Professional Documents

Culture Documents

ADDMIX 55-v3

Uploaded by

Ankita Baban GavadeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ADDMIX 55-v3

Uploaded by

Ankita Baban GavadeCopyright:

Available Formats

Last update on: 23-02-2023

Version: 3

PRODUCT DATA SHEET Dosage:

ADDMIX 55 is recommended for use at a rate of 3.0 to 20.0

ADDMIX® 55 L/m³ of concrete, depending upon the severity of the

corrosion environment and the anticipated chloride loading

ADDMIX 55 is a calcium nitrite-based corrosion of the structure. Chloride protection limits for ADDMIX 55 are

inhibiting super plasticizer for RCC. as given in the dosage table. The limits for applications

involving the use of chloride-bearing materials are based on

Specification: a critical chloride-to-nitrite ratio of 0.90 in accordance with

The corrosion inhibitor shall be ADDMIX 55, calcium nitrite the recommendations of the Federal Highway Administration

based, water based, and solvent free formulation. (FHWA). The chloride protection limits given for all other

applications, such as parking structures and bridges are

Uses:

based on critical chloride-to-nitrite ratios that range from 1.20

RCC structures requiring corrosion protection

to 1.50.

against chlorides for ground water and marine

Dosage Chloride Protection Limit, kg/m³

exposure.

All RCC Structures including precast/ prestressed

L/m³ With Chloride- All Other

and post tensioned applications.

Bearing Applications

Parking garages, bridge decks, marine structures,

Materials

slabs, floors, foundations, etc.

3.0 1.2 ---

Advantage: 7.0 2.4 3.6

Provides effective corrosion protection against 10.0 3.6 5.9

chlorides in concrete. 12.0 4.8 7.7

Extends the service life of reinforced concrete

structures. 16.0 6.0 8.9

20.0 7.2 9.5

Non-toxic, eco-friendly.

Does not affect bond strength of new concrete to Alternatively, dosage can be computed using the following

reinforcement bars. expression:

Does not entrain air.

Does not affect mechanical strength characteristics

of concrete/mortar. 3.69 X anticipated chloride loading

(kg/m3)

Packaging:

Dosage (L/m3) =

ADDMIX 55 is supplied in 5 kg, 20 kg & 220 kg Packing.

Chloride-to-Nitrite ratio

Standards:

ASTM C-494 Type C.

The water content of ADDMIX 55 admixture is approximately

Typical Properties:

62% by weight. This water contributes to the consistency of

Appearance Pale yellow free flowing the concrete mixture and the hydration of the cementitious

liquid materials. The water contributed by ADDMIX 55 should be

Relative Density 1.15 ± 0.02 at 25°C used in the calculation of the water-to cementitious material

pH 8± 1 ratio of the concrete.

Chloride ion content < 0.2%

Solids, by weight > 32 %

Mechanism of Action:

Performance (ASTM-G- Rate of corrosion with

In the alkaline environment of concrete, a natural passive

109) ADDMIX 55 when subjected

ferric oxide layer forms on the surface of embedded

to 09 cycles is 0.70

reinforcing steel and protects the steel from corrosion. This

coulombs (max) compared

passive oxide layer may break down in the presence of

to control sample having a

chlorides and moisture resulting in corrosion of the steel.

standard value of 25

ADDMIX 55 admixture delays corrosion by re-passivating

coulombs.

defects on the steel surface. These defects are ferrous oxide

ions that are susceptible to chloride attack.

SP CONCARE PVT. LTD.

CS No. 1471, DB House 1st Floor,

Madhavnagar Road, Near Auto India,

info@spconcare.com www.spconcare.com Sangli-416416, Maharashtra, (INDIA)

Last update on: 23-02-2023

Version: 3

When chloride ions attack the ferrous ions, they combine to Disclaimer:

create a ferrous chloride complex (rust) and initiate pitting Whilst any information contained herein is true, accurate and

corrosion on the reinforcing steel. If untreated, chloride ions represents our best knowledge and experience, no warranty

continue to attack newly exposed ferrous ions and form is given or implied with any recommendations made by us,

additional expansive corrosion products leading to staining, our representatives, or distributors, as the conditions of use

cracking, and spalling of the concrete. and the competence of any labor involvedin the application

are beyond our control.

Nitrite ions contained in ADDMIX 55 admixture are effective

in preventing ferrous chloride complex formation by reacting

with defective ferrous oxide ions prior to chloride attack and

reforming the passive layer.

Nitrite ions surround the defective ferrous oxide ion and

convert it to a more stable ferric ion species less susceptible

to corrosion. This oxidation reaction serves to re-passivate

the reinforcing steel and re-establish the barrier between

the steel and chlorides that initiate corrosion.

Compatibility:

ADDMIX 55 admixture may be used with Portland cements

and mineral admixtures approved under ASTM, AASHTO,

or CRD specifications. It is compatible with other chemical

admixtures, including water reducers, superplasticizers,

retarders, and air entrainers.

Chemical admixtures should be added separately to the

concrete to ensure desired results.

Corrosively and Non-Corrosive:

ADDMIX 55 admixture will neither initiate nor promote

corrosion of reinforcing steel embedded in concrete,

prestressed concrete or concrete placed on galvanized

steel floor and roof systems. Neither calcium chloride nor

any calcium chloride-based ingredients are used in the

manufacture of ADDMIX 55 admixture.

Storage and Shelf life All:

ADDMIX 55 must be stored where temperatures do not drop

below +5°C. If product has frozen, thaw at +5°C or above

and completely reconstitute using mild mechanical

agitation. Store under cover, out of direct sunlight and

protect from extremes of temperature. Shelf life is 12

months when stored as above.

Safety precautions:

As with all chemical products, care should be taken during

use and storage to avoid contact with eyes, mouth, skin, and

foodstuffs (which can also be tainted with vapor until the

product is fully cured or dried). Treat splashes to eyes and

skin immediately. If accidentally ingested, seek immediate

medical attention. Keep away from children and animals.

Reseal containers after use. Do not reuse containers for the

storage of consumable items.

SP CONCARE PVT. LTD.

CS No. 1471, DB House 1st Floor,

Madhavnagar Road, Near Auto India,

info@spconcare.com www.spconcare.com Sangli-416416, Maharashtra, (INDIA)

You might also like

- Addmix 55: ADDMIX 55 Is A Calcium Nitrite-Based Corrosion Inhibiting Super Plasticizer For RCC MembersDocument4 pagesAddmix 55: ADDMIX 55 Is A Calcium Nitrite-Based Corrosion Inhibiting Super Plasticizer For RCC MembersAnkita Baban GavadeNo ratings yet

- Chloride Attack On ConcreteDocument12 pagesChloride Attack On Concretevikram kumarNo ratings yet

- Concrete Construction Article PDF - Concrete CoverDocument3 pagesConcrete Construction Article PDF - Concrete CoverTharach JanesuapasaereeNo ratings yet

- Silva et al. Materials Research: Factors Affecting Chloride Ion Penetration of Recycled Aggregate ConcreteDocument1 pageSilva et al. Materials Research: Factors Affecting Chloride Ion Penetration of Recycled Aggregate ConcretelucaNo ratings yet

- Mci - 2020 / Mci - 2020 V/oDocument4 pagesMci - 2020 / Mci - 2020 V/oOmar Mukthar100% (1)

- Factors for Concrete Structure DurabilityDocument38 pagesFactors for Concrete Structure DurabilitySharath WankdothNo ratings yet

- ICE-Qatar 18Apr22-Durability Design of Concrete StructuresDocument55 pagesICE-Qatar 18Apr22-Durability Design of Concrete StructuresShokry AlkissyNo ratings yet

- 129 - Download - Application of Corrosion Protection TechniqueDocument4 pages129 - Download - Application of Corrosion Protection TechniqueAli BahraniNo ratings yet

- KP200Document4 pagesKP200DrGanesh Kame100% (1)

- L2 - MRCS - Embedded Metal Corrosion - 2Document35 pagesL2 - MRCS - Embedded Metal Corrosion - 2Kaushal KumarNo ratings yet

- Corrosion Inhibiting AdmixturesDocument3 pagesCorrosion Inhibiting AdmixturesMalak HindiNo ratings yet

- Concrete Silica ReactionDocument4 pagesConcrete Silica ReactionHusain Masood ChandharNo ratings yet

- Corrosion of Embedded Metal: (Carbonation-Induced and Chloride-Induced Corrosion)Document37 pagesCorrosion of Embedded Metal: (Carbonation-Induced and Chloride-Induced Corrosion)Jagannathan KNo ratings yet

- Corrosion of Steel in ConcreteDocument2 pagesCorrosion of Steel in ConcreteaaNo ratings yet

- Chloride ResistanceDocument37 pagesChloride ResistanceRaghava KumarNo ratings yet

- Overcoming Performance Challenges - JPCL - 2016rev091416Document46 pagesOvercoming Performance Challenges - JPCL - 2016rev091416Ana Mae Estaniel-QuezonNo ratings yet

- Burgos 2017Document9 pagesBurgos 2017Ali HassanNo ratings yet

- Repair and RehabilitationDocument115 pagesRepair and RehabilitationBala Subramanian0% (1)

- Repair and RehabilitationDocument115 pagesRepair and RehabilitationBala SubramanianNo ratings yet

- Progress in Organic Coatings: Corrosion Protective Performance Studies of Coating Systems in Soda Ash Chemical IndustryDocument7 pagesProgress in Organic Coatings: Corrosion Protective Performance Studies of Coating Systems in Soda Ash Chemical Industryisan.structural TjsvgalavanNo ratings yet

- Renderoc PlugDocument5 pagesRenderoc PlugtalatzahoorNo ratings yet

- Construction and Building Materials: Mohamed Rabehi, Bouzidi Mezghiche, Salim GuettalaDocument7 pagesConstruction and Building Materials: Mohamed Rabehi, Bouzidi Mezghiche, Salim GuettalaMickey DalbeheraNo ratings yet

- Materials Corrosion - 2024 - Ooi - A New Index To Estimate The Corrosion Resistance of Aluminium Containing SteelDocument12 pagesMaterials Corrosion - 2024 - Ooi - A New Index To Estimate The Corrosion Resistance of Aluminium Containing SteelSteve OoiNo ratings yet

- CRA Glossery of TermsDocument11 pagesCRA Glossery of TermsDC1234No ratings yet

- Cec 225 PDFDocument14 pagesCec 225 PDF8790922772No ratings yet

- Durability of ConcreteDetail Discrition of Durability of ConcreteDocument34 pagesDurability of ConcreteDetail Discrition of Durability of ConcreteVinodh GbNo ratings yet

- Aguirre-Guerrero, Mejía de Gutiérrez - 2021 - Alkali-Activated Protective Coatings For Reinforced Concrete Exposed To Chlorides-AnnotatedDocument16 pagesAguirre-Guerrero, Mejía de Gutiérrez - 2021 - Alkali-Activated Protective Coatings For Reinforced Concrete Exposed To Chlorides-AnnotatedGnneth Milln RamrezNo ratings yet

- A Review of Concrete Corrosion InhibitorsDocument9 pagesA Review of Concrete Corrosion InhibitorsJohnNo ratings yet

- Galvanic Protection For Reinforced Concrete Structures: Case Studies and Performance AssessmentDocument10 pagesGalvanic Protection For Reinforced Concrete Structures: Case Studies and Performance AssessmentSteve LukatherNo ratings yet

- Effect Polypropylene of Fiber On Drying ShrinkageDocument12 pagesEffect Polypropylene of Fiber On Drying ShrinkageHusain Masood ChandharNo ratings yet

- Pamphlet On Corrosion Protection of SteelDocument4 pagesPamphlet On Corrosion Protection of SteelRVNLPKG6B VBL-GTLMNo ratings yet

- Laser Cladding Remanufacturing of Aircraft Landing Gear Based On 30CrMnSiNi2A SteelDocument13 pagesLaser Cladding Remanufacturing of Aircraft Landing Gear Based On 30CrMnSiNi2A Steelzixin chenNo ratings yet

- Corrocrete BrochureDocument12 pagesCorrocrete Brochuresubhasishg1985No ratings yet

- Alternatives to Conventional Concrete: Lightweight, Fiber-Reinforced & MoreDocument6 pagesAlternatives to Conventional Concrete: Lightweight, Fiber-Reinforced & MoreKerby Brylle GawanNo ratings yet

- Armix CIDocument2 pagesArmix CIHarishkumar KNo ratings yet

- Comparison of Reinforced Concrete Corrosion TechnologiesDocument6 pagesComparison of Reinforced Concrete Corrosion Technologiesmahesh sherkhaneNo ratings yet

- Award Winning Paer-Concrete Structure ProtectionDocument10 pagesAward Winning Paer-Concrete Structure ProtectionAsif KhanzadaNo ratings yet

- Applied SciencesDocument29 pagesApplied Sciencesziko23No ratings yet

- Evaluation of Corrosion Resistance of As Sprayed Wc-Co-Cr On DH 36 Steel With Addition of 3% GnpsDocument9 pagesEvaluation of Corrosion Resistance of As Sprayed Wc-Co-Cr On DH 36 Steel With Addition of 3% GnpsTarkes DoraNo ratings yet

- RCPTDocument7 pagesRCPTosama anterNo ratings yet

- Durability of High Performance Concrete in Relation To 'External' Chemical AttackDocument5 pagesDurability of High Performance Concrete in Relation To 'External' Chemical AttackGeraldNo ratings yet

- Sulfate Resistance of Filler Cement MortarDocument4 pagesSulfate Resistance of Filler Cement MortarAbd El Nour KahlochNo ratings yet

- 108304-9191 Ijcee-IjensDocument6 pages108304-9191 Ijcee-IjensHumamNo ratings yet

- TDS - Rheocrete CNIDocument3 pagesTDS - Rheocrete CNIAlexi ALfred H. TagoNo ratings yet

- Mortar Durability Enhanced with Blast Furnace SlagDocument8 pagesMortar Durability Enhanced with Blast Furnace SlagAbd El-nour RamdNo ratings yet

- Is 456Document26 pagesIs 456Tommy JohnsonNo ratings yet

- Mbs-Astm-C1202 06 24 2020Document1 pageMbs-Astm-C1202 06 24 2020DI- CARPNo ratings yet

- 463 Galley 3564 2 10 20221105Document7 pages463 Galley 3564 2 10 20221105Kk KumarNo ratings yet

- Report On Mix DesignDocument6 pagesReport On Mix DesignForood Torabian IsfahaniNo ratings yet

- Concrete Repair Techniques and Deterioration ProcessesDocument3 pagesConcrete Repair Techniques and Deterioration ProcessesBenharzallah KrobbaNo ratings yet

- Refurbishment: Total Corrosion Management OverviewDocument8 pagesRefurbishment: Total Corrosion Management OverviewHamkarNo ratings yet

- A Study of Carbonation in Concrete Structues in Marine EnvironmentDocument57 pagesA Study of Carbonation in Concrete Structues in Marine EnvironmentHaniAminNo ratings yet

- Service Life Prediction of R.C Structure Incorporated With GGBS & Silicafume Subjected To Chloride Ion PenetrationDocument8 pagesService Life Prediction of R.C Structure Incorporated With GGBS & Silicafume Subjected To Chloride Ion PenetrationnagarajuNo ratings yet

- Bahrain 131003Document21 pagesBahrain 131003siranepNo ratings yet

- Mci-2005 NSDocument3 pagesMci-2005 NSMalak HindiNo ratings yet

- 5 - Durability and Concrete Cover - 2020 PDFDocument46 pages5 - Durability and Concrete Cover - 2020 PDFIrma MedomNo ratings yet

- Construction and Building Materials: Philip Van Den Heede, Mathias Maes, Nele de BelieDocument7 pagesConstruction and Building Materials: Philip Van Den Heede, Mathias Maes, Nele de BelieMarden Rengifo RuizNo ratings yet

- Guidelines on Concrete AdmixturesDocument9 pagesGuidelines on Concrete Admixturesamitkap00rNo ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- Corrosion Engineering and Cathodic Protection Handbook: With Extensive Question and Answer SectionFrom EverandCorrosion Engineering and Cathodic Protection Handbook: With Extensive Question and Answer SectionNo ratings yet

- Con Inject 1kDocument2 pagesCon Inject 1kAnkita Baban GavadeNo ratings yet

- ADDMIX 105-v4Document2 pagesADDMIX 105-v4Ankita Baban GavadeNo ratings yet

- ADDMIX 109 PCCI-v1Document2 pagesADDMIX 109 PCCI-v1Ankita Baban GavadeNo ratings yet

- Con Inject 1kDocument2 pagesCon Inject 1kAnkita Baban GavadeNo ratings yet

- ADDMIX 152-v4 PDFDocument1 pageADDMIX 152-v4 PDFAnkita Baban GavadeNo ratings yet

- ADDMIX 210-v5Document2 pagesADDMIX 210-v5Ankita Baban GavadeNo ratings yet

- ADDMIX 200-v4Document2 pagesADDMIX 200-v4Ankita Baban GavadeNo ratings yet

- Ripstar 109: SpecificationDocument3 pagesRipstar 109: SpecificationAnkita Baban GavadeNo ratings yet

- RIPSTAR Saturant-V3Document3 pagesRIPSTAR Saturant-V3Ankita Baban GavadeNo ratings yet

- Poly Urea Coating: Smart & Reliable Chemical SolutionsDocument12 pagesPoly Urea Coating: Smart & Reliable Chemical SolutionsAnkita Baban GavadeNo ratings yet

- 450 Case StudyDocument11 pages450 Case StudyAnkita Baban GavadeNo ratings yet

- Report On Crystaline WaterproofingDocument11 pagesReport On Crystaline WaterproofingAnkita Baban GavadeNo ratings yet

- Nanofines 822Document1 pageNanofines 822Ankita Baban GavadeNo ratings yet

- MR. DRY 701-v3Document3 pagesMR. DRY 701-v3Ankita Baban GavadeNo ratings yet

- Lejell210 MSDS(英文版)Document16 pagesLejell210 MSDS(英文版)Ankita Baban GavadeNo ratings yet

- MR DRY195-v3Document3 pagesMR DRY195-v3Ankita Baban GavadeNo ratings yet

- Polymers 13 00189Document13 pagesPolymers 13 00189Ankita Baban GavadeNo ratings yet

- SPLANDEK 2100v3Document4 pagesSPLANDEK 2100v3Ankita Baban GavadeNo ratings yet

- RIPSTAR 49v5Document4 pagesRIPSTAR 49v5Ankita Baban GavadeNo ratings yet

- Lejell210 MSDS(英文版)Document16 pagesLejell210 MSDS(英文版)Ankita Baban GavadeNo ratings yet

- RIPSTAR 49v5Document4 pagesRIPSTAR 49v5Ankita Baban GavadeNo ratings yet

- Strenghthning ResultsDocument1 pageStrenghthning ResultsAnkita Baban GavadeNo ratings yet

- JONTSIL PU (PG) - v2Document4 pagesJONTSIL PU (PG) - v2Ankita Baban GavadeNo ratings yet

- FRP Strengthening Systems for Concrete StructuresDocument15 pagesFRP Strengthening Systems for Concrete StructuresAnkita Baban GavadeNo ratings yet

- MR - DRY 830EL-v4Document4 pagesMR - DRY 830EL-v4Ankita Baban GavadeNo ratings yet

- Quotation (JB Construction)Document2 pagesQuotation (JB Construction)Ankita Baban GavadeNo ratings yet

- Polymers 13 00189Document13 pagesPolymers 13 00189Ankita Baban GavadeNo ratings yet

- Question BankDocument1 pageQuestion BankAnkita Baban GavadeNo ratings yet

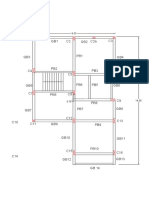

- Column PositionsDocument1 pageColumn PositionsAnkita Baban GavadeNo ratings yet

- Reactive Print AlternativeDocument3 pagesReactive Print AlternativeSuyash PratikNo ratings yet

- Biology 1 - 12 - Q2 - M1PSPCDocument16 pagesBiology 1 - 12 - Q2 - M1PSPCHera Victrix100% (2)

- Risk Assessment in ToxicologyDocument5 pagesRisk Assessment in ToxicologysaberNo ratings yet

- Chapter 2 Design of Water Treatment Plants PDFDocument55 pagesChapter 2 Design of Water Treatment Plants PDFwedjefdbenmcveNo ratings yet

- This Is A Sample Cover Image For This Issue. The Actual Cover Is Not Yet Available at This Time.Document8 pagesThis Is A Sample Cover Image For This Issue. The Actual Cover Is Not Yet Available at This Time.Denise Maria CandidoNo ratings yet

- Bourdon Tube Pressure Gauge Stainless Steel Case Type 212.53 - Dry Case Type 213.53 - Liquid-Filled CaseDocument3 pagesBourdon Tube Pressure Gauge Stainless Steel Case Type 212.53 - Dry Case Type 213.53 - Liquid-Filled CasecarlosNo ratings yet

- Functional GroupCH5Document36 pagesFunctional GroupCH5syedmcgarretNo ratings yet

- NutriMost Coconut Oil LiteratureDocument2 pagesNutriMost Coconut Oil LiteratureTheophilus TyavNo ratings yet

- Poultry Meat Quality: World's Poultry Science Association 2002 131Document15 pagesPoultry Meat Quality: World's Poultry Science Association 2002 131adin dazaNo ratings yet

- Bubble Dew Point CalculationDocument87 pagesBubble Dew Point Calculationaspen hysysNo ratings yet

- Chapter 02 Drilling Cost ControlDocument25 pagesChapter 02 Drilling Cost ControlRobertNo ratings yet

- Marathon 1000XHB Technical Data SheetDocument5 pagesMarathon 1000XHB Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Designing of A TPH Fire Tube Boiler: December 2019Document25 pagesDesigning of A TPH Fire Tube Boiler: December 2019Hélder PascoalNo ratings yet

- Earth Science q2 w2Document20 pagesEarth Science q2 w2Mykhaela Louize GumbanNo ratings yet

- Sea Transport of Ammonium Nitrate Based FertilizersDocument28 pagesSea Transport of Ammonium Nitrate Based FertilizersJEET yadav100% (1)

- Hydroprocessing Reactor and Process Design To Optimize Performance (Topsoe - 1998)Document18 pagesHydroprocessing Reactor and Process Design To Optimize Performance (Topsoe - 1998)yliangcaNo ratings yet

- C882Document4 pagesC882Jorge Luis Arevalo LopezNo ratings yet

- 05 Catpg 016Document1 page05 Catpg 016naseema1100% (1)

- Whey BeverageDocument18 pagesWhey BeverageAtonmai WijunamaiNo ratings yet

- Book Review - Thermal Safety of Book Review - Thermal Safety of Chemical ProcessesDocument3 pagesBook Review - Thermal Safety of Book Review - Thermal Safety of Chemical ProcessesbeaNo ratings yet

- Chemical Equilibrium Part 2Document26 pagesChemical Equilibrium Part 2adityayadav18julyNo ratings yet

- Abdullah Mohd Chemistry Lab Report 4Document2 pagesAbdullah Mohd Chemistry Lab Report 4somratNo ratings yet

- Tugas Pak AliDocument38 pagesTugas Pak Alianon_484647789No ratings yet

- 02-781 Protection of SW SystemsDocument28 pages02-781 Protection of SW SystemsHattar MNo ratings yet

- QCS 2010 Section 1 Part 22 Part 22 New Technologies and Innovations PDFDocument3 pagesQCS 2010 Section 1 Part 22 Part 22 New Technologies and Innovations PDFbryanpastor106No ratings yet

- Restriction EnzymesDocument17 pagesRestriction EnzymesSatyam AryaNo ratings yet

- 141 Darley254Document1 page141 Darley254Jose MelloNo ratings yet

- AEES Excellence Examination Question Paper and Answer Key-2019Document18 pagesAEES Excellence Examination Question Paper and Answer Key-2019Dr-Swarnima AgarwalNo ratings yet

- Paul 2010Document18 pagesPaul 2010DianaMarcelaBurbanoNo ratings yet

- Guadalupe Clay LoamDocument1 pageGuadalupe Clay LoamMeanne AzucenaNo ratings yet