Professional Documents

Culture Documents

WJB Series 2

Uploaded by

slmanov2ysOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WJB Series 2

Uploaded by

slmanov2ysCopyright:

Available Formats

88

Water & Steam Boilers – Series 2

Flame retention burners for

Gas, Light Oil, & Gas/Light Oil firing

Burner Specification Webster

Models WJB1 & WJB2

& Data Sheet

Models WJB1 & WJB2 Gas/light oil burner

Gas burner

W

L

E

C

B A

Part Number 550-142-022/0509

Webster – Model WJB

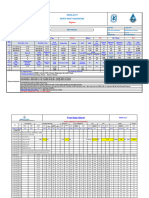

Standard Burner Model Standard Combustion Standard Control Burner Motor

Boiler Burner Input Positive Designation Control System 3450 RPM H.P.

Model Pressure in Standard

Number No. 2 Gas/ Gas/

88 Gas Firebox Light Gas/ Light Gas/ Light Gas Light Voltage

Oil

MBH In. W.C. Gas Oil Light Oil Gas Oil Light Oil

Gas

Oil

Light

H.P. Oil

Light

Series 2 GPH Oil Oil

488R 6.9 996 0.68 WJB1G-03 WJB1O-03 WJB1C-03 RM7897A R7184A RM7897C A A A 1/3 1/3 1/3 See notes

488 7.0 1010 0.70 WJB1G-03 WJB1O-03 WJB1C-03 RM7897A R7184A RM7897C A A A 1/3 1/3 1/3 See notes

588 9.4 1357 0.60 WJB1G-05 WJB1O-05 WJB1C-05 RM7897A R7184A RM7897C LFS LFS LFS 1/2 1/2 1/2 See notes

688 11.8 1701 0.58 WJB1G-07 WJB1O-07 WJB1C-07 RM7897A R7184A RM7897C LFS LFS LFS 3/4 3/4 3/4 See notes

788 14.2 2046 0.65 WJB1G-07 WJB1O-07 WJB1C-07 RM7897A R7184A RM7897C LFS LFS LFS 3/4 3/4 3/4 See notes

888 16.6 2382 0.66 WJB2G-07 WJB2O-10 WJB2C-10 RM7897A RM7897A RM7897C LFS LFS LFS 3/4 1 1 See notes

988R 17.2 2482 0.54 WJB2G-10 WJB2O-10 WJB2C-10 RM7897A RM7897A RM7897C LFS LFS LFS 1 1 1 See notes

988 18.8 2737 0.63 WJB2G-10 WJB2O-10 WJB2C-10 RM7897C RM7897A RM7897C LFS LFS LFS 1 1 1 See notes

1088R 20.0 2887 0.68 WJB2G-10 WJB2O-15 WJB2C-15 RM7897C RM7897A RM7897C LFS LFS LFS 1 1 1/2 1 1/2 See notes

1088 21.5 3082 0.78 WJB2G-10 WJB2O-15 WJB2C-15 RM7897C RM7897A RM7897C LFS LFS LFS 1 1 1/2 1 1/2 See notes

1188 23.5 3428 0.78 WJB2G-15 WJB2O-15 WJB2C-15 RM7897C RM7897A RM7897C LFS LFS LFS 1 1/2 1 1/2 1 1/2 See notes

1288 26.0 3773 0.76 WJB2G-15 WJB2O-15 WJB2C-15 RM7897C RM7897A RM7897C LFS LFS LFS 1 1/2 1 1/2 1 1/2 See notes

1388 28.5 4119 0.77 WJB2G-20 WJB2O-15 WJB2C-20 RM7897C RM7897A RM7897C LFS LFS LFS 2 2 2 See notes

1488 31.0 4464 0.78 WJB2G-20 WJB2O-15 WJB2C-30 RM7897C RM7897A RM7897C LFS LFS LFS 2 2 3 See notes

1588 33.0 4809 0.73 WJB2G-20 WJB2O-30 WJB2C-20 RM7897C RM7897A RM7897C LFS LFS LFS 2 3 2 See notes

1688R 34.5 4979 0.68 WJB2G-30 WJB2O-30 WJB2C-30 RM7897C RM7897A RM7897C LFS LFS LFS 3 3 3 See notes

1688 35.5 5155 0.74 WJB2G-30 WJB2O-30 WJB2C-30 RM7897C RM7897C RM7897C LFS LFS LFS 3 3 3 See notes

1788 38.0 5494 0.82 WJB2G-30 WJB2O-30 WJB2C-30 RM7897C RM7897C RM7897C LFS LFS LFS 3 3 3 See notes

1888 40.5 5845 0.80 WJB2G-30 WJB2O-30 WJB3C-50 RM7840L RM7897C RM7840L MOD LFS MOD 3 3 5 See notes

Standard Voltage Notes: 1/3 HP blower motor through ¾ HP – 120V/60/3 phase, 1 HP blower motor – 240V/60/3 phase, 1-½ HP blower motor through 5 HP- 240V/60/3 phase

Standard Gas Components and Sizes in Inches

Boiler Manual Low Gas Diaphragm Motorized Motorized Operat- Manual High Gas

Gas Pressure Safety Gas

Model Hand Pressure Operating Operating ing Gas Valve w/ Checking Pressure

Regulator Valve

Number Valve Switch Gas Valve Gas Valve Proof of Closure Gas Valve Switch

488R 1-¼ Optional 1-¼ 1 n/a n/a 1-¼ 1 Optional

488 1-¼ Optional 1-¼ 1 n/a n/a 1-¼ 1 Optional

588 1-¼ Optional 1-¼ n/a 1-¼ n/a 1-¼ 1-¼ Optional

688 1-½ Optional 1½ n/a 1-½ n/a 1-½ 1-½ Optional

788 1-½ Optional 1½ n/a 2 n/a 2 2 Optional

888 1-½ Optional 1½ n/a 2 n/a 2 2 Optional

988R 1-½ Optional 1½ n/a 2 n/a 2 2 Optional

988 1-½ Standard 1½ n/a 2 n/a 2 2 Standard

1088R 1-½ Standard 1½ n/a 2 n/a 2 2 Standard

1088 2 Standard 2 n/a 2 n/a 2 2 Standard

1188 2 Standard 2 n/a 2 n/a 2 2 Standard

1288 2-½ Standard 2-½ n/a 2 n/a 2-½ 2 Standard

1388 2-½ Standard 2-½ n/a 2 n/a 2-½ 2 Standard

1488 2-½ Standard 2-½ n/a 2 n/a 2-½ 2 Standard

1588 2-½ Standard 2-½ n/a 2 n/a 2-½ 2 Standard

1688R 2-½ Standard 2-½ n/a 2 n/a 2-½ 2 Standard

1688 2-½ Standard 2-½ n/a 2 2” 2-½ 2 Standard

1788 2-½ Standard 2-½ n/a 2-½ 2-½ 2-½ 2-½ Standard

1888 2-½ Standard 2-½ n/a 2-½ 2-½ 2-½ 2-½ Standard

Notes

1. Burner capacities listed for elevations up to 2,000 feet. For higher elevations, consult local Weil-McLain distributor/agent or sales office.

2. Light Oil ratings based on No. 2 fuel oil with heating value of 140,000 Btu per gallon.

3. Gas ratings based on natural gas with heating value of 1,000 Btu per cubic foot and specific gravity of 0.60. Gas burners for other gases are available. Consult local

Weil-McLain distributor/agent or sales office.

4. Boiler-burner unit to be adjusted to achieve +0.10 inches W.C. pressure at the flue collar, resulting in positive pressure in firebox as listed.

5. Minimum gas pressures listed are subject to variations due to job conditions. Gas burners for other gas pressures are available. Consult local Weil-McLain distribu-

tor/agent or sales office.

6. Gas orifice pressures shown are for initial start-up. Final pressures should be determined after checking actual gas flow and combustion readings.

2 Part Number 550-142-022/0509

Burner Specification and Data Sheet

7. Gas Control Systems:

A (OO): On-off operation, low fire start, high fire run. Single-position air, adjustable opening gas valve.

L (LFS): On-off operation, low fire start, high fire run. Two-position air controlled by damper arm on motorized gas valve.

H (LHL): Low-high-low-off firing conditions. Two-position air controlled by damper arm on motorized gas valve.

M (MOD): On-off operation, with proven low fire start and full modulating firing conditions with combustion air control.

Proportional motor drives fuel metering valve and combustion air damper according to the firing conditions.

Fixed damper pre-purge on 488-988R, open damper pre-purge on 988-1888.

Gas

Pressure Initial

Fuel Unit

required at Initial Damper Damper Initial Damper

Oil Burner-Motor

Pressure Gas Gas Control Setting Inches Setting Setting Inches Oil Nozzle(s)

Pressure Driven

Boiler drop thru orifice Inlet (Oil) Inches (Gas/Light Oil)

PSIG 3450 RPM

Model gas train pressure Inches (Gas)

Number Inches Inches W.C.

W.C. W.C.

High High GPH @

Low Spray High Low Gear

Min. Max. High Fire High Fire Fire Fire Qty. 100 Brand Type

Fire Angle Fire Fire GPH

(Gas) (Oil) PSIG

488R 2.3 2.4 5.5 14 1/4 1 1-1/4 1-5/16 1 1 4.00 Hago P 45º 300 100 22R220D 45

488 2.3 2.5 5.7 14 1/4 1-13/16 1-7/16 1-9/16 1-3/16 1 4.00 Hago P 45º 305 100 22R220D 45

588 3.7 2.8 7.0 28 1/2 13/16 1-7/8 1-7/8 1-3/16 1 5.50 Hago P 45º 290 100 22R220D 45

688 2.7 3.2 6.2 28 7/16 7/8 1-3/16 1-5/16 1 1 7.00 Hago P 45º 290 100 22R220D 45

788 2.9 2.8 5.1 28 1/2 1-3/8 1-13/16 1-7/8 1-1/2 2 4.25 Hago P 60º 280 100 22R221D 70

888 2.55 1.8 4.5 28 5/8 1-1/2 1 1-3/4 1-1/2 1 10.00 Hago P 45º 280 100 22R221D 70

988R 3.15 1.7 4.9 28 5/8 1-3/4 1-1/8 1-7/8 1-3/4 1 10.00 Hago P 45º 300 100 22R221D 70

988 3.8 1.8 5.8 28 1-3/16 1-5/16 1-1/4 1-1/2 1-3/16 1 11.00 Hago P 45º 290 100 22R221D 70

1088R 4.4 2.2 6.6 28 5/8 1-1/8 1-3/8 1-1/4 1-1/8 2 6.00 Hago P 45º 280 100 22R221D 70

1088 3.2 2.4 6.0 28 3/4 1-5/16 1-7/16 1-7/16 1-5/16 2 6.50 Hago P 45º 280 100 22R221D 70

1188 4.0 2.0 6.4 28 3/4 1-3/4 1-13/16 1-7/8 1-3/4 2 7.00 Hago P 45º 280 100 22R221D 70

1288 3.0 2.4 6.0 28 13/16 2-1/16 2-5/16 2-5/8 2-1/8 2 7.50 Hago P 45º 300 100 22R221D 70

1388 3.8 2.0 6.3 28 3/4 1-1/2 2-1/2 2-1/2 1 7/8 2 8.50 Hago P 60º 290 100 22R322D 105

1488 4.6 2.6 7.7 28 15/16 2-3/16 2-1/8 2-1/4 2 2 9.00 Hago P 60º 300 100 22R322D 105

1588 5.1 2.8 8.7 28 1 2-1/8 3-3/8 3-1/4 2-1/4 2 10.00 Hago P 60º 280 100 22R322D 105

1688R 4.6 2.9 9.2 28 1 1/16 2-1/2 1-7/8 2-1/4 1-1/2 2 10.00 Hago P 60º 300 100 22R623D 135

1688 6.1 3.1 9.8 28 1 2-5/8 2-1/4 2-1/2 2-1/8 2 10.50 Hago P 60º 295 100 22R623D 135

1788 5.25 4.5 9.1 28 9/16 2-1/4 3-1/4 3-1/4 3 2 11.00 Hago P 60º 300 100 22R623D 135

1888 5.7 6.0 10.4 28 1 3 1-3/4 1-7/8 1-7/8 3 8.0 Delevan 60º 300 65 SG0550 108

Standard Oil Pump Location:

488R through 1488 Gas / Oil – Integral to Burner, 1588 through 1888 Remote Pump

488R through 1688 Oil – Integral to Burner, 1788 and 1888 Remote Pump

8. Light Oil Control Systems:

LF (FALFS): On-off operation, fixed air, reduced fuel low fire start, high fire run. Single-position air, two-position oil.

L (LHO): On-off operation, low fire start, high fire run. Two-position air, two-position oil.

H (LHL): Low-high-low-off firing conditions. Two-position air, two-position oil.

M (MOD): On-off operation, with proven low fire start and full modulating firing conditions. Proportional motor drives fuel metering valve and combus-

tion air damper according to the firing conditions. Fixed damper pre-purge on 488-1088R, open damper pre-purge on 1088-1888.

9. Gas/Light Oil Control Systems:

A/LF (OO/FALFS): Combines gas and light oil characteristics listed above.

L/L (LHO/LHO): Combines gas and light oil characteristics listed above.

H/H (LHL/LHL): Combines gas and light oil characteristics listed above.

M/M (MOD/MOD): Combines gas and light oil characteristics listed above.

10. 120/60/1 control circuit is used for all burners.

11. Control circuit transformer is available as an option.

12. Motor starter contact will be furnished for all units.

13. Combustion Controls:

a) R8184G combustion control uses cadmium cell for flame detector to monitor oil burner flame, also furnishes intermittent ignition.

b) RM7897 flame safeguard control uses ultraviolet electronic flame detector to monitor gas or oil burner flame and provides pre-purge programming. “A”

models provide intermittent pilot; “C” models provide interrupted pilot and RUN/TEST switch.

c) RM7840M, E110/EPD390 flame safeguard control monitors the oil or gas burner flame, provides pre-purge and post-purge programming. Timed low fire

start is provided by means of timing built into control. Control is used with UL on-off (low fire start) systems. Ultraviolet sensitive electronic flame detector

is standard with infrared detector available.

d) RM7840L, E110/EPD170 flame safeguard control monitors the oil or gas burner flame, provides pre-purge and post-purge programming, provides switch-

ing necessary to allow firing rate motor to be driven to both low fire and high fire positions, prevents start-up if pre-ignition interlocks are open and has low

fire start proving circuit. In the event pre-ignition interlock circuit or running interlock circuit does not “prove”, system will lock out on safety. Ultraviolet

sensitive electronic flame detector is standard with infrared detector available.

Part Number 550-142-022/0509 3

Webster – Model WJB

Notes

e) RM7800L, E110/EP170 flame safeguard control monitors the oil or gas burner flame with digital readout control system, provides pre-

purge and post-purge programming, provides switching necessary to allow firing rate motor to be driven to both low fire and high fire posi-

tion, prevents start-up if pre-ignition interlocks are open and has low fire start proving circuit. In the event pre-ignition interlock circuit or

running interlock circuit does not “prove”, system will lock out on safety. Ultraviolet sensitive electronic flame detector is standard with

infrared detector available.

14. Airflow safety switch is standard for all gas and combination gas/light oil units.

15. Burners will be completely assembled and wired (except gas train) and factory test-fired.

16. Burners listed by Underwriters Laboratories, Inc., state of Connecticut, Fire Marshal state of Massachusetts, city of New York MEA, and others.

17. Special controls can be provided to meet other code requirements not listed. Consult your local Weil-McLain distributor/agent or sales office.

18. Electric gas pilot is standard equipment on all gas and combination gas/light oil units and on oil units 1688R-1888.

Direct spark ignition is standard on light oil units 488R-1588. Direct spark ignition is optional on combination gas/ light oil units 488R-1588.

Consult your local Weil-McLain distributor/agent or sales offices.

19. Available for Low NOx applications. Consult your local Weil-McLain distributor/agent or sales offices.

Flame Safeguards Provided with Listed Control Systems by Code

GAS BURNERS

Boiler UL FM CSD-1 IRI

model

number OO LHO LHL MOD OO LHO LHL MOD OO LHO LHL MOD OO LHO LHL MOD

488R-488 RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897C RM7897C RM7897C RM7840L

588-988R –– RM7897A RM7897A RM7897A –– RM7897A RM7897A RM7897A –– RM7897A RM7897A RM7897A –– RM7897C RM7897C RM7840L

988-1888 –– RM7897C RM7897C RM7840L –– RM7897C RM7897C RM7840L –– RM7897C RM7897C RM7840L –– RM7897C RM7897C RM7840L

LIGHT BURNERS

Boiler UL FM CSD-1 IRI

model

number FALFS LHO LHL MOD FALFS LHO LHL MOD FALFS LHO LHL MOD FALFS LHO LHL MOD

488R R8184G R8184G R8184G R8184G R8184G R8184G R8184G R8184G R8184G R8184G R8184G R8184G RM7897C RM7897C RM7897C RM7840L

488-588 R8184G R8184G R8184G R8184G R8184G R8184G R8184G R8184G RM7897A RM7897A RM7897A RM7895A RM7897C RM7897C RM7897C RM7840L

688-988R –– R8184G R8184G R8184G R8184G R8184G R8184G R8184G –– RM7897A RM7897A RM7895A –– RM7897C RM7897C RM7840L

988-1088R –– R8184G R8184G R8184G R8184G R8184G R8184G RM7840L –– RM7897A RM7897A RM7895A –– RM7897C RM7897C RM7840L

1088-1888 –– RM7896C RM7896C RM7840L –– RM7896C RM7896C RM7840L –– RM7897C RM7896C RM7840L –– RM7896C RM7896C RM7840L

GAS/LIGHT OIL BURNERS

Boiler UL FM CSD-1 IRI

model OO/ OO/ OO/ OO/

number LHO LHL MOD LHO LHL MOD LHO LHL MOD LHO LHL MOD

FALFS FALFS FALFS FALFS

488R-488 RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7897A RM7840L

588-988R –– RM7897A RM7897A RM7897A –– RM7897A RM7897A RM7897A –– RM7897A RM7897A RM7897A –– RM7897A RM7897A RM7840L

988-1888 –– RM7897C RM7897C RM7840L –– RM7896C RM7896C RM7840L –– RM7896C RM7896C RM7840L –– RM7896C RM7896C RM7840L

4 Part Number 550-142-022/0509

You might also like

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Vol. V PDFDocument249 pagesVol. V PDFDragonta Gonta100% (1)

- Um2kc1 Oil PanDocument2 pagesUm2kc1 Oil PanBurik8No ratings yet

- It CHDocument31 pagesIt CHGung Wira WicaksanaNo ratings yet

- DONGILDocument8 pagesDONGILIvan OmarNo ratings yet

- IAE Engines: A320 Light TestDocument1 pageIAE Engines: A320 Light TestcwzjhonNo ratings yet

- Max GasDocument12 pagesMax GasGuillermo E.No ratings yet

- Aux Engine Hyundai-Man-B-W-8l2832h PDFDocument1,044 pagesAux Engine Hyundai-Man-B-W-8l2832h PDFDimitris KNo ratings yet

- Instrument GTGDocument6 pagesInstrument GTGAl faruq distromuslimbontangNo ratings yet

- 04 - Operating MaintenanceDocument11 pages04 - Operating MaintenanceKoné SékouNo ratings yet

- ProOil-278 20,000 BPD Refinery PresentationDocument12 pagesProOil-278 20,000 BPD Refinery PresentationM Alim Ur RahmanNo ratings yet

- Simple Amine System V1.0Document7 pagesSimple Amine System V1.0alNo ratings yet

- s700 Part Nos. AnalyzersDocument12 pagess700 Part Nos. AnalyzersZiyaur RahmanNo ratings yet

- Gas Compressor Reference ListDocument8 pagesGas Compressor Reference Listaegean227No ratings yet

- Industrial Gas Generator Illustrated Parts CatalogueDocument3 pagesIndustrial Gas Generator Illustrated Parts CataloguejuanaNo ratings yet

- ReportDocument17 pagesReportMuhammad Fahmi MahmudNo ratings yet

- Basic Symbals P&ID PDFDocument736 pagesBasic Symbals P&ID PDFPavar RavitejaNo ratings yet

- 新冷媒相关Document5 pages新冷媒相关ruoqi.chengNo ratings yet

- Motor 2.4L MMC - 4.3L GM - Manual de Serviço (2007)Document116 pagesMotor 2.4L MMC - 4.3L GM - Manual de Serviço (2007)José MaliciaNo ratings yet

- Partsbook R1600G 9PP1-UpDocument966 pagesPartsbook R1600G 9PP1-UpAlberto JáureguiNo ratings yet

- Waukesha Gas Engines: Fuels & Lubrication Gaseous Fuel Specification For Waukesha EnginesDocument12 pagesWaukesha Gas Engines: Fuels & Lubrication Gaseous Fuel Specification For Waukesha EnginesJuly E. Maldonado M.No ratings yet

- Boiler MIURA - LX-300-16Document2 pagesBoiler MIURA - LX-300-16LuizPauloCostaNo ratings yet

- Equipo1 Surface-Sampling-Bench Data-Sheet en WebDocument2 pagesEquipo1 Surface-Sampling-Bench Data-Sheet en WebEladio Daniel Aquino ChanNo ratings yet

- IAE Engines: A320 TakeoffDocument1 pageIAE Engines: A320 TakeoffaoonjaiNo ratings yet

- 1Document3 pages1Catalina CuzminNo ratings yet

- Fuel Specification For Waukesha EngineDocument12 pagesFuel Specification For Waukesha Enginezubair1951100% (3)

- Maintenance Quick Guide - SB4312E07Document98 pagesMaintenance Quick Guide - SB4312E07joe100% (1)

- Fuel Gas Capacity CurveDocument1 pageFuel Gas Capacity Curveanwar sadatNo ratings yet

- Fuel Oil System GT 5-8: Muhammad Arshad Mukhtar Trainee EngineerDocument36 pagesFuel Oil System GT 5-8: Muhammad Arshad Mukhtar Trainee EngineermuddasirmasoodNo ratings yet

- Description of Gas Conditioning SkidDocument27 pagesDescription of Gas Conditioning SkidRaHuL PaTeLNo ratings yet

- PM 2 Metric (500 Hour Interval) : D8T Track-Type Tractor J8B78013Document3 pagesPM 2 Metric (500 Hour Interval) : D8T Track-Type Tractor J8B78013Jhon Omar Cusipuma JulónNo ratings yet

- Compressor Data Sheet Rev3 - Updated by EFXDocument9 pagesCompressor Data Sheet Rev3 - Updated by EFXmanuNo ratings yet

- 320 & 365 Kva PDFDocument156 pages320 & 365 Kva PDFManish AgarwalNo ratings yet

- Oil CentrifugeDocument2 pagesOil CentrifugeMuttappa T JainapurNo ratings yet

- Lubrication Specifications ChartDocument1 pageLubrication Specifications Chartמסגרת רוצחNo ratings yet

- Sebp3612 19 01 AllDocument631 pagesSebp3612 19 01 AllJose CarmonaNo ratings yet

- Wa0008Document812 pagesWa0008JoelNo ratings yet

- March2023 - Geneartors Alarm SD LISTDocument1 pageMarch2023 - Geneartors Alarm SD LISTkhanhptscNo ratings yet

- Partsbook R1700G 8XZ CCRC3045-21-1Document776 pagesPartsbook R1700G 8XZ CCRC3045-21-1Alberto JáureguiNo ratings yet

- Eaton Fuel HoseDocument6 pagesEaton Fuel HoseKeron TrotzNo ratings yet

- NWRA-0021T Main Result, TDS, Barton, Manual Reading, GraphDocument8 pagesNWRA-0021T Main Result, TDS, Barton, Manual Reading, Graphhp9mzbjzsfNo ratings yet

- Shin-Etsu Chemical Co., LTD Instrument ListDocument3 pagesShin-Etsu Chemical Co., LTD Instrument List12mchc07No ratings yet

- DSPradhanDocument27 pagesDSPradhanapi-3767061No ratings yet

- Neo InfoDocument9 pagesNeo InfoAnurag MishraNo ratings yet

- Manual de Partes Del R1600G 9PPDocument1,019 pagesManual de Partes Del R1600G 9PPZavaleta S. EmersonNo ratings yet

- Pages From GEK105059Document29 pagesPages From GEK105059phoenix609No ratings yet

- Manual Partes r1600g 9yzDocument781 pagesManual Partes r1600g 9yzElder BautistaNo ratings yet

- Dual Fuel Gas/Light-Oil Burners at Two Stages: SK073506 - C - enDocument4 pagesDual Fuel Gas/Light-Oil Burners at Two Stages: SK073506 - C - ensteam mastersNo ratings yet

- PDF Document ViewDocument31 pagesPDF Document Viewrobson lopes bezerraNo ratings yet

- Model CB Boilers 15-100 HP: Dimensions and RatingsDocument10 pagesModel CB Boilers 15-100 HP: Dimensions and Ratingsleonel lopezNo ratings yet

- Shell Side Pneumatic Testing 16 KWDocument1 pageShell Side Pneumatic Testing 16 KWHEPL VATVANo ratings yet

- Model CB Boilers 15-100 HP: Dimensions and RatingsDocument9 pagesModel CB Boilers 15-100 HP: Dimensions and RatingsMauricio RojasNo ratings yet

- CBLE DNR 05 2018 CUSTOMERDocument15 pagesCBLE DNR 05 2018 CUSTOMERJ. Gabriel GuevaraNo ratings yet

- Manual Partes R1600G 9PPDocument998 pagesManual Partes R1600G 9PPHector Javier Aguirre GallardNo ratings yet

- Ecoflam MAX GAS 250Document11 pagesEcoflam MAX GAS 250Pattaravoot SutiphanNo ratings yet

- 88 Riello Rls 550 142 023 - 1Document4 pages88 Riello Rls 550 142 023 - 1slmanov2ysNo ratings yet

- Gas Change 73BDocument21 pagesGas Change 73BAjay VarmaNo ratings yet

- SKF Dialset - Relubrication Calculation ProgramDocument1 pageSKF Dialset - Relubrication Calculation Programestebang956No ratings yet

- Filt RosDocument3 pagesFilt RosJosé roberto PoblanoNo ratings yet

- Dle4 8CNTDocument12 pagesDle4 8CNTBryant TorresNo ratings yet

- Pull Cord Switch JayashreeDocument1 pagePull Cord Switch JayashreeNCNo ratings yet

- Machine Design 2021 Guidelines and MechanicsDocument2 pagesMachine Design 2021 Guidelines and Mechanicsreneil llegueNo ratings yet

- 1 AlarmvalveDocument9 pages1 AlarmvalveAnandNo ratings yet

- The Teacher Research Movement: A Decade Later: Cite This PaperDocument13 pagesThe Teacher Research Movement: A Decade Later: Cite This PaperAlexandre NecromanteionNo ratings yet

- Hackerearth Online Judge: Prepared By: Mohamed AymanDocument21 pagesHackerearth Online Judge: Prepared By: Mohamed AymanPawan NaniNo ratings yet

- World of Self, Family and Friends UNIT 4 - Lunchtime Speaking 37 Wednesday Friendship LanguageDocument11 pagesWorld of Self, Family and Friends UNIT 4 - Lunchtime Speaking 37 Wednesday Friendship LanguageAin NawwarNo ratings yet

- Or HandoutDocument190 pagesOr Handoutyared haftu67% (6)

- Writing About Graphs, Tables and DiagramsDocument68 pagesWriting About Graphs, Tables and DiagramsLangers BastasaNo ratings yet

- Effects of Corneal Scars and Their Treatment With Rigid Contact Lenses On Quality of VisionDocument5 pagesEffects of Corneal Scars and Their Treatment With Rigid Contact Lenses On Quality of VisionJasmine EffendiNo ratings yet

- Teaching PowerPoint Slides - Chapter 5Document19 pagesTeaching PowerPoint Slides - Chapter 5Azril ShazwanNo ratings yet

- Grua Grove 530e 2 Manual de PartesDocument713 pagesGrua Grove 530e 2 Manual de PartesGustavo100% (7)

- Some Studies On Structure and Properties of Wrapped Jute (Parafil) YarnsDocument5 pagesSome Studies On Structure and Properties of Wrapped Jute (Parafil) YarnsVedant MahajanNo ratings yet

- Product Handbook Arendal 1961 Series SubwoofersDocument44 pagesProduct Handbook Arendal 1961 Series SubwoofersDomagoj KovacevicNo ratings yet

- The Handmaid's TaleDocument40 pagesThe Handmaid's Taleleher shahNo ratings yet

- Handout Waste Catch BasinDocument2 pagesHandout Waste Catch BasinJonniel De GuzmanNo ratings yet

- PedagogicalDocument94 pagesPedagogicalEdson MorenoNo ratings yet

- Exemption in Experience & Turnover CriteriaDocument4 pagesExemption in Experience & Turnover CriteriaVivek KumarNo ratings yet

- Innocent Words That Make Her HornyDocument14 pagesInnocent Words That Make Her HornyH69% (13)

- General Return Service Agreement (RSA) GuidelinesDocument2 pagesGeneral Return Service Agreement (RSA) GuidelinesJune Francis AngNo ratings yet

- Charter of The New UrbanismDocument4 pagesCharter of The New UrbanismBarabas SandraNo ratings yet

- Half Yearly Examination, 2017-18: MathematicsDocument7 pagesHalf Yearly Examination, 2017-18: MathematicsSusanket DuttaNo ratings yet

- WD Support Warranty Services Business Return Material Authorization RMA Pre Mailer For ResellerDocument3 pagesWD Support Warranty Services Business Return Material Authorization RMA Pre Mailer For ResellerZowl SaidinNo ratings yet

- 2021 Individual 20546 (Lawrence, Stephen R. and Bette F.) ClientDocument18 pages2021 Individual 20546 (Lawrence, Stephen R. and Bette F.) ClientVANDA MOORENo ratings yet

- Intercultural Personhood and Identity NegotiationDocument13 pagesIntercultural Personhood and Identity NegotiationJoão HorrNo ratings yet

- Chapter 3 Extension - Game Theory-StDocument25 pagesChapter 3 Extension - Game Theory-StQuynh Chau TranNo ratings yet

- Sub-Wings of YuvanjaliDocument2 pagesSub-Wings of Yuvanjalin_tapovan987100% (1)

- What Is Urban PlanningDocument33 pagesWhat Is Urban PlanningDivine Grace FernandoNo ratings yet

- Brochure - OasisDocument24 pagesBrochure - OasisVivek RNo ratings yet

- A Structural Modelo of Limital Experienci Un TourismDocument15 pagesA Structural Modelo of Limital Experienci Un TourismcecorredorNo ratings yet

- Dress Code19sepDocument36 pagesDress Code19sepapi-100323454No ratings yet