Professional Documents

Culture Documents

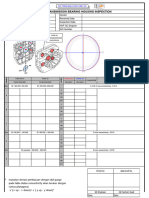

QAR-QD403-2 Magnetic Particle Inspection Report

Uploaded by

Irwanto ManafCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QAR-QD403-2 Magnetic Particle Inspection Report

Uploaded by

Irwanto ManafCopyright:

Available Formats

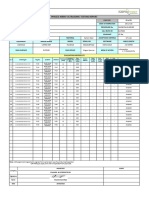

Document No.

: QAR-QD#403-2

Revision : 00

MAGNETIC PARTICLE INSPECTION Date : 15-Nov-07

PT. Sanggar Sarana Baja

REPORT Responsibility : QC Department

Remanufacturing Division

Page : 1 of 1

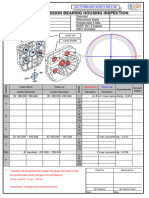

No. : 14691 Customer PT.TU Part Name : Crankshaft

PO. No. : 2-00712 Location : JAKARTA Model : 3512

NRC-ID : ENP 0696 Cust. WO. No. : 1089050/02 Part No 128-6786

REFERENCES & EQUIPMENT USED :

1. Guideline for Reusable Parts - Inspection of Crankshaft for Crack - SEBF8039

2. Reuse and Salvage Guidelines - Procedure to Inspect Crankshafts in 3500 Family of Engines - SEBF8156-09

3. ASNT (The American Society for Nondestructive Testing) - Magnetic Particle Method

4. Equipment Used : MPI Bench A-940 XL

CURRENT RECOMMENDATIONS :

Head Shot Current Coil Current

Main Journal Diameter Current (Amperes) Time Main Bearing Diameter Current (Amperes) Time

Up to 3.500" (90mm) 1500 2 seconds minimum Up to 3.500" (90mm) 2500 2 seconds minimum

Over 3.500" (90mm) 2000 3 seconds minimum Over 3.500" (90mm) 3000 3 seconds minimum

CONNECTING ROD JOURNALS MAIN JOURNALS

No Description Result No Description Result No Description Result

A A A

1 NO CRACK VISIBLE 9 NO CRACK VISIBLE 1 NO CRACK VISIBLE

R R R

A A A

2 NO CRACK VISIBLE 10 NO CRACK VISIBLE 2 NO CRACK VISIBLE

R R R

A A A

3 NO CRACK VISIBLE 11 NO CRACK VISIBLE 3 NO CRACK VISIBLE

R R R

A A A

4 NO CRACK VISIBLE 12 NO CRACK VISIBLE 4 NO CRACK VISIBLE

R R R

A A A

5 NO CRACK VISIBLE 13 N/A 5 NO CRACK VISIBLE

R R R

A A A

6 NO CRACK VISIBLE 14 - 6 NO CRACK VISIBLE

R R R

A A A

7 NO CRACK VISIBLE 15 - 7 NO CRACK VISIBLE

R R R

A A A

8 NO CRACK VISIBLE 16 - 8 N/A

R R R

A : Accept R : Reject A

9 -

R

Reviewed by Prepared by

QC Engineer : Denny Cahyono Inspector : ob Dede K

Signature : Date : 3/25/2008 Signature : Date : 3/25/2008

You might also like

- Ga Drawing With Bom and GTP of Indoor Type DB Panel Mechanical WorkshopDocument1 pageGa Drawing With Bom and GTP of Indoor Type DB Panel Mechanical WorkshopHytech Pvt. Ltd.No ratings yet

- Ga Drawing With Bom and GTP of Indoor Type DB Panel FMHM LabDocument1 pageGa Drawing With Bom and GTP of Indoor Type DB Panel FMHM LabHytech Pvt. Ltd.No ratings yet

- Ga Drawing With Bom and GTP of Indoor Type DB Panel Electrical Machine LabDocument1 pageGa Drawing With Bom and GTP of Indoor Type DB Panel Electrical Machine LabHytech Pvt. Ltd.No ratings yet

- Ga Drawing With Bom and GTP of Indoor Type DB Panel Electronics LabDocument1 pageGa Drawing With Bom and GTP of Indoor Type DB Panel Electronics LabHytech Pvt. Ltd.No ratings yet

- Ga Drawing With Bom and GTP of Indoor Type DB Panel Electrical Machine Lab Ii PDFDocument1 pageGa Drawing With Bom and GTP of Indoor Type DB Panel Electrical Machine Lab Ii PDFHytech Pvt. Ltd.No ratings yet

- Detalji Krovova - OluciDocument31 pagesDetalji Krovova - OluciSamirNo ratings yet

- Cascade Thinline4port Hydraulic Hose Reel PartsDocument6 pagesCascade Thinline4port Hydraulic Hose Reel PartssandmsolutionsNo ratings yet

- 4PortTHINLINEPartsDocument6 pages4PortTHINLINEPartsbenjaminNo ratings yet

- 4PortTHINLINEPartsDocument6 pages4PortTHINLINEPartsLKNo ratings yet

- Ga Drawing With Bom and GTP of Indoor Type DB Panel Heat Power LabDocument1 pageGa Drawing With Bom and GTP of Indoor Type DB Panel Heat Power LabHytech Pvt. Ltd.No ratings yet

- Design Checked by Drawing Checked by Drawn by MMT SSR .Document10 pagesDesign Checked by Drawing Checked by Drawn by MMT SSR .mukesh_kht1No ratings yet

- Schem e For Tie, Trafo, MotorDocument52 pagesSchem e For Tie, Trafo, Motormukesh_kht1No ratings yet

- Top Roll GroupDocument1 pageTop Roll GroupthaivinhtuyNo ratings yet

- 01 - Coordination Drawing (B1) - 22.3.2021 Draft - RoofDocument1 page01 - Coordination Drawing (B1) - 22.3.2021 Draft - RooffanhaoheNo ratings yet

- Circuit With Series-Parallel Resistor CombinationsDocument6 pagesCircuit With Series-Parallel Resistor CombinationsMuhammad HasnainNo ratings yet

- DPR - 20-06-2023Document2 pagesDPR - 20-06-2023Muhammad AftabNo ratings yet

- s60 ElectricDocument2 pagess60 Electricaup100% (5)

- Gad PSVDocument1 pageGad PSVNARAYAN DESAINo ratings yet

- Ruggerini MD350, MD351, MD358, MD350NRDocument17 pagesRuggerini MD350, MD351, MD358, MD350NRPaky PakicNo ratings yet

- Varsity Elite Helmets - Titanium Guards: Vengeance DCT Faceguards Vengeance DCT FaceguardsDocument4 pagesVarsity Elite Helmets - Titanium Guards: Vengeance DCT Faceguards Vengeance DCT FaceguardsortizhamNo ratings yet

- ATOD Feb 4 EditedDocument5 pagesATOD Feb 4 EditedJayvee JuniorNo ratings yet

- O-Level Instructions: 150SG122Q and 150SG122Q-4 Starter-GeneratorsDocument18 pagesO-Level Instructions: 150SG122Q and 150SG122Q-4 Starter-GeneratorsDouglas de Oliveira0% (1)

- Clark Reliance: Bill of MaterialDocument3 pagesClark Reliance: Bill of MaterialMohammed NouzalNo ratings yet

- Adobe Scan Jan 13, 2023Document1 pageAdobe Scan Jan 13, 2023Shahnawaz AlamNo ratings yet

- Ra3 011Document3 pagesRa3 011Alejandro Romero SepulvedaNo ratings yet

- PCR20Document5 pagesPCR20Yunus HeryNo ratings yet

- Fit-Up Piping B192-5-S2Document22 pagesFit-Up Piping B192-5-S2Prathamesh OmtechNo ratings yet

- 1.clamp Arm: Clamp Mini Bench ViseDocument10 pages1.clamp Arm: Clamp Mini Bench VisexnumericallyNo ratings yet

- Altronic Ignition-Systems PDFDocument12 pagesAltronic Ignition-Systems PDFNabeel AhmadNo ratings yet

- D Y ConversionDocument1 pageD Y Conversionmstan11No ratings yet

- 6191 - 0005 - R02 - Fes InternationalDocument1 page6191 - 0005 - R02 - Fes InternationalEsuMaticNo ratings yet

- Federation Commander North Polar Ship Card PackDocument37 pagesFederation Commander North Polar Ship Card PackOsNo ratings yet

- Part Catalogue Satria HiuDocument56 pagesPart Catalogue Satria HiuAldi KusumawNo ratings yet

- Plano de ControlDocument1 pagePlano de ControlGianmarco Facho ReyesNo ratings yet

- Stiker OkDocument2 pagesStiker OkOk Rs ubayaNo ratings yet

- 6A 20th Edition Purch Guidelines R1 20120429Document3 pages6A 20th Edition Purch Guidelines R1 20120429Vincent PaulrajNo ratings yet

- Daftar PekerjaanDocument11 pagesDaftar Pekerjaanrooney chaniagoNo ratings yet

- Data Sheet - 007-SU-RCLM-001Document1 pageData Sheet - 007-SU-RCLM-001Luis Miguel Torres SayasNo ratings yet

- Formato Lomos SGSCMDocument2 pagesFormato Lomos SGSCMyoyanoobNo ratings yet

- Shell RLA - Step - 4pp - Lo - v4 PDFDocument2 pagesShell RLA - Step - 4pp - Lo - v4 PDFfrancisNo ratings yet

- Mounting InstructionsDocument5 pagesMounting InstructionsGiovanni BoninNo ratings yet

- AVNV 4N G 6.5K ModelDocument1 pageAVNV 4N G 6.5K ModelrodimarproNo ratings yet

- ElectricalDocument3 pagesElectricalsid8ismNo ratings yet

- Hydrotest Header - Spread BDocument1 pageHydrotest Header - Spread BVijay Allimuthu AvathipalayamNo ratings yet

- RTG Range.: Ready To Go StockDocument56 pagesRTG Range.: Ready To Go StockFercomil S.A.SNo ratings yet

- Catalog of Replacement Parts: Model Rs22A & Aw Series Prewash UnitDocument24 pagesCatalog of Replacement Parts: Model Rs22A & Aw Series Prewash UnitPedro SantanaNo ratings yet

- حسابات التأريضDocument4 pagesحسابات التأريضHemo A AlsharifNo ratings yet

- 00 Ec D 43105 - 5Document1 page00 Ec D 43105 - 5ganesh kumarNo ratings yet

- Granddink 125 Euro3Document139 pagesGranddink 125 Euro3Andrei_C10No ratings yet

- AWR1642BOOST: Sheet Name Sheet NoDocument20 pagesAWR1642BOOST: Sheet Name Sheet NoImran AkramNo ratings yet

- Left Side: Waktu Proses Tanggal: Start: Finish: MODEL: D375A - 5 S/N: COMP.: SA6 D 170E - 3 S/NDocument4 pagesLeft Side: Waktu Proses Tanggal: Start: Finish: MODEL: D375A - 5 S/N: COMP.: SA6 D 170E - 3 S/NMay FattahNo ratings yet

- Dual Plate Swing Check ValveDocument2 pagesDual Plate Swing Check ValveAnshumanNo ratings yet

- 2 Frame Rack Shown: Parts ListDocument2 pages2 Frame Rack Shown: Parts Listjaouad id boubkerNo ratings yet

- Scania Dc16: Disassembling Check SheetDocument3 pagesScania Dc16: Disassembling Check SheetJaya PranataNo ratings yet

- Valve Service Final Report - SampleDocument4 pagesValve Service Final Report - SampleNazmiNo ratings yet

- Dimensions in Millimetres and Kilograms: Prepered by Checked by Costomer Appd Drawn DateDocument1 pageDimensions in Millimetres and Kilograms: Prepered by Checked by Costomer Appd Drawn DateAnggi SujiwoNo ratings yet

- P-400 Swivel & UniflexDocument4 pagesP-400 Swivel & UniflexIvan Villarreal LopezNo ratings yet

- Gambar Alumunium KacaDocument2 pagesGambar Alumunium KacaWinadi KurniawanNo ratings yet

- Organic Elemental Analysis: Ultramicro, Micro, and Trace MethodsFrom EverandOrganic Elemental Analysis: Ultramicro, Micro, and Trace MethodsNo ratings yet

- Centricity Pto Ex 2500Document3 pagesCentricity Pto Ex 2500Irwanto ManafNo ratings yet

- Case Pto Only IdDocument5 pagesCase Pto Only IdIrwanto ManafNo ratings yet

- Flange Grease Ex 2500aDocument1 pageFlange Grease Ex 2500aIrwanto ManafNo ratings yet

- Case Pto 3600Document2 pagesCase Pto 3600Irwanto ManafNo ratings yet

- Casing Travel MotorDocument2 pagesCasing Travel MotorIrwanto ManafNo ratings yet

- HOUSING SWING EX-3600 (Before)Document7 pagesHOUSING SWING EX-3600 (Before)Irwanto ManafNo ratings yet

- Carrier Ex 2500Document6 pagesCarrier Ex 2500Irwanto ManafNo ratings yet

- Spindle Center JointDocument2 pagesSpindle Center JointIrwanto ManafNo ratings yet

- Concentricity PtoDocument3 pagesConcentricity PtoIrwanto ManafNo ratings yet

- QAR-QD418-51 Rod As-Rear SuspensionDocument5 pagesQAR-QD418-51 Rod As-Rear SuspensionIrwanto ManafNo ratings yet

- Bucket Re BushingDocument2 pagesBucket Re BushingIrwanto ManafNo ratings yet

- QAR-QD418-79 Housing As-Rear SuspensionDocument6 pagesQAR-QD418-79 Housing As-Rear SuspensionIrwanto ManafNo ratings yet

- Casing Travel Motor 2Document3 pagesCasing Travel Motor 2Irwanto ManafNo ratings yet

- QAR-QD418-5 Rod-Front Susp 797 (191-8043)Document6 pagesQAR-QD418-5 Rod-Front Susp 797 (191-8043)Irwanto ManafNo ratings yet

- QAR-QD#419-15 Feed Cylinder GPDocument8 pagesQAR-QD#419-15 Feed Cylinder GPIrwanto ManafNo ratings yet

- QAR-QD418-50 Rod As-Rear SuspensionDocument5 pagesQAR-QD418-50 Rod As-Rear SuspensionIrwanto ManafNo ratings yet

- QAR QD418 115 Rod As Lift CylinderDocument5 pagesQAR QD418 115 Rod As Lift CylinderIrwanto ManafNo ratings yet

- QAR-QD#419-15 Feed Cylinder GPDocument8 pagesQAR-QD#419-15 Feed Cylinder GPIrwanto ManafNo ratings yet

- QAR-QD#419-15 Feed Cylinder GPDocument8 pagesQAR-QD#419-15 Feed Cylinder GPIrwanto ManafNo ratings yet

- QAR-QD418-5 Rod-Front Susp 797 (191-8043)Document6 pagesQAR-QD418-5 Rod-Front Susp 797 (191-8043)Irwanto ManafNo ratings yet

- QAR-QD#419-15 Feed Cylinder GPDocument8 pagesQAR-QD#419-15 Feed Cylinder GPIrwanto ManafNo ratings yet

- QAR-QD#419-15 Feed Cylinder GPDocument8 pagesQAR-QD#419-15 Feed Cylinder GPIrwanto ManafNo ratings yet

- QAR-QD#419-24 Edmo Jack Cylinder GPDocument2 pagesQAR-QD#419-24 Edmo Jack Cylinder GPIrwanto ManafNo ratings yet

- QAR-QD#419-15 Feed Cylinder GPDocument8 pagesQAR-QD#419-15 Feed Cylinder GPIrwanto ManafNo ratings yet

- QAR QD#406 3 Pre Post Salvage Inspection Long Shift1Document2 pagesQAR QD#406 3 Pre Post Salvage Inspection Long Shift1kipak.s.at.uNo ratings yet

- QAR QD#406 3 Pre Post Salvage Inspection Long Shift1Document2 pagesQAR QD#406 3 Pre Post Salvage Inspection Long Shift1kipak.s.at.uNo ratings yet

- QAR-QD#407-7 Hollow Printing RollsDocument2 pagesQAR-QD#407-7 Hollow Printing RollsIrwanto ManafNo ratings yet

- QAR-QD#407-19 Line Shaft (697-LINE SHAFT)Document2 pagesQAR-QD#407-19 Line Shaft (697-LINE SHAFT)Irwanto ManafNo ratings yet

- Form-Qc-001-616 Washer Pin Pivot StopDocument1 pageForm-Qc-001-616 Washer Pin Pivot StopIrwanto ManafNo ratings yet

- PPT-QC AcDocument34 pagesPPT-QC AcAmlan Chakrabarti Calcutta UniversityNo ratings yet

- Preblending of Raw Materia1Document26 pagesPreblending of Raw Materia1Mohammed Abdo100% (1)

- International Business ManagementDocument3 pagesInternational Business Managementkalaiselvi_velusamyNo ratings yet

- Category (7) - Installation and Maintenance of Instrumentation and Control SystemsDocument3 pagesCategory (7) - Installation and Maintenance of Instrumentation and Control Systemstafseerahmed86No ratings yet

- DLL in Health 7 3rd QuarterDocument2 pagesDLL in Health 7 3rd QuarterJuna Lyn Hermida ArellonNo ratings yet

- Pds Hempel's Maestro Water Borne Primer 28830 En-GbDocument2 pagesPds Hempel's Maestro Water Borne Primer 28830 En-GbKalaiyazhagan ElangeeranNo ratings yet

- Skilled Worker Overseas FAQs - Manitoba Immigration and Economic OpportunitiesDocument2 pagesSkilled Worker Overseas FAQs - Manitoba Immigration and Economic OpportunitieswesamNo ratings yet

- NJEX 7300G: Pole MountedDocument130 pagesNJEX 7300G: Pole MountedJorge Luis MartinezNo ratings yet

- Geopolymer Book Chapter1 PDFDocument37 pagesGeopolymer Book Chapter1 PDFDick ManNo ratings yet

- Early Christian ArchitectureDocument38 pagesEarly Christian ArchitectureInspirations & ArchitectureNo ratings yet

- Products ListDocument11 pagesProducts ListPorag AhmedNo ratings yet

- NATO Obsolescence Management PDFDocument5 pagesNATO Obsolescence Management PDFluisNo ratings yet

- Purification of Dilactide by Melt CrystallizationDocument4 pagesPurification of Dilactide by Melt CrystallizationRaj SolankiNo ratings yet

- 353 Version 7thDocument1 page353 Version 7thDuc NguyenNo ratings yet

- IGCSE 0408 Unseen Poem QuestionsDocument5 pagesIGCSE 0408 Unseen Poem QuestionsMenon HariNo ratings yet

- Under Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisDocument13 pagesUnder Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisMahmud RahmanNo ratings yet

- Adding and Subtracting FractionsDocument4 pagesAdding and Subtracting Fractionsapi-508898016No ratings yet

- BS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDocument16 pagesBS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDayan Yasaranga100% (2)

- 377 Situational Expression Advanced Level Test Quiz Online Exercise With Answers 1Document7 pages377 Situational Expression Advanced Level Test Quiz Online Exercise With Answers 1zdravkamajkicNo ratings yet

- DR Afwan Fajri - Trauma - Juli 2023Document82 pagesDR Afwan Fajri - Trauma - Juli 2023afwan fajriNo ratings yet

- MotorsDocument116 pagesMotorsAmália EirezNo ratings yet

- (QII-L2) Decorate and Present Pastry ProductsDocument30 pages(QII-L2) Decorate and Present Pastry ProductsLD 07100% (1)

- Ebook Stackoverflow For ItextDocument336 pagesEbook Stackoverflow For ItextAnonymous cZTeTlkag9No ratings yet

- Landcorp FLCC Brochure 2013 v3Document6 pagesLandcorp FLCC Brochure 2013 v3Shadi GarmaNo ratings yet

- Edtpa Lesson 3Document3 pagesEdtpa Lesson 3api-299319227No ratings yet

- Aashirwaad Notes For CA IPCC Auditing & Assurance by Neeraj AroraDocument291 pagesAashirwaad Notes For CA IPCC Auditing & Assurance by Neeraj AroraMohammed NasserNo ratings yet

- Sweat Equity SharesDocument8 pagesSweat Equity SharesPratik RankaNo ratings yet

- Group 4&5 Activity Syntax AnalyzerDocument6 pagesGroup 4&5 Activity Syntax AnalyzerJuan PransiskoNo ratings yet

- Diazonium Salts Azo DyesDocument8 pagesDiazonium Salts Azo DyesAnthony Basanta100% (1)

- Name of The Business-Rainbow Blooms LLC. Executive SummaryDocument17 pagesName of The Business-Rainbow Blooms LLC. Executive SummaryAhamed AliNo ratings yet