Professional Documents

Culture Documents

Meccanica Gervasoni Welding Procedures

Uploaded by

Arun JaffersonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Meccanica Gervasoni Welding Procedures

Uploaded by

Arun JaffersonCopyright:

Available Formats

ORTON DOCUMENT No.

D-OR2240061-E-738

MECCANICA GERVASONI WELDING PROCEDURES FOR ALLOY 625

DOCUMENT TITLE

REPAIRS

CUSTOMER NAME CCI ITALY S.R.L.

PROJECT NAME NORTH FIELD EXPANSION PROJECT (NFXP)

CUST. P.O. NUMBER 722030

ORTON IWO No. OR2240061

CUSTOMER DOCUMENT No. 4665_19-17210200201-00245

1 APPROVED

2 REVIEWED WITH MINOR COMMENTS

REVIEWED WITH COMMENTS

3 REVISE AND RESUBMIT

4 REJECTED

5 FOR INFORMATION ONLY

BY:

DATE:

Rev Date Page Description Prpd Chkd Appd

0 22/12/2023 1 of 202 Issued for review A.Codini E.Sartori A.Fracchioni

THIS DOCUMENT AND THE DATA DISCLOSED HEREIN OR HEREWITH IS NOT TO BE REPRODUCED,

USED OR DISCLOSED IN WHOLE OR IN PART TO ANYONE WITHOUT THE PERMISSION OF ORTON s.r.l.

Orton S.r.l. | Via Dei Bazachi, 50 - Piacenza - 29121 Piacenza (PC)

Tel. +39 0523 762 511 / Fax. +39 0523 762 512 | www.ortonvalve.com

Orton S.r.l. | Via Grilli 2/A, San Nicolò a Trebbia -Rottofreno- 29010 (PC)

Tel. +39 0523 766 111 | www.imi-critical.com

4665_19-17210200201-00245 Rev.B 3 of 204

Index

Subject Page

WPS No. CRO/100/A 3 of 202

PQR No. LD0033/23 (CRA WO repair without PWHT) 5 of 202

WPS No. CRO/101/A 77 of 202

PQR No. LD0034/23 (CRA WO repair with PWHT) 79 of 202

4665_19-17210200201-00245 Rev.B 4 of 204

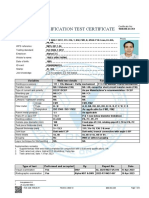

IIS Job / Comm. N. C00015257/01

Welding Procedure WPS-n° CRO/100/A Rev. 0

Specification Date 12/12/2023

Via dell’Industria,21 ASME Section IX (2023)

24010 LENNA (BG) & Project Spec.NFEO-MCD-QM-SPC-00017 Supp. PQR-n° LD0033/23

Welding Process(es) a) GTAW (With high frequency arc starting equipment) b)

Type(s) a) Manual b)

JOINTS (QW-402)

Joint Design Corrosion Resistant Overlay – Inconel 625 to inconel 625 repair Retainers NA

Backing/Material (Type) a) Yes – Weld Metal

BASE METAL (QW-403) (QW-402)

P number – Group number 1-2

Specification – Grade SA-694 F65 (See other) clad acc.to

WPS CRO/99/A

Chemical Anal. & Mech. Prop. --

Base metal thickness (mm) ≥25 + WMO ≥5,5 (T+t)

Base metal fillet (mm) NA

Pipe diameter (mm) NA

to

P number – Group number NA - NA

Specification – Grade NA

Chemical Anal. & Mech. Prop. NA

Base metal groove (mm) NA α≥30°; T≥25; t≥5,5 (After machining); A (Excavation width)≥5; H≥1,5 above

Base metal fillet (mm) NA approximate weld interface; (mm); Minimum two (2) passes; Corner radius

Pipe diameter (mm) NA concerning lead in/lead out angle ≥ 2(mm); Overlapping of beads: from 1/3

to 1/2 of bead width; Refer to Other of QW-410 for dimensional check of

Other C%=0,199÷0,239;Ceq=0,396÷0,456; exacavation;

FILLER METAL (QW-404) a) b)

Specification number (SFA) 5.14

AWS number (Class) ERNiCrMo-3

F-No. 43

A-No. NONE

Size of filler metal (mm) 2,4

Filler metal trade name Thermanit 625 (See Other)

Consum insert NA

Product form Bare, solid

Manufacturer VOESTALPINE

Thk of overlay layer(s) (mm)) Up to filling the excavation

Thk range fillet (mm) NA

a) b)

Flux trade name NA

Alloy flux NA

Alloy elements NA

Supplemental filler metal NA

Manufacturer NA

Electr. Flux (Classification) NA

Recrushed slag NA

Other Heat: 106287 - PREN 51,8; C ≤ 0,03%; Minimum Nb/C ratio ≥ 347;

POSITIONS (QW-405)

Position(s) of groove FLAT

Welding Progression NA

Position(s) of fillet NA

Other NONE

PREHEAT (QW-406)

Preheat Temperature (°C) 20 - Preheat temperature shall be measured at 75 (mm) from the weld

Interpass Temperature (°C) 175 - Interpass temperature shall be measured on the bead just before welding restart

Preheat maintenance (h) NONE

Other Preheat and interpass shall be checked by digital contact thermometer in order to verify temperature uniformity;

Mod. CSP 002 rev. 4 Sheet 1/2

4665_19-17210200201-00245 Rev.B 5 of 204

IIS Job / Comm. N. C00015257/01

Welding Procedure WPS-n° CRO/100/A Rev. 0

Specification Date 12/12/2023

Via dell’Industria,21 ASME Section IX (2023)

24010 LENNA (BG) & Project Spec.NFEO-MCD-QM-SPC-00017 Supp. PQR-n° LD0033/23

PWHT (QW-407)

Temp. Range (°C) NA Time Range (h) NA

Heat rate (°C/h) NA Cool rate (°C/h) NA

Other NONE

GAS (QW-408) Percent Composition Gas(es) Flow rate (l/min)

Plasma NA NA

Shielding process a) SG-A (99,999%) 14÷20

Shielding process b) NA NA

Trailing NONE NA

Backing NA NA

GAS for OFW NA NA

Other NONE

ELECTRICAL CHARACTERISTICS (QW-409) a) b)

Current DC

Polarity EN

Mode of Met. Transf. (for GMAW) NA

Tungst. Electr. Type & Size SFA 5.12 EWTh-2 Diam. 3,2 (mm)

Electr. wire feed speed range NA

Other NONE

TECHNIQUE (QW-410)

String or Weave Bead Root pass: string – Filling passes: weave with max amplitude two (2) bare electrode

Orifice or Gas Cup Size 8÷12 (mm)

Initial & Interpass Clean. Grinding and/or brushing and/or machining (*)

Method of Back Gouging NA

Contact Tube to Work Dist. NA

Multiple/Single pass per Side Multiple Electrode spacing NA

Multiple/Single Electrodes Single Peening NONE

t pass < ½” NA Use of thermal processes NONE

Sup. Powder NA Close to out chamber NA

Other (*)Only stainless brushes and tools shall be used; Grinding disk sulphur free; QW-410.52: in front of the torch

Filler metal Current Travel Speed

Weld Welding Volt Range Heat Input

AWS Class. or Size (mm) Type & Polarity Ampere Range Range

Pass Process (kJ/mm)

Trade Name 1E 2E 1E 2E 1E 2E 1E 2E (mm/min)

1 GTAW ERNiCrMo-3 2,4 -- DCEN -- 160÷175 -- 12÷13 -- 95÷105 1,1÷1,44

2÷n GTAW ERNiCrMo-3 2,4 -- DCEN -- 160÷170 -- 12÷14 -- 90÷100 1,15÷1,59

Other: - Liquid Penetrant test shall be carried out after defect removal and after repair completion; Cosmetic grinding is permissible; Minimum

thickness of weld overlay shall be measured after grinding ensure minimum clad requirement are met

- Surface to be welded shall be clean and free from paint, oil, dirt, oxides and other detrimental to welding

- In case of any grinding is required at start/stop overlay locations prior to commenced next overlay bead, the overlaid area shall be

protected to ensure that any risk of cross contamination generated by the grinding operation of carbon/clad interface are completely

eliminated

- Excavation obtained by machining or grinding – Excavation depth shall be measured using a calibrated depth gouge

- The removed portion area by grinding or machining shall be sufficiently deep and long to remove the defect but not less than 1,5 time

the rod diameter used

- Everywhere indicated “grinding”, only SS grinding discs, sulphur free suitable for alloy 625 shall be employed

- Acceptable range for PREN of welding consumable: 51,8÷61,8;

- H.I. calculation formula according to ASME BPVC, Section IX, QW-409.1(a)

00 12/12/2023 A. EGMAN G. GERVASONI

Rev. Date Issued Verified

Mod. CSP 002 rev. 4 Sheet 2/2

4665_19-17210200201-00245 Rev.B 6 of 204

Examining body / Ente Esaminatore

IIS CERT

IIS - Founding Member of

PRD 0021 Corporate Governance

Istituto Italiano della Saldatura

Membro degli accordi di mutuo IIS CERT is Notified Body n° 0475 for the approval of permanent joining

riconoscimento EA, IAF e ILAC procedures according to Annex I § 3.1.2 of the Directive 2014/68/EU

Signatory of EA, IAF and ILAC (PED)

Mutual Recognition Agreements IIS CERT è Organismo Notificano n° 0475 per l’approvazione delle

procedure di giunzioni permanenti in accordo all’Allegato I § 3.1.2 della

Direttiva 2014/68/EU (PED)

WELDING PROCEDURE QUALIFICATION RECORD

QUALIFICAZIONE PROCEDURA DI SALDATURA

Certificate No. / Certificato No. LD0033/23 rev. 0

WE HEREBY CERTIFY THAT /

SI CERTIFICA CHE

The procedure MECCANICA GERVASONI SRL WPS No. pCRO/100/A

IS QUALIFIED ACCORDING TO / E' QUALIFICATA IN ACCORDO A

the section IX of ASME Code BPV

2023 plus supplementary requirements accordig to ANNEX A to WPS CRO/100/A

ISSUE DATE /

DATA DI EMISSIONE 04/12/2023

CERTIFICATION AREA CSP

AREA CERTIFICAZIONE CSP

Renato Della Ragione

Il presente certificato è soggetto al rispetto delle condizioni stabilite nel Regolamento IIS Cert QAS 023 R.

This certificate complies with the terms estabilished by IIS Cert document QAS 023 R.

IIS CERT S.r.l. Lungobisagno Istria 29 R - 16141 GENOVA - www.iiscert.it

Corporate Governance Istituto Italiano della Saldatura

4665_19-17210200201-00245 Rev.B 7 of 204

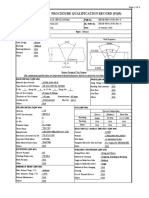

IIS Job/Comm. N. C00016524.01 PRQ N. LD0033/23 rev. 00 WPS N. pCRO/100/A Sheet/Foglio 1/2

PROCEDURE QUALIFICATION

RECORD

PQR

Company Name MECCANICA GERVASONI SRL - VIA DELL'INDUSTRIA, 21 - 24010 LENNA (BG)

Proc. Qualification Record No. LD0033/23 Date 30/10/2023

WPS No. pCRO/100/A Rev. 1 Date 06/09/2023

Welding Process(es) a) GTAW b) c)

Type(s) a) Manual b) c)

JOINTS (QW-402) Overlay - Inconel 625 to Weld Welding Filler metal Ampère Volt Travel Heat

Join Design Inconel 625 repair Pass Process Size (mm) Speed Input

mm/min kJ/mm

1E 2E 1E 2E 1E 2E

1 GTAW 2,4 -- 180 -- 13,5 -- 100 1,46

2÷4 GTAW 2,4 -- 180 -- 14 -- 95 1,59

Alfa=30°; T=50; t~6 from BM surface; A=5; H~1 above BM surface;Corner radius concerning lead in/lead out angle ~2;(mm);BM plus WMO acc.to WPS

pCRO/99/A;

Groove Design of Test Coupon

(For combination qualifications, the deposited weld metal shall be recorded for each filler metal or process used)

BASE METAL (QW-403) from to POSTWELD HEAT TREATMENT (QW-407)

Temp. Range (°C) NA - Time Range (h) NA

P-No. 1 Gr.No. 2 to P-No. NA to Gr.No. NA

Heat rate (°C/h) NA - Cool rate (°C/h) NA

Spec.Type-Grade ASTM A 694 - F65 - K03014

Other NONE

to Spec.Type-Grade NA - NA -

GAS (QW-408) Percent Composition Gas(es) Flow Rate(l/min)

Thick. of Test Coupon 50+6 (mm)

Plasma NA NA

Diam. of Test Coupon NA

Shield. a) SG-A (99,999%) 16

Other Heat:(F65)25923;C%=0,219;CE=0,426;(Alloy

625)107492; Shield. b) NA NA

FILLER METAL (QW-404) Trailing NONE NA

a) b) c)

Spec.No. (SFA) AWS A5.14 Backing NA NA

AWS No. (Class) ERNiCrMo-3 GAS for OFW NA

F-No. 43 Other NONE

A-No. NONE ELECTRICAL CHARACTERISTICS (QW-409)

Size of filler metal (mm) 2,4 a) b) c)

F.M. Trade Name Thermanit 625

Current DC

Manufacturer VOESTALPINE

Polarity EN

BÖHLER

Thk.range Groove (mm) ~5(*) Mode of Met. Transf. for GMAW NA

Size of filler metal (mm) NONE Tungst. Electr. Type & Size AWS A5.12 EWLa-1,5 Diam. 3,2 (mm)

Electr. wire feed speed range NA

a) b) c)

Flux Trade Name NA Other Welding unit with high frequency arc starting equipment;

Manufacturer NA

TECHNIQUE (QW-410)

Electr.-Flux (Class) NA String or Weave Bead String

Other Heat:106287;PREN:50,8;QW-404.23:bare(solid);See QW-

Orifice or Gas Cup Size 10 (mm)

410

Initial & Interpass Cleaning Grinding and/or brushing

POSITIONS (QW-405)

Method of Back Gouging NA

Position(s) of groove 1G (Flat)

Welding Progression ¡ Up ¡ Down l NA Contact Tube to Work Distance NA

Oscillation Ampl. NAFreq. NA

Position(s) of fillet NA

Multiple/Single Pass per Side l Multiple ¡ Single ¡ NA

Other NONE

Multiple/Single electrodes ¡ Multiple l Single ¡ NA

PREHEAT (QW-406) t Pass<1/2 ¡ Yes ¡ No l NA

Preheat Temp. 23°C Sub Powder ¡ Yes ¡ No l NA

Interpass Temp. 133°C Alloy elements ¡ Yes ¡ No l NA

QW-410.15,.26:NA;QW410.52:in front of torch;Used only stainless brushes and tools; Grinding

Preheat maintenance NONE Other disks for CRA product;(*)WMO repair thk from external WMO surface;

Other Preheat and interpass temperature checked by digital contact

thermometer

4665_19-17210200201-00245 Rev.B 8 of 204

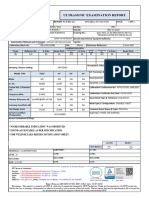

IIS Job/Comm. N. C00016524.01 PRQ N. LD0033/23 rev. 00 WPS N. pCRO/100/A Sheet/Foglio 2/2

PROCEDURE QUALIFICATION

RECORD

PQR

TENSILE TESTS (QW-150)

Specim Type & Figure Dimensions (mm) Area Ult. Total Ult. Unit Type of Failure & Location

Width Thickness (mm) Load (kN) Stress N/mm2

Other

GUIDED BEND TESTS (QW-160)

Type & Figure No. Result

Transverse side QW-462.2 - Four samples 180° Satisfactory

Other NONE

TOUGHNESS TESTS (QW-170)

Sp. size Notch Locations Notch Type Test T. Impact Tests Drop W. Break

(mm) (°C)

Values/Average % shear (mm) (Y/N)

10x10x55 BM (See Other) KV8 -29 66-56-54/59 -- 0,90-0,82-0,80 ¡ Yes l No

Other Sampling performed in Base Metal at 2mm from approximate weld interface, transversal to the direction of weld repair, with notch

perpendicular to the overlaid surface

FILLET WELD TEST (QW-180)

Result - Satisfactory ¡ Yes l No Penetration into Parent Material ¡ Yes ¡ No

Macro - Results

OTHER TESTS

Type of Test Visual examination according to QW-144:Satisfactory;Liquid penetrant examination acc.to QW-194:Satisfactory;For other NDE

examinations:see ANNEX 1 to PQR LD0033/23

Deposit Analisys PMI and chemical analysis:see ANNEX 1 to PQR LD0033/23

Other Bond shear strength, macro,hardness,micro and corrosion tests:see ANNEX 1 to PQR LD0033/23

Welder's Name ANNOVAZZI DIEGO Stamp No. A1

Welding Test conducted by MECCANICA GERVASONI srl - LENNA (BG)

Laboratory Test by QUALITY CONTROL srl - MEDOLAGO (BG) Laboratory Test No. 23/1824RP19;For all others

reports see ANNEX 1 to PQR

LD0033/23

We, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded and tested in conformance with

the requirements of the section IX of ASME Code BPV(2023 plus supplementary requirements accordig to ANNEX A to WPS CRO/100/A)

Date 24/11/2023

Test supervised by Italian Institute of Welding

CERTIFICATION AREA CSP Manufacturer

Renato Della Ragione (Stamp and Signature)

4665_19-17210200201-00245 Rev.B 9 of 204

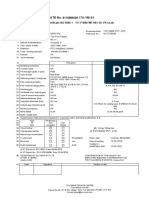

IIS Job / Comm N° C00016254

PROCEDURE QUALIFICATION PQR-N. LD0033/23

RECORD

PQR Sheet 1 of 1

ANNEX 1

WELDING DETAILS

Base metal ASTM A694 F65 - Thickness 50mm - Heat 25923 plus WMO acc.to WPS pCRO/99/A

Filler metal SFA 5.14 ERNiCrMo-3 - Diam. 2,4 (mm) - Thermanit 625 Heat 106287 - PREN 50,8

Welder ANNOVAZZI Diego - Stamp A1

WPS pCRO/100/A (4665_19-17210200201-00225 Annex A)

SUPPLEMENTARY CUSTOMER'S REQUIREMENTS

(For requirements and acceptance criteria, were applicable, see ANNEX A to WPS CRO/100/A)

IN PROCESS EXAMINATIONS

Type of test Description Reference

PMI Welding rods Satisfactory;See report 144/23 (1)

Visual examination WMO repair 1st, 2nd and 3rd (final) layers Satisfactory;See reports 130/23, 131/23 & 132/23 (1)

WMO repair 1st & 2nd layers Satisfactory;See report 152/23 & 153/23 (1)

PT examination

WMO repair 3rd layer (final) Satisfactory;See report 154/23 (1)

PMI WMO repair 3rd layer (final) Satisfactory;See report 145/23 (1)

Note (1) Meccanica Gervasoni report

NDE AND MECHANICAL TESTS

Type of test Description Reference

Visual examination WMO repair and adjacent areas Satisfactory;See report 23/1824RP06 Sheet 2 (2)

PT examination Satisfactory;See report 23/1824RP06 Sheet 3 (2)

WMO repair as welded

UT examination Satisfactory;See report 23/1824RP06 Sheet 4 (2)

Visual examination Satisfactory;See report 23/1824RP24 Sheet 2 (2)

WMO repair in final machined condition

PT examination Satisfactory;See report 23/1824RP24 Sheet 3 (2)

(3,5mm from BM surface)

UT examination Satisfactory;See report 23/1824RP24 Sheet 4 (2)

Type of test Reference and test result

PMI - WMO in final machined condition Satisfactory;See report 23/1824RP19 Sheet 15 (2)

(3,5mm from BM surface) Ni 62,31 - Cr 21,22 - Mo 8,12 - Nb 3,42 - Fe 1,56

Bond shear strength Satisfactory;See report 23/1824RP19 Sheet 4 (2)

WMO / WMO 1st layer Obtained value: 527MPa

Chemical analisys performed at 1,5mm below Satisfactory;See report 23/1824RP19 Sheet 14 (2)

machined surface - about 2,5mm from C 0,028 - Mn 0,091 - Fe 4,444 - P 0,003 - S 0,0001 - Si 0,078 - Cu 0,023 - Ni 62,166 - Al 0,107 - Ti

approximate weld interface 0,161 - Cr 21,945 - Nb+Ta 3,432 - Mo 8,514 - PREN 49,1

Satisfactory;See report23/1824RP19 Sheets 6 & 8 (2)

Hardness test HV10 Performed according to the scheme indicated in ANNEX A

Max values:BM (F65) 202 - WMO 280 - HAZ (625) 289 - WMO repair 288

Satisfactory;See report 23/1824RP19 Sheets 6 & 9 (2)

Hardness test HRC

Performed five indents according to the scheme indicated in ANNEX A - All readings < 20

Satisfactory;See report 23/1824RP19 Sheets 7 & 9 (2)

Hardness test HV10 Performed six indents in final machined condition at 3,5mm from BM surface

WMO average: 251 with max value 274

Satisfactory;See report 23/1824RP19 Sheet 13 (2)

Corrosion test ASTM G48 - Method A

Mass loss/Unit area:0,696g/m² - No pits at 20X magnification

Satisfactory;See report 23/1824RP19 Sheet 5 (2)

Macrographic examination

Performed at 5X & 10X magnification:no defects and conform to ISO 5817 level C

Satisfactory;See report 23/1824RP19 Sheets 10 & 12 (2)

Micrographic examination Performed at 500X magnification WMO, HAZ & BM

WMO shows no grain boundaries precipitation, no delta phases or secondary phases

Note (2) Quality Control report

Date Rev.

24/11/2023 0

4665_19-17210200201-00245 Rev.B 10 of 204

4665_19-17210200201-00245 Rev.B 11 of 204

4665_19-17210200201-00245 Rev.B 12 of 204

4665_19-17210200201-00245 Rev.B 13 of 204

4665_19-17210200201-00245 Rev.B 14 of 204

4665_19-17210200201-00245 Rev.B 15 of 204

4665_19-17210200201-00245 Rev.B 16 of 204

4665_19-17210200201-00245 Rev.B 17 of 204

You might also like

- SANYO ELEVATORS AND ESCALATORS CO.LTD USER GUIDE Warnings and CautionsDocument158 pagesSANYO ELEVATORS AND ESCALATORS CO.LTD USER GUIDE Warnings and CautionsAliRouyou64% (11)

- NORSOK Z-006 - PreservationDocument20 pagesNORSOK Z-006 - Preservationjoaocavti100% (4)

- NORSOK Z-006 - PreservationDocument20 pagesNORSOK Z-006 - Preservationjoaocavti100% (4)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingPutry NHy Saya0% (1)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Audit EngagementDocument2 pagesAudit EngagementMohamoud A. Nour71% (7)

- STRUCTURAL DESIGN ReportDocument25 pagesSTRUCTURAL DESIGN ReportRajendra AcharyaNo ratings yet

- UN Manual of Test and Criteria PDFDocument83 pagesUN Manual of Test and Criteria PDFNicolasNo ratings yet

- A-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- EPC Main Contract for Column Pipe Welding ProcedureDocument4 pagesEPC Main Contract for Column Pipe Welding ProcedureRamzi ZoghlamiNo ratings yet

- Welding Operators & WeldersDocument20 pagesWelding Operators & WeldersArun JaffersonNo ratings yet

- PDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-TemplateDocument1 pagePDF NCP X-Form WSX03 HDG Zinc-Coated-Steel WPS AWS-D11-D190-72 Pre-prepared-Templateيوسف عادل حسانينNo ratings yet

- 2005-05 - WPS & PQR C5Document6 pages2005-05 - WPS & PQR C5misthahNo ratings yet

- Linepipe Specification SummaryDocument36 pagesLinepipe Specification SummaryRokan PipelineNo ratings yet

- Iqwq Ce1091 VPWLD D7 4590 - ADocument120 pagesIqwq Ce1091 VPWLD D7 4590 - Ajacksonbello34No ratings yet

- Welder Qualification CertificateDocument2 pagesWelder Qualification CertificateNguyen Thanh BinhNo ratings yet

- 1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Document2 pages1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Nguyen Thanh Binh0% (1)

- TOFD and PAUT For Weld Root CorrosionDocument38 pagesTOFD and PAUT For Weld Root CorrosionMuthumonickamNo ratings yet

- Bis-Dk-Rt-1049 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1049 - Ip2022-CeTomasPavlovicNo ratings yet

- Welder Qualification CertificateDocument2 pagesWelder Qualification CertificateNguyen Thanh BinhNo ratings yet

- Ec-2692-220-2 - Void 4SDocument3 pagesEc-2692-220-2 - Void 4SMatheus Fabrício TeixeiraNo ratings yet

- Procedure Qualification RecordDocument6 pagesProcedure Qualification RecordGaurang PandyaNo ratings yet

- WHCP - Rust Prevention Procedure: 3426-100-I-PT-BNT-06174Document6 pagesWHCP - Rust Prevention Procedure: 3426-100-I-PT-BNT-06174Yasin ElaswadNo ratings yet

- 1036330-23-352 Al 467 KT H I Smaw+fcaw Iso 9606 CS 6G (H-L045)Document2 pages1036330-23-352 Al 467 KT H I Smaw+fcaw Iso 9606 CS 6G (H-L045)Nguyen Thanh BinhNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- 26071-100-GQI-GCQ-00011-003 ITP For AG Piping Fabrication & InstallationDocument27 pages26071-100-GQI-GCQ-00011-003 ITP For AG Piping Fabrication & InstallationLothar MatheusNo ratings yet

- Ahp 2X660 (WPS) )Document17 pagesAhp 2X660 (WPS) )Hema NandhNo ratings yet

- Juba Export Refinery Piping Quality ProcedureDocument15 pagesJuba Export Refinery Piping Quality ProcedureMd ShariqueNo ratings yet

- Format For Manufacturer Record of Welding Operator QualificationDocument1 pageFormat For Manufacturer Record of Welding Operator QualificationRajeev KumarNo ratings yet

- Ultrasonic Inspection ReportDocument3 pagesUltrasonic Inspection ReportTomasPavlovicNo ratings yet

- QT1 1 L18 61 Nde 000008Document4 pagesQT1 1 L18 61 Nde 000008Triệu HiếuNo ratings yet

- QT1-0-Q-030-05-00030 - C - ITP For Steel Structure ErectionDocument14 pagesQT1-0-Q-030-05-00030 - C - ITP For Steel Structure ErectionLâm HuyNo ratings yet

- 114486-UT-008 Attemperator Outlet T-PieceDocument2 pages114486-UT-008 Attemperator Outlet T-PieceDave CheungNo ratings yet

- DRP001 Ouf Gal Pro Q 000 064 S1Document26 pagesDRP001 Ouf Gal Pro Q 000 064 S1Rafat KhanNo ratings yet

- Essential welding procedure qualification recordDocument2 pagesEssential welding procedure qualification recordmainur mechanical engineer0% (1)

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- Binder 1234Document19 pagesBinder 1234Roshan George PhilipNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Gpti Qicl J931 Mut 004Document3 pagesGpti Qicl J931 Mut 004uselessinstaid52No ratings yet

- 26071-100-GQI-GCQ-00012-003 ITP For UG Piping Fabrication & InstallationDocument30 pages26071-100-GQI-GCQ-00012-003 ITP For UG Piping Fabrication & InstallationLothar MatheusNo ratings yet

- 48 BD 08Document34 pages48 BD 08Mayur UrkudeNo ratings yet

- Bis-Dk-Rt-1047 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1047 - Ip2022-CeTomasPavlovicNo ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- WPS PQR A106Document5 pagesWPS PQR A106Dilip PatilNo ratings yet

- 000 A Ee 0230028 513 R0Document13 pages000 A Ee 0230028 513 R0onur gunesNo ratings yet

- 20 PC e 00165 R1Document20 pages20 PC e 00165 R1isan.structural TjsvgalavanNo ratings yet

- MECHANICAL WORKS PROGRESS REPORTDocument17 pagesMECHANICAL WORKS PROGRESS REPORTRakesh SahaNo ratings yet

- Examination Data Sheet: Walter TostoDocument3 pagesExamination Data Sheet: Walter TostoasdasdasdasdNo ratings yet

- 2037-PL-PL-0058-IR-T-014 Dated 10.12.19Document16 pages2037-PL-PL-0058-IR-T-014 Dated 10.12.19Dadaso Baburao Jamdar100% (1)

- A545-736-11-42-DS-0034 - A - Flow TeeDocument2 pagesA545-736-11-42-DS-0034 - A - Flow TeeMurli ramchandranNo ratings yet

- Coating Inspection Report: MC-A-004-MT - Site Testing of Protective CoatingsDocument4 pagesCoating Inspection Report: MC-A-004-MT - Site Testing of Protective CoatingsSiva KumarNo ratings yet

- NM1 Product ManualDocument11 pagesNM1 Product ManualJorge Antonio Cossio RamirezNo ratings yet

- Welder Certificate ISO 9606-1 QualificationDocument1 pageWelder Certificate ISO 9606-1 QualificationDeepak Das100% (1)

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- Pipeline HSS Coating Inspection ReportDocument1 pagePipeline HSS Coating Inspection Reportcsc EXPERTISENo ratings yet

- Sko0061283 R2Document52 pagesSko0061283 R2ciwidop390No ratings yet

- Ga-24 Aws E7024Document1 pageGa-24 Aws E7024Bang OchimNo ratings yet

- p22MNVMB MN Gtaw+Smaw (Pipe)Document2 pagesp22MNVMB MN Gtaw+Smaw (Pipe)abidaliabid1No ratings yet

- Piping Material SpecificationDocument120 pagesPiping Material SpecificationMubashir fareedNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Tech Unit Baker Hydraulic PackerDocument26 pagesTech Unit Baker Hydraulic PackerArun Jafferson100% (1)

- Risk List SampleDocument1 pageRisk List SampleLuis Eduardo Villalba QuimbayoNo ratings yet

- Es Tsf0010 Aflas70Document1 pageEs Tsf0010 Aflas70Arun JaffersonNo ratings yet

- Technical Supply Conditions For ValvesDocument27 pagesTechnical Supply Conditions For ValvesArun JaffersonNo ratings yet

- D0573 04R15Document6 pagesD0573 04R15Arun JaffersonNo ratings yet

- Equivalent Cross Valve CastDocument2 pagesEquivalent Cross Valve CastArun JaffersonNo ratings yet

- D0471 16aDocument16 pagesD0471 16aArun JaffersonNo ratings yet

- Tutorial Sheet 03Document2 pagesTutorial Sheet 03Mr. Praveer SaxenaNo ratings yet

- SVC Avr HossoniDocument2 pagesSVC Avr Hossonijohn wardNo ratings yet

- ReferencesDocument5 pagesReferencesMohammed AliNo ratings yet

- Skoog Chapter 22 JawabanDocument11 pagesSkoog Chapter 22 JawabanmarisaaaNo ratings yet

- Formula To Calculate Cutting ProcessDocument19 pagesFormula To Calculate Cutting ProcessMangesh KetkarNo ratings yet

- 2016OilSafeCatalog PDFDocument76 pages2016OilSafeCatalog PDFwilmerNo ratings yet

- The Affinity Laws of Centrifugal PumpsDocument5 pagesThe Affinity Laws of Centrifugal PumpsJohannis ReyNo ratings yet

- TBC COMBINED W ACCESS 3.40 - 4 PDFDocument194 pagesTBC COMBINED W ACCESS 3.40 - 4 PDFlynkx864No ratings yet

- Han2017Document28 pagesHan2017Riston SinagaNo ratings yet

- Solomon Nigatu 0859/16 2. Getawa Melese ..... .0427/16Document32 pagesSolomon Nigatu 0859/16 2. Getawa Melese ..... .0427/16عبدالقادر مكونن سعيدNo ratings yet

- Huawei P20 User Guide - (EML-L09&L29,02, EN) PDFDocument150 pagesHuawei P20 User Guide - (EML-L09&L29,02, EN) PDFBojan PetrovicNo ratings yet

- Hive Wavetable Script Language WIPDocument8 pagesHive Wavetable Script Language WIPAdam SmithNo ratings yet

- CO2 Baseline Database For The Indian Power Sector.Document41 pagesCO2 Baseline Database For The Indian Power Sector.Pooja JainNo ratings yet

- EXP5Document2 pagesEXP5UsamaIjaz100% (1)

- (Original) Comprehensive Land Transport and Traffic Code of GSC RevisedDocument149 pages(Original) Comprehensive Land Transport and Traffic Code of GSC RevisedXIANo ratings yet

- Reaction Rate Unit 1 NotesDocument40 pagesReaction Rate Unit 1 NotesdrsinagNo ratings yet

- Engine Familiarization 4-39: Number 1 and 2 Bearing Support SubDocument6 pagesEngine Familiarization 4-39: Number 1 and 2 Bearing Support SubKishan MalhotraNo ratings yet

- GB 643 4PGDocument4 pagesGB 643 4PGHoàng Sơn NgôNo ratings yet

- Hydraulic Overload Protection: The Silent SentinelDocument7 pagesHydraulic Overload Protection: The Silent SentinelSerdar FildisNo ratings yet

- ModelSim Users Manual v10.1c PDFDocument733 pagesModelSim Users Manual v10.1c PDFAmshi AbooNo ratings yet

- Consultancy ListDocument1 pageConsultancy Listrajpre1213No ratings yet

- HUADA LW Decanter CentrifugesDocument5 pagesHUADA LW Decanter CentrifugesАндрей МанышкинNo ratings yet

- 2 User Interface 2: Menu 2 General Options 2 Create SVG Map: The SVG Map Creation Wizard 3Document10 pages2 User Interface 2: Menu 2 General Options 2 Create SVG Map: The SVG Map Creation Wizard 3Appolinaire EmaniNo ratings yet

- Importance of Reliable Geotechnical Investigation For Safe and Economical Foundation Design of Civil StructuresDocument5 pagesImportance of Reliable Geotechnical Investigation For Safe and Economical Foundation Design of Civil StructuresAshwini ShettyNo ratings yet

- Assignment List With Due DatesDocument1 pageAssignment List With Due DatesRacaz EwingNo ratings yet

- Consolidation Test - Lab ManualDocument5 pagesConsolidation Test - Lab ManualAmira SyazanaNo ratings yet

- Concep PlusDocument1 pageConcep PlusgerzaelNo ratings yet