Professional Documents

Culture Documents

Swms NPG Rev2 Smeg Warehouse

Uploaded by

mhwjgcnsnz0 ratings0% found this document useful (0 votes)

15 views9 pagesOriginal Title

Swms Npg Rev2 Smeg Warehouse

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views9 pagesSwms NPG Rev2 Smeg Warehouse

Uploaded by

mhwjgcnsnzCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

PAINTING AND DECORATING WORK

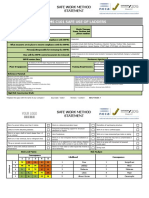

SAFE WORK METHOD STATEMENT

COMPANY DETAILS

Company name: National Painting Group NSW Pty Ltd Contact name: Dany Sawaya

ABN: 95 614 461 764 Position: Project Manager

Address: Unit A1 35-39 Bourke Rd, Alexandria NSW 2015 Phone number: 0412655589

Client: INONE Projects Pty Ltd

Project Name: SMEG Warehouse

Project Address:

35-47 STENNET RD, INGLEBURN

Scope of Works: SWMS developed by: Dany Sawaya Date : 05/02/2024

Internal Painting Works SWMS Developed in consultation with: Armin Ameertabar

Nominated Supervisor:

Persons allocated to Signature: (All Duties and responsibilities: (List details of Qualifications / Certificates of Competency / Training /

carry out task: (List all persons working on duties and responsibilities of specific personnel, Experience required carrying out task: (List details of

persons who will be site are required to e.g., daily safety checks, maintenance checks, qualifications, certificates, training and experience and needed

working on site for the read fully and sign etc). to carry out the tasks required).

contractor at any time). SWMS).

DOCUMENT #: 0001 VERSION #:02

PAINTING AND DECORATING WORK

PAINTING AND DECORATING WORK

SAFE WORK METHOD STATEMENT

The SWMS has been read and signed by all employees on site: Site Supervisor: Date: / /

COMMENTS OR REVIEW AMENDMENTS

Signed: Date: Signed: Date:

Plant and equipment required: (List all plant and equipment to be used by Safety and maintenance checks required: (Provide details of maintenance schedules

contractor this for job). on high-risk plant, including testing of electrical equipment).

None

Hi-Vis, Gloves, Glasses and Hard hat, Steel cap boots as required.

Engineering details / Certificates/Approvals required: (Provide details Legislation / Standards / Codes of Practice applicable: (Ensure that work methods

required for work listed as hazardous or requiring specific work methods, e.g., comply with or exceed legislated requirements or applicable Codes of Practice and that

demolition, formwork, false work, tilt slab construction, etc). the relevant Codes, etc., are available on site).

N/A

WHS Act NSW 2011 and WHS regulations NSW 2017

WHS regulations NSW 2017 Chapter 3 Division 3, 3.2 & 6

WHS regulations NSW 2017 Chapter 4, part 4.4, Falls

Code of Practice: How to manager Work Health and Safety Risks

Code of Practice: Managing the Work Environment and facilities

Code of Practice: Managing Noise and Preventing Hearing Loss

Code of Practice: Managing the Risks of Falls in the workplace

DOCUMENT #: 0001 VERSION #:02

PAINTING AND DECORATING WORK

PAINTING AND DECORATING WORK

SAFE WORK METHOD STATEMENT

Code of Practice: Hazardous Manual Tasks

COMPILATION OF SWMS

STEP Number each discrete step in the task in sequence - e.g.: 1, 2, etc.

ACTIVITY Briefly describe the activity to be carried out in each step

HAZARDS Identify what in each activity could cause harm to a person, the job, materials or the environment

RISK (1) The degree of risk posed by the hazard. ( Use Risk Level Matrix to determine risk ranking before controls implemented)

RISK CONTROLS What precautions or control measures must be taken to control the risk?

RISK (2) The degree of risk following implementation of risk controls (Use Risk Level Matrix to determine ranking of residual risk).

BY WHOM The name or the position of the person responsible for the implementation of the risk controls.

RISK LEVEL MATRIX

RISK LEVEL CALCULATOR

RISK LEVEL CONSEQUENCES OF EXPOSURE CONSEQUENCES OF EVENT OCCURRING

LIKELIHOOD

H (1) Potential death, permanent disability or major structural Death or Long-term Medical First Aid treatment

OF

(High level of failure or damage. Off-site environmental discharge or permanent illness or attention, required

OCCURRENC disability serious time off work

harm) release not contained and significant long-term

E injury

environmental harm. Will require detailed pre-planning.

Record actions on SWMS.

M (2) Potential temporary disability or minor structural failure or 1 1 2 3

(Medium level damage. On-site environmental discharge or release Very Likely

of harm) contained, minor remediation required, short-term

environmental harm. Will require operational planning. 1 2 3 4

Record actions on SWMS. Likely

L (3-6) Incident has the potential to cause persons to require first 2 3 4 5

(Low level of aid treatment. On-site environmental discharge or release Unlikely

harm) immediately contained, minor level clean-up with no

environmental harm. Will require localised control 3 4 5 6

measures. Very unlikely

DOCUMENT #: 0001 VERSION #:02

PAINTING AND DECORATING WORK

PAINTING AND DECORATING WORK

SAFE WORK METHOD STATEMENT

DESCRIPTION / TASK: SMEG WAREHOUSE

Internal painting Date: 05/02/24

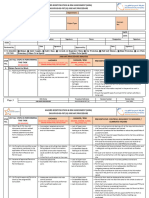

JOB SAFETY ANALYSIS

STEP DESCRIPTION OF JOB FINAL RISK

POTENTIAL HAZARDS RISK SCORE HAZARD CONTROL MEASURES

NO. OR ACTIVITY SCORE

1 Select area to set up Spills, trips, falls fumes. 3 Select flat area that is not adjacent to a set up bund 6

equipment. to contain any potential spills.

2 Set up of application Spills, trips, falls fumes. 3 Open coating stored and rollers and brushes are 6

equipment stored and set up in the bunted area.

3 Application of Injury to operator from being exposed by 3 Coating applicators to wear task specific PPE. 6

paint/coating coating splashes/ fumes and coating

onto exposed skin. SDS to be submitted and requirements to be

complied with.

Equipment is to be thoroughly checked prior to use to

ensure that everything is clean, secure and in good

order.

4 Personal Protection Injury, illness, permanent 3 Check condition of hard hats - brim or neck flaps, 6

Equipment (PPE) disability and in extreme cases gloves, safety boots, sunscreen, high visibility

death. reflective clothing or vests, ear plugs or earmuffs and

any other Personal Protective Equipment (PPE)

appropriate for this work.

Inspect all PPE prior to use making sure it is suitable

for use.

Make sure all workers are issued with and wear the

recommended PPE as required for safety on the

worksite and specific to the activities and tasks; and

DOCUMENT #: 0001 VERSION #:02

PAINTING AND DECORATING WORK

PAINTING AND DECORATING WORK

SAFE WORK METHOD STATEMENT

5 Electricity and Electricity /tools - electrocution 3 Train workers in the correct use of the equipment 6

power tool use Impact injuries and supervise until they demonstrate they can

Cuts and abrasions operate the tool safely.

Amputations

Noise – hearing damage Use tools and fittings to manufacturers

Flying debris – eye injuries recommendations.

Burns – hot fittings/equipment

Check equipment is tested and tagged and are in

good condition,

- Monthly test and tag

- Submit electrical equipment register.

Device (RCD) to prevent electrocution.

Use stands and hooks to raise power cords off the

ground in wet or high traffic areas.

Wear the appropriate PPE such as safety boots,

hearing protection, dust mask or half or full-face

respirator, gloves etc.

Keep hair, jewelry, and loose clothing etc. away from

moving parts.

6 Using hand tools Tools – Cuts 3 Use tools and equipment to manufacturers 6

Flying debris – eye injuries recommendations.

Damage to property Check tools are in good working condition; and

Wear eye protection.

7 Truck deliveries and Injuries to workers and others: 3 All workers must always wear high visibility clothing 6

vehicle / plant and Traffic and moving plant - and boots and hardhats, hearing protection, dust

equipment movement impact and crushing injuries mask and gloves as required.

on site Hit by falling objects.

Dust / fumes – lung damage Provide clear access for vehicles to enter, exit and

Slips, trips, and falls move on site.

Access and egress

DOCUMENT #: 0001 VERSION #:02

PAINTING AND DECORATING WORK

PAINTING AND DECORATING WORK

SAFE WORK METHOD STATEMENT

Property damage

8 Manual handling – Strains, sprains, and soft tissue 3 Train workers in correct lifting techniques – bend the 6

lifting, carrying, damage knees to lift and lower, use thighs (DO NOT bend

pushing, pulling and Back injuries over to lift), head up, chin in and keep elbows close

holding Crushing injuries to body - never twist while lifting, lowering, or

carrying a load.

Property damage

Make sure load is stable before lifting.

Heavy and awkward items get help or use lifting

equipment.

9 Dust Inhaling dust can cause rhinitis, 2 Wet down area to reduce dust or provide ventilation. 6

bronchitis, lung.

damage, allergic reactions, asthma Use tools with water attachment to reduce dust; and

attacks and fibrosis

Wear a dust mask or half or full-face respirator.

Dust from sanding can cause damage to

surrounding electrical switch boards

10 Sanding Flying debris - eye Injury 2 Make sure all workers are wearing suitable hearing 6

Dust – lung damage and eye protection and respiratory masks when

exposed to dust.

11 Use of platform ladder to Falls 2 Use platform ladders only (not a frames) 6

complete task Slippery or unstable floor platform /

surface Ensure that your footwear is clean and dry before

Ladder use & ladder not fit for purpose. climbing ladder.

Fractures

Dislocations Only one person on the ladder always

Sprains & Strains

Cuts / Contusions Always ensure three points of contact while

ascending & descending ladder i.e., two feet and one

hand.

Always face the ladder

DOCUMENT #: 0001 VERSION #:02

PAINTING AND DECORATING WORK

PAINTING AND DECORATING WORK

SAFE WORK METHOD STATEMENT

Work within arm’s reach from the ladder & never

overreach.

If necessary, climb down ladder and reposition ladder

so you are closer to the task.

12 Clean up of work area. Dust, pressure, eye damage, poly 3 PPE- hearing protection, safety boots, helmet. 6

NPG NSW Pty Ltd are primer/fumes inhalation pinch points,

responsible for cleaning poor housekeeping, environment. When lifting take care bending and lifting, use correct

up and disposing of Hearing damage, manual handling. techniques. Proper disposal of waste material.

contaminated waste.

13 Working in line with Not following instructions, possible 5 At all times SWMS must be followed. If the scope 6

SWMS injuries, rework changes or conditions change, the SWMS must be

reassessed and changed where necessary to cover

the new situation. Supervisors/leading hands must

be present at the work face to review SWMS and

carry out a risk assessment with the work crew. No

work is to commence prior to action being taken.

14 House keeping Slips trips falls environment 4 Ensure work area left tidy barricades & tools packed 6

away.

DOCUMENT #: 0001 VERSION #:02

PAINTING AND DECORATING WORK

PAINTING AND DECORATING WORK

SAFE WORK METHOD STATEMENT

This SWMS developed in consultation and cooperation with workers and relevant organisation representatives. I have read the above

SWMS, and I understand its contents. I confirm that I have the skills and training, including relevant certification, to conduct the task as

SWMS SIGN-OFF described. I agree to comply with safety requirements within this SWMS, including risk control measures, safe work instructions and PPE

described.

LICENCES, COMPETENCIES & QUALIFICATIONS (add as applicable)

JOB ROLE / POSITION

WORKERS’ NAME TYPE / DESCRIPTION CLASS NUMBER DATE SIGNATURE

E.G. SUPERVISOR, WORKER, TRAINEE

Construction Card

Construction Card

Construction Card

Construction Card

Construction Card

Construction Card

Construction Card

DOCUMENT #: 0001 VERSION #:02

PAINTING AND DECORATING WORK

PAINTING AND DECORATING WORK

SAFE WORK METHOD STATEMENT

This SWMS developed in consultation and cooperation with workers and relevant organisation representatives. I have read the above

SWMS, and I understand its contents. I confirm that I have the skills and training, including relevant certification, to conduct the task as

SWMS SIGN-OFF described. I agree to comply with safety requirements within this SWMS, including risk control measures, safe work instructions and PPE

described.

LICENCES, COMPETENCIES & QUALIFICATIONS (add as applicable)

JOB ROLE / POSITION

WORKERS’ NAME TYPE / DESCRIPTION CLASS NUMBER DATE SIGNATURE

E.G. SUPERVISOR, WORKER, TRAINEE

Construction Card

DOCUMENT #: 0001 VERSION #:02

PAINTING AND DECORATING WORK

You might also like

- OMV Yemen EPF Project Job Safety AnalysisDocument12 pagesOMV Yemen EPF Project Job Safety Analysissayuj karuvathil100% (1)

- Checklist For Access Control System InstallationDocument6 pagesChecklist For Access Control System Installationnsadnan71% (7)

- Save Work Method of StatementDocument11 pagesSave Work Method of Statementpaansaeng50% (4)

- Hot Work Safety MeasuresDocument6 pagesHot Work Safety Measurestamoor sarwarNo ratings yet

- Drilling Piling Swms 10 15763 SAMPLEDocument7 pagesDrilling Piling Swms 10 15763 SAMPLEAlok JagannathNo ratings yet

- 1-Risk Assessment For Hot Work ParmitDocument4 pages1-Risk Assessment For Hot Work Parmitsudeesh kumarNo ratings yet

- GDCL Hazard Identification and Risk Assessment Hira Register Part I PDFDocument16 pagesGDCL Hazard Identification and Risk Assessment Hira Register Part I PDFReddy sekharNo ratings yet

- Method Statement WeldingDocument9 pagesMethod Statement Weldingkiki270977No ratings yet

- 001 SWMS - Piling WorkDocument20 pages001 SWMS - Piling Worksasi kumar0% (1)

- SWMS Piling Machine Assembly RKDocument14 pagesSWMS Piling Machine Assembly RKrakeshkhanna78100% (1)

- SWMS Piling Works RKDocument22 pagesSWMS Piling Works RKrakeshkhanna78100% (3)

- Hse PlanDocument62 pagesHse Plannsadnan91% (11)

- Caterpillar 627g Wheel Trator Scraper Operation and Maintenance ManualDocument3 pagesCaterpillar 627g Wheel Trator Scraper Operation and Maintenance Manualcornelia100% (37)

- Secure & Simple – A Small-Business Guide to Implementing ISO 27001 On Your Own: The Plain English, Step-by-Step Handbook for Information Security PractitionersFrom EverandSecure & Simple – A Small-Business Guide to Implementing ISO 27001 On Your Own: The Plain English, Step-by-Step Handbook for Information Security PractitionersNo ratings yet

- Offshore Safety Case TrainingDocument114 pagesOffshore Safety Case TrainingPillai Sreejith100% (131)

- Swms-Fencing Work Revised-1Document10 pagesSwms-Fencing Work Revised-1JanakiramanNo ratings yet

- Safe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201Document18 pagesSafe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201mkash028100% (1)

- Work at Height ProcedureDocument7 pagesWork at Height Procedurecy2sonar50% (2)

- UCHA SWMS Safe Work Method Statement ExcavationDocument20 pagesUCHA SWMS Safe Work Method Statement Excavationyash shahNo ratings yet

- Hse PlanDocument62 pagesHse Plannsadnan70% (10)

- JSA for safe fence installationDocument5 pagesJSA for safe fence installationMoaatazz Nouisri50% (2)

- Excavation Working in Trenches Swms 10281-6Document17 pagesExcavation Working in Trenches Swms 10281-6JamesNo ratings yet

- GGH Basket RemovelDocument9 pagesGGH Basket Removeltamoor sarwarNo ratings yet

- SWMS 010 MLT Block Erection RKDocument28 pagesSWMS 010 MLT Block Erection RKrakeshkhanna78No ratings yet

- SWMS Template 30013 14Document6 pagesSWMS Template 30013 14Zeeshan AliNo ratings yet

- Method Statement for Replacement of Scats ConveyorDocument7 pagesMethod Statement for Replacement of Scats ConveyorCobbinah MarkNo ratings yet

- Ms-Wet Fire Fighting SystemDocument23 pagesMs-Wet Fire Fighting Systemachusanachu100% (3)

- Swms Pile Test RKDocument13 pagesSwms Pile Test RKrakeshkhanna78No ratings yet

- 11 - MS For Painting WorkDocument9 pages11 - MS For Painting Workgulzaman100% (1)

- BSH Safe Work Method StatementDocument9 pagesBSH Safe Work Method StatementHariprakash karuppannanNo ratings yet

- Painting (General Safety) SWMS 10183-4 - SAMPLEDocument6 pagesPainting (General Safety) SWMS 10183-4 - SAMPLEKunal PanchalNo ratings yet

- JSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentDocument10 pagesJSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentAbdul Rasheed Mangrio50% (2)

- JSP For SS No. 1 Battery Charging and TestingDocument11 pagesJSP For SS No. 1 Battery Charging and TestingmohammedtofiqahmedNo ratings yet

- Method Statement Core Drilling WorksDocument7 pagesMethod Statement Core Drilling WorksUgur100% (1)

- SafetyDocument16 pagesSafetyAlexandra SyNo ratings yet

- SWMS Mobilisation of Blocks For MLT TEST RKDocument14 pagesSWMS Mobilisation of Blocks For MLT TEST RKrakeshkhanna78100% (1)

- SWMS Site Establishment Office Works RKDocument24 pagesSWMS Site Establishment Office Works RKrakeshkhanna7867% (3)

- Mission Training Plan for Military Intelligence BattalionDocument1,168 pagesMission Training Plan for Military Intelligence BattalionChris WhiteheadNo ratings yet

- Method Statement For Testing & Commissioning of Feeder PillarDocument28 pagesMethod Statement For Testing & Commissioning of Feeder PillarhusamNo ratings yet

- Arapahoe Emergency Response Plan 2019Document51 pagesArapahoe Emergency Response Plan 2019drainoNo ratings yet

- DIN 2403 Identification of PipelinesDocument15 pagesDIN 2403 Identification of PipelinesGenerosa Ferreira100% (1)

- P - PF52x Syslib-Rm048 - En-PDocument64 pagesP - PF52x Syslib-Rm048 - En-PwillianlazzaretticreNo ratings yet

- MS-001 - Trial TrenchesDocument5 pagesMS-001 - Trial Trenchesgeriaxavier2022No ratings yet

- Waverley RAMSDocument16 pagesWaverley RAMSJakub WiechaNo ratings yet

- Documents - Pub - Heights Working at Swms No Safe Work Method This Swms Covers The Risk ManagementDocument16 pagesDocuments - Pub - Heights Working at Swms No Safe Work Method This Swms Covers The Risk ManagementVepxvia NadiradzeNo ratings yet

- Safety Plan - Sample For Reference V1.0Document6 pagesSafety Plan - Sample For Reference V1.0krish659No ratings yet

- Construction Labourer Swms 10556-4Document16 pagesConstruction Labourer Swms 10556-4JamesNo ratings yet

- Concrete Placement Finishing Swms 10064-7Document12 pagesConcrete Placement Finishing Swms 10064-7JamesNo ratings yet

- Roofing WorkDocument5 pagesRoofing WorkSsenyonjo EricNo ratings yet

- OHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelDocument9 pagesOHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelEbrahsm ElshenawyNo ratings yet

- Blank PDFDocument14 pagesBlank PDFArshad Rashid ShahNo ratings yet

- Safe Work Method StatementDocument20 pagesSafe Work Method StatementMALAYIL UNNINo ratings yet

- JSP For SS No. 4 Commissioning of High Voltage EquipmentDocument21 pagesJSP For SS No. 4 Commissioning of High Voltage EquipmentmohammedtofiqahmedNo ratings yet

- MS FSK PSK Fiber Optic 031120Document3 pagesMS FSK PSK Fiber Optic 031120DilxazNo ratings yet

- Job Safety SiteDocument11 pagesJob Safety SiteMohd Arfeen RezaNo ratings yet

- Aea 1305 WC El MS 0003Document15 pagesAea 1305 WC El MS 0003Adil HasanovNo ratings yet

- Page - 1: (In Sequence) (Injuries, Damage, Illness, Pollution, Etc)Document10 pagesPage - 1: (In Sequence) (Injuries, Damage, Illness, Pollution, Etc)shafiezubier5No ratings yet

- 7-23 Barricade & Signage (RV)Document10 pages7-23 Barricade & Signage (RV)Lee JungNo ratings yet

- JSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)Document16 pagesJSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)mohammedtofiqahmedNo ratings yet

- Coring HirarcDocument6 pagesCoring Hirarcz6z2fjzyvbNo ratings yet

- MS FSK Demolition 071119Document2 pagesMS FSK Demolition 071119DilxazNo ratings yet

- LCC - DOCS 11099218 v1 HS SWMS 006 Confined Space Entry SWMSDocument6 pagesLCC - DOCS 11099218 v1 HS SWMS 006 Confined Space Entry SWMSManu MohanNo ratings yet

- 101.08 Job Hazard AnalysisDocument5 pages101.08 Job Hazard AnalysisnihadNo ratings yet

- Activity Hazard Analysis ReviewDocument3 pagesActivity Hazard Analysis ReviewJaycee PagadorNo ratings yet

- SWMS C101 Safe Use of LaddersDocument6 pagesSWMS C101 Safe Use of LadderssouravrobinNo ratings yet

- DEECD Working at Heights ProcedureDocument7 pagesDEECD Working at Heights ProcedureJarrett MathewsNo ratings yet

- Life Saving Talk SampleDocument1 pageLife Saving Talk SampleCharleston VillamorNo ratings yet

- Safe Work Method Statement Summary Form - EDITABLE PDFDocument6 pagesSafe Work Method Statement Summary Form - EDITABLE PDFOsama HassanNo ratings yet

- ManufacturingDocument3 pagesManufacturingreyiNo ratings yet

- Concept of DRR and DRRM ModuleDocument8 pagesConcept of DRR and DRRM ModuleJonathan PoloNo ratings yet

- How Do You Maintain Process Safety in Times of Change?Document4 pagesHow Do You Maintain Process Safety in Times of Change?Vikas NigamNo ratings yet

- Hazard Report Form - Checklist 3 Vomit - 16252-Rebeca RaducuDocument3 pagesHazard Report Form - Checklist 3 Vomit - 16252-Rebeca RaducuRebeca RaducuNo ratings yet

- Flooding NewDocument15 pagesFlooding Newronalddelosreyes2No ratings yet

- Chapter 6 Event MarketingDocument9 pagesChapter 6 Event MarketingGowtham SgNo ratings yet

- JARUS Sora Annex I v1.0Document15 pagesJARUS Sora Annex I v1.0Agri AdityaNo ratings yet

- An Introduction To Performance Based Design in NFPA ... - WOBODocument48 pagesAn Introduction To Performance Based Design in NFPA ... - WOBOAgustín Rosas PérezNo ratings yet

- TR - System Formwork Installation NC IIDocument51 pagesTR - System Formwork Installation NC IIAnskey berthomeNo ratings yet

- Bsbsus201 Task 2of2Document13 pagesBsbsus201 Task 2of2Znb TechNo ratings yet

- 4 - S&T and Nation BuildingDocument80 pages4 - S&T and Nation BuildingAngelica LlamasNo ratings yet

- Portfolio Reflection on Hazards, Disasters, and SafetyDocument4 pagesPortfolio Reflection on Hazards, Disasters, and SafetyMaeGadiazaNo ratings yet

- 089e Risk Assessment PDFDocument1 page089e Risk Assessment PDFTATATAHERNo ratings yet

- TOR-Region IIIDocument31 pagesTOR-Region IIIfranz ramosNo ratings yet

- 06 Overview of Ra1Document71 pages06 Overview of Ra1Dana GuerreroNo ratings yet

- Seminar Setting: ObjectivesDocument34 pagesSeminar Setting: ObjectivesMary CallejaNo ratings yet

- A Definition of Cascading Disasters and Cascading Effects - Going Beyond The Toppling Dominos MetaphorDocument10 pagesA Definition of Cascading Disasters and Cascading Effects - Going Beyond The Toppling Dominos MetaphorEduardo SilvaNo ratings yet

- Safety Officer QuizDocument5 pagesSafety Officer QuizAbdulmajeedNo ratings yet

- Briefing Note - Climate Security and National SecurityDocument3 pagesBriefing Note - Climate Security and National SecurityThe American Security ProjectNo ratings yet

- Review On Tsunami Risk Reduction in Indonesia Based On Coastal and Settlement TypologyDocument9 pagesReview On Tsunami Risk Reduction in Indonesia Based On Coastal and Settlement TypologyHarryNo ratings yet

- Stress Risk Assessment Form: Name Role Date DepartmentDocument2 pagesStress Risk Assessment Form: Name Role Date Departmentbirhane gebreegziabiherNo ratings yet

- RHS00041 Wildlife StandardDocument35 pagesRHS00041 Wildlife StandardRod DiazNo ratings yet