Professional Documents

Culture Documents

Untitled 7

Uploaded by

Alireza KhodabandehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Untitled 7

Uploaded by

Alireza KhodabandehCopyright:

Available Formats

Introduction 5

l

To verify the pipeline against design and code requirements for installation,

commissioning, and operation.

l

To prepare authority applications.

l

To perform a material takeoff sufficient to order the line pipe (should the pipe fabrication

be a long lead item, hence requiring early startup).

The level of this engineering design is sometimes specified as being sufficient to

detail the design for inclusion into an engineering, procurement, construction, and

installation (EPCI) tender. The EPCI contractor should then be able to perform the

detailed design with the minimum number of variations as detailed in their bids.

3. Detail engineering. The detailed engineering phase is, as the term suggests, the

development of the design to a point where the technical input for all procurement and

construction tendering can be defined in sufficient detail. The primary objectives can be

summarized as

l

Route optimization.

l

Selection of wall thickness and coating.

l

Confirmation of code requirements regarding strength, vortex-induced vibrations (VIV),

on-bottom stability, global buckling, and installation.

l

Confirmation of the design and additional design as defined in the preliminary

engineering.

l

Development of the design and drawings in sufficient detail for the subsea scope. This

may include pipelines, tie-ins, crossings, span corrections, risers, shore approaches, and

subsea structures.

l

Preparation of detailed alignment sheets based on most recent survey data.

l

Preparation of specifications, typically covering materials, cost applications, construc-

tion activities (i.e., pipe laying, survey, welding, riser installations, spoolpiece instal-

lation, subsea tie-ins, subsea structure installation), and pre-commissioning (i.e.,

flooding, pigging, hydrotesting, cleaning, drying).

l

Preparation of material take off (MTO) and compilation of necessary requisition in-

formation for the procurement of materials.

l

Preparation of design data and other information required for the certification

authorities.

Design Process

The object of the design process for a pipeline is to determine, based on given

operating parameters, the optimum pipeline size parameters. These parameters

include

l

Pipeline internal diameter.

l

Pipeline wall thickness.

l

Grade of pipeline material.

l

Type of coating-corrosion and weight (if any).

l

Coating wall thickness.

The design process required to optimize the pipeline size parameters is an iterative

one, summarized in Figure 1.2. The design analysis is illustrated in Figure 1.3.

Each stage in the design process should be addressed whether it is a conceptual,

preliminary, or detailed design. However, the level of analysis varies, depending on

You might also like

- Technical Specifications For Peb For Pune Ware House 17.10.11Document21 pagesTechnical Specifications For Peb For Pune Ware House 17.10.11chepurthiNo ratings yet

- Checklist For Cable Raceway Layout: (Optional)Document3 pagesChecklist For Cable Raceway Layout: (Optional)RahulNo ratings yet

- Chapter 9Document27 pagesChapter 9Fuad AhmedinNo ratings yet

- Checklist Pre-Tender Civil ProjectsDocument8 pagesChecklist Pre-Tender Civil Projectssarathirv6No ratings yet

- OCC 132/33kV Grid Station Scope of ServicesDocument10 pagesOCC 132/33kV Grid Station Scope of ServicesParag Lalit SoniNo ratings yet

- (Spec) Steel Truss Bridge (NMHEP)Document37 pages(Spec) Steel Truss Bridge (NMHEP)S RastogiNo ratings yet

- Concept Preliminary DesignDocument11 pagesConcept Preliminary Designricosanojuan100% (2)

- NCR7830 - MegatwrmktncrkDocument127 pagesNCR7830 - MegatwrmktncrkAldrin Jonas EduarteNo ratings yet

- Guide Instruct US-PICP+w+LWD Permeable PaversDocument8 pagesGuide Instruct US-PICP+w+LWD Permeable Paversandrew_sfiNo ratings yet

- Instructor 693Document13 pagesInstructor 693nodyyyNo ratings yet

- KPS method statement for concrete worksDocument14 pagesKPS method statement for concrete worksWufei Chang95% (21)

- Bid Bulletin No 6 - MTCL PACKAGE 4 BOSO-BOSO PUMPING STATION AND RESERVOIRDocument7 pagesBid Bulletin No 6 - MTCL PACKAGE 4 BOSO-BOSO PUMPING STATION AND RESERVOIRFrancis Nano FerrerNo ratings yet

- Tag Dfccil Ambala 01Document8 pagesTag Dfccil Ambala 01soujanya rajeshNo ratings yet

- Checklist For AllDocument5 pagesChecklist For AllMohamed AbbasNo ratings yet

- Mechanical Engineer with 3+ years experience seeking challenging positionDocument6 pagesMechanical Engineer with 3+ years experience seeking challenging positiondavidgeorge143No ratings yet

- Construction of Petroleum Storage Depot at Pali, RajasthanDocument1,135 pagesConstruction of Petroleum Storage Depot at Pali, RajasthanMangukiya GopalNo ratings yet

- Saquib Gilani 2020Document7 pagesSaquib Gilani 2020gradeateacher2aNo ratings yet

- Professional Qualification: Career ObjectiveDocument8 pagesProfessional Qualification: Career ObjectiveMayoo LaxmanNo ratings yet

- Elements of Tech SpecDocument6 pagesElements of Tech SpecJc RacelisNo ratings yet

- Nepal Electricity Authority Distribution Network Improvement Project Bidding DocumentsDocument563 pagesNepal Electricity Authority Distribution Network Improvement Project Bidding DocumentsSamsonNo ratings yet

- Scope of WorkDocument7 pagesScope of WorkKriengsak Ruangdech100% (2)

- Technical Specifications For PEB WorksDocument46 pagesTechnical Specifications For PEB Worksvenugopal BedadakotaNo ratings yet

- Ahmed Tawfik CV PIP DDocument5 pagesAhmed Tawfik CV PIP DAhmed TawfikNo ratings yet

- Shotcrete Connstructed Cut and Cover Tunnel PortalDocument8 pagesShotcrete Connstructed Cut and Cover Tunnel PortalSrinu DegalaNo ratings yet

- Specifications: Documentation Iii 1 Revision 2021Document12 pagesSpecifications: Documentation Iii 1 Revision 2021MpumiNo ratings yet

- Technical ReportDocument16 pagesTechnical ReportBrahammanand BairwaNo ratings yet

- Cai Mep International Container Terminal Concrete Work Method StatementDocument10 pagesCai Mep International Container Terminal Concrete Work Method StatementFilipe PereiraNo ratings yet

- 2006-Post-Tensioning Manual - 6th Edition PDFDocument370 pages2006-Post-Tensioning Manual - 6th Edition PDFArdiaTiaraR93% (14)

- The Piping Material EngineerDocument10 pagesThe Piping Material EngineerFazlur Rehman ShahNo ratings yet

- 03 4110 Precast Double Tees1Document11 pages03 4110 Precast Double Tees1M OdebrechtNo ratings yet

- communications-backbone-cabling-08.2021Document10 pagescommunications-backbone-cabling-08.2021derickoti45No ratings yet

- Estimating and Costing EngineeringDocument71 pagesEstimating and Costing EngineeringPURUSHOTTAMNo ratings yet

- Ce702 Estimation PDFDocument71 pagesCe702 Estimation PDFDanish BhatNo ratings yet

- Chimney Specification DraftDocument157 pagesChimney Specification DraftKrm Chari100% (1)

- Project Standards and Specifications Piping Construction Standards Rev01Document10 pagesProject Standards and Specifications Piping Construction Standards Rev01hiyeonNo ratings yet

- Sewer Construction: Energy Environment InfrastructureDocument25 pagesSewer Construction: Energy Environment InfrastructureNobodyNo ratings yet

- Overhead TankDocument4 pagesOverhead TankChungath LineshNo ratings yet

- Lesson 1. Introduction 2024Document23 pagesLesson 1. Introduction 2024Cherry Mae LiteratusNo ratings yet

- MGB-MS-003-ST-003 Formwork InstallationDocument8 pagesMGB-MS-003-ST-003 Formwork InstallationImho Tep100% (1)

- QUS 316 recentDocument5 pagesQUS 316 recentjudexnams1on1No ratings yet

- Railway Electrification and Double Tracking Project Technical SpecificationsDocument137 pagesRailway Electrification and Double Tracking Project Technical SpecificationsFaikar Luthfi AndrishaNo ratings yet

- NCR 882 - SagittarDocument41 pagesNCR 882 - SagittarAldrin Jonas EduarteNo ratings yet

- Chapter 1 3 - MergedDocument73 pagesChapter 1 3 - MergedAldrin Jonas EduarteNo ratings yet

- ITS DUCT SpecificationDocument2 pagesITS DUCT SpecificationTobin DonNo ratings yet

- RKSDocument11 pagesRKSDanang HermawanNo ratings yet

- Method Statement For Installation of Electrical PVC Conduits and Accessories in The Concrete Slabs, Columns, Block Works and Concrete WallsDocument12 pagesMethod Statement For Installation of Electrical PVC Conduits and Accessories in The Concrete Slabs, Columns, Block Works and Concrete WallsMohammed Ghareib NasrNo ratings yet

- Chapter 10 Foundations and Equipment PadsDocument30 pagesChapter 10 Foundations and Equipment PadsNyan LinNo ratings yet

- S.O.R. Bridge WorksDocument48 pagesS.O.R. Bridge WorksUmar KarimiNo ratings yet

- Section - 1 Scope, Specific Technical Requirements & QuantitiesDocument2 pagesSection - 1 Scope, Specific Technical Requirements & QuantitieskrmcharigdcNo ratings yet

- CH 1.specificationsDocument27 pagesCH 1.specificationsAbreham AddNo ratings yet

- U.S. ARMY CORPS OF ENGINEERS DESIGN CHECKLISTDocument15 pagesU.S. ARMY CORPS OF ENGINEERS DESIGN CHECKLISTSankar CdmNo ratings yet

- Understanding Personnel FormartsDocument58 pagesUnderstanding Personnel FormartsMwesigwa DaniNo ratings yet

- Adil Naseer Khawaja's 25+ Years Piping Engineering ExperienceDocument5 pagesAdil Naseer Khawaja's 25+ Years Piping Engineering ExperienceAdil KhawajaNo ratings yet

- 33kV Indoor Metered Connection GuidanceDocument50 pages33kV Indoor Metered Connection GuidanceKhalid HameedNo ratings yet

- Mech Eng 1Document5 pagesMech Eng 1sharif339No ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Soil Investigation and Foundation DesignFrom EverandSoil Investigation and Foundation DesignRating: 4.5 out of 5 stars4.5/5 (9)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Bending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiDocument1 pageBending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- References: 20 Qiang Bai and Yong BaiDocument1 pageReferences: 20 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- Finite Element Analysis: Pipeline Installation by Tow or PullDocument1 pageFinite Element Analysis: Pipeline Installation by Tow or PullAlireza KhodabandehNo ratings yet

- 23Document1 page23Alireza KhodabandehNo ratings yet

- Wall Thickness and Material Grade Selection: GeneralDocument1 pageWall Thickness and Material Grade Selection: GeneralAlireza KhodabandehNo ratings yet

- Wall Thickness and Material Grade Selection: GeneralDocument1 pageWall Thickness and Material Grade Selection: GeneralAlireza KhodabandehNo ratings yet

- 23Document1 page23Alireza KhodabandehNo ratings yet

- 16 Qiang Bai and Yong Bai: Pipeline InstallationDocument1 page16 Qiang Bai and Yong Bai: Pipeline InstallationAlireza KhodabandehNo ratings yet

- Untitled 3Document1 pageUntitled 3Alireza KhodabandehNo ratings yet

- Untitled 1Document1 pageUntitled 1Alireza KhodabandehNo ratings yet

- Untitled 6Document1 pageUntitled 6Alireza KhodabandehNo ratings yet

- Untitled 2Document1 pageUntitled 2Alireza KhodabandehNo ratings yet

- Bending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiDocument1 pageBending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- References: 20 Qiang Bai and Yong BaiDocument1 pageReferences: 20 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- Rec Erc 84 317Document1 pageRec Erc 84 317Alireza KhodabandehNo ratings yet

- Rec Erc 84 329Document1 pageRec Erc 84 329Alireza KhodabandehNo ratings yet

- Pipe Laying by Lay Vessel: Mode 1 Buckle Mode 2 Buckle Mode 3 Buckle Mode 4 BuckleDocument1 pagePipe Laying by Lay Vessel: Mode 1 Buckle Mode 2 Buckle Mode 3 Buckle Mode 4 BuckleAlireza KhodabandehNo ratings yet

- Rec Erc 84 334Document1 pageRec Erc 84 334Alireza KhodabandehNo ratings yet

- Rec Erc 84 315Document1 pageRec Erc 84 315Alireza KhodabandehNo ratings yet

- Rec Erc 84 332Document1 pageRec Erc 84 332Alireza KhodabandehNo ratings yet

- Rec Erc 84 322Document1 pageRec Erc 84 322Alireza KhodabandehNo ratings yet

- Rec Erc 84 313Document1 pageRec Erc 84 313Alireza KhodabandehNo ratings yet

- Rec Erc 84 36Document1 pageRec Erc 84 36Alireza KhodabandehNo ratings yet

- 14 S. K. Gawali Et AlDocument1 page14 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

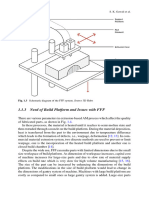

- 1.2.1 Design Methodology: 6 S. K. Gawali Et AlDocument1 page1.2.1 Design Methodology: 6 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- Rec Erc 84 38Document1 pageRec Erc 84 38Alireza KhodabandehNo ratings yet

- Rec Erc 84 311Document1 pageRec Erc 84 311Alireza KhodabandehNo ratings yet

- 2 S. K. Gawali Et Al.: 1.1.1 Additive ManufacturingDocument1 page2 S. K. Gawali Et Al.: 1.1.1 Additive ManufacturingAlireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 317Document1 pageCERTILAS EN Edition2023 317Alireza KhodabandehNo ratings yet

- 1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlDocument1 page1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- 2003 June Calc Paper 6 (H)Document20 pages2003 June Calc Paper 6 (H)abbasfazilNo ratings yet

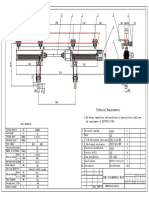

- 2X16-24 Monorail Hoist-04 - 2Document1 page2X16-24 Monorail Hoist-04 - 2RafifNo ratings yet

- Robotic Surgery History and SystemsDocument28 pagesRobotic Surgery History and SystemsLidhi DileepNo ratings yet

- Gek 106852aDocument10 pagesGek 106852awednetoxNo ratings yet

- DataSheet ULCAB300Document2 pagesDataSheet ULCAB300Yuri OliveiraNo ratings yet

- Business Plan For Mobile Food CourtDocument13 pagesBusiness Plan For Mobile Food CourtMd. Al- AminNo ratings yet

- SDSU PhD Research on Soil HealthDocument2 pagesSDSU PhD Research on Soil HealthTiruneh GA25% (4)

- Tinas Resturant AnalysisDocument19 pagesTinas Resturant Analysisapi-388014325100% (2)

- AOC AW INSP 010 Rev04 AOC Base Inspection ChecklistDocument6 pagesAOC AW INSP 010 Rev04 AOC Base Inspection ChecklistAddisuNo ratings yet

- File Signature LabDocument3 pagesFile Signature LabGheorghe RotariNo ratings yet

- Baja2018 Unisa Team3 Design ReportDocument23 pagesBaja2018 Unisa Team3 Design ReportDaniel MabengoNo ratings yet

- ClassifiedrecordsDocument23 pagesClassifiedrecordsChetana SJadigerNo ratings yet

- Aviation Mechanic Powerplant Question Book1990Document112 pagesAviation Mechanic Powerplant Question Book1990LohnJittleNo ratings yet

- Sjzl20061019-ZXC10 BSCB (V8.16) Hardware ManualDocument69 pagesSjzl20061019-ZXC10 BSCB (V8.16) Hardware ManualAhmadArwani88No ratings yet

- Service Driven Logistics System - Basic Service CapabilityDocument12 pagesService Driven Logistics System - Basic Service CapabilityAnusha Sunkara80% (5)

- RCT Methodology ChecklistDocument6 pagesRCT Methodology ChecklistSyahidatul Kautsar NajibNo ratings yet

- Internship Projects: Rotor Shaft Analysis and DesignDocument19 pagesInternship Projects: Rotor Shaft Analysis and DesignSanjay IraniNo ratings yet

- Designing An AirshipDocument100 pagesDesigning An AirshipFrik van der Merwe100% (2)

- Connect Debug LogDocument20 pagesConnect Debug LogrohanZorba100% (1)

- Automatic Transaxle and Transfer Workshop Manual Aw6A-El Aw6Ax-ElDocument212 pagesAutomatic Transaxle and Transfer Workshop Manual Aw6A-El Aw6Ax-ElVIDAL ALEJANDRO GARCIAVARGASNo ratings yet

- CRAPAC Monthly JanDocument4 pagesCRAPAC Monthly JanJasonMortonNo ratings yet

- Arduino ProjectsDocument584 pagesArduino ProjectsJoão Francisco83% (12)

- Standards PoolsDocument26 pagesStandards PoolsKimMyPatZaNo ratings yet

- Contractor DatabaseDocument10 pagesContractor DatabaseVishal SaxenaNo ratings yet

- Geotextile Its Application To Civil Engineering ODocument7 pagesGeotextile Its Application To Civil Engineering OezequilNo ratings yet

- 20-Sdms-02 (Overhead Line Accessories) Rev01Document15 pages20-Sdms-02 (Overhead Line Accessories) Rev01Haytham BafoNo ratings yet

- Document - University Admission SystemDocument100 pagesDocument - University Admission SystemNaresh SharmaNo ratings yet

- 2015 Idmp Employee Intentions Final PDFDocument19 pages2015 Idmp Employee Intentions Final PDFAstridNo ratings yet

- Water Quality For Irrigation Free PPT - Google SearchDocument3 pagesWater Quality For Irrigation Free PPT - Google SearchJames NeoNo ratings yet

- JohnsonJohnson 2006 PDFDocument84 pagesJohnsonJohnson 2006 PDFakfar b417No ratings yet