Professional Documents

Culture Documents

Pipeline HSS Coating Inspection Report

Uploaded by

csc EXPERTISEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipeline HSS Coating Inspection Report

Uploaded by

csc EXPERTISECopyright:

Available Formats

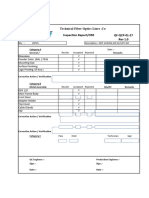

Ain Tsila Development Project

INSPECTION & TEST RECORD-PAINTING

PIPELINE HSS COATING INSPECTION

REPORT ITR No:JI-

2045- V-0501A Rev 1

Tag No: 01 Project No: JI-2045 Record No: GCB-COAT-0001

Plant/Unit: NA Sub-System No: 240

Drawing No: NA Rev: NA Location: GCB work shop

Report No: 1 Date: 13-10-2021 Area: GCB work shop

Pipeline/ISONo: 12''-CONDENSATE-EXPORT PIPELINE Section NA Diameter 12.75"

Primer Type liquid epoxy S1401 Primer Batch No. (A)1330329 &(B)1330330

HSS TYPE HTLP80-HP HSS Batch No. 50105730

Grade of surface preparation Steel Temp. 50-60°c

From Joint No. To Joint No. From Joint No. To Joint No. From Joint No. To Joint No.

PQT-GCB-001 / / / / /

PQT-GCB-002 / / / / /

PQT-GCB-003 / / / / /

PQT-GCB-002R / / / / /

Adhesive yes

Coating (Smooth without surface defects/ wrinkles) yes

Sleeve width (correct overlap with coated pipe) yes

Damage Repair Acceptable (on pipe body/HSS) yes

Adhesion Test (Peel Strength) Result yes

To steel (adhesion strength as required by manufacturer recommendation/project specification) > 4.5 N/m

To Pipeline Coating System (adhesion strength as required by manufacturer recommendation/project

specification) > 4.5 N/m

Destructive Test Result

Minimum 95% of steel surface shall be covered with adhesive upon complete removal of sleeve (or

as required by project specification) NA

Coating has been inspected in accordance with project specification and found acceptable YES

Remarks:

See attched Heat shrink sleeve inspection raport No : GCB-COAT-0001

peel test done on: PQT-GCB-001/PQT-GCB-002/PQT-GCB-003

Company signiture: Applicable Not Applicable

Record Acceptance GCB QC PIUL QC GIS

Name

Signature

Date

You might also like

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- PEC-QU-ITR-X-11129 Rev-1, ITR-V-0501ADocument1 pagePEC-QU-ITR-X-11129 Rev-1, ITR-V-0501AMidhun K ChandraboseNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- SSV QTN 2022 2023 01277Document1 pageSSV QTN 2022 2023 01277Sachin Kumar SinghNo ratings yet

- Mepl CPCLCBR Eil Qap&ds 001 2022 2023Document7 pagesMepl CPCLCBR Eil Qap&ds 001 2022 2023Mathi Vinoth PillaiNo ratings yet

- Ir 006 - 230629Document6 pagesIr 006 - 230629이훈No ratings yet

- Odf Sliding, 24f, Sc-Upc SMDocument1 pageOdf Sliding, 24f, Sc-Upc SMOdetallah MajedNo ratings yet

- Quality Assurance PlanDocument1 pageQuality Assurance PlanGuru Mishra100% (1)

- Pre-Pour Concrete Checklist R00Document2 pagesPre-Pour Concrete Checklist R00Taiwo OshinNo ratings yet

- Ferrite in Stainless Steel Weld MetalDocument1 pageFerrite in Stainless Steel Weld MetalElizabeth SpenceNo ratings yet

- Cement Plug ProgramDocument9 pagesCement Plug ProgramMarvin OmañaNo ratings yet

- MI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3Document29 pagesMI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3EduardNo ratings yet

- Welding Procedure B69AWDocument2 pagesWelding Procedure B69AWMastram HatheshNo ratings yet

- Inspection Report for Duqm Refinery Project Hot Induction BendsDocument18 pagesInspection Report for Duqm Refinery Project Hot Induction BendsDadaso Baburao JamdarNo ratings yet

- Daily Report-018 (Su Jinlong)Document8 pagesDaily Report-018 (Su Jinlong)sujinlongNo ratings yet

- Inspection Release for Jacket Leg CoatingDocument2 pagesInspection Release for Jacket Leg CoatingjeswinNo ratings yet

- 2037-PL-PL-0058-IR-T-014 Dated 10.12.19Document16 pages2037-PL-PL-0058-IR-T-014 Dated 10.12.19Dadaso Baburao Jamdar100% (1)

- H2o Process, Quote 210026Document4 pagesH2o Process, Quote 210026gomez johnNo ratings yet

- Quotation For TP-ALP-21-213 SURGE VESSEL 1m3Document2 pagesQuotation For TP-ALP-21-213 SURGE VESSEL 1m3Port VideoNo ratings yet

- Bolted Flange and Gasket Joints Assembly ProcedureDocument9 pagesBolted Flange and Gasket Joints Assembly ProceduremohdNo ratings yet

- PO Ordered Pipe BendsDocument4 pagesPO Ordered Pipe BendsDadaso Baburao JamdarNo ratings yet

- T-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight GlassDocument3 pagesT-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight Glassvinoj chandranNo ratings yet

- A545-736-11-42-DS-0034 - A - Flow TeeDocument2 pagesA545-736-11-42-DS-0034 - A - Flow TeeMurli ramchandranNo ratings yet

- DataSheet 2 More 300# BV - FB - BW - NT-77 PDFDocument1 pageDataSheet 2 More 300# BV - FB - BW - NT-77 PDFSachin KumarNo ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- CS PLATE-TS NO-SA-516-2-222051-R0 - Dish End Plate (Commented 3Document2 pagesCS PLATE-TS NO-SA-516-2-222051-R0 - Dish End Plate (Commented 3PRADEEP GAIKWADNo ratings yet

- Flexible Hose DatasheetDocument7 pagesFlexible Hose DatasheetchintanNo ratings yet

- Drain Pump, Data Sheet and Performance Curve: Genral Arrangement ofDocument11 pagesDrain Pump, Data Sheet and Performance Curve: Genral Arrangement ofAshish Gupta100% (1)

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Mir Pipe NewDocument11 pagesMir Pipe NewDimas agungNo ratings yet

- DDFC Technical Cum Commercial Proposal PV 811Document8 pagesDDFC Technical Cum Commercial Proposal PV 811Siddiqui Muhammad AshfaqueNo ratings yet

- 1.internal Concrete Pour Register Updated On 25-01-2023Document9 pages1.internal Concrete Pour Register Updated On 25-01-2023721917114 47No ratings yet

- Ibo Pm9s Exe I19 99 Qac RPT 0006 - Rev. B (Amended)Document6 pagesIbo Pm9s Exe I19 99 Qac RPT 0006 - Rev. B (Amended)Gokhula KannanNo ratings yet

- NDT Request for Butt WeldsDocument3 pagesNDT Request for Butt WeldsFiras AlbaweiNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- 2005 S003 NBPG Rfi 04957 - R00Document1 page2005 S003 NBPG Rfi 04957 - R00RPDeshNo ratings yet

- A-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- EPC Main Contract for Column Pipe Welding ProcedureDocument4 pagesEPC Main Contract for Column Pipe Welding ProcedureRamzi ZoghlamiNo ratings yet

- WHCP - Rust Prevention Procedure: 3426-100-I-PT-BNT-06174Document6 pagesWHCP - Rust Prevention Procedure: 3426-100-I-PT-BNT-06174Yasin ElaswadNo ratings yet

- SVDN-CPP-I-0023-D01-0003-Rev.02-General Arrangement Drawing Isolation Valve Instrusive SignalerDocument6 pagesSVDN-CPP-I-0023-D01-0003-Rev.02-General Arrangement Drawing Isolation Valve Instrusive SignalerjfdlksaNo ratings yet

- Final Wellhead ReportDocument53 pagesFinal Wellhead ReportAli BoubeniaNo ratings yet

- VV216A-109-A-801 - 1 Installation & Oper Main. Procedure PDFDocument253 pagesVV216A-109-A-801 - 1 Installation & Oper Main. Procedure PDFLê Phước PhúNo ratings yet

- Certificate Compliance Project Power PlantDocument3 pagesCertificate Compliance Project Power PlantVinay YadavNo ratings yet

- DRP001 Ouf Gal Pro Q 000 064 S1Document26 pagesDRP001 Ouf Gal Pro Q 000 064 S1Rafat KhanNo ratings yet

- 0127-Tp-01ab - Sample Tie in PackageDocument11 pages0127-Tp-01ab - Sample Tie in Packagemengelito almonteNo ratings yet

- Gpti Qicl J931 Mut 004Document3 pagesGpti Qicl J931 Mut 004uselessinstaid52No ratings yet

- 2037-PL-PL-0058-FR-T-025 Dated 18.12.19 PDFDocument14 pages2037-PL-PL-0058-FR-T-025 Dated 18.12.19 PDFDadaso Baburao JamdarNo ratings yet

- Visual Examination ReportDocument47 pagesVisual Examination ReportalouisNo ratings yet

- Submit-Deviation Clarification Sheet - 006a (02-Sept)Document29 pagesSubmit-Deviation Clarification Sheet - 006a (02-Sept)Ibnu - CHCNo ratings yet

- 2037-PL-PL-0058-IR-T-015 Dated 17.12.19-IRN IR PDFDocument22 pages2037-PL-PL-0058-IR-T-015 Dated 17.12.19-IRN IR PDFDadaso Baburao JamdarNo ratings yet

- Pipeline Coatings PDFDocument29 pagesPipeline Coatings PDFAsimNo ratings yet

- Pressure Vessel High Pressure Stripper R0 Final Report R1Document5 pagesPressure Vessel High Pressure Stripper R0 Final Report R1AJ NugrohoNo ratings yet

- Datasheet for Saisanket Pressure Relief ValveDocument4 pagesDatasheet for Saisanket Pressure Relief ValveYogesh GawadeNo ratings yet

- Datasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFDocument4 pagesDatasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFYogesh GawadeNo ratings yet

- TGP-JE-GTPT-000-QC-ACP-0012-Heat Exchanger Action PlanDocument4 pagesTGP-JE-GTPT-000-QC-ACP-0012-Heat Exchanger Action PlanRami KsidaNo ratings yet

- Final inspection and test reportsDocument7 pagesFinal inspection and test reportssami maNo ratings yet

- Zakum Development Company (Zadco) : Description of Inspection SL. No. Fit-Up Inspection Date Weld Visual Inspection DateDocument4 pagesZakum Development Company (Zadco) : Description of Inspection SL. No. Fit-Up Inspection Date Weld Visual Inspection DateYousab CreatorNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- P Qac Pro 240 39467 CDocument24 pagesP Qac Pro 240 39467 Ccsc EXPERTISENo ratings yet

- Otdr 1Document2 pagesOtdr 1csc EXPERTISENo ratings yet

- PQR 001Document2 pagesPQR 001csc EXPERTISENo ratings yet

- PQR 005Document2 pagesPQR 005csc EXPERTISENo ratings yet

- API 570 Open BookDocument9 pagesAPI 570 Open BookMusa ÇelikNo ratings yet

- Activité Antioxydante PDFDocument16 pagesActivité Antioxydante PDFcsc EXPERTISENo ratings yet

- Warehouse SimulationDocument14 pagesWarehouse SimulationRISHAB KABDI JAINNo ratings yet

- Terex Operator TrainingDocument4 pagesTerex Operator TrainingJohn100% (48)

- CMC 63rd Batch Class Routine for Thorax CardDocument5 pagesCMC 63rd Batch Class Routine for Thorax CardMath NewNo ratings yet

- EONSOLV 135 MSDS Safety DataDocument11 pagesEONSOLV 135 MSDS Safety DataChristiyan Chandra AntonoNo ratings yet

- How To Prepare For The CFA Exam - QuoraDocument10 pagesHow To Prepare For The CFA Exam - QuoraaduragbeNo ratings yet

- RIYAGUPTA MidSemDocument14 pagesRIYAGUPTA MidSemanaya jianaNo ratings yet

- Overview of Medicine - Its Importance and ImpactDocument9 pagesOverview of Medicine - Its Importance and ImpactDuffosNo ratings yet

- Group 4 (Ap229d 3c)Document11 pagesGroup 4 (Ap229d 3c)aremyulNo ratings yet

- Perret Mahindra SeminarDocument32 pagesPerret Mahindra SeminarBeowulf StarkNo ratings yet

- DLP For UCSPDocument6 pagesDLP For UCSPruth taccadNo ratings yet

- Ecotourism EssayDocument2 pagesEcotourism EssayKarenNo ratings yet

- Graduate School: Mariano Marcos State UniversityDocument2 pagesGraduate School: Mariano Marcos State UniversityLeslie Anne BiteNo ratings yet

- Full Scale Tests of Heat Strengthened Glass With Ceramic FritDocument17 pagesFull Scale Tests of Heat Strengthened Glass With Ceramic FritKároly FurusNo ratings yet

- RPH Sains DLP Tahun 2Document10 pagesRPH Sains DLP Tahun 2myra ungauNo ratings yet

- Lenze 8400 Electrical Shaft Technology Application - v1-0 - ENDocument50 pagesLenze 8400 Electrical Shaft Technology Application - v1-0 - ENNilo AninonNo ratings yet

- Lesson 1: Organs of Speech and Phonemic SymbolsDocument5 pagesLesson 1: Organs of Speech and Phonemic Symbolsnoah granja2No ratings yet

- Prompt Engineering Cheat SheetDocument3 pagesPrompt Engineering Cheat SheetJuan Pablo Dell'OroNo ratings yet

- A. Badal', R. Barbera, A. Bonasera, M. Gulino, A. Palmeri (Auth.), Wolfgang Bauer, Hans-Georg Ritter (Eds.) - Advances in Nuclear Dynamics 4 (1998, Springer US)Document389 pagesA. Badal', R. Barbera, A. Bonasera, M. Gulino, A. Palmeri (Auth.), Wolfgang Bauer, Hans-Georg Ritter (Eds.) - Advances in Nuclear Dynamics 4 (1998, Springer US)ramiphysicsNo ratings yet

- Current TransformerDocument12 pagesCurrent TransformerSyed AbbasNo ratings yet

- Early Childhood Physical DevelopmentDocument34 pagesEarly Childhood Physical DevelopmentEditha100% (1)

- Amazon Food Review Clustering Using K-Means, Agglomerative & DBSCANDocument79 pagesAmazon Food Review Clustering Using K-Means, Agglomerative & DBSCANkrishnaNo ratings yet

- M5 - Freedom of The Human PersonDocument8 pagesM5 - Freedom of The Human PersonMarisol OtidaNo ratings yet

- Effectiveness of STEM learning approach among Malaysian secondary studentsDocument11 pagesEffectiveness of STEM learning approach among Malaysian secondary studentsJHON PAUL REGIDORNo ratings yet

- Produk Fermentasi Tradisional Indonesia Berbahan Dasar Pangan Hewani (Daging Dan Ikan) : A ReviewDocument15 pagesProduk Fermentasi Tradisional Indonesia Berbahan Dasar Pangan Hewani (Daging Dan Ikan) : A Reviewfebriani masrilNo ratings yet

- CorpusRembrandt 3Document819 pagesCorpusRembrandt 3Yuliya UdotNo ratings yet

- 104 Question Papers - MergedDocument19 pages104 Question Papers - MergedRozy RayliNo ratings yet

- Dosi ResDocument2 pagesDosi Resapi-270166579No ratings yet

- Armstrong ANFDocument2 pagesArmstrong ANFBramandito DamarNo ratings yet

- Non Aqueous Titrations by Gunja ChtaurvediDocument10 pagesNon Aqueous Titrations by Gunja ChtaurvediGunja Chaturvedi88% (8)

- Attractive Celebrity and Peer Images On Instagram. Effect On Women's Mood and Body ImageDocument7 pagesAttractive Celebrity and Peer Images On Instagram. Effect On Women's Mood and Body ImageDesiré Abrante RodríguezNo ratings yet