Professional Documents

Culture Documents

Distribution Board

Uploaded by

sparkCEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Distribution Board

Uploaded by

sparkCECopyright:

Available Formats

1.1.

AC DISTRIBUTION BOARD

1.2. The substation service loads shall be supplied through an AC distribution

board (ACDB), sheet steel clad (2 mm thick) free standing ,floor mounted

confirming to degree of protection IP54.

1.3. The board shall be designed for operation on 415V+_10%,3ph ,50HZ,

+_5%,4W,35KA system.

1.3.1. INCOMER (fuse switch)

1.4. Suitably rated incoming TPN fuse switch feeder . Incomer shall be

provided with lamps ,voltmeter and ammeter with selector switches.

1.4.1. OUTGOING FEEDER

1.5. Suitably rated TPN fuse switch feeders as required shall be provided.

this shall take care of the power supply required for the transformer

OLTC, breaker ,Battery charger, Oil filtration socket and yard lighting.

1.5.1. LIGHTING DISTRIBUTION BOARDS

2. The enclosure shall be made out of 14/16 SWG , CRCA sheet steel with the

following segregation.

2.1. Incomer

2.2. Bus chamber

2.3. Single phase outgoing MCBs for different phases with partitions between

each phase compartment.

2.4. The panel shall be of double door construction with IP54 Degree of

protection.

3. Incomer shall be provided with 40A , 4pole MCB +ELCB with door interlock

and pad locking facility. RYB LED TYPE indication lamps

4. Incoming terminal shrouding by acrylic sheet

5. Bus chamber with FRP support insulator and set of Al/CU busbars to suit the

rating fully sleeved with colour identification. Tapping to various MCB feeders

shall be made separate and back to back connections shall not be permitted.

The cross section of bus shall take into the account of the reduction in cross

section due to various tapings.

6. Each single phase outgoings shall be controlled by DP 40A incomer with 10A

SP MCB outgoings. The connections between DP MCB to the bus shall be by

solid copper connections.

7. The panel shall be of wall mounted type with incomer having a separate

door and a common door for outgoing feeders and a separate cable alley for

outgoing feeders. each single phase sections shall be compartmentalized and

Mcbs shall be fixed on a DIN rail with only knobs projecting outside for

operation after opening the common door.

8. An earth bus of 25 x 6 Al shall be provided through out the length of the

panel and brought out for external earthing.

9. Danger labels shall be pasted outside the door. The name plates for board

shall be of minimum 10 mm letter and for feeders with 4 mm letter. The

engravings shall be done on 3 ply/aluminium anodized /Acrylic sheet with

black background and white letters. The name plate shall be fixed with self

threaded screws. The dimensions of name plates shall be uniform for

interchangeability of feeders.

9.1. Each outgoing feeder circuit number shall be identified by respective

phase/way marking in the form of wiring diagram, which shall be pasted

inside the compartment door.

9.2. All MCB shall be rated for 10KA fault level. MCBs shall be marking of the

contacts below the operating knob. The Knob shall be of black colour.

9.3. Paint shade: The complete cubicle shall be painted with RAL 7032 shade.

You might also like

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Free Electricity From The Earth Rotating Through Its Own Magnetic Field Using The Homopolar Generator EffectDocument3 pagesFree Electricity From The Earth Rotating Through Its Own Magnetic Field Using The Homopolar Generator EffectmarcelogiovaneNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document17 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768wong waras100% (1)

- Financial Tender ElectricalDocument6 pagesFinancial Tender ElectricalTaiwo MorakinyoNo ratings yet

- 11KV VCBDocument3 pages11KV VCBeagles1109No ratings yet

- Lighting SystemDocument10 pagesLighting SystemJyoti ShekharNo ratings yet

- El Panel BoqDocument5 pagesEl Panel BoqJMB INFONo ratings yet

- 5-Power & Control Cables PDFDocument11 pages5-Power & Control Cables PDFAnonymous ufMAGXcskMNo ratings yet

- Check List For Power DBsDocument13 pagesCheck List For Power DBsjeetNo ratings yet

- 1A - 11kV HT PanelDocument10 pages1A - 11kV HT PanelPraveen KumarNo ratings yet

- LT PN GTP - BDDocument6 pagesLT PN GTP - BDDarshit VyasNo ratings yet

- Internal Road Light BOQ, Rev 2Document3 pagesInternal Road Light BOQ, Rev 2DEBARSHEECHAKRABARTI4245No ratings yet

- 3406Document2 pages3406ibrahem100% (1)

- C3) SMC LTDB Spec 63 100 200 Kva For Urban 2011Document37 pagesC3) SMC LTDB Spec 63 100 200 Kva For Urban 2011Sanjay Kumar100% (1)

- Electrical BOQ BOI MhasrulDocument14 pagesElectrical BOQ BOI MhasrulVenkata Suresh MandavaNo ratings yet

- Specification of LT Capcitor PannelDocument12 pagesSpecification of LT Capcitor PannelPrashant TrivediNo ratings yet

- Circuit Breaker TestingDocument38 pagesCircuit Breaker Testingm khNo ratings yet

- XPDocument9 pagesXPsureshn829100% (1)

- MNS-MCC LV SpecificationDocument16 pagesMNS-MCC LV SpecificationRaju MbkNo ratings yet

- 06-POWER AND CONTROL CABLE - Rev5 PDFDocument14 pages06-POWER AND CONTROL CABLE - Rev5 PDFSanjay RoutNo ratings yet

- Sandwhich BusductDocument5 pagesSandwhich BusductHarmandeep Ahluwalia100% (1)

- Copper Bus Duct SpecDocument135 pagesCopper Bus Duct SpecChilamkurti Siva Sankara Rao100% (2)

- Volume IIpart IIItechnicalspecificationDocument245 pagesVolume IIpart IIItechnicalspecificationtejzabNo ratings yet

- 11kv and 33KVDocument43 pages11kv and 33KVArun KumarNo ratings yet

- Enquiry - PanelDocument14 pagesEnquiry - Panelrkpatel40No ratings yet

- Maharashtra State Electricity Distribution Co. LTD.: Technical Specifications FOR A. C. Distribution Board B' TypeDocument13 pagesMaharashtra State Electricity Distribution Co. LTD.: Technical Specifications FOR A. C. Distribution Board B' TypeRamesh KumarNo ratings yet

- Boq ElcDocument12 pagesBoq ElcRicardo JuliusNo ratings yet

- Schedule-A.3 BOQ For Electrical Works and Surveillance EquipmentDocument5 pagesSchedule-A.3 BOQ For Electrical Works and Surveillance EquipmentQuality LimitedNo ratings yet

- LV Distribution - BoardsDocument6 pagesLV Distribution - BoardsNATHANNo ratings yet

- Techs 1Document5 pagesTechs 1Pasupuleti007No ratings yet

- Document No PCPL-0532-4-407-04-06 Contol & Relay Panel Section - 4 PAGE: 1 of 6 ScopeDocument6 pagesDocument No PCPL-0532-4-407-04-06 Contol & Relay Panel Section - 4 PAGE: 1 of 6 ScopetceterexNo ratings yet

- BOQ AnalysisDocument589 pagesBOQ Analysisexpertplanners1111No ratings yet

- Project Subject DateDocument68 pagesProject Subject DateMohammad SaquibNo ratings yet

- Section - 16445 - Feeder PillarDocument3 pagesSection - 16445 - Feeder Pillarahmadove1100% (1)

- CRP SpecDocument19 pagesCRP SpececplpraveenNo ratings yet

- Bus Coupler Specs PDFDocument11 pagesBus Coupler Specs PDFRaj ChavanNo ratings yet

- Technical Specification of 11Kv 630A VCB Panel With 5 Nos 11Kv Lbs O/GDocument9 pagesTechnical Specification of 11Kv 630A VCB Panel With 5 Nos 11Kv Lbs O/GShayarrn KhatiwodaNo ratings yet

- Enquiry - PanelDocument8 pagesEnquiry - Panelrkpatel40No ratings yet

- DocumentationDocument8 pagesDocumentationMushonif MarsholiNo ratings yet

- Aktpl 1000kva Dry Type Css 4.9.23 1Document1 pageAktpl 1000kva Dry Type Css 4.9.23 1binesh_shahenggcoNo ratings yet

- Uflex@sanand Elect Est R0Document28 pagesUflex@sanand Elect Est R0ranjeet.globalgreenNo ratings yet

- Standard Circuit Arrangements: 2 5 13 15, 30 Amp (The 13 A Size Is Always Fused)Document8 pagesStandard Circuit Arrangements: 2 5 13 15, 30 Amp (The 13 A Size Is Always Fused)Hassen LazharNo ratings yet

- ExcelcDocument2 pagesExcelcAkhilesh GuptaNo ratings yet

- 05 Electrical BoqDocument27 pages05 Electrical Boqdrjonesg19585102No ratings yet

- Ra-11 RNSDocument64 pagesRa-11 RNSArif AnsariNo ratings yet

- Section 8 GeneralDocument9 pagesSection 8 GeneralmatzoyekNo ratings yet

- 878 SpecDocument2 pages878 Specrdeepak99No ratings yet

- Civil Works For Data Center Sr. N0. Item Description Units QtyDocument13 pagesCivil Works For Data Center Sr. N0. Item Description Units QtyGypsum ChennaiNo ratings yet

- View TendDocument11 pagesView TendMohamed AnwarNo ratings yet

- High Voltage Switchgear DistributionDocument3 pagesHigh Voltage Switchgear DistributionMuruganNo ratings yet

- Salient Features of E&m, Lifts & Escalators FeaturesDocument8 pagesSalient Features of E&m, Lifts & Escalators FeaturesGphoneNo ratings yet

- Electrical BOQDocument3 pagesElectrical BOQRakesh Mitra100% (1)

- InquiryDocument30 pagesInquiryrdeepak99No ratings yet

- Boq For Electrical Works Description of Item / Work Unit Qty Total Rate Part - A: Electrical Works SL NO. Rate / UnitDocument11 pagesBoq For Electrical Works Description of Item / Work Unit Qty Total Rate Part - A: Electrical Works SL NO. Rate / UnitAjay MedikondaNo ratings yet

- Epc Tender Specification: M.P. Power Generating Company Ltd. 2X660 MW, SSTPP, Stage-Ii Distt.-KhandwaDocument1 pageEpc Tender Specification: M.P. Power Generating Company Ltd. 2X660 MW, SSTPP, Stage-Ii Distt.-KhandwaPrashant TewariNo ratings yet

- 1801201432-Electrical BOQ SMEDocument11 pages1801201432-Electrical BOQ SMEVardhan NadellaNo ratings yet

- 5.section-Lt Switchgear, Rev 05Document28 pages5.section-Lt Switchgear, Rev 05Uday Sankar YadavNo ratings yet

- Deogarh Court Boq Garden LightDocument7 pagesDeogarh Court Boq Garden Lighttsadkans59No ratings yet

- Electrical Specification For Food CourtDocument13 pagesElectrical Specification For Food CourtIndraneel BhawoorjarNo ratings yet

- Financial Bid - Electrical - DO PathanamthittaDocument4 pagesFinancial Bid - Electrical - DO PathanamthittaHarendra SinghNo ratings yet

- BOQ SpecsDocument38 pagesBOQ SpecsSubodh KhandekarNo ratings yet

- 312 Flat Street Lighting 2Document23 pages312 Flat Street Lighting 2rajveer kumarNo ratings yet

- It. Description Unit Qut Rate Amount 1. Electrical Installation 1.1 Distribution BoardsDocument6 pagesIt. Description Unit Qut Rate Amount 1. Electrical Installation 1.1 Distribution BoardsdaveadeNo ratings yet

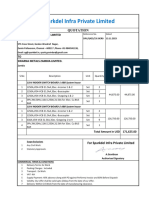

- Hiriyur Bay MDLDocument12 pagesHiriyur Bay MDLsparkCENo ratings yet

- 132kV Substation Accessories BOQ-20231101Document2 pages132kV Substation Accessories BOQ-20231101sparkCENo ratings yet

- Sparkdel BOQ 20231108Document1 pageSparkdel BOQ 20231108sparkCENo ratings yet

- Sec BoxDocument1 pageSec BoxsparkCENo ratings yet

- SPARK LT Panel Offer - XLSX - 1Document1 pageSPARK LT Panel Offer - XLSX - 1sparkCENo ratings yet

- Q469 For Siemens, 11KV Vacuum Circuit BreakerDocument1 pageQ469 For Siemens, 11KV Vacuum Circuit BreakersparkCENo ratings yet

- SPARK LT Panel Offer - XLSX - 1Document1 pageSPARK LT Panel Offer - XLSX - 1sparkCENo ratings yet

- SWITRON Make SiwitchesDocument8 pagesSWITRON Make SiwitchessparkCENo ratings yet

- RB - Bus Bar Sizing Calculation - 20231029.xlsx - 1Document1 pageRB - Bus Bar Sizing Calculation - 20231029.xlsx - 1sparkCENo ratings yet

- SPARK HT Panel Offer - XLSX - 1Document1 pageSPARK HT Panel Offer - XLSX - 1sparkCENo ratings yet

- CodificationDocument4 pagesCodificationsparkCENo ratings yet

- Kanchi - It - ParkDocument35 pagesKanchi - It - ParksparkCENo ratings yet

- 3VL Type RefDocument2 pages3VL Type RefsparkCENo ratings yet

- Light FittingDocument8 pagesLight FittingsparkCENo ratings yet

- 3ah0 MLFBDocument1 page3ah0 MLFBsparkCENo ratings yet

- 132kV Tandem Isolator MKDDocument1 page132kV Tandem Isolator MKDsparkCENo ratings yet

- Detailed Price Break-Up (Annexure - I) (R3)Document2 pagesDetailed Price Break-Up (Annexure - I) (R3)sparkCENo ratings yet

- 33kv SLD C2PA-ModelDocument1 page33kv SLD C2PA-ModelsparkCENo ratings yet

- Auxiliary RelayDocument8 pagesAuxiliary RelayTaresh MittalNo ratings yet

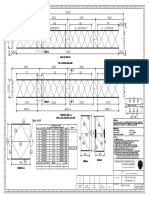

- 33kv BEAM B4-Model PDFDocument1 page33kv BEAM B4-Model PDFsparkCENo ratings yet

- Grounding & Ground Fault Protection of Multiple Generator InstallationsDocument22 pagesGrounding & Ground Fault Protection of Multiple Generator InstallationssparkCE100% (1)

- 132kV Normal Isolator Sheet 1 of 2Document1 page132kV Normal Isolator Sheet 1 of 2sparkCENo ratings yet

- 132kv B1 REV-ModelDocument1 page132kv B1 REV-ModelsparkCENo ratings yet

- 132kV Current Trafo. MKDDocument1 page132kV Current Trafo. MKDsparkCENo ratings yet

- 132kV Bus Post Insulator MKDDocument1 page132kV Bus Post Insulator MKDsparkCENo ratings yet

- 132kv B1 REV-ModelDocument1 page132kv B1 REV-ModelsparkCENo ratings yet

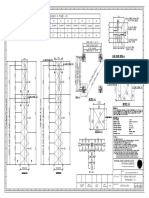

- BPS Arp - SS-01BDocument12 pagesBPS Arp - SS-01BsparkCENo ratings yet

- 132kvT3 REV-ModelDocument1 page132kvT3 REV-ModelsparkCENo ratings yet

- BPS Arp - Ss-01aDocument9 pagesBPS Arp - Ss-01asparkCENo ratings yet

- Power ElectronicsDocument29 pagesPower ElectronicschetanNo ratings yet

- Swinv2000 ManualDocument6 pagesSwinv2000 ManualventerhermanjNo ratings yet

- L2341 e ZX1.2 08.2008Document16 pagesL2341 e ZX1.2 08.2008Adi jayaNo ratings yet

- Zeftronicsr25101 2a TSNDocument2 pagesZeftronicsr25101 2a TSNScott HartleyNo ratings yet

- Surge Filters, Low Current Dinsafe: Technical Information Sheet Sf105Din/ADocument1 pageSurge Filters, Low Current Dinsafe: Technical Information Sheet Sf105Din/AjohnarllanNo ratings yet

- Elektrik K2BhgCK3BhgB PelajarDocument2 pagesElektrik K2BhgCK3BhgB PelajarA. SuhaimiNo ratings yet

- Instrument Transformers 1Document39 pagesInstrument Transformers 1Joseph B Delos ReyesNo ratings yet

- Electrical Machines - IIDocument9 pagesElectrical Machines - IIvenkat0% (1)

- Recloser and SectionalizersDocument3 pagesRecloser and Sectionalizersjames komeNo ratings yet

- Kaic Rating EatonDocument20 pagesKaic Rating EatonGlenn Parado CairoNo ratings yet

- Notifier FDM 1 FlashScan Dual Monitor ModuleDocument2 pagesNotifier FDM 1 FlashScan Dual Monitor ModuleJhonNo ratings yet

- Ultrasonic Wave Production-Piezoelectric MethodDocument6 pagesUltrasonic Wave Production-Piezoelectric MethodNIKHIL SOLOMON P URK19CS1045No ratings yet

- MV and Synch Gear As Built-3Document21 pagesMV and Synch Gear As Built-3Sayed Younis SadaatNo ratings yet

- International Islamic University Chittagong: Department of Computer Science and EngineeringDocument4 pagesInternational Islamic University Chittagong: Department of Computer Science and EngineeringMD.Hasanuzzaman CSENo ratings yet

- AC DC RelaysDocument2 pagesAC DC RelaysIsuru WijewardeneNo ratings yet

- An 16Document32 pagesAn 16Hasan SAYINNo ratings yet

- Sitop Psu8200 24 v20 ADocument108 pagesSitop Psu8200 24 v20 Achao wangNo ratings yet

- Dynam Esc ManualDocument3 pagesDynam Esc ManualjozoceNo ratings yet

- The Direct Current MotorGenerator PDFDocument4 pagesThe Direct Current MotorGenerator PDFRenz carlosNo ratings yet

- Cummins: Fault Code: 366 PID: P1287 SPN: FmiDocument5 pagesCummins: Fault Code: 366 PID: P1287 SPN: FmiEnrrique LaraNo ratings yet

- Recloser Joslyn PDFDocument6 pagesRecloser Joslyn PDFDaniel CareNo ratings yet

- 2N60 PDFDocument7 pages2N60 PDFFady HachemNo ratings yet

- Voltage Sensitive Relay 12V 140A SpecificationDocument1 pageVoltage Sensitive Relay 12V 140A SpecificationRimsky ChengNo ratings yet

- ThyristorDocument3 pagesThyristorEdevPaulaDeVera0% (1)

- 2-Ex No - 1-18-Jul-2019Material - I - 18-Jul-2019 - Ex - No - 1Document18 pages2-Ex No - 1-18-Jul-2019Material - I - 18-Jul-2019 - Ex - No - 1Balaji SrinivasNo ratings yet

- Unconventional Airsoft - Com 2009-08-26 How To Make A Basic Mosfet SwitchDocument6 pagesUnconventional Airsoft - Com 2009-08-26 How To Make A Basic Mosfet SwitchGolodin Octavian0% (1)