Professional Documents

Culture Documents

Pioneer CT-7R Manuals en

Uploaded by

John WalesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pioneer CT-7R Manuals en

Uploaded by

John WalesCopyright:

Available Formats

0) rrloNfeen!

E a

a

a

DER NO.

T-667-O

M O D E LC T - 7 RC O M E SI N S E V E NV E R S I O N S

D I S T I N G U I S H EADS FOLLOWS:

22OV and 24OV (Switchabtel

2NV and 2ztOV(Swirchabte)

12OV,22OV and 2zlOV (Switchabtel

12OV,2nV and 24OV (Switchabtel

U.S. military model

o This servicemanual is applicable to

the KU Çpe. For servicingof the oûrer types, please

additional servicemanual.

r For the circuit & mechanismdescription,

pleaserefer to the supplementof cT-7R

(ARP-æ1-0).

o ce manuer

d'instructionserefèreaumodederégrage,

o Estemanualdeservicio enfançais.

tratadermétodoaeaiuËeËilriil;n espaiïor.

CONTENTS

1. SPECIFICATIONS

2 9. PACKING

2 . F R O N T P A N E LF A C I L I T I E S u

....... 3 1 0 . E L E C T R I C A LP A R T SL I S T . . .

3. DISASSEMBLY 35

5 1 1 . M E C H A NI C A L A D J U S T ME N T S.

4. PARTS LOCATION 40

7 1 2 . E L E C T R I C A LA D J U S T M E N T S.

5 . E X P L O D E DV I E W SA N D P A R T SL I S T . 42

.. .. . 9 1 1 . nÉclecesnltÉceruroues ....

6. BLOCK DTAGRAM 49

t6 12. n É c l a c e s É l e c r n r o u.E. s. 51

7 . p . c . B o A R D S C O N N E C T T OD

NT A G R A M le 1 1 . AJUSTES ruecÂrurcos

8 . S C H E M A T I CD I A G R A M 58

27 12. A"lusrESetÉctnrcos ...... 60

YZ O MAY I98I

Downloaded from www.Manualslib.com manuals search engine

,t.spEclFlcAlfôNs

Miscellaneous

"" AC12OV/60H2

PowerRequirements

PowerConsumption " ' 43/Vatts

Dimensions - - -42O(W) x 99'5 (Hl x 270 (D) mm

1 6 - 9 / 1 6{ W ) x 3 - 1 5 / 1 6( H ) x 1 0 - 5 / 8( D } i n '

. . . APProximatelY90 seconds 5'3ks (l2lb)

FastWindingTime Weight(without package)

(C-60tape)

than 0.04% (WRMS) FurnishedParts

Wow and Flutter . . . . . No more

Connectioncord with pin plugs " " " ' 2

-20d8 recording:

FrequencyResponse

. . - . 2 Ot o 1 6 , 0 0 0 H 2 Operatinginstructions

Normal, LH taPes

(25 to 14,000H2J3dB) NOTE:

to posible modifications

.20 to 18,000H2 Specifications and the design subiect

Chromiumdioxidetape without notice due to improvements

(25 to 16,000H2r3dB)

(OdBrecording; 25 to I 0,000H2)

M e t atl a p e . . . .

Siganl-to-NoiseRatio

20 to 20,000H2

(25to 17,500H2

(OdBrecording;25

È3dB)

to 15,000H2)

NOTE:

rapes:

1. Reference

ï::ïlii

tt: DrN45513/BLArr

CrOz DIN 45513/BLATTT (CrOz)

or equiv.

I

Dolby NR OFF Morethan 59dB

B Type morethan 69dB 2. Reference Recording Level: Meter OdB indicating

Dolby NR ON . . " "

C TYPemore than 79dB level (160nwb/m magnetic level = Philips cassette

(at SkHz) referencelevel)

3. Reference Signal:333H2

4. Wow & Flurter: o JIS [3kHz, with acoustic

compensation (weightedl,rms valuel

5. Frequency ResPonse:' Measuredat -20d8 level,

DOLBY NR OFF, level deviation is tGdB without

indication.

Output ( Referencelevel/Load impedance)

jack 6. Signal to Noise Ratio: ' Measuredat the third har'

L I N E ( O U T P U T )x 2 " '450mV/50kQ'Pin

' 60mV/8Sl' 6mm diam' iack monic distortion 3% level,weighted.

Headphones

7. Sensitivityl Input level (mV) required for reference

Subfunctions recording level with input (REC) controls set to

a Auto reverse,auto repeat functions maximum.

. MS/SKIP(MusicSearch/Skiplsystem 8. Maximum Allowable lnput: While decreasing settings

. REC MUTE switch of input (REC) level controls and increasinglevel at

LED input iacks, this is the maximum input level (mV) at

o Dolby NR system (B tvpe/C tvpe/OFF) with

indicator lamp the point where recordingamplifier output waveform

o Stand'by mechanism with unattended recording and becomescliPPed.

playback 9. ReferenceOutput Level: Playbackoutput levelwhen

o 3 position Auto tape selector meter indicatesodB.

(NoRM/CrozlMETAL) 10. This modeldoesn'temploywith a recording/playback

. Full automaticstop mechanism connector(DlN-type).

. MEMORY STOPfunction (FF, REW)

. 2 color digital levelmeter

r 3 digit mechanicaltape counter

o lC-basedlogic control

o Cassettecompartmentillumination

. INDEX SCAN system

o MUSIC REPEATsystem

O SKIP

. BLANK SEARCH SYSTEM (

Downloaded from www.Manualslib.com manuals search engine

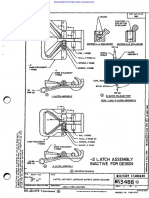

IndicatorAssemblyRemoval CapstanBelt Removal

Removethe two hooks O of the panelstay and

pull the indicator assemblytoward you.

1. Remove the four screws €) ana rcmove the

capstanmotor control assembly.

I

2. Remove the capstan belt from the capstan

Level Meter Assembly Removal assembly.

Remove the hook @ of the panel stay and

pull the level meter assemblytoward you.

Gontrol Switch Assembly Removal

Remove the two hooks O of the panel stay and

pull the control switch assemblytoward you. ".-o

Level motor assembly removal

_l

.,O

Capstlr motor

.control at*mbly

-d

__) .

- Sub caostan

assemblv

Fig. 3-5

e@

l d l e r P u l l e Ya s s e m b l Y

Capstan belt removal

I

Control switch

assemblV

Level meter assembly

o

F i g .3 - 3 Disassembly

Head Assembly Removal

1. Remove the stopper.

2. Turn the head assembly clockwise (FWD

direction).

3.

assembly

Fig. 3-4 Head assemblyremoval

Downloaded from www.Manualslib.com manuals search engine

2. FRONT PANEL FACILITIES

f,t tr'

-c

_8.

':f,."

OHO^EI srÊFEo cassETTE TAÆ æcK cr 7H

o powenswitch @ Recordingfunction switches

The power comes on when this switch is depressed;it is Recordingoperationscan be performedwhen the switches

turned off when the switch is released. with the following symbolsare depressed:

@ EJECTswitch/cassettedoor PAUSE: The tape travel (during recording)

can be temporarily suspended(re-

The cassette door opens when this switch is depressed.

cording standby mode). Depressthis

NOTE:

switch againto resumerecording.

Thedoorwill not open when the tape is running or when the

pause function is working, NOTE:

The tape will not stop whan this switch îs depreæd during fast

@ TapeCOUNTER/RESET

switch forqard or rewind operations.

The tape counter indicatesthe tape's traveling position.

Recordingcan be started.

Depressthe resetswitch before recordingor playback to

R E CM U T E : This enablesunrecordedblanksto be

resetthe counter to "000."

created between programs for con-

e LEVELmeters venient play functions (MS/SKlp,

Theseindicatethe input or output levelduring recording MUSIC REPEAT, INDEX SCAN,

or playback. BLANK SEARCH).

B L A N K S E A R C H : This automatically searchesfor the

@ Playbackfunction switches

remaining part of the loaded tape

Playback operationscan be performedwhen the sections

which has not been recorded.

with the followingsymbolsare depressed:

É (fastforwardl: The tape runs at high speed from @ rus/srlPsritch

left to right. This switch is for skipping the program now being heard

The tape runs at high speed from and finding the start of the next program. When this

right to left. switch is depressedduring play (ON; MS/SKIP indicator

Cif (direction): The direction of the tape travel is lightsl and then the fast forward switch (rewind switch

reversed(evenin the pausemode). play starts

when traveling in other direction) is depressed,

PLAY: The tape is played. from the next program.

STOP: The tape is stopped. Wheneverthere is a long interval betweentape programs

(unrecordedblanks of over I seconds),the tape is auto-

matically fast forwardedand playbackresumes.

Downloaded from www.Manualslib.com manuals search engine

F R O N TP A N E LF A C I L I T I E S

Indicatorsbelowshowthe ON-OFFpositionof eachswitch

Forward running ind,

Recording ind.

(T-0-dlE

PAUSE ind.

oÆtaTroN|\æ Recording MUTE ind.

\ \ _-Y- | Ê

Tap€ travel ind, ---

---d\o'^.="

l4

-*oj€ Tape travel ind.

-

Reverse running ind.

= !5â æ'-q:=,c REæar

M U S I CR E P E A Ti n d .

AUTO TAPE SELECTOR

ind. POWERind.

DOLBY B/C type ind.

@ fNDEX SCANswitch @ f trUenstartswitch

This plays only the start of the recordedprogramfor

This switch is oærated for unattendedrecording play-

about 7 secondsand then fast forwards the tape. When or

backusingthe timer.

used in combinationwith the rewind ( << ) switch,this

REC: For automaticallyrecordingat the lime

operationcan be performedwith the tape beingrewound. set on

the timer.

@ MUSICREPEATswitch O F F : F o r w h e nt h e t i m e r i s n o t b e i n gu s e d .

This repeatsonly the program now being heard for PLAY: For automatic playbackat the tim6

up to $t on the

e i g h tp l a y s( O N ;M U S T CR E p E A Ti n d i c a t o tri g h t s ) . timer.

@ INPUTfevelconûols @ rupxFTLTER

switch

These are used to adjust the input signal level Depressthis when recordingan FM stereobrCd$st

during using

recording.The insideleft channeland outside right the Dolby noisereductionsystem.

chan-

nel controls can be usedseparately. @ ooLev NR B/c type setector

@ MlCjacks Depressthis to selecttype B or type C Doltry

Nfi system

Insert the microphoneplugs (L and R) into with the Dolby NR switch in the ON position.ffhe

thesejacks indi-

when recordingwith microphones. catorBorClights).

@ PHOrueSjack @ OOLAVNR ON/OFFswitch

Insertthe plugof rhe stereoheadphones Depressthis to the ON positionwhen

into this jack. recordingOr playing

backa tapewith the Dolby noisereduction

@ ruOOeselector ,ia*.

: : Whenthe tape has beenwound

up on one of the

@ rueruoRY

ON/OFFswitch

reels, it automaticallystops traveling (oneride Whenthe tape is to be stopped

automaticallyat a desired

travel). position,use this switchalong

with the tapeâunter/reset

.= : The tape startsmoving switch and rewind switch (fast

in the forward direction, to.*arj ,Witd,, Ouring

the direction is reversedat the reversetape travel). Normally,

end of the tape, it is kept at ths released

the tape .startsmoving in the reverse ( r O F F Ip o s i t i o n .

direction

and then stopsat the end {two-side

cr travel}.

: The tape is repeatedlyplayed

back.

The repeat function

stops when the direction

tape travel hasbeenreversed of

eight times.

The word "Dorby" and

Do are trademarkof Dorby Laboratories

NoiseReductionsystem corporation.

manufacturedunde. licens.from Dorby

Laboratories

Licensingcorporation.

Downloaded from www.Manualslib.com manuals search engine

3. DISASSEMBLY

Door AssemblyRemoval Bonnet Removal

1. Depress the EJECT button and open the Removethe four screw l)

cassetteholder. lndicator PanelRemoval

2 . Remove the door assembly from the hooks 1. Pushthe two hooks @ of the panel stay with

attached to cassette holder with the small the small screwdriver.

screwdriver. 2. Pull the indicator panel toward you and re-

3 . Remove the spring with the small screwdriver. move it.

4. Slid the door assembly to the left and remove

it pulling toward You. Sub panelR Removal

1. Pull off the INPUT knobs.

2. Push ttre four hooks @ of the panel stay

with'small screwdriver.

3. Pull the sub panel R toward you and remove

it.

Smallscrewdriver Switch EscutcheonRemoval

1. Push the three hooks O of the escutcheon'

2. Pull the escutcheontoward you and remove

it.

MechanismAssemblYRemoval

1. Removethe counter belt'

Fig. 3-l Door assemblYremoval ,:. Removethe six screws @

Switch escutcheon

Switch esoJtcheon removal

o o

V

I

,

)

lndicator Panel removal

Pânelstay

lndicator Panel

Sub Panel Fl

Sub Panel R

Knobs(INPUT)

s[6-panet R removal

Fig.3'2 Disassemblv

Downloaded from www.Manualslib.com manuals search engine

T

o 5. EXPLODEDVIEWS AND PARTS LIST

5 . 1 M E C H A N I S MA S S E M B L Y

I B

o-

'Î',

r

#{

Îp

I

r09

Downloaded from www.Manualslib.com manuals search engine

48

ù

--t

87

104

\6/

0

I

Downloaded from www.Manualslib.com manuals search engine

4. PARTS LOCATION

NO?ES:

c Parts without parl number cannot be supplied

e The .t marh found on some component parts indicates thc împortance of the

safety factor of the part. Therefore, when replacing, be sure to usc parts of identical

designation.

c For your Parts Stoch Controt, the fast mouing items are indioated with the marhs

** and *

** GENEÀALLY MOVES ,FAS"ER THAN *.

This classification shall be adjusted by each distributor because it depends on model

number , temperature, humidity, etc.

Front PanelView

Knob C (FF. REW)

RAC-209 Knob D (REC)

RAC-193

Knob (EJECTI Knob E

RAC-208 RAC.194

Door lens

Knob ilNPUT R)

I nAA-36r

I

Knob (INPUT L)

Switch escutcheon

o RAA-362

R N L.338 \9 Knob (MODE)

t* RAA-359

Door panel assembly--

RX8.595 o Sub panel R

R N 1.378

Knob (POWER)

RAC-195 Knob E

RAC.192

KnobG (MEMORY) KnobD (PLAY, STOP)

RAC-196

RAC-'10

Indicator panel

R N L-357 Knob S (DlRECTTON)

RAC-[ 11

Front View with Front PanelRemoved

* Indicator æsembty (A) ** Flotary switch (A)

RAW-162 RsB-029

** Counter V a i b b l 0 r e s i s t o r( t N P U T )

RAW-167 RCV-CXI6

Cassetteplate assembly

RXX.338

tfr Jack assembly

RKN.O75

Erase head

Èi notary switch (Bl

RPB-095

*t

nsB-O30

H e a d a s s e m b t y( R E C / P B )

* P u s hs w i t c h ( B )

F XX.333

RSG-126

Erase head

RP8-094 F u n o t i o l Ns w i t c h a s s e m b l y

R W $ f1 3 8

** P u s hs w i t c h

R S G - 12 6 * bw| meter æsembly

RAW-161

Downloaded from www.Manualslib.com manuals search engine

Removd

?opUb* *ltfr Bonnet

Remote control æsemblY

Mother assembly

RWX497

I t* Fuse(2A)

NR assembly(Ll

A ft Fuse(1.2 Rwx-499

REKO59 (Rl

DOLBYNR assembly

,RWX-49S'

Amplifier assembly

[ * eovrnrtransformer (1

RWF-O95

RTT.239

Reel motor control æsembly

RWX.491

Jack assembly

Capstanmotor control RWX.498

æsemblyC

RWX489

Switch æsembly

Panel stay

RNT-OI7

Meter drive assembly

Mechanism assemblY RWX.sOO

RearPanelView

Bonnet

Remote control socket RNA.563

RKP-222

Strain relief

Main chassis REC-376

Terminal(LINE)

RKB.O18

Downloaded from www.Manualslib.com manuals search engine

5.2 EXTERIOR

r6

a.-

o- 70

70É

2

t

C

s)

I

u

1À

30

r0

D

ll

PI

Downloaded from www.Manualslib.com manuals search engine

T-

4 6l

z

/

=-

ft

È

I

-f

--J

.1

Downloaded from www.Manualslib.com manuals search engine

Mark No. Part No. Description Mark No. Part No.

8't RBH-855 Spring 101 YE3OFUC Wæher

82. RNH-064 FG plate 102 YS2SFBT Washer

83. RXX-334 FG coil assembly 103. ATZ?ôPOEOFMC Screw

84..RNH-061 FG shieldplate 104 VCZ30P06OFMC Screw

85. RXB-553 B e a r i n gh o u s i n ga s s e m b l y r0 5 . BMZ3OP06OFMC Screw

86 RNL-257 't06

Trigger lever B vcz26P100FMc Screw

87. RWX-491 Reel motor control æsembly 107. YE25FUC Washer

B 108 VCZ26P140FMC Screw

88. Heat sink A 1æ. ATZ3OPOSOFMC Screw

89. P.C.B. 11 O YE2OFUC Wæher

90. RWX-489 Capstan motor control assembly C

111 WA21D040D025 Washer -

't12

91 Cord clamper PMA26P050FMC Screw

92. RXX-335 Capstan motor coil assembly 113. BMZ26P050FMC Screw

93. RNL-247 Thrust receptacle 114 BMZ26PO80FMC Screw

94. RBH-862 Pinch return spring R 115. BBZ26PO80FNi Screw

95. RNL-268 Sub pinch arm R

116. VCZ30P100FMC Screw

96. BBH-852 P i n c h p r e s s u r es p r i n g B 117. RNH-117 Sield plate B

97. RNL-264 Eject lever

98. Side frame B2 assembly

99. Heat sink B

100. WAot7D03SD025 Washer

Downloaded from www.Manualslib.com manuals search engine

NO?ES:

c Partswithout part number cannot be supplied'

o The tf marh found on some component parts indicates the importance of the

safeti-'factor of the part. Therefore, when replacing, be sure to use parts of identical

designation.

o For-your Parts Stoch Control, the fast moving items are indicated utith the marhs

,h* and *.

*T GENERALLY MOVES FASTER THAN *.

This classifieation shall be adjusted by each distributor because it depends on model

number , temperature, humidity, etc.

Parts List

Mark No. Part No. D6cription Mark No. Part No. D€scription

Lock arm 41. REF-O22 Steel ball (30)

1. RNL-266

42. RNG.3O6 Housing

2. RBH-849 Lever spring

Eject prevent lever ** 43. RXX-333 Headæsembly

3. RNL-265

Spring 4. Headbaseæsembly

4. RBH€5O

Cylinder 45. RNL.317 Slideplate

5. RNL-261

O ring 46. RNH.O76 Headbæe spring

6 . REB447

Piston 47. Main shaft

7 . RNL.269

Connector P.C.B, ,lg. RBH€59 Arm spring

8.

Cord damper 49. Arm æsembly

9.

Side frame L2 assembly 50. RBH€68 Switch le\rerspring A

10.

Pincù pressurespring L 5 1 . RNC-267 Switch lever

11. R8H€51

** 52. RNL-272 REC detector arm

12. RXB.55O Pinch roller arm æsembly

Sub pinch arm L 53. RNL.271 Detector arm

13. RNL.267

il. RBH€69 Switch leverspring B

14. RBH€61 Pinch return spring L

55. RNL-273 METAL detector arm

15. Cam follow lever

16. RNL-253 Hook L * 56. REB45O Brakeshoe

17. RNL-254 Hook R 57. RNL-258 Brakeplate L

18. RNL-255 Connection plate 58. RBH.848 Brakespring

19. HNL-306 Pinch plate 59. RNL.259 Brakeplæe R

20. RNL-305 Actuater 60. RBK.lEI Half set spring

21. RNHO77 Change plate. 6 1. RBH€47 SpringR

22. Beel molor drive assembly A Â* 62. R X P . I1 1 Plungersolenoid

23. RXX.3i:t6 Reel motor coil æsembly 63. RNL.256 Trigçr lever L

24. Rêel motor P.C.B. 64. RBF.OSB Washer

*i 25. RXB-548 Rotor æsembly 65. RNL.3O8 Assist çar R

26. RNL-313 Pocket L 66. RNL-307 Assistgpar L

27. RBK-I67 Pressurespring 67. Pulleyshaft

24. RNL-3r4 Pocket R 68. FXB.620 ldler pulley assembly

29. Holder B 69. RBH€46 SpringL

30. RBA-073 Special nut 70. Chassisassembly

r 31. RPB-G)s Eræe head 71. REF-O23 Steel ball (4O)

32. RBH€63 Height adiust spring L 72. REB-260 Stopper

33. RPB-Og4 Erase head 73. RLB434 Guide roller

34. R8H-864 Height âdiust spring R 74. RBF-tr'o Oil stop wæher

35. Eræe head base æsembly 75. RBH-857 RatchspringL

36. RNL.262 Stopper 76. RBH-858 RatchspringR

37. FBA.O74 Azimuth screw 77. RX8-552 Sub capstanæsembly

38. RBH.853 Azimuth spring 78. BXB-551 Capstanæsembly

39. RBH-906 Gear spring 79. BE8-467 Capstanbelt

40. RNL-312 Sector gear 80. BBF-O5g Washer

Downloaded from www.Manualslib.com manuals search engine

10 11 12

-6

-@

-o

-o

-(l

AsCy(L) RWX-499

IC60l Q601 IC602

vR601 vR602 vR604

-o

rc603 Ic604 Q6O1 IC602

vR601 vR602 vR604

.(,q I IC6O3,604 rC40668P I e 0601,503,604,€07152473or

or x884o66BM ' usto4o

lcrz, 1!g;

- r$e-jgj . ' i .,0*, o'H0'40668 ] I ^

;.0' ? ; , l.(.E F6.s56v - ç^'-i.":l ?r"o. ::6@-9

i !'-r',rrt à"J* -^^^^^i"'?,' à ^-.1.-^'*L'-,"';1,

- - rTr'r'_-.ttii.'1,I

lÏ. l*iÈ,'."utlto.oiÀ" ï----.--

r à "'&d;ït é d<

, f,* i#l -'i;-"r , I ç1 t,,t

l"J'"'ilg;' #"5 c{--1'os0'-".

.P

r"r *'Ï. , l ii",t ,";' :#ç .,.: '. -.."::1,' '

fsi:"î;"ti;'i : "

f is"l

;#l,,1..,j,*.,.*;...i,,oi..:@]..l.'.Ê=Ëj"*"*iT.l

\ss'y(Rl RWX- 499

-o

-(D

o

o

Downloaded from www.Manualslib.com manuals search engine

I 7 I I I

ootl

S J] P O W E R

CASSETIE

HALF

S2

TAPECOUNTER

REMOTECONTROL

Ags'y

Downloaded from www.Manualslib.com manuals search engine

I I

P.C. BOARDS CONNECTIONDIAGRAM

I

lz 3

HtaL qSSt

; ûH . ar

A CONNECTOR

Ass'y

AMP Ass'y

RwF-O95

QSOJ O5Or Q5O7

vÊ50r L5G L$4

o-

c

JACK Ass'y RfVX-4ge

D SVtITCH Ass'y

Downloaded from www.Manualslib.com manuals search engine

I

I

I

f

I

/rI

1t

JI hl

\J

MOTHER Atss'y RWX- 497

Q3æ a331 O306 Q3O7 aoz Icrc6 Oæ8 a3O9 a01 Q325 erj I err' e3o4 u.u. o.ro o.rïtto" 331"to.

ta92 lcg Q3o3 Ic3o7 IcJoi O3ro rcg Icæ3 Q 324 Q326 a327 a:

.w-- VRæ3 L 3 06 vBæi vR305

vR304 vm02 vR306

r aû2-Z07.r12,3tt

a,315,319,Q3?4-327

c*r\ -Ltil€

, 0330,331

, 2æ174OLX s 2l

r5c634Nc o.2sct€t5 :]: À

.t.iar^ (t )

jll oroo,3os

ol

2sc2479 ôt 2SDt1a9

.i{ e31o31s

ZSCaO6Od 2sc2673Dl

-l

=-l

or ol's

@

C€

- - .T

-\ll ii l+ -

r s ol ' f

.I

I

ur{' ? I

220 7 i

J6

-' -tt30?

ltE?t?l

T;-

Downloaded from www.Manualslib.com manuals search engine

PartsList

Malk No. Part No. D.rcription No. Pan No. Do.cription

-

1. RNA-563 Bonnet 51. RCv096 V a r i a b l ec s i { e r ( t N p U T }

2. BX8-595 Door panel assembly ** 52. RS8029 Rotary switch (A)

3. Door panel ** 53. RSB-O3o Rotary srrirclr (B)

4. Door lans 54. RWX,49B Jack assembly

5. RBH€92 Door spring 55. RKN-07F Jack assembly

6. RNL-338 Switch escutcheon [. * 56. RTT-239 Power transfolmer (l 2OV)

7. RAC-195 Knob (POWER) 57. REC-355 Slide stopper

8. RNL-357 Indicator panel 58. Main cha$is

9. RAC-209 Knob C (FF. REW) ,A 59. RDGO22 Power cord

10. RAC-211 Knob S (DtRECT|ON) (RDG_O30)

11. RAC-210 Knob D (PLAY, STOPI A 60. REC-376 Strain rellf

12. RBH-902 Spring 61. Remote control assembly

13. RAA-362 Knob (INPUT Ll 62 Stud A

14. RAA-361 Knob (INPUT R) 63. Eanh terminrl {2P}

15. Meôanism assembly æ. UL cord *mppr

16. RXX-338 Cæsette plæe æsembly

** 65.

17. REL-O91 Lamp 66. Boftom pltte A

18. P . C . B .B r a c k e t 67. Bottom ptûe 0

19. RNT-OI7 Panel stay 68. REC-369 Foot as.serbly

20. RBH-9O1 Eject spring 69. vBz30P060FMc Screw

2 1. RAC-208 Knob (EJECT) 70. vBz30P080FMC Screw

** 22. RE8-456 Counter bolr 71. BBZ26P080FNi Screw

A 2s. RWX-109 Spark killer 72. PMZ30P060FMC Screw

o

{RWX-234}

73. FBT40PO6OFMC

A ** 24. RSA{46 Power srvitch

74.

Screw

PMZ30P060FzK Screw

25. RAC-l96 Knob G (MEMORy)

** 75. v8z4oP12oFMC Screw

26. RAW-167 Counter

27. 76. VBT3OPO6OFMC Screw

* 28. 77. VPZ3oP100FMC Screw

RAW-I62 Display assembly A

*æ. 78. RKP-353 Connector iodtèt

RAW-l6l Level meter assembly

æ. RAA.359 assembly (f)

K n o b { M O D E ,T T M E R }

79. RKP-352 Connector tocbt

3 1. RWS-138 Function switch assembly æsembly (S)

I

*rt 32. RsG{63 80. R ivet

Function switch

** 33. RSG-088 Push switch

34. 81. REC-378 VB shield pcprT

RAC-r94 Knob E

35. 42. R EC-380 Shield pap6t

RAC-193 Knob D (BECI

83. RNL-390 Transformaa plûte

36. 84. P.KP-222 Remote corrtrol socket

RAC-192 Knob E

37. RNL.378 Sub panel R

38. Rwx-497 Moth€r assombly

39. Heat sink

fi. RKB.O18 T e r m i n a l( L t N E )

t* 41. RSG-12s P u s hs w i t c h ( A )

** 42. RSG,126 Push s,vitch (B)

A t* 43. REK.O59 Fuse(1.2A)

** 44 REK-O55 Fuse (2Al

45. RWX-499 DOLBY NR assembty

46. RKP-273 Connector socket assembly C

47. RwF{95 Amplif ier assembly

8. RNL-375 P . C . B .H o l d e r

49. RWX€OO illeter drive assembly

50. Switch assembly

Downloaded from www.Manualslib.com manuals search engine

(

LEVEL I\,IETER

POI'YER SUPPLY

oil - oFF S9OI : REC MUTÊ o1{ - QEE

oil - oFF s9@ : FEC oil - oFF

û{ - oFF S9O3 : PLAY oil - oFF

ÎYPE 8 - TYPEC S9O4 : FÀUSE q{ - oFF

oir - çF S96 : FF ON - OFF

FTO- REV s906 : REW qr - gEq

o|r-6F s907:sToP o.{ - qE

=-? -o s90€ :DtRæTtr of{ - oFF

REC -çF- PLAY s909 :$<rP or{ - oFF

LtE- t rc sgro : tNoEx scaN ON - OFF

sgil : BLAir( SÊARCH ON - OFF

S9t2 : MUSICREPEAT or{- gEE

thr ua.fdhad indbot. tb rr,hn p6nbo.

1B

Downloaded from www.Manualslib.com manuals search engine

6. BLOCK DIAGRAM

MIC AMP

F-.o.'-t

rvG

E HEAO

FWD

E H€AO

RVE

Downloaded from www.Manualslib.com manuals search engine

DOLEY NR B-C TYPE SYSTEM

t1ar226 (/21

'-J

MP Dq-BY SW A MUTING

P.e

.l tcæ312/2t

ftc

:

swrTcHES

Sl : FO||ER

52 ÎAPE

S3OI: TP'( FILIER

S3O2: oO|-BYNR

S3O3 : DOLBYNR

S5O4 : FID/REV

5306 : ilEiilORY

S?Ol : L(D€

S7O2 : TIUER

SSO| ;rin T

Downloaded from www.Manualslib.com manuals search engine

- 7

0OLBY Arr,y (R)

ot'e506,3

- --1--;

zâ'-

, I l:i-

L.r/o)

] RESISlOBS

n d , c a i e d, . .W 5 , ro eran.r I j .s r)rfr.w

M Mi: lFr r , I)i 21 tt I ta%ktt..d.n1

A A d , u s rn q @ n r

CAPSTAN coNIROL Ass'y

2 CApACTTORS rie ma/k rôuôd on ine rcmrcsr .d,car6 rhe m

ô 4+

1 ti vo rrqr i! podà.ce or rh. srÊry rac'o, oi 'he odd Ïhetrfi'€ whe. ræ k ^q

ôa car,on w rhour vo rarr s 50V be arp ro !r pôilsol deni cà d6 q.àrû

I /O -Au'

iaj rh s a rhe bù( rhema, . r àeràm ilr ù æni+ .Æ,r! mâv B,y

Dc vo raç rvr ar no nDlr s qna

o u e r o ' m D f o v . m e n l s. d 6 r q n

-

7 I

Downloaded from www.Manualslib.com manuals search engine

12

The indicated semicond.uctors are representatiue ones

only. Other alternative semiconductors may be usedand

are listed in the parts list.

;l

I

INDICATOR A!!'y RAW - 162

|_---l

oOLBYA.t1 lRt

ôo2-3

oPsld

CO{TROLA..ry

no

I

I

N4J

M2i

REEL

"' I

MOlOR

comRol b't

taDl(!

tEo

I

L@ LO !@ @

*oJ

LEVEL METER A$'y

...=.-jr--l RAW-l6l

[_l

i$;1',*"

II

I+

lT* -

CPTd CdIru 4..'y

315-l

REEL MOÎOR

0ilvE A{'y

314- |

Downloaded from www.Manualslib.com manuals search engine

2

6

o

o

A3

FUNCTIONSWITCHAsCy

R W S- t 3 8

Do

(D

o

o

2

Downloaded from www.Manualslib.com manuals search engine

10

FIEEL MOTOR CONTRCI-Asdy

RWX-491

IC2A1 Q204 Q205

vR202

Q201 0,202 A

f8tùtt R2o7

*

rooK I vRioz

"&a *w_ QM Rzos49

f- llooK-8 t-* L-*

tc2ôtPA2O09 d\M

Q20r 2S4934

{.^"^.fiË-' Q2o2 2sos82

1ô:i7so Rzos

roK

ô + - -

LC2a2

{

{ H 254

\adA?

t-E

l"l

I l"l

I l_e.J

' \

l:l

teJ

{*..,

TR?55 \',,, l3bo

I 360

ô

't'J "'\ t ' * R z 53r 5 0

DRIVEAss!

Downloaded from www.Manualslib.com manuals search engine

8. SCHEMATIC DIAGRAM

MOTHERA3s,y ( I,/ 3J

s w rl c H

:lï:,I

L C H

Ér l:r, R

1'f::* | *

t---J

soz q"J

t

l€o? JACK as3'y ( l/2 ) Rwx-494 97 . - l

-'l vl

FKr

'3) L

o?5 I'Tl

- lÈa

o.og I

t-r

c

'\: I t,)o

tr{-

"iî

t

r( ql- a

ca!3 |

lT' :T

!u

I .

vl L

Ë -Æ

Hts

,*f r l F

: :€- --1 srcr-z r+ 4

l +

Q AAa,AO4 tî I

", tl

s roz rrven

l*",

lcs L-

-''l .r

I .rl

1"".T""'

oæÈ

,/98 \

L o a o t ,a o 2

or 2$

ô. 2SC 263, N C

20à or 25Cl€ 5

2SC r ?40 LN

B {-ltt , n*r-ogs

Q.5t3,5r4

L CH

a503{514 2SClT4OLid

2SC2O2l o. 2SCl6!5 or

2S C2 6t4NC

RCH

vi!ot,5o_2 p 6 L E a É La D J

o3ot ts2473 d

6ro40

swtTcHEs

SI POWER oN o,FJ

5? TAPÊ COUNÎER ON AlJ

53OI MPX F LTER oN - qEf

5302 DOLEYNR ON OÊF

53O3 DOLEY NR IYPES - IYPEC

S3O4 FWO/ REV SELECTOR FWo - REv

S]O5 MEMORY oN - qff

s70r Mo0E

S7O2 TIMER REC ffi pLAy

sa o I rNPUT sÊLECTOR LlilE _ Mt C

sgo REc MJrE -N - off

s9oz REc oN _ qlf

5905 PLAY ON _ Q.EE

59 04 PÂUSE O N OEE

s9o5 FF oN _ qlli

5906 REw ON - OFF

ssoT srop or - oi;

s9 o8 olRECttoN oN _ q_[-E

S9O9 SKIP ON OFF

S9IO INDEX SCAN ON - OFF

Sgtl 8LAilK SEARCH ON - qlf

59I2 MUsIc R€PEAÎ oN -

QfI

Th. !d.ilind idicatd rhê *ilch æ!ilDn

Downloaded from www.Manualslib.com manuals search engine

4 5 6

DoLBYAo'y (R ,

60Fr 60r-ro

5Or_9looL8Y

Arr'ytLl

602- t.)

M O T H E RA e ! ' y ( 3 / 3 ) R w x - 4 9 7

o30r

2SASL{ q zSAiOl5 d

2SA937 6 2SAI27NC

fCSOf Mg 74LSt22 o. HO 74LSl22

st 74 LSt22 d D M 7 4 L Sr 2 2

+-i L

| "*-";-

I

vi$r, ro4 OsOa. 3Og 2sollag or

Nro BrÂsÂoJ 2SC2497 o? 2SDA82 ÂEG!LArcR

Q 3II:

cÂPsrÂÎ{ | il9

coNlROta.rry L

tti

*.'tt*;-* I

@+5e

o 3t2, 3!4, J13,3!9

2 SC | 7æLX o.

ræ 2SC2634NC o.

2SCIal5

580 o?

zSC2o2l ol

52

2SOô00 0. 2S0313

CASTN CffiROL Â..', P O W E Ê O N/ O F F t!al

MUTING 2à

0313'31? O317,32O!323

R€GULATOR 2SA933lil o. 2SAlotg o.

O3lO,sl8 23c2060 o.

2SA 937 o. 2SA I l27Nc -

2sc2673 o.2SCl383ilC

0320 , 326

M4 M3 il2 N6

REEL rcTOR UKS

C(il1ROL AdY COxnoL Âo'Y

-

4 6

Downloaded from www.Manualslib.com manuals search engine

2

o

@

o

A3

FUNCTIONSWITCH Asdy

R W S- t 3 8

"_:-

B tSFl

S!t2 L-l

Do

o

o

o

2

Downloaded from www.Manualslib.com manuals search engine

6

METER DRIVE Ass'y

RWX-5'o0

' € - - -: " - : ,,

llo o 1 o o o o o o o o o o o o oll'. -1

l_.- :-.''"::_ l

Downloaded from www.Manualslib.com manuals search engine

JackAssembly(RWX-498) RESISTORS

CAPACITORS Note: When ordering resisfors, conuert ïcsistance ualue

into code form, and then reutrite û)art no. as before.

Part No. SYmbol& Description

Part No.

c E A 0 1 0 M5 0 c801-c804 Symbol &

cEA r00M16 c80 7, c808, c81 1-C81 4 * RCP-009 V R 5 O 1V, 2 S e m i - fi x e d 2 2 k - B

c E A 1 0 1 M1 6 c 8 15

.q.LEvEL)

c c D S L ' t 0 1 K5 0 c805, c806, c809, c810

CKDYF 473250 c816 RDI/4PM!O!J R 5 0 1-

RESISTORS SEMICONDUCTORS

- Note: When ordering resistors, convert the resistance value Mark Part No.

into code form, and, then reutrite the part no. as before.

t* NJM4558D

Mark Part No. & Description

(AN6552)

ùmbol

(BA4s58)

RDl /4PMNtr!J R801-8828

2SC22Q osol-os0f

SEMICONDUCTORS

*t 2SCr740LN o50s-o51

|

Mark Part No. Symbol & Description ÉSC2021l

(2SC181s)

** 2sc174oLN o801 -0804 (2SC2634NC)

l2sc2021l 152473

(2SC158 )1

(us1040)

(2SC2634NCl

OTHERS OTHERS

Mark Part No. ùmbol & Dcscription Mark Pert No. Symbol & Dtcrhtion

** RKN{75 s801 Jack assembly t* RSR-O35 RYsOI Retay

RTF{85 LsO1,L5O2 Pe*ing coit (3.9mH)

AmplifierAssembly( RWF-095) BTF{84 L503, L504 Trç coil

CAPACITORS

Mark Part No.

DOLBY NR Assembty

(RWX-4991

Symbol & Description

CAPACITORS

aatt a"- - c 5 0 1 c. 5 0 2

C E A N L1 O O M :6 c505,c506 Mark Part No.

c E A 1 0 0 M1 6 c 5 1 5 , C 5 1 6 , C 5 1 9 , C 5 2 0 ,C 5 2 5 ,

c526 c Ê A 1 0 0 M1 6 c601,c614]C6frs,cozz.cosr

C E A4 R 7 M 5 0 cs29, cs30 c E A 4 7 1 M1 0 c630

c E A 3 3 0 M1 6 c503, c504, C523, C524 c E A 1 0 l M1 6 c604

c E A 0 1 0 M5 0 c 6 r 0 .c 6 2 5

c E A 4 7 0 M1 0 c 5 11 , C 5 12 C E A R 4 7 M5 0 c621. C606

CEA R33M50 c527,C528

-

ccDsl 10rK 50 c507, c508 C E A R l O M5 0 c 6 1 2C , 6 r s c6f6

ccDSL 220K s0 c509, c510 C E A R 3 3 M5 0 c 6 17 . C 6 1

8

coMA 103J50 c 5 1 3 ,C 5 1 4 C E A R 1 5 M5 0 c629

coMA 394K 50 c626

coMA 153J50 c533, C534

coMA 183 50 c531,C532,C537,Cs38 coMA 104K50 c 6 13

coMA 182K50 c535, C536 coMA 473K 50 c628

coMA 222K 50 c539, C540 c o M A 1 8 3 K5 0 c620

coMA 223K 50 c 5 17 , C 5 1 8 coMA 153K 50 c608,C6r1 c6p., c623

coMA 472K 50 c609,c624

cosH 471K 50 c501, c502

cEA 010M50 c521,C522 coMA 182J50 c6o2

cEA 101M25 c54'l CKDYF103250 c603

ccosl 221K50 c607

coMA 393K50 c6o5

CKDYB222K50 c640.c641

-

.a/

Downloaded from www.Manualslib.com manuals search engine

ÊESr$ônS

Note: lYhen oîdefing resistort, convert

into codeform, ond thén rewrtte

the resi*ance vclue

the part no' æ before'

OTIIERS

Mark P.rt ltlo,

RKP.355

srîrbol & Oe.cription

CN1O02 Connectorsocket

a

ascemblY(4Pl

Mark Part No. Symbol & DotctiPtaon

* RCP.Oss VR6Oî , VR602 Semi'fixed

2.2k-B(P.8.GAIN, $,YitchAssemblY

REC GA.IN)

* RCP-O32 VR6O3, VR604 Semi'fixed Mûk P.rt t{o. Symbot & D.|criPtaon

IOK.B(DOLBY

t* RSB.O29 STO1 Rotary svvitch(Al

LEVEL, REC

ff RSBOæ S7O2 Rotary srruitch(Bl

LEVELI

R601-R641 RCV{)96 VRTOI Variablorssistor

RDl/4PMtrtrtrJ

(100k-Al

SEMICONDUCTORS

Mart Plrt No. Symbol & Dercription RemoteControl AssemblY

rc601 Symbol & D..Griptaon

I

i* HA11226 Mark P.rt No.

ff TC/IO66BP rc602, lc6o3

(M8840668M) RKP-222 Remote @ntrol sockot

(HD140668)

fi TD62507P 1c604

FunctionSwitchAsembly (RWS'1381

ff 2SA933LN 0601

(2SA9371 ijfùk P.rt No.

(2SA1127NC) s901. 5902. 5904. S909-S91 2

RSG-063

(2SA1015) Fundaonsu\ritch

RSGO88 S9o3, SSOS-S9O8 Push witett

1s.2473 D601, D603. D604, D@7

{us10/to}

1K344

(1K60Al

D602, D605, D606 RKP.35O CN9OI Connsclor sockst

æsembly (4P) I

(oA90l

OTHERS

Mark P.rt No. Symbol & De$riPtion

RTF.O92 L6O1 Coil (36mH)

MeterDriveAssenrblY

{RWX'5001

CAPACITORS

Mark P.rt No- Svmbol & Dercrintion

cEA l(x)M16 cl001 -cl004

cKoYF 103250 c1005

RESISTORS

resistanceuolue

Note: Whenordering resistors,convert the

part no' as before'

into code form, and then rewrite the

Mark Pirt No. Symbol & DescriPtion

RD1/4PMtrOEJ R1001-81011

SEMICONDUCTOR

Mark Pârt No. Symbol & DoæriPtion

{

ft tR2E02 1c1001,1cl002

Downloaded from www.Manualslib.com manuals search engine

10. ELECTRICALPARTS LIST

NO?ES:

o When ordering resisfors, first conuert resistarce ualues into code form as shown in

the following examples

Ex. 1 When there are 2 effectiue digits (any digit apart from 0), such os 560 ohm

and 47h ohm (tolerance is shown by J: 5%, and K = 107n)

56Oa 56xtot 561 ... .. .. RD%PS t56tr.,t

47ha 47 x 103 473 . . R D t / e P SA A g . /

05a 0R5.... ..... RN2HOEtrÂ

/a 010 RS/P OtrCI Â

Ex. 2 When there are 3 effectiue digits (such as in high precision metat film resis-

tors)

- 5 62he 562x 100 5621. . . . R N t / t S RE 6 A D I'

o The $, marh found. on some component parts indicates the importance of the

safety factcr of the part Therefore, when replacing, be sure to use parts of identical

designatiot

t For your Parts Stoch Control, the fast mouing items are indicated uith the ntarhs

t* and ,

''GENERALLY MOVES FASTER THAN *

This classificationshall be adjusted by each distributor becauseit depends on n'todel

number , temperature, humidity, etc.

Miscellaneous

PartsList

P.C.BOABD ASSEMBLIES

Mark PEr-tNo. Symbol & Dercription MErk Parrs No. Symbol & qllrcr.htion

RWX.497 Mother assemblv r RPB-095 Crar head

RWX.498 Jack assembly * RAW-162 Indilator æsemblv

RWF095 Amplifier assembly

RWX-499 lAl

DOLBY NR assembly R KP-353 C N 11 0 2 Gomector socker

RWX-500 M e t e r O r i r æa s s e m b l v

sscmbly {4P)

R KP-352 CNl 103 Connector socket

Switch assembly

tsoltrbly (5Pl

Remote Control assembly

RWS-138 Function Switch assembly

RWX-489 Capstan Motor Control assembly C MoûrerAssembly(RWX-4971

HWX-491

CAPACITORS

Reel Motor Control assembly B

Reel Motor Drive assembly A Merk Pârt No. Symbol & qascdtstaon

coMA 332K 50 c301, c3o2fc3a4.C325

OTHERS cEA 102M50 c334.C335

c E A 4 7 1 M1 6 c341

Mark Part No. Symbol & Description cEA 221M 25 c314,C3151 C3E9

cÊA221M16 æ04, ca46lC301

A * Rrr-239 T1 Power transformer

l120v',t cEA 22tM 6.3 c358 i

- A ** RsA-046 S1 Power switch c E A 1 0 1 M3 5 c336

A BDco22 Power cord cEA 101t{t25

(RDG430) c333. C363

^ c E A 1 0 1 M1 0 C3rf4, C366

a BEC-376 Strain relief RCH-O42 c327

A Rwx-1og cRl Spark killer cEA 470M 10

(RWX_234) cu7,C34'&

caf,6

cEA 330M 16 c3f,2,ca26

** REL-ogl Lamp c E A 2 2 0 M1 6

* RAW-161 Level Meter assembly cEA 220M 10

** RAW_167 s2 Counter c E A 1 0 0 M1 6 c303,c350]rcatll.ca54

A ** REK-osg c368,CaTolcatl

F u s e( 1 . 2 A )

4 ** REK-oss Fuse (2A) CEA R47M50

L * Rxp-1ll

** P l u n g € rs o l e n o i d C E A 2 R 2 M5 0

RXX_333

H e a d a s s e m b t y( R E C / p B ) cEAol0M 50

* RPB094

Erase head C E A 4 R 7 M5 0

C E A R 1 O M5 0

-

35

Downloaded from www.Manualslib.com manuals search engine

Mark Part t\lo. Symbol & Dercription

Mrrk Pqrtl No. Svmbol & DeccriPtion

** 2SC17.!0LN o302-o3p7,o312,O314,O315,

coMA 473K50 c359 0319, 0324-0327, O:t30.0331

{2SC2021}

coMA 1o3Kso c322

(2SC1815)

coMA 182J50 c312,c313

(2SC2634NCl

coMA 103J50 c323

CKDYF479250 c365,c369 ** æc2060 o310,o318

CKDYF1O3z50 c329, c3|:}o'c3/m' c345',C372' (2SC2673)

c373 (2SC1æ3NCl

CKDYB1o2K50 cg'7

ccosL lolK sfl) c319'c32o (1æP/5oo) A ** 2sD88o o311,o313,0316

coPA 182Jloo c321{0'0018/100} (25D313)

cEA 1o2M6.3 c352 ** 25C2497

cEA 220M6.3NP c380 t2sDl18S) 0308. 0309

CEA4TOM16 c32A (2SD8821

RESISTORS * 1s.2473 D3o1-D303, D307-D315,D321,

(usl0401 E|323 D325.D329-D335

resistancewlue

Note: Whenordertrq resistors,conuert the * 1K344 D322

then rewrite the part no' as before'

into code form, and (1K60Al

(0A901

Mrrk Part No. SYmbol & DercriPtion

RcP-l55 VR3OI-VR3O4 Semi-fixed 150k-B

(BIAS ADJI

(BcP-2001 t s3vc10 D317

VRg)s Semi'fixedl'Sk'B À

RCP-I88 A t s3vc10R D316

(OSC LEVEL ADJ/ o318

METAL A t s2vc10F

D320.D326

t WO38

* RCP-Iil VR306 Semi'fixedl00k-B (wo3c)

(RCP-199) (LEADER TAPE

DETECT LEVELI zoæ1

* sz-l2(J

* BZ-081 zoæ2

R303-R307, R315-R343, R345- zDæ3,2D304

RDl/4PMÛOTU

R359, R363-R372, R374, F376-

A t RD5.6EB2

R393, R395, R39?, R398,8400-

R409, R411-R413, R415-R424, S1'VITCHESAND GOILS

R427-R433, R/S4(FR450 S]'mbol & DercriPtion

Mart Prrt No.

R425 8{osistorsnetwork (10k) (B)

RM8.lGIJ.B g'rssistorsnetuork (10k) S3Ol-5303 Pushswitch

R426 t* RSG-126

RM9.1(BJ-B Sæ4 Slide svi'itch

ft RSXO5l

S3O5 Pushwitch (Al

R314, R344 t* RSG-125

RSlPFlOlJ

RDl /2PSF1O2J R380-R362

RTF.O89 L301, L3O2 MPX filter

RDl/2PSF82OJ R373

L3OO OSC coil

RTDO27

RTF.O9O L303, L3O4 Coil (36mH)

L30'5 Line coil

SEMICONDUCTORS RTF.()57

Pan No. Symbol & De:crlPtion

Mark

1c301 OTHERS

MB74Ls122

tHD?4LS122) Part No. Symbol & Doccript'on

i,la]k

(sN74LS122)

RKH.OOS lngrlator wafer

(DM?4LS122) I\

lcæ5 ,ft REE051 lnsulatorwafer

PD6006

lcæ4 RKB.OI8 Terminal(LINE)

ff PAæî0

rc303

il PM3001

1c30s RSS-O33 X4Ol (C4Ol) Ceramicnesonator

** 1R2/mg æsombly

ff M5218L

lcæ2

FU3OI Fuse1'2A

TC4066BP

rc306 a*r REKO59

FU3O2 Fuse2A

(M8840668M) a** BEK.O55

1OP

(HDl4668) Connectorsocket æsembtY

lc307,lcs)8 RKP-347 5P

*t TD62504P éonn."aot socket æsembly

ff 2SA933LN

0301,o317.0320-0323

RKP.348

RBAO39

SPecialscrew

I

t2sA937l

(2SA101s)

(2SA1127NCl

Downloaded from www.Manualslib.com manuals search engine

4 5

NOTE

The indicated semiconductors

tative ones

only. Other alternatiue semicond

be used and

are listed in the parts list.

0602.605,6O6

1X 3 4 a o .

! (60A or

oa 90

tctot PA200_7

SIOI CA!3ETTÉ HIL' DfrECTOF so6 auTo r^É sÊLEcbF

]SLN or 25499 ol

S I02 E F À S EP 8 È N T O E l E C T f i I F * O )

o. 2SA tO!3

s ro! FYoIFEV S!€CIOF

srff €taaE mEvÊrT ÉEClOi {R€Vl

MOTHE R Ar.'y

REEL MOÎOR CONTROL As3'y RWX-49i

Ic 201

PA 2009

1i'!F it3f, eoi

REEL MOTOR ORIVE

TOTHER Arr't

l316-la5 )

I ozoq

2 S CI l 7 !

o205

2SC2q5A

l_

4 5

Downloaded from www.Manualslib.com manuals search engine

7 I I

ternalApprearance

of Transistors

andlCs

\881 .Lot No 2SC2458 PA2010

Lot No

Type No

25C2497 PA2012

rlra

Typq No

2SC2673

Type No/

25D313 PM3001

25D880 H411226

I-

2SC1173

1015 25D8{t2 TC4066BP

r815 M884066BM

2240 Type No

Type No HD140668

MB74LS122

HD74LS122

sN74LS122

DM74LS122

tR24æ

AN6552

844558 -

NJM4558D

P42007 M5218L

PA2009

Type No PA3010

TD62504P

TD62507P

tR2EO2

7 8 I

Downloaded from www.Manualslib.com manuals search engine

2

oOLBY Ais,

MOlHER

{ !06-ln4)

r c 603, 6o4 TC4O66BP o.

HO

tI

rcIER At

IL

t7/al

o2

TOTHER Â..t tatB-l -1At

swt Tc HEs

1 RESISTOFS

SIO1 CASSETTE tsÂlF OETECIOR NO BALF- HALF

Indrcàtd 'n !) iw 5 % r o l ê r a o c €ù n t s o l n e r w r s en o l s k kli sro2 ERAf pRMNI - NO POLE

M MlJ lFl t% lcr D E T E C T O FI F W 6 Æ

2% (K) to%rote,dnce

slo3 M/REV SELECrcR Fwo _ REv

2 CaPACTTOÂS sr@ EFÂ5É pcLvENr oF-€c-op roF.; Èo-E - \o Ho-Ê

5p5 &TO - a P t

I n d r c â t d I n c â p à c { V { o F ) v o r l a g el V l u ^ t 6 3 o r h e r w r E n o r d SELEC-æ !æM_re

D DF 5 1 6 Â U T o . A P E S E L F C- o R / c I A N I \ G

lndcar,on wrhout vora€ 5 50v exceor c@-oN _ M € T A L/ o r F

ererrorylrc caDaclo.

The uhdenind rdicalfr ihe,wtrch F5,rio,

3 VOLTA6Ê

:ll 0c vorr+ r v r a r n o l n D ù rs , e n a l

4 OTHEFS

T h E r s t h e b à s i ce h e m a r r c d r 4 r 6 m b u r r h e

Adiurins æ,nr d(!ar cncuil may vô.y

3 d u e r o r m p r o v e m e n rIjn d 6 q .

The m a * r ù ô d o ô b m e c o m p o n ê n rp . d s , n d E a r 6 r h e

A m

ænace ol lhe etety l*ror ot rhe oâd Thêrelore when r@

kinq

h !.e ro ue Èd3 ot ideni,cat dsignarion

/ ' 1 r t r l r r : L 1 . .r t ; , t , ,

/i,'L rrrllirtr, r

_,

1 2

Downloaded from www.Manualslib.com manuals search engine

9. PAEKING

PartsList

a

Mark No. Part No. Dercdption

1. RHG.437 Packing case

2. RHA.239 Pad

3. RHXO3t Shoot C

4. RR 8 . 1 5 2 Operating instructions

5. RDE.OlO Connection cord

6. RCH-1 9 Styrene paper

Downloaded from www.Manualslib.com manuals search engine

12. ELECTRICALADJUSTMENTS

Precaution

1. Mechanica.ladjustment should be completed.

12.1 DOLBY NR ADJUSTMENT I

Step 1.

2. Clean the following parts with an alcohol

Setting:

moistened swab; Record/Playback head, pinch

roller, Erase head, Rubber belts and Capstan. Mode . .. Record/pause

3. Demagnetizerecord/playback head with a head InputSignal .... 7OOHa-10dBv

(from INPUT) (316mV)

demagnetizer.

4. Do not use magnetized screwdriver for adjust- AC mV meter 1 . . . .. . TP601 of the DOI.BY NR

ments. assembly(L & Rch)

5. Adjustment and measurementsshould be per- AC mV meter 2 . . . . . . TPG}2of the DOI"BY NR

formed for both L-ch and R-ch with rated assembly(L &Rch)

power supply voltage.

6 . Adjustments should be performed in the order

given in this service manual. Altering the order

can hinder proper adjustments,resulting in loss

of performance.

7æHr

7 . Level during measurements are based on l@8!

1 3 1 6 n vI ^hç2

r-J 'l-

OdBv:1V. Connect a 50kO dummy resistor TPbor

\*_i/ |

acrossthe OUTPUT terminals. t\l

lutL_

2 ?dAv -2

8 . Let the CT-7R warrn up (aglng) for a few al

'e!2s^vtl -I trClv

'1!lttrÈ!

minutes before proceeding with the adjust-

ment. Procedure:

L Set the DOLBY NR switch OFF unlessdirect- 1. Adjust the INPUT level control so that the AC

ed otherwise. mV meter 1 reads- 2.2dBv (ZZbmV).

2. Adjust the VR602 so that AC mV rneter 2

reads- 2.2dBv(775mV).

Test Equipment/ToolsRequired;

1. Test tape Step 2.

STD-331A for general playback pur_ Setting:

Mode . . Playback

STD-341A lo"rt"ptuyuu"t adjustment InputSignal .... 7OOHz.-10dBv

STD-608A NORMAL blank tape (316mV) to TPIN of

STD-603 . .'CrO, blank tape the AMP assembly

STD-604 . . METAL blank tape A C m V m e t e r 1 . . . . . . T p 6 0 1o f t h e m L B y N R

2. Audio oscillator assembly(L & Bchi)

3. AC millivoltmeter (AC mV) AC mV meter 2 . . .. . . Tp602 of the DOLBY NR

4. Attenuator assembly(L & BchD

5. Oscilloscope

6. Resistor5OkSl(1/4W)

LEVEL (dB}

o Eg^

-20 TmHz

,\

!tuAv t'vl

l3l6mVl

1OC)sec lO0 sec b0 sec 1OOsec

û

Fig. 12-1 Contents of the test tape STD-341A

Procedure:

1. Adjust the ATT so that the AC mV neter 2

reads- 2.2dBv(Z?bmV).

2. Adjust the VR601 so that the AC mV $eter 1

reads- 2.2dBv(TZbmv).

Downloaded from www.Manualslib.com manuals search engine

Gapstan Conùo! Assembly C (RWX-tf8gl Mark Partr No. Svmbol & Dercraotaon

CAPACITORS coMA 473K50 c213

CKDYF473250 c215

Mark Prrt No. ùmbol & Doæription

coMA 822K50 c101 RESISTORS

CEAR47M50 c104,c114

cEA 100M16 c 1 0 7 ,c l 0 9 Note: When ordering rcsistots, conuert the reeistance ualue

cEA l(x)M25 cl 10 into code form, and then rewrite the part no. as before.

Maûk Part No. ùmbol & Dercript'ron

coMAh73Kt50 c112

coMA 272K50 c103 RCP-OOg VR2OI Sêmi-fjxed22k-B

coMA 273K50 c102 (TOROUEADJ/TAKE-

CKDYF4732æ cî 17 UP)

CKDYF103250 c106,cl I 1 * RCPO56 VR2O2 Semi-fixedl00k-B

C K D Y F1 O 2 Z æ c105 (SPEEDADJ/FF, REWI

RDl/4PMOOBJ R201. R204. R205, R207, R208,

RESISTORS R209

RDl/2PS 1R8J R203

Note: Whenordertng resistors,conuert the resistanceualue

into code form, and then rewrite the part no. as before.

SEMICONDUCTORS

Mrrk Part No. Symbol & Descraption

* RCP{n9 VR101 Semi-fixed 22k€ Mor& Part No. Symbol & Dolcraption

(SPEED) ** PAæO9 tc201

ffi PAæ10 1c202

RDl/4PMtrtrtrJ R 1 0 1 - R î 0 4 ,R 1 0 7 - R 1 1 0

RD1I2PS2R2J R105 2SA934 o201

(2SA881I

** 25D882 4202

SEMICONDUCTORS

(2SC24971

Mlrk Part No. Symbol & Do.criptaon (2SDI 18Érl

** PA2û7 tc101

ffi 2SC24S8 o205

ff PA2012 rc102

ff 2sct173 4204

wo3B D l 0 1 ,D l 0 2

OTHERS

(wo3c)

* 1s.2473 D103 Mark PartNo. Svmbol & Dæcriotion

i Rcx-010 H101, H012 Hall device REE.O51 Insulator

( R C X O1I l RKH.q)s Insulator

(RCXOl2l R8A.026 Screw

(RCXOl3l

slfiflTcHES ReelMotor Drive AssemblyA

Mark Part No. Symbol & Dotcription

Note: When ordering resætors, conuert the resistance value

** RSG-I16 sl 01, sl 02,sl 04-s106 into cod.e fonn, and then rewrite the part no. as before.

Pushsruitcn

slide switch Mark Part No. Symbol & Delcription

** RSH-063 s103

RDl/4PMOtrtrJ R251-R253,R255,R256

ReelMotor Control AssemblyB (RWX-491) * TLN1O4 D251

* RCXO1o H251-H254 Hall device

CAPACITORS (RCX-012t

Mark Part No. Symbol & D€scraPtaon

CKDYF103250 C207

cEA R47M50 c205

cEA 4R7M35 c201-c2m,C212

cEA 2R2M50 c211

cEA101M6R3 c2æ

Downloaded from www.Manualslib.com manuals search engine

1 1 . 4 F F / R E W R O T A T I N G S P E E DA D J U S T M E N T 1 1 . 6T A P E S P E E DA D J U S T M E i I T

1. Connect the frequency counter between FG 1 . Connect the frequency c to the OUT-

of reel motor control assemblv and GND PUT terminal (L or R).

(Fig. 11-5). 2 . Load the STD-301 test set it at the

2 . Set the DIRECTION switch to FORWARD beginningof REW.

and then the mode to FF. 3. Set the DIRECTION switc{ FORWARD

3 . Adjnst VP"2O2 so that the frequency counter and then the mode to PLAY. lr

indicates72Hz t 2Hz. 4. Adjust VR101 so that a of frequency

4 . Set the mode to REW and at this time check counter is 3005 t I0 Hz at beginning of

that a reading of frequency counter is within tape rewinding.

72Hz t 5 Hz. 5. Set the DIRECTION swi REVERSE

Capstan motor control and a reading of frequency ter is within

assemblv 3000t20H2 at the beginn tape rewind-

mg.

Reel motor control Cagstan motor

control

assembly

Connect the

frequency countor

F i g .1 1 - 5 F F l R E WR o t a t i n gs p e e da d l u s t m e n t

F i g .1 1 - 7 T a p es p e e d

1 1 . 5T A K E - U P T O R O U E A D J U S T M E N T

1. Mount a cassettetype torque meter.

2. Set the DIRECTION switch to FORWARD

and then the mode to PLAY. 11,7 FAST TOROUECHECK,r

3. Adjust VR201 so that the take-up torque is

1. Mount a cassettetype torque r.

45 t 5 g-cm (Fig. 11-5).

2. Set the DIRECTION swi FORWARD

4. Set the DIRECTION switch to REVERSE. I

and then the mode to FF.

5. Check that the take-up torque is within

3. Check that the FAST torqu$ within 100 t

45 I 10 g-cm (Fig. 11-6).

30 g-cm in the condition in above 2.

4. Set the mode to REW and [t time check

that the FAST torque is witffin 00 t 39 g-"-.

1 1 . 8 R E E L B A S EB A C KT E TOROUE

CHECK l

1 . Mount a cassettetype torq

I Set the DIRECTION switch RWARD and

then the mode to PLAY.

3 . At this time. check that the tension on a

supply reel side (left reel bd$e within 3.5 t

1.5 g-cm.

4 . Set the DIRECTION swi REVERSE.

F i g .1 1 - 6 T a k e - u pt o r q u ea d i u s t m e n l 5 . At this time. check that tension on

the supply reel side (right base) is within

3.5 t 1.5g-cm.

Downloaded from www.Manualslib.com manuals search engine

1 1 . MECHANICAL ADJUSTMENTS

11.1 PTNCHROLLER PRESSURECHECK

1. Put the tape deck into the playback mode

(FORWARD and REVERSE).

2. Gently push against the pinch roller arm with

the tension gauge (Part No. GGK-047) and

read the value when the pinch roller stops

rorating. If the reading fails to lie within

25O - 4009, replace the pinch roller pressure

spring.

Fig. 11-3 Azimuth Preadjustment

11.3 TAPE TRANSPORT ADJUSTMENT

Tension gauç

(PartNo. GGK{47}

1. Load a mirror-equipped cassettehalf.

2. Set the DIRECTION switch to FORWARD and

then the mode to PLAY.

3. Adjust the adjust nut Q so that no curling

I

takes place on REC/PB head guide and erase

head guide as shown in Fig. 11'4.

4. Set the DIRECTION switch to REVERSE.

5. Adjust the adjust nut @ so that no curling

occurs on REC/PB head guide and dummy

head guide.

6. Play a tape in both FORWARD and REVERSE

directions and check that no curling on tape

Eraæ head

is found.

Fig. 11-1 Pinchroller pressure

adjustment

1 1.2 AZIMUTH PREADJUSTMENT

1. Set the DIRECTION switch to FORWARD and

then the mode to STOP.

2. Adjust the azimuth screw O using a (- )

screwdriver as shown in F.lg. I7'2,3 so that the

distance (A) between housing and rotating

baseis 1.5 mm.

3. Set the DIRECTION switch to REVERSE.

4. Adjust the azimuth screw @ using a (- )

screwdriver as shown in Fig. 1L-2,3 so that the

distance (B) between housing and rotating base

is 1.5 mm.

Rotating base

a

.à

'+

1 . 5m m

3^

1 . 5m m

Housing

@ n e v Q rwo Fig. 11-4 Tapetransportadjustment

Fig. 11-2 Azimuth adjustmentpoint

Downloaded from www.Manualslib.com manuals search engine

1 2 . 6 E R A S U R EC U R R E N TA D J U S T M E N T

INPUT

The adjustment procedure is the same for both the FllD

€-

and REV directions, but if there is a difference between the

333az

two indications, adjust so that the lower of the two erasure 6.3kHz / - \

current indicatiotæ is t 80mV lon,^V ft8v

(3l6mV)

,. " /'

-

Setting:

Mode .... Record

rever +rdB :ù

INPUT Level Control . . . Min. 5dE

AC mV meter . . . . TP301 of the Mother

assembly d

Po'

Testtape .. STD-604

ri

I

#'1J

Procedure:

1. Adjust the INPUT level so tàat the

AC mV meter reads- 27dBv ( v).

2. Set the CT-?R to the FWD and record

and playback the input (333H2 and

6.3kHz) onto the Adjust the

Procedure: VR301 (Lch) and VR303 ( ) so that the

1. Set the CT-?R to the FWD position and

adjust the VR305 so that the AC mV meter difference between two is +1 s dB'

reads180mV. 3. Likewise. set the CT-?R to REV position

2. Likewise, set the CT-?R to the REV position and record and playback input signals

(333H2 and 6.3kHz) onto e STD-608A.

and confirm that AC mV meter reads 180mV

*0 mV. Then adjust the VR302 ( and VR304

-40 (Rch) so that the diffe ou@uts is

+1dBlô5dB.

12.7 RECORDING/PLAYBACFK

REOUENCY * As listed in the specifications Fig. 12-5 and

RESPONSE

ADJUSTMENT check to see that perf specifica-

Setting: tions.

Mode . .. .. Record

Record/Playback Frequency Response

Input Signal 333H2.- 30dBv Using STD-331A with DOLBY NR O

(from INPLIT) (31.6mV) Houeue\ the ight channel is co ed by -ldB ot

6.3kHz, - 30dBv 63H2, ond -0.5d8 at 125H2 b the insulation

(31.6mV) effect.

Test tape STD-608A

AC mV meter OUTPU'I terminals

u.lr.,rJ". .s1".,*1".

OverallFrequencyResponse

UsingSTD-6OBA

with DOLBYNR O

63Hz 125H2

Downloaded from www.Manualslib.com manuals search engine

U"i"cSîD-6ô8AwithDOLBVNRoN (B tvpe) Ueing S?D-604 with DOLBY NR OFF

6ixz t25xz 333n2 2ki{z lokHz

LJsingSTD-608A with DOLBY NR ON (C tvpe) IJsingSTD-604 with DOLBY NB ON (B type)

1k H z

2kHz

UsingSTD-603withDOLBY NR OFF

tlsing STD-604 with DOLBy Nn ON (C type)

I

3dB

63Hz 125H2 333H2 lkHz

tlsing STD-603 with DOLBYNA ON @ tvpe) Fig. 12-5 Frequency response

12.8 RECORDINGLEVEL ADJUSTMENT

Mode. .... Record

Record/Playback

Input Srgnal 333H2,- 10dBv

63Hz 125H2 333H2 lkHz 12 (316mV)

(from INPUT)

Test tape . . STD-608A(NORM)

STD-603(CrOz)

using STD'603 with DOLBYNR ON (C type)

sTD-604 (METAL)

AC mV meter TP601of the DOLBY

NR assemblyL

TP601of the DOLBY

NR assemblyR

333H!

-l6av

t3r6mvl

Downloaded from www.Manualslib.com manuals search engine

Step 3. Procedure:

Setting: Play a tape in both forward reverse direc-

Mode . Record/Pause tions. Adjust the head azimuth to the posi-

Input Signal 7OOHz,- 40dBv tion of maximum output level.

(from INPUT) (1OmV)

AC mV meter TP603 of the DOLBY NR ENT

12.3 TAPE TRANSPORT

assembly

1. Load a mirror-equipped casse f.

2. Set the DIRECTION switch RWARD and

then the mode to PLAY.

3. Adjust the adjust nut l) no curling

-- takes place on REC/PB h and erase

head guide as shown in Fig. 1

f æHz

4GBv Â\ 4. Set the DIRECTION switch VERSE.

I 1o m v )

Y 5 . Adjust the adjust nut @ t no curling

occurs on REC/PB head and erase

head guide.

6 . Play a tape in both FORWA d REVERSE

Procedure: directions and check that no g on tape rs

1 . Adjust the INPUT level control so that the found.

AC mV meter reads- 32.6dBv (23.4mV).

2. Set the DOLBY NR switch ON, and C type Capstan

position.

3 . Adjust the VR603 so that the AC mV meter

reads- 21.6dBv (83mV).

12.2 HEAD AZIMUTH ADJUSTMENT

Setting:

Mode . Playback

(FWD and REV)

Test tape STD-3414, 10kHz

portion

AC mV meter OUTPUT terminals

vR501, VR502 Max.

9r

Screwdriver

50k1r ^

3 (t'v

? \ /Mà'

v-

Fig. 12-3 Tapetransportadj

12.4 PLAYBACKLEVEL NT

Since this adjustment determ the DOLBY

NR level during playback, it sho performed

precisely.

Setting:

Mode . Play wD)

Test tape STD-3 333H2OdB

portion

AC mV meter TP601 DOLBY

NR L

FiS.12.2 Azimuth preadjustment TP6Ol DOLBY

NR R

Downloaded from www.Manualslib.com manuals search engine

12.5 PLAYBACKEOUALIZERCHECK

Setting:

{

Mode Playback (FWD and

REV)

Test tape STD-341A,333H2 and

6.3kHz portions

AC mV meter OUTPUT terminals

Procedure:

Adjust the VRb01 (Lch) and VR5O2 (Rch)

of

the AMP assembly so that the AC mV

- meter

reads 7.2dBv (8Z1mV).

Procedure:

Play the 3B3Hz and 6.BkHz portions of the

test

tape. Check that the difference between the

two

output levelsdoes not exceed +0.bdBr2dB.

ys5g3 TP6O3

AMP assembly

VR5O2 (Rchl

P.B. levet adj.

DolbyNRassembly (Lchl

Dolby NR assembty(Rchl

rP6ogi

VRSOI (Lchl

P.B.tevetddi.

Fig. 12-4 Adjustment points

Downloaded from www.Manualslib.com manuals search engine

Procedure:

1. Set the test tane adjust the

NP U T INPLIT level control so that C mV meter

€ reads - 5.2dBv (549mV).

2. Set the DOLBY NR switch ON position.

Set the CT-7R to the position and

record and playback the i nal onto the

rn STD-608A. Adjust the V (Lch) and

VR604 (Rch) so that the A meter reads

- 5.2dBv(549mV).

3. Set the test tape STD-603 I DOLBY NR

OUTPUT

switch to the ON positioni record and

)

playback the input signal e STD-603.

Confirm that the AC mV r - 5.2dBvt

1.5d8 (653mV - 462mV).

4. Set the test tape STD-604 DOLBY NR

switch to the ON position and play-

back the input signal sTD-604.

Confirm that the AC mV r - 5.2dBvt

1 . 5 d B( 6 5 3 m V- 4 6 2 m V ) .

Dolbv

assembly

Dolby

assembly

F i g . ' 1 2 - 6A d j u s t m e npt o i n t s

Downloaded from www.Manualslib.com manuals search engine

12.9 LEVEL METER CHECK Step 2.

Setting:

MODE Record pause

Setting:

Mode Playback

I

Input signal 333H2, - 10dBv Tape . Cassette half without

(from INPUT) (316mV) tape

AC mV meter TP601 of the DOLBY AC mV meter TP302 of the Mother

NR assemblyL assembly

TP601 of the DOLBY

NR assembly R

333H2

-lfrBv

{316mvl

Procedure:

Adjust the INPUT level control so that the level

Procedure:

1. Confirm that the AC mV meter reads - 10dBv

(0.6V P-P squarewave).

2.If l- 10dBv is exceeded,bridge the section shown

I

meter reads 0 VU. Then check the AC mV meter in Fig. 12-7 by soldering.

reads- 5.2dBvt2dB.

Soldering point

12.10. LEADER TAPE DETECT ADJUSTMENT

Step 1.

Setting:

Mode . Stop

Input Slgnal 2kHz, - 17dBv (0.4V P-P

Sin wave) to TP302 of

the Mother assembly

DC mV meter TP303 of the Mother

assembly

Procedure:

1. Remove the connector cN315 of the Mother

assembly.

2. Adjust the VR306 so that the DC mV meter

reads10.5V10.25V.

3. Return the connector cN315 to the original

position.

Downloaded from www.Manualslib.com manuals search engine

12. RÉcLAGES

ÉlecrRtouEs

Précautions 12 .1 R ÉCU C e D U C IR CU |TD qLB Y N R

1. Les réglagesmécaniquesdoivent être terminés. Etape1.

2. Nettoyer les pièces suivantes à I'aide d'un

Montaç:

bâtonnet imbibé d'alcool: tête d'enregistre-

Mode Enregistfrrent/pause

ment/lecture, galet presseur,tête d'effacement,

Signald'entrée . .. . :. : : 700H2, - [OdBv

courroies en caoutchouc et cabestan. (de INP[/I) (316mV)

3. Démagnétiserla tête d'enregistrement/lectureà

Millivoltmètre . . . TP601 d(ll'ensemble

I'aide d'un démagnétiseurde tête.

alternatif 1 Dolby Nt

4. Ne pas utiliser de toumeyis magnétisépour les

(Canatu<fle gaucheet de

réglages.

droite)

5. Les réglageset les mesuresdoivent être réalisés

Millivoltmètre. . . TP602 dtll'ensemble

pour les canaux de gauche et de droite avec la

lalternatif 2 Dolby Nt

tension d'alimentation nominale.

(canarn ft gaucheet de

6 . Les réglages doivent être effectués dans I'ordre

droite) 1

indiqué dans ce manuel de service. Une modifi-

cation de cet ordre peut empêcher la réalisation

de réglages corrects et peut provoquer une Ent* {INPUT)

baisse de performance. -€ -

t1

a. Les niveaux en cours de mesure sont basés sur

OdBv = 1V. Raccorder une charge fictive de

7æHz

tftB, i_.,1 Voltdt.. I

1 3 r o m v ,\ 7 ^

50 kS, entre les bornes de sortie (OUTPUT). J .'\4

\-/'"ooi

8 . Laisser chauffer (vieillissement) le CT-?R 111

pendant quelques minutes avant de procéder

aux réglages. Procédure:

9. Placer le commutateur DOLBY NR sur OFF

1. Régler la commande de niveau dl'entréeINPLIT

sauf indication contraire.

Equipements/outilsd'esai requis

1. Banded'essai

STD-331A Pour la reproduction

générale.

STD-341A Pour Ie réglagede Ia Etape 2.

reproduction Montage:

STD.6O8A Bande"NORMAL" Mode ... Lectuæ

vlerge Signald'entrée ..200H4-fiOaev

STD-603 ... .. Bande"CrO2"vierge (316mV) [ TPIN de

STD-604 Bande "METAL" vierge I'ense6bllf AMP.

2 . OscillateurBF Millivoltmètre... . TP60ldql'ensemble

3 . Millivoltmètre altematif (mV CA) altematif 1 Dolby NS

4 . Atténuateur (canaux ft gaucheet de

5 . Oscilloscope droite)

6 . Résistance50 kSt (ll4W) Millivoltmètre... . TP602ddll'ensemble

altematif 2 Dolby NS

(canaux dt gaucheet de

N i v e a u( d B l

droite)

0

-20

Tal. d 6rq,nrc'rFr

100 sec 100 sec 50 sec 100 sec F;-ls" t,

t\

3l6mv i

/-)\vorrdk.2

Fig. 12-1 C o n t e n u d e l a b a n d ed ' e s s a S

i TD-341A v{

-:_

2 2dqr

2 lls^v

Downloaded from www.Manualslib.com manuals search engine

Procddure: Procédure:

Lire la bande en sens avant et en sens arrière'

1. Régler ATT de manière à ce que le millivolt'

mèire alternatif 2 indique

-2'2dBv (775mV)' Régler la vis d'azimut de tête sur la position

donnant le niveau de sortie maximum'

2. Régler VR601 de manière à ce que -2,2dBv

le milli-

uoù-ètt" alternatif 1 indique

(775mV). 12.3 NÉCUEE DE L'ENTRAINEMENT

Etape 3. DE LA BANDE

Montaç: 1 . Charger une demi'cassette munie d'un miroir'

Mode Enregistrement/Pause 2. Placer le commutateur de DIRECTION sur la

... position FOR\IIARD (avant) et le mode sur

Signald'entre 7OOHz,-40dBv

(de INPUT) (10 mV)

Miilivoltmètre ... TP603del'ensemble 3.

alternatif DolbY NR

4. Placer le commutateur de DIRECTION sur la

o. I

Procédure: ment.

1. Régler la commande de niveau d'entÉe INPUT 6. Faire défiler une bande en avant (FORWARD)

de manière à ce que le millivoltmètre CA et en a.rrière (REVERSE) et vérifier qu'aucune

indique -32,6d8v (23'4 mV)' ondulation ne se Produit.

2. Enclàncher le circuit Dolby NR (ON) et le

régler sur la Position C.

3. Ràgter VR6O3 de manière à ce que le millivolt-

mètle alternatif indique -21,6dBv (83 mV)'

DE rÊre

1z.z nÉclece DE L'AZIMUT

Montage:

Mode. .... Lecture(FWDetREV)

Banded'essai .... STD'841A,partiede

10kHz

Millivoltmètre . . . Bornesde sortie

alternatif OUTPUT

Maximum

$NI' {OUTPUTI

Fig. 12-3 Régtage de l'entraînement de la bande

12.4 RÉCIECE DU NIVEAU DE LECTURE

Ce réglagedoit être effectué avecprécision car il

détermine le niveauDolby NR pendant la lecture'

I

FiS. 12-2 d'azimut

Préréglage

Downloaded from www.Manualslib.com manuals search engine

11. REGLAGES

MECANIOUES

r.r coNTnôleoe LA PRESSIONDU GALET.

FRESSEUR

1. Régler la platine de magnétophonesur le mode

de reproduction [Avant (FORWARD) et In_

verse(REVERSE)].

2. Pousser doucement sur le bras du galet_pres_ @

REV

seur avec I'indicateur de tension (pièce no

GGK-047) et observer le niveau de I'indicateur

de tension lorsque le galet-presseur arrêt

à

tourner. Remplacer le ressort de pression du Fig. 1 | -3 Préréglage

de I'az

galet-presseur lorsque la lecture de f indicateur

1 1 . 3 R E G L A G ED ' E N T R A I N E

de tension est inférieirre à 250t400 g.

BANDE

1 . Chargerune cassetteà miroir.

2 . Régler le commutateur DI N sur FOR-

WARD et la position de f

PLAY.

I n d i c a t e u rd e t e n s i o n

( P i è c en o G G K - 0 4 7 1 3. Régler l'écron de réglage Q

ne s'enroule pas sur le gui la tête de

reproduction /enregistrement le guide de

la tête d'effacement comme iqué sur la

Fig.77-4.

4. Régler Ie commutateur ION sur

REVERSE.

a 5. Régler l'écrou de réglage @

ne s'enroule pas sur le

reproduction/enregistrement

la tête de

le guide de

Téæ d'effacement la tête factice.

F i g .11 - 1 R é g l a gdee l a p r e s s i odnu g a l e t _ p r e s s e u r

6. Faire défiler une bande sens avant

(FORWARD) et dans le verse (RE-

VERSE) et s'assurerque la ne pÉsente

1 1 . 2 P N É N É C U G ED E L ' A Z I M U T pas d'ondulations.

1. Régler le commutateur DIRECTION sur

FORWARD et la position de fonctionnement

surSTOP.

2.

3. C a s s e t t eà m i r o i r

4.

@E@

Tête de reproduction/

I

F i g . 1 1 - 2 N i v e a ud e r é g l a gdee l . a z i m u t Fig. 11-4 Réglage

d'entra la bande

49

Downloaded from www.Manualslib.com manuals search engine

11.4 REGLAGE DE LA VITESSE DE ROTA- 11.6 REGLAGE DE LA VITESSEDE LA BANDE

TION D'AVANCE RAPIDE ET DE l. Raccorder le fréquencemètre à la borne OUT-

REBOBINAGEDE LA BANDE {

PUT (L ou R).

1. Raccorder le fréquencemètre entre FG du 2. Introduire la bande d'essai STD-901, le début

moteur d'entraînement du mécanisme de de la bande étant dirigé dans le sens inverse.

bobinage et GND (Fig. 11-b). 3. Régler le commutateur DIRECTION sur

2. Régler le commutateur DIRECTION sur FOR\ryARD et le mode de fonctionnement sur

FORIryARD et le mode de fonctionnement sur PLAY.

FF (avance rapide). 4. Régler le VR101 de manière à ce que le fré-

3. Régler le VR202 de manière à ce que le fré- quencemètre indique 3005ttOgz au début du

quencemètreindique 12Hz ! 2Hz. rebobinage de la bande.

4. Régler le mode de fonctionnement zur REW 5. Régler le commutateur DIRECTION sur

et vérifier alors que I'indication du fréquece- REVERSE. Le fréquencemètre doit indiquer

mètre n'est pas supérieureà? 2Hzt1Hz. 3000 t 2OHz au début du rebobinage de la

Moteurd'entraînementdu bande.

Moteurdtntrainement du cabestanMoteur

d'entrainement

I

du mécanisme

de bobinæe

Fig. 11-7 Réglagede la vitessede la bande

Fig. 11-5 Réglagede la vitessede rotationd'avancerapide

et de rebobinagede la bande 11.7 VERIFICATION DU COUPLERAPIDE

1 1 . 5 R É G L A G ED U C O U P L ED ' E N R O U L E M E N T 1. Introduire un dynamomètre à cassette.

1. Introduire un dynamomètre a cassette. 2. Régler le commutateur DIRECTION sur

2. Régler le commutateur DIRECTION sur FORIryARD et le mode de fonctionnement sur

FORWARD et le mode de fonctionnement sur FF (avancerapide).

PLAY. 3. Vérifier si le couple rapide (FAST) est égal

3. Régler le VR201 de manière à ce que le couple à 100 t 30 g-cm lorsque I'appareil est réglé

d'enroulement soit égal à 45 t b g-cm. de la manière indiquée ei-dessus dans le

(Fig. 11-5). chapitre 2.

4. Régler le commutateur DIRECTION sur 4. Régler le mode de fonctionnement sur REI{

REVERSE. et vérifier si le couple rapide (FAST) est égal

5. Vérifier si le couple d'enroulement est égal à 100 t 30 g-cm.

à 45 t 10 g-cm(Fig.11-6).

11.8 NÉCIECE DU COUPLE DE TENSION

Dynamomètre

INVERSE DU SUPPORT DE DE BOBINE

1. Introduire un dynamomètre à cassette.

2. Régler le commutateur DIRECTION sur

FORWARD et le mode de fonctionnement sur

PLAY.

3. Vérifier alors si la tension inverse sur la bobine

dérouleuse gauche (support de bobine gauche)

est égaleà 3,5 t 1,5 g-cm.

4. Régler le commutateur DIRECTION sur

REVERSE.

5. Vérifier alors si la tension inverse sur Ia bobine

dérouleuse droite (support de bobine droit)

Fig. 11-6 Réglage

du coupled'enroulement est égaleà 3,5 t 1,5 g-em.

Downloaded from www.Manualslib.com manuals search engine

Montage: 12.5 CONTRÔLEDE L'E RDE

Mode. .....Lecture(avant(FwD)) LECTURE

Banded'essai .... STD-341A,partiede Montage:

333H2, OdB Mode ant (FWD)

Millivoltmètre .. . TP601 de I'ensemble ))

alternatif Dolby NR de gauche Bande d'essai parties de

(L) 333 6,3kHz

TP601 de I'ensemble Millivoltmètre . . .

Dolby NR de droite (ouT

(R)

va$l tùd ô Ftu {L})

VR5O2{ùd ô drois (Rll

Procédure:

Régler VR501 (canal de gauche) et VR502 Procédure:

(canal de droite) de I'ensembleAMP, de mianière à Lire les parties 333H2 et 6 de la bande

- d'essai. Vérifier que la dif.fé ntre les deux

ce que le millivoltmètre altematif indique 1,2dBv

(871mV). niveaux de sortie ne dépassepas B rzdB.

TP6trI

ys5s3 TP6O3

o

Ensemble AMP

\Ensemble (L)

oiruv run (canalde grauche E n s e m b l eD o l b y de droite (R)f

VR501 (canat de

Réglage du

Fig. 12-4 Pointsde réglage

53

Downloaded from www.Manualslib.com manuals search engine

',2.6 nÉalncr DU couRANT

Téb d'enq'.tcmsnt

D'EFFACEMENT

La procédure de réglage est la même daræ les deux

directions, auant (FWD) et arrière (REV),.mris les deux

valeurs indiquées sont différentes. Le réglage doit être

effectué de manière à ce que le plus faible des deux cou-

rants d'effacement soit de I SOtV+ OOO

mV.

erÉG. Niwau 6,3kHz - niwau g3Hz = +tdB :

;.rdB

d Fp=ql

)

FWù VR30l lcoôl gâuds lLll

sÉnio louTPuT)

VRAn3 (Cs€l dro't (Rl)

REV

vR@

vRS)4

{cmd

lhd

@dê

drdt lBl)

lL}l

,tj J

Montage: Proédure:

Mode Enregistrement 1. Régler le niveau d'entrée (INPUT) de manière

Réglage du niveau à ce que le millivoltmètre alternatif indique

d'entrée (INPUT) . . . . Minimum -27dBv (44,6mV).

Millivoltmètre 2. Placer le CT-7R en position de défilement

altematif TP301 de I'ensemble avant (F\[D) puis enregistrer et lire les signaux

principal d'entrée (333H2 et, 6,3kHz) sur STD-OOBA.

Banded'essai .... STD€04 Régler VR301 (canal de gauche(L)) et VRgOg

Procédure: (canal de droite (R)), de manière à ce que la

1. Régler le CT-?R sur la position de défilement différence entre les deux soit de +1dB

avant (F\ryD) et régler VR305 de manière à lf,ude.

ce que le millivoltmètre alternatif indique

180mV. 3. De la même manière, placer le CT-?R en posi-

2. De la même manière, régler le CT-?R sur la tion de défilement arrière (REV) puis enre-

position de défilement arrière (REV) et vérifier gistrer les signaux d'entrée (333H2 et G,BkHz)

que le millivoltmètre altematif indique 180mV sur STD-608A. Régler VR-302 (canal de

*0 mV. gauche (L)) et VR304 (canal de droite (R)),

-40 de manière à ce que la différence entre les

deux sorties soit de +ldBlâ,5d8.

12.7 NÉCIECE DE LA REPONSE EN

* Comme indiqué dans les spécifications de la

F R E O U E N C ED ' E N R E GI S T R E M E N T /

LECTURE Fig. l2-5, et vérifier que les performances

Montaç: conespondent aux spécifications.

Mode Enregistrement Réponseen fréquence

Enregistrement[ecture Utilistion de STD-331A,avecDolby NR DECLENCHE

Signal d'entree A cause de l'effet d'isolement, le canal de droite est com-

pensé de - ldB ,à 63Hz et de -O,6dB à I25Hz.

(à INPUT) 333H2, -30dBv

(31,6mV)

6,3kHz,30dBv

(31,6mV)

Banded'essai .... STD-608A

Millivoltmètre

alternatif .....Bomesdesortie Réponseen fréquenceglobale

(ouTPUT) Utilistion de STD-608A, avecDolby NR DECLENCHE

!.û& {lNPUTl

t

T 63Hz 125H2 333H2 2kHz 6,3kHz 1

ùj

Downloaded from www.Manualslib.com manuals search engine

1 1. AJUSTESMECANICOS

1 1 . 1 C O M P R O B A C I ODNE L A P R E S I O N

DEL

I

R O D I L L OD E P R E S I Ô N

1. Establecer el magnetôfono en el modo de

reproduciôn [Avance (FORWARD) y Rebo-

binado (REVERSE)].

2. Presionar con cuidado contra el brazo del

rodillo de presiôn con el calibrador de tensiôn

(pieza nrimero GGK-047) y leer el valor cuando

el rodillo de presiôn para a girar. Si el valor no

estâ dentro del margen de 250-4009., re-

cambiar el meulle del rodillo de presi6n. F i g . 1 1 - 3 P r e a j u s t ed e l a c i m u t

1 1 . 3 A J U S T ED E L T R A N S P O R T D

EE

CINTA

1 . Insertar un caseteprovisto de espejo.

2 . Ponerel selectorde DIRECTION en n

FORWARD y el de modo en la posic Y.

3 . Ajustar el tomillo de ajuste O a" que

no haya enrollamiento en la qufa de

de GRAB/REPROD y gufa de la de

borrado como se muestra en la 11-4.

4 . Poner el selector de DIRECTION en

REVERSE.

5 . Ajustar el tomillo de ajuste O a" que

no haya enrollamiento en la gufa de

Cabezade borrado

de GRAB/REPROD y gufa de la ticia.