Page 18

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Slurry Classification 37

HI 12.1-12.6 – Service Class for Heterogeneous Slurries

Based on Specific Gravity and d50 Particle Size

Larger solids, or higher concentrations will result in a more erosive slurry

Slurry pump service can be

classified by “standard” slurry

application

• Severe

• Heavy

• Medium

• Light

Corresponding ANSI/HI Slurry

Pump Standard service classes

4,3,2,1

HI Head Recommendations Based on Slurry Classification 38

Class 1: 105 m

Class 2: 73 m

Class 3: 55 m

Class 4: 40 m

Wear history has shown these recommendations are not conservative

Weir’s Slurry Wear Type Classification is a more in-depth methodology which is

discussed in advanced modules

Version 2.0 20 September, 2018 IP Category: Confidential Page 19

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

What is Tip speed? 39

Recommended Tip Speed & Head Limits for Slurry Type

Tip speed is the tangential component of an impeller rotation at a

specific diameter.

Tip speed at OD

Tip speed at ID

Units:

Diameter in Meters to get m/s

Diameter in Ft to get ft/s

Speed in RPM (revolutions per minute)

Recommended Tip speed limits depend generally on service types to limit the wear

on the pump liners. For example: Impeller wear can exponentially increase at 2.5 to

3 exponent with an increase in Tip Speed.

Slurry Application 40

Service Class 4 Service Class 1

Version 2.0 20 September, 2018 IP Category: Confidential Page 20

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Slurry Pump Groups 41

Service Class 4 Service Class 1

Preferred Operating Range (POR) 42

Service Duty Preferred Operating Range

Classification General Guideline

Wet Crushing,

Mill Discharge > 1% 75% 90%

of Underflow from Severe

crusher, Oil Sands

Hydrotransport…

SAG Mill, Heavy

Media, Sand & Heavy 70% 100%

Gravel >.25”…

Ball Mill, Pebble Mill,

Sand and Gravel < Medium 65% 110%

.25”

Flotation, Dewater

Pump with SG close 50% 130%

to 1 Light

*FGD 80% to 110%

100

Version 2.0 20 September, 2018 IP Category: Confidential Page 21

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Performance Test

650 MCR initial validation test

▪ Used to confirm actual pump operating

condition

Customer witness tests

▪ Offsite Online viewing

MC Pump – Typical Predicted Performance Curve

Curve number

starts with a “P”

Created using

affinity rules and

scale factors

Bears a note:

“PREDICTED, USE

AS FIRST GUIDE

ONLY”

Version 2.0 20 September, 2018 IP Category: Confidential Page 22

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

MC Pump – Typical Tested Performance Curve

Curve number

starts with a “T”

Reflects actual test

on water

Contains

information on test

date and location

Pump Curve vs. System Curve 46

Weir Minerals Division 11

So where does the customer come up with a flow and head value in

order for us to select a pump?

The flow is generally process driven where the customer is trying

to process so many tons per hour.

The head requirement is completely dependent on the customers

system and the flow rate required for their process.

A system curve would typically be generated to show the

head requirements as a function of flow rate.

The system curve is dependent on the customer’s installation and

piping system.

Version 2.0 20 September, 2018 IP Category: Confidential Page 23

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

System Curve Components – reintroduced for Slurry 47

Weir Minerals Division 12

Discharge Static Head

Elevation difference between surface of the liquid in the suction tank and discharge

point.

Friction Losses

Energy loss due to the affect of fluid viscosity.

Losses are dependent on:

Piping length, diameter, roughness, elbows, valves, entrance & exit losses

Use Darcy-Weisbach and Hazen-Williams equations for friction losses (See section

5 – Friction Losses in Pipes of Weir Slurry Pumping Manual Pg. 25)

Additional terminal pressure

Feeding cyclones

Spray nozzles

Filter feed

Pressurized tank

Actual Process Data – Single Pump System Variations 48

Version 2.0 20 September, 2018 IP Category: Confidential Page 24

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Centrifugal Pump Performance Curve 49

Pump Type Horizontal Pump

Pump Model 550 MCR

CURVE SHOWS APPROXIMATE PERFORMANCE FOR CLEAR WATER (ANSI/HI 1.6-2000 Centifugal Pump Test Standard unless otherwise specified). For media other than water,

corrections must be made for density, viscosity and/or other effects of solids. WEIR MINERALS reserves the right to change pump performance and/or delete impellers without notice. Frame

suitability must be checked for each duty and drive arrangement. Not all frame alternatives are necessarily available from each manufacturing centre.

80 Pump

Discharge 559mm

Nozzle

Suction 660mm Size

Impeller

70 Vanes 4

Vane ø 1580mm Impeller

Speed Curve Type Closed Data

50% 60% Part No Material

375 rpm 70% UMC55145EL1 Metal

75%

60 80% UMC55451EL1 Metal Bearing

84% Frame (Rating - KW) Frame Power

86% U 2000 Rating

350 rpm

86% Seal

50 84%

Gland Sealed Pump Seal Type

NPSH r

IENC Y

80%

Head, H (m)

Tip speed

E FFIC

Liner (Norm Max r/min)

limit

9.14m

40 300 rpm Elastomer 375

Min Passage Size Spherical

215.9mm Impeller

7.62m

Passage

Curve

30 Revision 2

Test Data

6.1m

250 rpm Revision Notes

Max speed changed

or Curve

Reference Reference

4.57m

20 Madison test 080302 Data

Last Issued Mar 08

200 rpm Issued May 10

3.05m

10

Curve Name:

“T” and

“WPA” are

© 3/2018 Weir Minerals North America

All Rights Reserved

Tested.

2000 4000 6000 8000 “P” and

TYPICAL PUMP PERFORMANCE CURVE

“ESY” are

Available in gpm and ft Flow Rate, Q (m³/hr) T-4943/2 Predicted

Weir Minerals Division

New from Competitors

MCPT Meeting – What is new from our Competitors?

Presented to: MC2 7th May 2012

Prepared by: John Otten, Aleks Roudnev and Ron Bourgeois

Confidential Information

This document contains information which is confidential to companies forming the Weir Minerals Division.

It should not be disclosed in whole or in part to parties other than the recipient without the express written

permission of Weir Minerals Division authorized personnel.

Version 2.0 20 September, 2018 IP Category: Confidential Page 25

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

GIW

GIW Industries – Market Focus

Primary activity in the following sectors:

▪ Mining (Mill Circuit & Tailings)

▪ Phosphate

▪ Iron Ore

▪ Copper/Gold

▪ Oil Sands

▪ FGD

▪ Dredging, Sand & Gravel

▪ General Industry and International

▪ ~28% Market share in US

Version 2.0 20 September, 2018 IP Category: Confidential Page 26

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

GIW Industries – Primary Product Offerings

MDX

Designed for SAG and ball mill discharge

duties as well as cyclone feed and screen

feed applications in ore mining

- Comparable to: MC®

HVF

For use in all froth pumping applications in

both the Mineral Processing and Industrial

Minerals industries

- Comparable to: AHF

LSA-S

Pumps are widely used in ore transport,

mill discharge, cyclone feed, tailings and

plant process applications

- Comparable to: AH®

Key Competitors – KSB-GIW

Version 2.0 20 September, 2018 IP Category: Confidential Page 27

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Key Competitors – KSB-GIW

Past History Note: Test work done in the mid 2000’s. Appeared to have early encouraging results.

GIW Industries – General Highlights

Strengths

▪ Well designed and high performing slurry pumps

▪ Lower cost point compared to Weir

▪ Highly regarded for technical solutions

▪ Slurry testing capabilities

▪ US based foundry

▪ Large Oil Sands installation ~ 40-50% of current revenue

▪ Aggressively pursue trials

▪ Broad product offering to cover almost any application, very

similar to Weir

Weaknesses

▪ Loss of the Linatex® material for their LCC-R line

▪ Do not seem to price aggressive enough on project bids and

then have to push for installations through trials

▪ Primarily a metal unlined offering which has inherent safety risks

▪ Do not have a good offering to compete when the applications

benefits from rubber liners, especially the MCR in mill circuit

applications

Version 2.0 20 September, 2018 IP Category: Confidential Page 28

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

FLS Krebs / millMAX

FLS – Krebs/MillMax – Market Focus

▪ Mining: Active

▪ Phosphate Limited

▪ Iron Ore Lacking Success but Active

▪ Copper/Gold Successful and Highly Active

▪ Pot Ash Successful and Active

▪ Coal: Highly Successful and Highly Active

▪ FGD/Power: Very Limited

▪ Dredging, Sand & Gravel & Oil Sands: Active

▪ General Industry: Limited

Version 2.0 20 September, 2018 IP Category: Confidential Page 29

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Key Competitors – FLS Krebs millMAX UMD

FLS – Primary Product Offerings (Krebs - Horizontals)

Krebs millMAX metal unlined

▪ Similar to: XU, AH®, WBH® , MCU®

Krebs slurryMAX rubber lined

▪ Similar to: AH®, L, WBH®

Krebs gravelMax metal unlined

▪ Similar to: XU, AHU, MD

Version 2.0 20 September, 2018 IP Category: Confidential Page 30

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

FLS Summary

Strengths

▪ Successful in leveraging mill equipment to package and sell total portfolio where possible

▪ GravelMAX in Heavy Media Classification applications in Coal

▪ Pull pumps through with cyclones and/or other FLS products.

▪ Aggressive pricing, especially if mills / flotation equipment have been secured.

▪ Low Cost sourcing; primarily is China

▪ Continue to invest in product development and now offer a very complete product range

▪ Very active trial program with aggressive promises and focus on benefits

▪ Extended life of wear components

▪ Wear adjustment technology

▪ Energy savings

▪ Offer complete engineering services (Purchase of CEntry)

Weaknesses

▪ Primarily a metal unlined offering which has inherent safety risks

▪ Do not have a good offering to compete with when the applications benefits from rubber liners, especially the MCR

in mill circuit applications

Version 2.0 20 September, 2018 IP Category: Confidential Page 31

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Key Competitors – Metso Minerals

• XM – eXtra heavy-duty with Metal wear parts

• XR – eXtra heavy-duty with Rubber wear part

XM Extra Heavy Duty Metal Slurry pump XR Extra Heavy Duty Rubber Lined Slurry Pump

Metso – Primary Product Offering (Horizontals)

MM – Mining-duty with Metal parts (Orion)

MR – Mining-duty with Rubber parts (Orion)

Mining & mineral processing

Industrial processing

Coal and power plant

Sand and gravel

Comparable to: L, XU

VERY LOW COST

Version 2.0 20 September, 2018 IP Category: Confidential Page 32

Technical Learning Program Centrifugal Slurry Pump Introduction

Mill Circuit University

Metso Summary

Strengths

▪ Highly recognizable and know brand names

▪ Relatively large install base

▪ Ability to package pumps with the mills

▪ Extremely aggressive on projects, when they want to be

▪ Extremely aggressive on offering no cost trials to customers

▪ Plans to introduce own cyclone line in the future to package with the rest of the mill offering

Weaknesses

Quality issues

Inferior wear life

Issues supporting the aftermarket of their install base

Little to no product development – using what they have

Questions 66

Version 2.0 20 September, 2018 IP Category: Confidential Page 33

You might also like

- AUMUND Apron FeedersDocument12 pagesAUMUND Apron Feederschannakeshava pandurangaNo ratings yet

- MPE Chute Design PDFDocument24 pagesMPE Chute Design PDFHenry SaenzNo ratings yet

- Paper # 074 - SAG MILL OPERATIONS IN SOSSEGO MINE PDFDocument9 pagesPaper # 074 - SAG MILL OPERATIONS IN SOSSEGO MINE PDFcarloscjunoNo ratings yet

- Cavex Hydrocyclones CVXTDocument2 pagesCavex Hydrocyclones CVXTRANAIVOARIMANANANo ratings yet

- 05 - Todd Swinderman - Belt Wear Fron Loading and Belt CleaningDocument42 pages05 - Todd Swinderman - Belt Wear Fron Loading and Belt Cleaningluis martinezNo ratings yet

- Weir HPGRDocument15 pagesWeir HPGRW ZuoNo ratings yet

- Flsmidth Slurry PumpDocument67 pagesFlsmidth Slurry PumprvkheavenNo ratings yet

- Conveyor Design Report: Batch Plant Coveyor System Cv1 - Receiving Conveyor - Wacom - Gmi MaliDocument35 pagesConveyor Design Report: Batch Plant Coveyor System Cv1 - Receiving Conveyor - Wacom - Gmi MaliRichmond YarrickNo ratings yet

- Krebs Products For The Coal IndustryDocument20 pagesKrebs Products For The Coal IndustryANo ratings yet

- 09 Tailings Pumps MCU Oct 2017 John OttenDocument48 pages09 Tailings Pumps MCU Oct 2017 John OttenYerko VillcaNo ratings yet

- Outotec Mineral Processing Solutions: BenefitsDocument12 pagesOutotec Mineral Processing Solutions: BenefitsAndi FaesalNo ratings yet

- 15 - Load - Construction - Type - Resultado Cabeceras (Area 3000)Document66 pages15 - Load - Construction - Type - Resultado Cabeceras (Area 3000)Juan Jose San Martin AlfaroNo ratings yet

- A New Large Pump For Oil SandsDocument62 pagesA New Large Pump For Oil SandsAdam BartonNo ratings yet

- HPGR en WebDocument11 pagesHPGR en WebFranciscoNo ratings yet

- Ball Mill ShowDocument20 pagesBall Mill ShowAldo PabloNo ratings yet

- Chute Calculation ExampleDocument1 pageChute Calculation ExampleBimal DeyNo ratings yet

- Technical Particulars Doc 2119-2120-01 PDFDocument10 pagesTechnical Particulars Doc 2119-2120-01 PDFAnonymous YwlEXh5No ratings yet

- FLSmidth - HPGR - High Pressure Grinding Roll - BrochureDocument9 pagesFLSmidth - HPGR - High Pressure Grinding Roll - BrochureTHAKARAR HARSHILNo ratings yet

- R05323 P 001a X009 0042 PDFDocument464 pagesR05323 P 001a X009 0042 PDFcquibajoNo ratings yet

- Comminution Process Fundamentals Training CourseDocument91 pagesComminution Process Fundamentals Training CourseFrida Paucar AlbarracinNo ratings yet

- Enduron High Pressure Grinding Rolls HPGR Product BrochureDocument27 pagesEnduron High Pressure Grinding Rolls HPGR Product BrochurerecaiNo ratings yet

- Outotec Oktop Agitator Unit UpgradeDocument2 pagesOutotec Oktop Agitator Unit UpgradegicntNo ratings yet

- Planos SAG Shell PDFDocument1 pagePlanos SAG Shell PDFA̶l̶x̶a̶n̶d̶e̶r̶ PaniNo ratings yet

- Equipment Selection For HPGR-Based Comminution Circuits Part 1 - Chris - MorleyDocument14 pagesEquipment Selection For HPGR-Based Comminution Circuits Part 1 - Chris - MorleyWilson VicencioNo ratings yet

- Options For Plant Design/ Upgrading of Comminution Circuits: LD Michaud July 14, 2016Document14 pagesOptions For Plant Design/ Upgrading of Comminution Circuits: LD Michaud July 14, 2016Rodrigo GarcíaNo ratings yet

- Test Report: Flowsheet Development For Recovery and Concentration of Iron Sands: Phase IIDocument11 pagesTest Report: Flowsheet Development For Recovery and Concentration of Iron Sands: Phase IIRavikumarAraliNo ratings yet

- Technical Bulletin 1Document8 pagesTechnical Bulletin 1RANAIVOARIMANANANo ratings yet

- V-2172-0009-0078 - 3 Status 1Document97 pagesV-2172-0009-0078 - 3 Status 1Jonathan Alexander De Los Rios OrdoñezNo ratings yet

- Low Res Outotec Thickening 18022011Document12 pagesLow Res Outotec Thickening 18022011Juan Alberto Giglio FernándezNo ratings yet

- Inclined Belt Conveyors For Underground Mass Mining OperationsDocument6 pagesInclined Belt Conveyors For Underground Mass Mining OperationsIsmaelNo ratings yet

- Apron FeederDocument12 pagesApron FeederMidDeL'Orme100% (1)

- Secondary and Tertiary Cone CrushersDocument4 pagesSecondary and Tertiary Cone CrushersDanielSantosNo ratings yet

- Krebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsDocument4 pagesKrebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsPhaniNo ratings yet

- Grinding Mill Plan PDFDocument1 pageGrinding Mill Plan PDFBender Doblador RodriguezNo ratings yet

- 5 Rene Orellana Codelco (Modulo II)Document18 pages5 Rene Orellana Codelco (Modulo II)Rodrigo BartoloNo ratings yet

- Grindex'S Great Pump Guide: Pump Features and BenefitsDocument44 pagesGrindex'S Great Pump Guide: Pump Features and BenefitsCựu SV Bách KhoaNo ratings yet

- Warman International LTD: Intake FlangeDocument3 pagesWarman International LTD: Intake FlangerickNo ratings yet

- Chinalco - PresentationDocument34 pagesChinalco - PresentationRobert Artica M.No ratings yet

- Apron Feeder 7Document1 pageApron Feeder 7cumpio425428100% (1)

- Rilmar OjedaDocument17 pagesRilmar Ojedaavca65No ratings yet

- Hydro-Cyclone Separation Unit: Cost EstimationsDocument20 pagesHydro-Cyclone Separation Unit: Cost EstimationsMuhammad Hussain BilalNo ratings yet

- CertifiedDocument1 pageCertifiedIta BarreraNo ratings yet

- KREBS slurryMAX Pump BrochureDocument12 pagesKREBS slurryMAX Pump Brochuredavidgaro12No ratings yet

- IB-1015 Apron Feeder 3-10Document30 pagesIB-1015 Apron Feeder 3-10Vladimir100% (1)

- 11 - Transport Cross-Beam For Roll UnitsDocument43 pages11 - Transport Cross-Beam For Roll UnitsCHRISTIAN ROJAS VALENZUELANo ratings yet

- Espesadores Caserones, Enero 2014Document12 pagesEspesadores Caserones, Enero 2014Juan MichaudNo ratings yet

- Folleto Slurry PumpsDocument5 pagesFolleto Slurry Pumpsdiana.isbal0% (1)

- Pans PDFDocument8 pagesPans PDFJorge Prado DiazNo ratings yet

- Alimentador VibratorioDocument24 pagesAlimentador VibratoriojgarciacochachiNo ratings yet

- Delkor EspesadorDocument21 pagesDelkor Espesadorrichard gutierrezNo ratings yet

- LCC M150 500 3 LCCPump Metal PDFDocument8 pagesLCC M150 500 3 LCCPump Metal PDFFrancisco Loyola CarrascoNo ratings yet

- Belt ConveyorsDocument7 pagesBelt ConveyorsPMA1No ratings yet

- MANUAL1 - Copia - 4Document50 pagesMANUAL1 - Copia - 4Jose NoriegaNo ratings yet

- Catalog & DrawingDocument89 pagesCatalog & Drawingronal siagianNo ratings yet

- Energy and Cost Comparisons Wang Et AlDocument17 pagesEnergy and Cost Comparisons Wang Et AlJD FCNo ratings yet

- Automation and Optimization of Primary Gyratory CrusherDocument55 pagesAutomation and Optimization of Primary Gyratory Crusherthe requiem LastNo ratings yet

- Dunlop Conveyor Belt Design ManualDocument16 pagesDunlop Conveyor Belt Design ManualTabor TamiruNo ratings yet

- NW1213 GA Primary (With TK11-42-2V)Document1 pageNW1213 GA Primary (With TK11-42-2V)darko1969No ratings yet

- Chapter-1: 1. Study of Organisation StructureDocument31 pagesChapter-1: 1. Study of Organisation StructureRNo ratings yet

- BTA2 Technical SheetDocument2 pagesBTA2 Technical SheetOnie Hammamz OylNo ratings yet

- Course Code Description Units Pre-Requisite: Obe CurriculumDocument2 pagesCourse Code Description Units Pre-Requisite: Obe CurriculumShyla ManguiatNo ratings yet

- тестовик SAMPLE TESTS 2022-2023Document64 pagesтестовик SAMPLE TESTS 2022-2023Алена ДимоваNo ratings yet

- Extra - Battle of The Brains QuestionsDocument8 pagesExtra - Battle of The Brains QuestionsNovrianti RumapeaNo ratings yet

- Harris, D. J. (1998) - On The Classical Theory of CompetitionDocument30 pagesHarris, D. J. (1998) - On The Classical Theory of Competitioncarlos rodriguesNo ratings yet

- Nov 2022 - Dela Cruz F - Set 1Document2 pagesNov 2022 - Dela Cruz F - Set 1cat buenafeNo ratings yet

- 2018 LLA Evaluation Forms - Final As of Sept 20, 2018Document25 pages2018 LLA Evaluation Forms - Final As of Sept 20, 2018nida dela cruz100% (1)

- Eng Grammar NotesDocument38 pagesEng Grammar NotesRohit D HNo ratings yet

- CH 09Document4 pagesCH 09farhan harahapNo ratings yet

- Introduction in Anesthesie, Critical Care and Pain ManagementDocument30 pagesIntroduction in Anesthesie, Critical Care and Pain ManagementSuvini GunasekaraNo ratings yet

- 2018KIO Flowmeter CatalogueDocument92 pages2018KIO Flowmeter CatalogueJBHSBNo ratings yet

- FCEC Application Form - 2022Document2 pagesFCEC Application Form - 2022Catherine AbabonNo ratings yet

- Analisis Soalan Sains Pt3 2014-2015Document6 pagesAnalisis Soalan Sains Pt3 2014-2015rosya100% (1)

- 1705 Service ManualDocument30 pages1705 Service Manualj.bycroft126No ratings yet

- Microsoft Word - 1 - ТитулDocument3 pagesMicrosoft Word - 1 - ТитулBody BuilderNo ratings yet

- Gorden Cullen - Concise TownscapeDocument20 pagesGorden Cullen - Concise TownscapeMuktha Sathish Singh100% (1)

- Formulas and Reference Chart EocDocument3 pagesFormulas and Reference Chart Eocapi-87739323No ratings yet

- ENGLISH RECOVERY 6th JDDocument3 pagesENGLISH RECOVERY 6th JDAdirene MoraisNo ratings yet

- PDFDocument2 pagesPDFashfaNo ratings yet

- Ágnes HellerDocument9 pagesÁgnes HellerGianni RossiNo ratings yet

- Leed NDDocument2 pagesLeed NDElnaz YousefzadehNo ratings yet

- AngmomcommutationproofDocument3 pagesAngmomcommutationproofGamma FactsNo ratings yet

- In-Sample Test 1Document6 pagesIn-Sample Test 1Han NguyenNo ratings yet

- Hack100 RulebookDocument36 pagesHack100 RulebookDanilo Gangly099 (Gangly)No ratings yet

- Advantages of Visual AidsDocument7 pagesAdvantages of Visual AidsMasta JackNo ratings yet

- Top 7 Benefits of Developing Strong Leadership SkillsDocument5 pagesTop 7 Benefits of Developing Strong Leadership SkillsRomana ChangeziNo ratings yet

- Commented List of The Lower Oligocene Fish Fauna From The Coza Valley (Marginal Folds Nappe, Eastern Carpathians, Romania)Document9 pagesCommented List of The Lower Oligocene Fish Fauna From The Coza Valley (Marginal Folds Nappe, Eastern Carpathians, Romania)Marian BordeianuNo ratings yet

- Use of AIDocument1 pageUse of AIyajav12960No ratings yet

- Exercises ILPDocument19 pagesExercises ILPAlexandre HaverbekeNo ratings yet

- 02 Objective and Interpretive WorldviewsDocument26 pages02 Objective and Interpretive WorldviewsHazim RazamanNo ratings yet

- Jaw &cone Rsi Service Schedule - Sheet1Document2 pagesJaw &cone Rsi Service Schedule - Sheet1Kilton BiswasNo ratings yet