Professional Documents

Culture Documents

Property

Property

Uploaded by

Mohd Zain KangdaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Property

Property

Uploaded by

Mohd Zain KangdaCopyright:

Available Formats

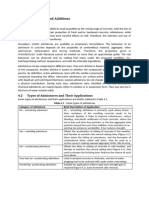

Fresh State of Concrete Hardened State of Concrete

Property

with Polypropylene Fibers with Polypropylene Fibers

Improves workability by

Generally does not affect

Workability reducing segregation and

workability significantly.

bleeding.

Helps in reducing the

Enhances crack resistance by

formation and propagation of

Crack Control controlling plastic shrinkage

cracks, improving overall

cracking.

durability.

Provides increased impact Enhances impact resistance,

Impact Resistance resistance, especially in thin reducing the risk of surface

sections. damage.

Enhances durability by

Improves freeze-thaw

minimizing cracking and

resistance and overall

increasing resistance to

durability.

environmental factors.

Adds some tensile strength to

Significantly improves post-

Durability the concrete in the plastic

crack tensile strength.

state.

May contribute to better fire

Provides limited

resistance due to reduced

Tensile Strength improvement in fire

crack width and improved

resistance.

structural integrity.

Needs proper mixing to

Requires careful mixing to achieve uniform distribution

Fire Resistance

ensure uniform dispersion. throughout the concrete

matrix.

May slightly affect the

Generally, does not surface finish due to the

Fiber Dispersion negatively impact surface presence of fibers. Proper

finish. finishing techniques can

minimize this impact.

Does not directly improve

corrosion resistance but can

Does not contribute to indirectly enhance durability

Surface Finish

corrosion resistance. and reduce the likelihood of

cracking, which may help

prevent corrosion.

You might also like

- Betongteknologi - Øving 2Document5 pagesBetongteknologi - Øving 2emilieshawNo ratings yet

- Pages From WorkPlans - Year2-Revised-Dec 08 - FHWA - DTFH61-07-H-00009-5 PDFDocument1 pagePages From WorkPlans - Year2-Revised-Dec 08 - FHWA - DTFH61-07-H-00009-5 PDFMEHDI FARROKHINo ratings yet

- Diamond-Like Carbon As A Protective Coating For Decorative GlassDocument4 pagesDiamond-Like Carbon As A Protective Coating For Decorative GlassSantiago TuestaNo ratings yet

- Articulo MTCIDocument10 pagesArticulo MTCIsergio solanoNo ratings yet

- Chapter 4Document21 pagesChapter 4MadNo ratings yet

- Thermal Healing of Realistic Flaws in GlassDocument9 pagesThermal Healing of Realistic Flaws in GlassCristian PerezNo ratings yet

- Unit 2 NotesDocument21 pagesUnit 2 NotesSandesh Kale100% (1)

- Water Reducing Concrete Admixture - Redwop - PLASTCONE AP211Document2 pagesWater Reducing Concrete Admixture - Redwop - PLASTCONE AP211Ameya ThanawalaNo ratings yet

- Fiberglass Insulation QuietflexDocument3 pagesFiberglass Insulation QuietflexNARAYANAN RNo ratings yet

- Concrete 2 DS Advanced Poly FibreDocument2 pagesConcrete 2 DS Advanced Poly FibreashishbhanderiNo ratings yet

- Fibrillated Micro Synthetic Polypropylene FibersDocument3 pagesFibrillated Micro Synthetic Polypropylene FibersVIVEKNo ratings yet

- Sika FibreDocument16 pagesSika FibreJorge Baños LloredoNo ratings yet

- Chapter 4Document21 pagesChapter 4Ravindu ThilakarathneNo ratings yet

- Bentofix: Advantages of Needle-PunchedDocument4 pagesBentofix: Advantages of Needle-PunchedKamal LatifNo ratings yet

- Aku Budak JpaDocument6 pagesAku Budak JpaMohd ShafiqNo ratings yet

- MYKSavemixSP111 PDFDocument2 pagesMYKSavemixSP111 PDFRanaware NandkishorNo ratings yet

- CESM 543 Assignment Sem 1 2021 2022 Q1Document2 pagesCESM 543 Assignment Sem 1 2021 2022 Q1Ho Chee SiangNo ratings yet

- Fiber Quality Optimization Enhanced Concrete Strength - 080834Document3 pagesFiber Quality Optimization Enhanced Concrete Strength - 080834Chaithrika D K 1DT20CV008No ratings yet

- Dry Film LaminationDocument9 pagesDry Film LaminationDieselJakeNo ratings yet

- Fiber Reinf. ConcreteDocument2 pagesFiber Reinf. ConcreteJithesh SukumaranNo ratings yet

- Hanson Fibrecrete Brochure PDFDocument7 pagesHanson Fibrecrete Brochure PDFEmalaith BlackburnNo ratings yet

- INT - Water Proofing SolutionsDocument7 pagesINT - Water Proofing SolutionsMrinal RoyNo ratings yet

- Unit IVDocument3 pagesUnit IVSRPC CIVILNo ratings yet

- Study Material PolypropyleneDocument4 pagesStudy Material PolypropyleneMihir patelNo ratings yet

- Experimental Study On Behavior of SteelDocument6 pagesExperimental Study On Behavior of Steelharshithak.cee21No ratings yet

- Defect - NewDocument2 pagesDefect - NewThilini ApsaraNo ratings yet

- Building Materials - CharacteristicsDocument2 pagesBuilding Materials - CharacteristicsDeneika MorganNo ratings yet

- Ways of Installing Dampers in An Existing BuildingDocument3 pagesWays of Installing Dampers in An Existing BuildingErica HerreraNo ratings yet

- Cafae-Building TechDocument3 pagesCafae-Building TechYSSHELL DALIDNo ratings yet

- Microfine Brochure FinalDocument6 pagesMicrofine Brochure Finalbineetmishra1990No ratings yet

- BROCHURE - AvantguardDocument8 pagesBROCHURE - AvantguardSan CandyNo ratings yet

- Bentofix: Geosynthetic Clay Liners (GCLS)Document3 pagesBentofix: Geosynthetic Clay Liners (GCLS)Maja AbdihodžićNo ratings yet

- Fiber Reinforced ConcreteDocument9 pagesFiber Reinforced ConcretesoulcivicNo ratings yet

- Cement: Effect of Fibres in ConcreteDocument9 pagesCement: Effect of Fibres in ConcreteMohammed RiyazNo ratings yet

- Ce 6002 - Concrete Technology: Department of Civil EngineeringDocument49 pagesCe 6002 - Concrete Technology: Department of Civil EngineeringMUKESH KUMAR ceNo ratings yet

- Presentation1 c3 160731151000Document52 pagesPresentation1 c3 160731151000Irshad KhanNo ratings yet

- CPN 35 - Fibres in ConcreteDocument12 pagesCPN 35 - Fibres in ConcreteRavi7654No ratings yet

- Miniproject Concrete - Literature ReviewDocument28 pagesMiniproject Concrete - Literature ReviewMadav BalgobinNo ratings yet

- Fibre Reinforced ConcreteDocument12 pagesFibre Reinforced ConcretePradeepLokhande100% (2)

- IStructE - Cracking in Concrete PDFDocument3 pagesIStructE - Cracking in Concrete PDFAnonymous sHS42JeJgNo ratings yet

- Data Sheet - Fosroc - Conplast WP AdmixtureDocument3 pagesData Sheet - Fosroc - Conplast WP AdmixtureLau Yenn YennNo ratings yet

- Effects of Comp-WPS OfficeDocument4 pagesEffects of Comp-WPS Officeebong abrahamNo ratings yet

- Brochure Structural-Bonding en PDFDocument3 pagesBrochure Structural-Bonding en PDFSlamet Tri UsadhaNo ratings yet

- Am NQ77306Document7 pagesAm NQ77306luckyNo ratings yet

- A Review On Engineered Cementitious Composite - Final - IJARESMDocument13 pagesA Review On Engineered Cementitious Composite - Final - IJARESMPartha SahaNo ratings yet

- Prestress TheoryDocument2 pagesPrestress TheoryHusain Masood ChandharNo ratings yet

- Understanding Self-Consolidating Concrete: Photo of SCCDocument1 pageUnderstanding Self-Consolidating Concrete: Photo of SCCYahabdo DashahNo ratings yet

- Concrete Technology: Engr. Faizan FaridDocument18 pagesConcrete Technology: Engr. Faizan FaridJi KkNo ratings yet

- BROCHURE - AvantguardDocument8 pagesBROCHURE - AvantguardFreddy Carl FredricksenNo ratings yet

- Ais 191Document3 pagesAis 191Hassan Ali SadiqNo ratings yet

- Durastran HB PdsDocument2 pagesDurastran HB Pdsuğur alparslanNo ratings yet

- 3 - Greenseal Flexi 201Document3 pages3 - Greenseal Flexi 201Faiz RahmatNo ratings yet

- Effects of Shrinkage On Concrete: I. Scope of ProjectDocument15 pagesEffects of Shrinkage On Concrete: I. Scope of ProjectSyed Arsalan AliNo ratings yet

- Mini Project in Concrete Technology SpecDocument29 pagesMini Project in Concrete Technology SpecOmer ElbalalNo ratings yet

- GFRCDocument15 pagesGFRCNitinSenNo ratings yet

- Fiber Reinforced ConcreteDocument17 pagesFiber Reinforced ConcreteSaidrona100% (1)

- Sunvik: Working Towards A Green Tomorrow, TodayDocument3 pagesSunvik: Working Towards A Green Tomorrow, TodayNavarang R KobbeNo ratings yet

- Book With SpallingDocument977 pagesBook With SpallingMohd Zain KangdaNo ratings yet

- PartDocument10 pagesPartMohd Zain KangdaNo ratings yet

- Energy PipelinesDocument12 pagesEnergy PipelinesMohd Zain KangdaNo ratings yet

- AKNaithanPCNawaniNGSVol 432011Document11 pagesAKNaithanPCNawaniNGSVol 432011Mohd Zain KangdaNo ratings yet

- Lec 10Document7 pagesLec 10Mohd Zain KangdaNo ratings yet

- Lec 9Document4 pagesLec 9Mohd Zain KangdaNo ratings yet

- 1 s2.0 S0141029619341926 MainDocument19 pages1 s2.0 S0141029619341926 MainMohd Zain KangdaNo ratings yet

- M18se1020 01Document11 pagesM18se1020 01Mohd Zain KangdaNo ratings yet

- Kinematics of Particle (Variable Acceleration)Document2 pagesKinematics of Particle (Variable Acceleration)Mohd Zain KangdaNo ratings yet

- Design of Precast ComponentsDocument4 pagesDesign of Precast ComponentsMohd Zain KangdaNo ratings yet

- PROBABILITIES and Probability DistributionDocument55 pagesPROBABILITIES and Probability Distributionsunflower100% (1)

- Finite Element Analysis 3+1: MEC606 Common With Mechanical Engineering ObjectivesDocument1 pageFinite Element Analysis 3+1: MEC606 Common With Mechanical Engineering Objectivesnavneetkpatil8409No ratings yet

- GENERAL MATHEMATICS M11GM Q1Module5Document11 pagesGENERAL MATHEMATICS M11GM Q1Module5Lemuel FajutagNo ratings yet

- Conventional Reflective Beam Detector: Feature and BenefitsDocument3 pagesConventional Reflective Beam Detector: Feature and BenefitsTâm Nguyễn ĐứcNo ratings yet

- Ai DissertationDocument8 pagesAi DissertationBuyAPaperOnlineSingapore100% (1)

- Chapter 1: Introduction To Personality: Personality Development With Social GracesDocument10 pagesChapter 1: Introduction To Personality: Personality Development With Social GracesJ Xio Thonzky CabbigatNo ratings yet

- Unit 3 Elements and Typologies of The CommunityDocument56 pagesUnit 3 Elements and Typologies of The CommunityKaye LumodNo ratings yet

- DFR117ECO-氯、溴-英文Document4 pagesDFR117ECO-氯、溴-英文BÍCH NGUYỄNNo ratings yet

- Palma Et Al. 2022. Vet Parasitol 302Document7 pagesPalma Et Al. 2022. Vet Parasitol 302Erlinda LacierdaNo ratings yet

- Design and Fabrication of Domestic Refrigeration UnitDocument81 pagesDesign and Fabrication of Domestic Refrigeration UnitSadhana DhepaleNo ratings yet

- Times NIE Web Ed December 3 2021 Page1 4 PDFDocument4 pagesTimes NIE Web Ed December 3 2021 Page1 4 PDFAnkit GuptaNo ratings yet

- Definition Essay The ArtsDocument5 pagesDefinition Essay The Artsapi-670514637No ratings yet

- 2 2 R20 Supply Dec 2023Document8 pages2 2 R20 Supply Dec 2023kailashNo ratings yet

- Penanganan Kawasan Permukiman Kumuh (Studi Mengenai Pemugaran Kawasan Permukiman Kumuh Di Kecamatan Semarang Utara)Document15 pagesPenanganan Kawasan Permukiman Kumuh (Studi Mengenai Pemugaran Kawasan Permukiman Kumuh Di Kecamatan Semarang Utara)Arga hijrianNo ratings yet

- Best Dream Catcher Quotes YouDocument6 pagesBest Dream Catcher Quotes YouRhea CarinoNo ratings yet

- IS-1121 Part-1 Compressive StrengthDocument8 pagesIS-1121 Part-1 Compressive StrengthSaurav KumarNo ratings yet

- New, Extended Capabilities of PASS/Nozzle-FEM: Improved Calculation Methods Enable Better Regulatory ComplianceDocument2 pagesNew, Extended Capabilities of PASS/Nozzle-FEM: Improved Calculation Methods Enable Better Regulatory CompliancesanthoshnlNo ratings yet

- Organic Black Pepper Essential Oil (Piper Nigrum) : Safety Data SheetDocument8 pagesOrganic Black Pepper Essential Oil (Piper Nigrum) : Safety Data SheetMohamed cherif terrabNo ratings yet

- CMOS Laser Sensor With Built-In Amplifier: Stable Detection of Level Differences in The Order of 0.1 MMDocument9 pagesCMOS Laser Sensor With Built-In Amplifier: Stable Detection of Level Differences in The Order of 0.1 MMĐào VĩnhNo ratings yet

- ACR AIP NewDocument4 pagesACR AIP NewJerric AbreraNo ratings yet

- Download textbook Energy Kingdoms Oil And Political Survival In The Persian Gulf Jim Krane ebook all chapter pdfDocument53 pagesDownload textbook Energy Kingdoms Oil And Political Survival In The Persian Gulf Jim Krane ebook all chapter pdfhenry.sinegal624100% (9)

- Corporate Social ResponsibilityDocument5 pagesCorporate Social Responsibilityvane rondinaNo ratings yet

- Answer Gerak Gempur Chemistry 2013Document11 pagesAnswer Gerak Gempur Chemistry 2013ryder1man6433No ratings yet

- Astm D 4221 - 99 Doble HidrometroDocument3 pagesAstm D 4221 - 99 Doble HidrometroNabucodonosor1980100% (1)

- Basic Math QuestionDocument20 pagesBasic Math QuestionChampions EventuallyNo ratings yet

- 4 PerceptionDocument8 pages4 PerceptionDaniel Saadi Hamid RazzaNo ratings yet

- Emerging Theories 11.1 Planned Unit Developments (PUD)Document19 pagesEmerging Theories 11.1 Planned Unit Developments (PUD)Amyr AmyrNo ratings yet

- 1629888174-Xam Idea Geography Solutions Class 9 Chapter 5 Natural Vegetation and WildlifeDocument11 pages1629888174-Xam Idea Geography Solutions Class 9 Chapter 5 Natural Vegetation and Wildlifenitin7876741498No ratings yet

- Making Animated Maps With QGISDocument35 pagesMaking Animated Maps With QGISLiliana Jimenez GonzalezNo ratings yet

- Step 1: Mathematical Modeling: 1 Vibration Analysis ProcedureDocument22 pagesStep 1: Mathematical Modeling: 1 Vibration Analysis ProcedureNirmal JayanthNo ratings yet