Professional Documents

Culture Documents

Con-Inject 1k

Con-Inject 1k

Uploaded by

Ankita Baban Gavade0 ratings0% found this document useful (0 votes)

10 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pagesCon-Inject 1k

Con-Inject 1k

Uploaded by

Ankita Baban GavadeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Last update on: 11-12-2021

Version: 1

PRODUCT DATA SHEET Water] at 25°C

Tensile Shear

4 N/mm² at 23°C

Con-Inject 1k Strength

Corrosiveness Non-Corrosive

Con-Inject 1k is hydrophobic foam based on polyurethane Resistant to most organic

Chemical

resin. solvents, Mild Acids, Alkalis,

Resistance

etc.

Specification:

Con-Inject 1k is a single-component, PU-based Application procedure:

hydrophobic foam used for grouting applications. Con- Surface preparation:

Inject 1k expands its volume to 27 times of original and Correct and high-quality preparation is critical for

forms a closed-cell rubber-like structure after coming in optimum performance.

contact with water. The denseness of the foam varies in line Cracks or cold joints:

with the injection pressure. Since water is not a component Clean the concrete surface, 2 cm on either side of the

of the foam structure, the cured material is essentially not crack or joint, free from dust, fungus, curing membrane,

affected by water or dryness. The reacted material does not and other such contaminants, or if necessary, remove the

shrink or swell. contaminated layer. For pressure injection, drill 10 mm

diameter, 50 mm deep holes at predetermined locations.

Uses: Use pneumatic drills underwater. Ensure that holes are

Deteriorated and honeycombed concrete. vacuumed before fixing Packers. The frequency of ports

Concrete joints or Packers depends on the crack severity and the nature

Pipe insertions of the structure. For reference, the maximum center-to-

Injection grout for soil stabilization center distance between adjacent ports can be

To fill cracks and crevices in wastewater tanks, considered as 1 m. If the crack runs through a section of

tunnels, dams, subways sewers, manholes, and more than 500 mm thick structural elements,

utility boxes. ports/Packers may be required on both the faces of the

elements.

Advantages:

Cavities and voids can be filled effectively as it Placing:

can increase the volume to ensure complete Place the grout into cracks using the injection method.

filling. Start the injection process from the widest part for a

Single component; easy to use. horizontal surface or from the lowest point for a vertical

It remains constant in volume upon curing with surface. Inject each port or nipple (keeping all others

zero shrinkage. closed except the adjacent one). When the resin starts

Excellent bond properties. gushing out of the next port/nipple, close it and continue

Superior adhesive strength, tolerant of movements injection. After maintaining the pressure for 1 to 5 minutes

This can be applied on the negative side to allow for total penetration, close the port and

Penetrates deeply into the substrate disconnect the pump. Continue the process until all the

ports or Packers are injected in a similar manner. After 24

Packaging: hours remove all the injection ports and Packers. Fill in

Con-Inject 1k is supplied in 10kg, 20kg, and 200kg packs. the resulting cavities using RIPSTAR 122.

Coverage: Storage and Shelf life All:

The quantity of Con-Inject 1k for a particular application Store under cover, out of direct sunlight and protect from

depends on the total volume of the void/crack to be filled, extremes of temperature. In tropical climates, the product

absorption of the substrate, loss, and wastage. must be stored in an air-conditioned environment. Shelf

life is 12 months when stored as above. All partly used

Typical properties: drums should be covered by nitrogen and resealed to

Appearance Dark brown liquid prevent the ingress of moisture

Density 1.12 kg/liter

Solubility in water Hydrophobic Safety precautions:

Viscosity 100-200 mPa.S at 25°C As with all chemical products, care should be taken during

110 sec [Ratio 2:1 Resin: use and storage to avoid contact with eyes, mouth, skin,

Gel time and foodstuffs (which can also be tainted with vapor until

Water] at 25°C

15 sec [Ratio 2:1 Resin: Water] the product is fully cured or dried). Treat splashes to eyes

Induction time and skin immediately.

at 25°C

Max. Expansion 3000 % [Ratio 10:1 Resin:

SP CONCARE PVT. LTD.

CS No. 1471, DB House 1st Floor,

Madhavnagar Road, Near Auto India,

info@spconcare.com www.spconcare.com Sangli-416416, Maharashtra, (INDIA)

Last update on: 11-12-2021

Version: 1

If accidentally ingested, seek immediate medical

attention. Keep away from children and animals. Reseal

containers after use. Do not reuse containers for the

storage of consumable items.

Disclaimer:

Whilst any information contained herein is true,

accurate and represents our best knowledge and

experience, no warranty is given or implied with any

recommendations made by us, our representatives, or

distributors, as the conditions of use and the

competence of any labor involvedin the application are

beyond our control.

SP CONCARE PVT. LTD.

CS No. 1471, DB House 1st Floor,

Madhavnagar Road, Near Auto India,

info@spconcare.com www.spconcare.com Sangli-416416, Maharashtra, (INDIA)

You might also like

- Book All TomorrowsDocument112 pagesBook All Tomorrowsmahmoud talaatNo ratings yet

- Powerproof: One Component Polyurethane Dispersion Waterproofing MembraneDocument2 pagesPowerproof: One Component Polyurethane Dispersion Waterproofing MembraneFritz Natividad67% (3)

- Pentens: Description Technical & Physical DataDocument2 pagesPentens: Description Technical & Physical DataArdian YuliantoNo ratings yet

- Con-Inject 1k-1Document2 pagesCon-Inject 1k-1Ankita Baban GavadeNo ratings yet

- Con-Inject 2kDocument2 pagesCon-Inject 2kAnkita Baban GavadeNo ratings yet

- Boscoflex: Flexible Cementitious Waterprofing MembraneDocument2 pagesBoscoflex: Flexible Cementitious Waterprofing MembraneCLENTH FLORentinoNo ratings yet

- TDS-EN-Contite Flex - Rev 007-Feb 22Document2 pagesTDS-EN-Contite Flex - Rev 007-Feb 22LONG LASTNo ratings yet

- 7 2 1 1 6 1 Polyflex 10 PDFDocument2 pages7 2 1 1 6 1 Polyflex 10 PDFFourier MakambioNo ratings yet

- Elastoroof PUDocument2 pagesElastoroof PUSunilNo ratings yet

- AquaflexDocument3 pagesAquaflexsmart construction solution solutionNo ratings yet

- FLEXCRETE1Document1 pageFLEXCRETE1Anil UdaleNo ratings yet

- Mr. Dry 425: MR. DRY 425 Is A Penetrative, Reactive, Crystalline Capillary Waterproofing System For ConcreteDocument4 pagesMr. Dry 425: MR. DRY 425 Is A Penetrative, Reactive, Crystalline Capillary Waterproofing System For ConcreteAnkita Baban GavadeNo ratings yet

- Pentens NPU-12 Data SheetDocument2 pagesPentens NPU-12 Data Sheetamelinda jocelinNo ratings yet

- DUFILLDocument3 pagesDUFILLvelmurug_balaNo ratings yet

- Acristar #150Document1 pageAcristar #150ChristinaNo ratings yet

- ChemFlex (2019 - 06 - 16 07 - 33 - 19 UTC)Document2 pagesChemFlex (2019 - 06 - 16 07 - 33 - 19 UTC)smart construction solution solutionNo ratings yet

- Ripstar Primer v3Document1 pageRipstar Primer v3john paulNo ratings yet

- Pentens E-501LN Data SheetDocument2 pagesPentens E-501LN Data Sheetamelinda jocelinNo ratings yet

- MR - DRY 830EL-v4Document4 pagesMR - DRY 830EL-v4Ankita Baban GavadeNo ratings yet

- PENESEAL PRO Data SheetDocument2 pagesPENESEAL PRO Data SheetAmer BenghaziNo ratings yet

- PU-300 (PU Grouting)Document2 pagesPU-300 (PU Grouting)S EfendiNo ratings yet

- TDS Hydroproof Xtra India2Document2 pagesTDS Hydroproof Xtra India2Sameehu TVNo ratings yet

- Solvent-Free, Low Viscosity Epoxy ResinDocument2 pagesSolvent-Free, Low Viscosity Epoxy ResinYASHICA VAITTIANATHANNo ratings yet

- SunkoteDocument2 pagesSunkoteSunilNo ratings yet

- BoscoflexDocument2 pagesBoscoflexGeloNo ratings yet

- TDS_FLEXICRETEDocument2 pagesTDS_FLEXICRETEmilmodchipsNo ratings yet

- DR Fixit Pidifin 2K Dec 19Document3 pagesDR Fixit Pidifin 2K Dec 19Nav Nirman Con SpecialitiesNo ratings yet

- KRETOP EPS PRIMER VEDocument1 pageKRETOP EPS PRIMER VEAmer FiqriNo ratings yet

- TDS-EN-Condur 41 - Rev 007-Jun 22Document2 pagesTDS-EN-Condur 41 - Rev 007-Jun 22LONG LASTNo ratings yet

- Polycrete FC: Polymer Modified Cementitious Fairing CoatDocument2 pagesPolycrete FC: Polymer Modified Cementitious Fairing Coatmohamed ragabNo ratings yet

- Boscoflex: Flexible Cementitious Waterprofing MembraneDocument2 pagesBoscoflex: Flexible Cementitious Waterprofing MembranenizarazuNo ratings yet

- Dura FlexDocument2 pagesDura FlexMuktaf Ajib El WatsiNo ratings yet

- Mirac Sealer ESDocument1 pageMirac Sealer ESChristinaNo ratings yet

- Condur 41: A 2 Component Epoxy Resin Patching MortarDocument1 pageCondur 41: A 2 Component Epoxy Resin Patching Mortarchriscivil12No ratings yet

- Aquaarm Multicrete Aquaarm Multicrete Aquaarm MulticreteDocument2 pagesAquaarm Multicrete Aquaarm Multicrete Aquaarm MulticreteShabbir LokhandwalaNo ratings yet

- Nanofines 822Document1 pageNanofines 822Ankita Baban GavadeNo ratings yet

- Olycryl Olycryl: Acrylic Based Waterproofing CoatingDocument2 pagesOlycryl Olycryl: Acrylic Based Waterproofing CoatingVaittianathan MahavapillaiNo ratings yet

- Curing Compound LN 353Document2 pagesCuring Compound LN 353Doby YuniardiNo ratings yet

- Drylok Extreme Masonry Waterproofer PdsDocument5 pagesDrylok Extreme Masonry Waterproofer Pdscarlos_raul_nNo ratings yet

- Renderoc PlasterDocument1 pageRenderoc PlasterNarutojane BorutoNo ratings yet

- Renderoc Plaster PDFDocument1 pageRenderoc Plaster PDFNarutojane BorutoNo ratings yet

- PDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKDocument2 pagesPDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKRoemaric AguasNo ratings yet

- Water-Tite 103: Premium Flexible Cementitious WaterproofingDocument2 pagesWater-Tite 103: Premium Flexible Cementitious WaterproofingGerald Ordoñez Delos ReyesNo ratings yet

- Cr-Durapatch - TDSDocument3 pagesCr-Durapatch - TDSMurali PokkunuriNo ratings yet

- Fosroc Chemical Breaker PDFDocument2 pagesFosroc Chemical Breaker PDFKishore Kumar RajaNo ratings yet

- SUNANDA Hack Aid Plast SPL PDFDocument2 pagesSUNANDA Hack Aid Plast SPL PDFSheezan KhanNo ratings yet

- Kan FlexDocument3 pagesKan FlexSunny SinghNo ratings yet

- Polycell Pu510 TdsDocument3 pagesPolycell Pu510 TdsnorlailiNo ratings yet

- Sikafix - 101: Single Component, Solvent-Free, Low Viscosity Polyurethane Resin For Flexible Crack SealingDocument3 pagesSikafix - 101: Single Component, Solvent-Free, Low Viscosity Polyurethane Resin For Flexible Crack SealingAlonso Aguilar SalasNo ratings yet

- Tds Onducoat CeDocument3 pagesTds Onducoat Cenabil sabah januarNo ratings yet

- E 500flexDocument2 pagesE 500flexamelinda jocelinNo ratings yet

- Renderoc CS: Single Part, Non Shrink, Cementitious, Crack Sealer For Plaster, Masonry and ConcreteDocument2 pagesRenderoc CS: Single Part, Non Shrink, Cementitious, Crack Sealer For Plaster, Masonry and Concreteharish babu aluruNo ratings yet

- Ideal Hard Plus Tec EngDocument3 pagesIdeal Hard Plus Tec EngPedroNo ratings yet

- Brushbond FlexDocument2 pagesBrushbond FlexMoniq NiqqNo ratings yet

- DR Fixit Pidifin 2KDocument3 pagesDR Fixit Pidifin 2KAsif AhmadNo ratings yet

- MR. DRY 800-v1Document1 pageMR. DRY 800-v1Ankita Baban GavadeNo ratings yet

- Ultrakote Stretchkote 2022 MinDocument2 pagesUltrakote Stretchkote 2022 MinAlex AcevedoNo ratings yet

- TDS-EN-Conflex PS - Rev 016-Aug21Document2 pagesTDS-EN-Conflex PS - Rev 016-Aug21LONG LASTNo ratings yet

- PENETRON INJECT Data SheetDocument2 pagesPENETRON INJECT Data SheetPatrick MooreNo ratings yet

- Alccofine 1108SR : Description Typical PropertiesDocument2 pagesAlccofine 1108SR : Description Typical Propertiesravi100% (1)

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEFrom EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENo ratings yet

- Msds Ripstar 122 Part 1Document7 pagesMsds Ripstar 122 Part 1Ankita Baban GavadeNo ratings yet

- ADDMIX 690-v3Document1 pageADDMIX 690-v3Ankita Baban GavadeNo ratings yet

- ADDMIX 105-v4Document2 pagesADDMIX 105-v4Ankita Baban GavadeNo ratings yet

- Msds-Mr. Dry 104Document4 pagesMsds-Mr. Dry 104Ankita Baban GavadeNo ratings yet

- Nanofines 822Document1 pageNanofines 822Ankita Baban GavadeNo ratings yet

- ADDMIX 109 PCCI-v1Document2 pagesADDMIX 109 PCCI-v1Ankita Baban GavadeNo ratings yet

- ADDMIX 152-v4 PDFDocument1 pageADDMIX 152-v4 PDFAnkita Baban GavadeNo ratings yet

- ADDMIX 55-v3Document2 pagesADDMIX 55-v3Ankita Baban GavadeNo ratings yet

- ADDMIX 210-v5Document2 pagesADDMIX 210-v5Ankita Baban GavadeNo ratings yet

- Ripstar 109: SpecificationDocument3 pagesRipstar 109: SpecificationAnkita Baban GavadeNo ratings yet

- MR. DRY 701-v3Document3 pagesMR. DRY 701-v3Ankita Baban GavadeNo ratings yet

- SPLANDEK 2100v3Document4 pagesSPLANDEK 2100v3Ankita Baban GavadeNo ratings yet

- MR DRY195-v3Document3 pagesMR DRY195-v3Ankita Baban GavadeNo ratings yet

- MR - DRY 830EL-v4Document4 pagesMR - DRY 830EL-v4Ankita Baban GavadeNo ratings yet

- RIPSTAR Saturant-V3Document3 pagesRIPSTAR Saturant-V3Ankita Baban GavadeNo ratings yet

- Lejell210 MSDS(英文版)Document16 pagesLejell210 MSDS(英文版)Ankita Baban GavadeNo ratings yet

- Report On Crystaline WaterproofingDocument11 pagesReport On Crystaline WaterproofingAnkita Baban GavadeNo ratings yet

- Poly Urea Coating: Smart & Reliable Chemical SolutionsDocument12 pagesPoly Urea Coating: Smart & Reliable Chemical SolutionsAnkita Baban GavadeNo ratings yet

- SP Concare Pvt. LTD.: Repair & RetrofittingDocument15 pagesSP Concare Pvt. LTD.: Repair & RetrofittingAnkita Baban GavadeNo ratings yet

- RIPSTAR 49v5Document4 pagesRIPSTAR 49v5Ankita Baban GavadeNo ratings yet

- Mr. Dry 425: MR. DRY 425 Is A Penetrative, Reactive, Crystalline Capillary Waterproofing System For ConcreteDocument4 pagesMr. Dry 425: MR. DRY 425 Is A Penetrative, Reactive, Crystalline Capillary Waterproofing System For ConcreteAnkita Baban GavadeNo ratings yet

- Quotation (JB Construction)Document2 pagesQuotation (JB Construction)Ankita Baban GavadeNo ratings yet

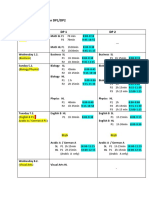

- ChartDocument1 pageChartAnkita Baban GavadeNo ratings yet

- Quotation-Municiple Waterproofing WorkDocument3 pagesQuotation-Municiple Waterproofing WorkAnkita Baban GavadeNo ratings yet

- Addmix 55: ADDMIX 55 Is A Calcium Nitrite-Based Corrosion Inhibiting Super Plasticizer For RCC MembersDocument4 pagesAddmix 55: ADDMIX 55 Is A Calcium Nitrite-Based Corrosion Inhibiting Super Plasticizer For RCC MembersAnkita Baban GavadeNo ratings yet

- Unit 4 Repair & Retro. TechniquesDocument16 pagesUnit 4 Repair & Retro. TechniquesAnkita Baban Gavade100% (1)

- Cambridge IGCSE™: Physics 0625/41 October/November 2021Document18 pagesCambridge IGCSE™: Physics 0625/41 October/November 2021Manya PunjabiNo ratings yet

- The FEECO Agglomeration Handbook PDFDocument48 pagesThe FEECO Agglomeration Handbook PDFHoa Nguyen ThaiNo ratings yet

- Revision Village Math AA HL - Functions - Medium Difficulty QuestionbankDocument42 pagesRevision Village Math AA HL - Functions - Medium Difficulty Questionbankmahesh tendulkarNo ratings yet

- Test 1 (PM)Document5 pagesTest 1 (PM)Nabil NizamNo ratings yet

- Climate Change Strategies' Model in Teaching Science 7Document10 pagesClimate Change Strategies' Model in Teaching Science 7Psychology and Education: A Multidisciplinary JournalNo ratings yet

- Chapter 4Document26 pagesChapter 4NUR 'AIN NAJIHAH BINTI MAAROFNo ratings yet

- Dear: Ma'am/SirDocument3 pagesDear: Ma'am/Sirkatrina DimlaNo ratings yet

- Who Am I EssaysDocument5 pagesWho Am I Essayskvydtmaeg100% (2)

- Cambridge City Strategic Plan Long VersionDocument20 pagesCambridge City Strategic Plan Long VersionKushaal SainNo ratings yet

- 資料探勘應用於醫藥物流中心消耗預測Document70 pages資料探勘應用於醫藥物流中心消耗預測Harper ChengNo ratings yet

- Verma2016 230104 123045Document5 pagesVerma2016 230104 123045Latha LathikaNo ratings yet

- Earth Science: Quarter 2 - Module 1 Weathering of RocksDocument15 pagesEarth Science: Quarter 2 - Module 1 Weathering of RocksRonian DuruinNo ratings yet

- Chapter Test B: Teacher Notes and Answers Motion in One DimensionDocument6 pagesChapter Test B: Teacher Notes and Answers Motion in One DimensionHans HenryNo ratings yet

- CLIMATEREASONSDocument3 pagesCLIMATEREASONSBBBBNo ratings yet

- Bombelli's Algebra (1572)Document3 pagesBombelli's Algebra (1572)BORNASCHNo ratings yet

- Potentiometric Determination of Chloride in Natural WatersDocument6 pagesPotentiometric Determination of Chloride in Natural WatersNaeem MalikNo ratings yet

- Mock Exam Schedule January 2023Document2 pagesMock Exam Schedule January 2023Maryam ShehataNo ratings yet

- Transactional and Interpersonal ConversationDocument11 pagesTransactional and Interpersonal ConversationGlendia fiscaNo ratings yet

- Analysis of Concrete Box Girder Bridges Using Csi Bridge 2014Document50 pagesAnalysis of Concrete Box Girder Bridges Using Csi Bridge 2014oday albuthbahakNo ratings yet

- 1 Introduction To Sets (Handout)Document2 pages1 Introduction To Sets (Handout)star fireNo ratings yet

- Reading Phase Diagrams and ILAR University of The Philippines DilimanDocument5 pagesReading Phase Diagrams and ILAR University of The Philippines DilimanAcademicBMNo ratings yet

- G5 Q3W7 DLL ENGLISH (MELCs)Document13 pagesG5 Q3W7 DLL ENGLISH (MELCs)REIANA MITZI M. FernandezNo ratings yet

- Earth Engine 201 - Introduction To Advanced FeaturesDocument11 pagesEarth Engine 201 - Introduction To Advanced FeaturesmfebiyanNo ratings yet

- JENSEN 2003 - Legitimation para EnviarDocument21 pagesJENSEN 2003 - Legitimation para EnviarLobo JoséNo ratings yet

- Chapter 4 OBDocument29 pagesChapter 4 OBashenafi chekolNo ratings yet

- New Ground Motion Requirements of ASCE 7 16 Building Seismic SafetyDocument63 pagesNew Ground Motion Requirements of ASCE 7 16 Building Seismic SafetyHusam AbuzeinahNo ratings yet

- Extech Ex330 PDFDocument2 pagesExtech Ex330 PDFOliviaNo ratings yet

- ED 7220C SpectsDocument1 pageED 7220C SpectsJiqbal_200No ratings yet

- Finale Business Report MARK2012Document14 pagesFinale Business Report MARK2012Patrick lealNo ratings yet