Professional Documents

Culture Documents

7-14-0001 Tolerence For Welded Support Tray

7-14-0001 Tolerence For Welded Support Tray

Uploaded by

arun sOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7-14-0001 Tolerence For Welded Support Tray

7-14-0001 Tolerence For Welded Support Tray

Uploaded by

arun sCopyright:

Available Formats

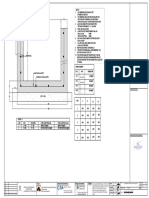

WELDED INTERNALS SHALL BE FABRICATED WITHIN THE FOLLOWING

TOLERANCES AND ALL PARTS SHALL BE INTERCHANGEABLE

E E

SYMBOL DESCRIPTION

EXIT WEIR HEIGHT SHALL BE IN LEVEL WITHIN ±1 mm RELATIVE TO THE SPECIFIED

A

DATUM SURFACE AND TO EACH OTHER.

E iE B

CLEARANCE BETWEEN BOTTOM EDGE OF DOWNCOMER BOLTING BAR AND TOP OF

SUPPORT RING SHALL BE WITH IN ±3 mm OF SPECIFIED DIMENSION.

M DISTANCE BETWEEN RELATED TRAY SUPPORT RING SHALL BE WITHIN ±3 mm OF

C

SPECIFIED DIMENSION.

THE DEPTH OF SEAL PAN AND DRAW—OFF PAN SHALL BE WITHIN ±1 mm OF

D

THE SPECIFIED DIMENSIONS.

DIMENSIONS IN THE HORIZONTAL DIRECTION OF VERTICAL DOWNCOMER BOLTING BAR,

E

SUPPORT BRACKET OR CUPS SHALL BE WITHIN TOLERANCES AS PER DRAWINGS.

BOLTING BARS WELDED ON OPPOSITE FACES OF COLUMN SHOULD UE EXACTLY ON

F

ONE LINE.

TRAY SUPPORT RING AND BOLTING BAR SHALL NOT HAVE WAVINESS EXCEEDING

G

1.5mm FOR ANY 500mm OF CIRCUMFERENTIAL LENGTH.

LEVEL DIFFERENCE OF A TRAY SUPPORT RING OVER ITS WIDTH SHOULD NOT EXCEED

H

0.75mm.

ORIENTATION OF DOWNCOMER REFERENCE UNE SHALL BE WITHIN ±3 mm OF ITS

J

NOMINAL DISTANCE FROM THE VESSEL REFERENCE CENTER UNE.

INCLINATION OF SUPPORT RING TO HORIZONTAL PLANE TO BE WITHIN TOLERANCES

GIVEN BELOW:

1.5mm FOR COLUMN I/D <= 1500mm.

K 3.0mm FOR 1500mm < COLUMN I/D <= 3000mm.

4.5mm FOR 3000mm < COLUMN I/D <= 4500mm.

6.0mm FOR COLUMN I/D > 4500mm.

HORIZONTAL SLOTS ON BOLTING BARS SHALL BE FABRICATED WITHIN FOLLOWING

jI TOLERANCES:

z L

+2.0mm

LENGTH—O.Omm WIDTH ±0.25mm, MAX. INCLINATION WITH HORIZONTAL ±1.0mm.

M THE VERTICALITY OF BOLTING BAR SHOULD BE WITHIN ±1 mm.

B

THE ELEVATION OF DOWNCOMER AND MAJOR BEAM STOOL WITH RESPECT TO

N —0 mm

REFERENCE TRAY SUPPORT RING SHOULD BE WITHIN + 6 mm

SLOT CENTERS FOR DOWNCOMERS (AS SHOWN) SHALL BE WITHIN TOLERANCES

P

AS SPECIFIED ON DRAWINGS.

NOTES:-

1. TOLERANCES SHOWN IN THE FABRICATION DRAWINGS TAKE PRECEDENCE OVER THOSE

SHOWN HERE IN.

2. IN CASE OF THESE TOLERANCES CLASHING WITH THAT OF VESSEL, THE DIMENSIONS ARE

WIDTH/2

TO BE MAINTAINED SO THAT IT SATISFIES BOTH TOLERENCES.

3. TOLERANCES ON CONSECUTIVE DIMENSIONS ARE NON—CUMULATIVE.

WORKING ELEVATION OF SUPPORT RING .1ACLINATION BETWEEN

CENTER LINE 4. FOR DETAILS SUCH AS WIDTH, THICKNESS OF BOLTING BARS, WELDING REQUIREMENTS,

TOLERANCES NOT COVERED IN THIS STANDARD, REFER TSR/BB DRAWINGS.

500

NNNNNNNNNNNNNNNNNNN,,,,,,;::."

SUPPORT RING

REFER 'L' BELOW

SP

21.03.2018 RE—AFFIRMED & REISSUED AS STANDARD STANDARD NO.

CONSTRUCTIONAL TOLERANCES

3 17-08-10 RE—AFFIRMED & ISSUED AS STANDARD SKJ/VDY KKG AKG ND

FOR WELDED SUPPORTS 7 -14 - 0001 Rev. 4

MIA LIMITED Rev Prepd Checked Stds. Committee Stds. Bureau

Convenor Chairman FOR TRAYS/TOWER INTERNALS

mew eneweememe (A Govt. of India Undertaking) Date Purpose

No by by Approved by

Page 1 of 1

Format No. 8-00-0001-F5 Rev. 0 Copyright EIL - All rights reserved

Page 21841 of 22455

You might also like

- Air Conditioning Principles and Systems by Edward G. PitaDocument543 pagesAir Conditioning Principles and Systems by Edward G. Pitapondu888100% (5)

- M AcuDocument3 pagesM AcuarkiTOM18100% (2)

- Trillium (Centrifugal Pump API 610)Document12 pagesTrillium (Centrifugal Pump API 610)Wibowo ArieNo ratings yet

- GENERAL PHYSICS 2 - Q3 - Week 4Document27 pagesGENERAL PHYSICS 2 - Q3 - Week 4ariinnggg onichaNo ratings yet

- Basic Erection Execution Sequence: GROUND RULE: Erection Always Starts On A Braced BayDocument7 pagesBasic Erection Execution Sequence: GROUND RULE: Erection Always Starts On A Braced BaypvmoorthiNo ratings yet

- Electrical Symbol Notes: Revised 15 DECEMBER 2015Document43 pagesElectrical Symbol Notes: Revised 15 DECEMBER 2015dawitgggNo ratings yet

- En 12600 Safety Glazing Testing Summary PDF0360SGTSINTDocument1 pageEn 12600 Safety Glazing Testing Summary PDF0360SGTSINTNistor AlexandruNo ratings yet

- Interview With Dr. Deagle On Geo-EngineeringDocument12 pagesInterview With Dr. Deagle On Geo-EngineeringCindy FurugoriNo ratings yet

- Medical Equipment TroubleshootingDocument28 pagesMedical Equipment TroubleshootingNarendran Ravi83% (6)

- P - ID Drawing StandardsDocument8 pagesP - ID Drawing StandardsObaid AliNo ratings yet

- RCC Drawing of Open Drain 11-10-2022Document16 pagesRCC Drawing of Open Drain 11-10-2022AKB CONSULTANTSNo ratings yet

- Proposed 2-Storey Residential House-FootingDocument1 pageProposed 2-Storey Residential House-FootingZiur18100% (1)

- Toureen Group: Stage3 - Piling + UnderpinningDocument1 pageToureen Group: Stage3 - Piling + UnderpinningAnonymous qEPNPwANo ratings yet

- Plinth Slab LVL (Rev.4) 10-08-2017 Sh.2Document1 pagePlinth Slab LVL (Rev.4) 10-08-2017 Sh.2Monali VarpeNo ratings yet

- FIREFLY™ Timber Suspended Ceiling RigDocument1 pageFIREFLY™ Timber Suspended Ceiling RigdasdaNo ratings yet

- JJ Cruz + Associates S-02: Standard HooksDocument1 pageJJ Cruz + Associates S-02: Standard HooksCarlo GarciaNo ratings yet

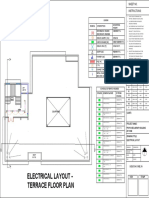

- Electrical Layout - Terrace Floor Plan: Sheet No. InstructionsDocument1 pageElectrical Layout - Terrace Floor Plan: Sheet No. InstructionsAbhishek AjayNo ratings yet

- Standard Drawing 4071 Guard Fence Layouts For Bridge Approaches July 2020Document1 pageStandard Drawing 4071 Guard Fence Layouts For Bridge Approaches July 2020soumya1986No ratings yet

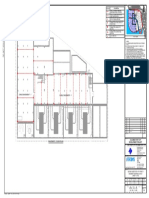

- Specification: Foundation PlanDocument1 pageSpecification: Foundation PlanRenzelNo ratings yet

- BH Plans ST 1Document1 pageBH Plans ST 1Soner, John LloydNo ratings yet

- Dewsbury Ol, PLT 5, H T Lydford - Beam Layout - Yh 13 0004 08Document1 pageDewsbury Ol, PLT 5, H T Lydford - Beam Layout - Yh 13 0004 08NitaiGauranga108No ratings yet

- Municipality of Pamplona: (Fill Side) Detail of Grouted RiprapDocument1 pageMunicipality of Pamplona: (Fill Side) Detail of Grouted RiprapArmand Mikhail TempladoNo ratings yet

- Solar System For 60m WellDocument3 pagesSolar System For 60m WellM.zahirNo ratings yet

- AB-036679-001 Fence Gate DetailsDocument1 pageAB-036679-001 Fence Gate DetailsAbdul Nazir - 11858 Hawiyah Branch - QCNo ratings yet

- Electrical Layout - Ground Floor Plan: Sheet No. InstructionsDocument1 pageElectrical Layout - Ground Floor Plan: Sheet No. InstructionsAbhishek AjayNo ratings yet

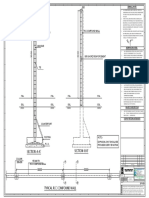

- Gantry Drawing - ApprovedDocument1 pageGantry Drawing - ApprovedTanveer IqbalNo ratings yet

- Revised Green and More-Layout1Document1 pageRevised Green and More-Layout1selvaNo ratings yet

- Element - 77 - 370-Electrical Drawing Umutoni NicoleDocument1 pageElement - 77 - 370-Electrical Drawing Umutoni NicolePatty GorospeNo ratings yet

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- 1009-S1-EL-EAR-4001 - 0 - SV1 - Electrical Outdoor Earthing LayoutDocument1 page1009-S1-EL-EAR-4001 - 0 - SV1 - Electrical Outdoor Earthing LayoutRashmi Ranjan MohantyNo ratings yet

- A LiftDocument1 pageA LiftAPS DESIGN INFRA PVT.LTD.No ratings yet

- Twin Home Struct-Plumb-ElecDocument13 pagesTwin Home Struct-Plumb-ElecDexter Lex F. SatanaNo ratings yet

- DRG 1Document1 pageDRG 1Palak BhatiaNo ratings yet

- Earthing BasementDocument1 pageEarthing BasementNad EemNo ratings yet

- Anthony Wanjiku Revised StructuralDocument1 pageAnthony Wanjiku Revised Structuralpatrickmore09No ratings yet

- 4525 S HSK Ew 010 SeriesDocument10 pages4525 S HSK Ew 010 SeriesBartosz ZaforemskiNo ratings yet

- AS05Document1 pageAS05Vic NairaNo ratings yet

- Specification:: Details Plumbing DrawingDocument1 pageSpecification:: Details Plumbing DrawingCarl Lou BaclayonNo ratings yet

- RCC Retaining Wall 150Mm Thick Leveling Coarse Final Grade Line After Backfill Top of Subgrade Line LegendDocument1 pageRCC Retaining Wall 150Mm Thick Leveling Coarse Final Grade Line After Backfill Top of Subgrade Line LegendSafi Zabihullah SafiNo ratings yet

- G FootingsDocument9 pagesG FootingsRiham Massoud SobhyNo ratings yet

- Toilet Sunken or Raised Waterproofing Detail - Smart PointDocument1 pageToilet Sunken or Raised Waterproofing Detail - Smart Pointajay kumarNo ratings yet

- COMP WALL WITH RETAINING WALL ModelDocument1 pageCOMP WALL WITH RETAINING WALL ModelAmarjit KulkarniNo ratings yet

- Abs SectionDocument1 pageAbs SectionSiddhi TambatNo ratings yet

- Dewsbury Ol, PLTS 24-27, H T Hadleigh - Beam Layout - Yh 13 0004 24Document1 pageDewsbury Ol, PLTS 24-27, H T Hadleigh - Beam Layout - Yh 13 0004 24NitaiGauranga108No ratings yet

- PS4 DEFT Tender Drawing-14Document1 pagePS4 DEFT Tender Drawing-14waskyconstructioncoNo ratings yet

- WH# 06 - Petrokemya NorthDocument4 pagesWH# 06 - Petrokemya NorthEAC Alim KhanNo ratings yet

- General Notes-1: Table 1: Lap Splices For RebarsDocument1 pageGeneral Notes-1: Table 1: Lap Splices For RebarsTanvir IslamNo ratings yet

- Unit 17 Lighting LayoutDocument1 pageUnit 17 Lighting Layoutnikkoelbao96No ratings yet

- 23 - Sheet-ELEVATIONS 1&2Document1 page23 - Sheet-ELEVATIONS 1&2Fun TonNo ratings yet

- Temporary Strand Cutting Sequence: Single Span Prestressed Girder Construction SequenceDocument1 pageTemporary Strand Cutting Sequence: Single Span Prestressed Girder Construction SequenceJesús Rodríguez RodríguezNo ratings yet

- General Construction Notes: Typical Connection Detail of Masonry WallDocument1 pageGeneral Construction Notes: Typical Connection Detail of Masonry WallMItchNo ratings yet

- General Notes:: Fillet Weld TableDocument1 pageGeneral Notes:: Fillet Weld Tablefrancis sebastian lagamayoNo ratings yet

- Adobe Scan 07-Aug-2021Document1 pageAdobe Scan 07-Aug-2021Mohammad TaushifNo ratings yet

- Legend:: Service EntranceDocument1 pageLegend:: Service EntranceRODEAN HOPE LACSINo ratings yet

- RCC COMPOUND WALL-ModelDocument1 pageRCC COMPOUND WALL-ModelkalpanaNo ratings yet

- Mild Steel Roof Trusses: To Prevent Secondary Shear and SDocument2 pagesMild Steel Roof Trusses: To Prevent Secondary Shear and Sweeds newNo ratings yet

- ACM-TSC-VS-MF-GFC-DWG-ST-2001 - Rev 1Document1 pageACM-TSC-VS-MF-GFC-DWG-ST-2001 - Rev 1Aecom IndiaNo ratings yet

- 21 - Sheet-GROUND FLOOR PLANDocument1 page21 - Sheet-GROUND FLOOR PLANFun TonNo ratings yet

- RW 2-03Document1 pageRW 2-03kigonyaNo ratings yet

- 10 Precast - Pre-Stress Conc - ConstDocument1 page10 Precast - Pre-Stress Conc - ConstChhaganNo ratings yet

- Office Section - Acit PlanDocument1 pageOffice Section - Acit PlannavisNo ratings yet

- A B C D E: Ground Floor Plan 1.1Document1 pageA B C D E: Ground Floor Plan 1.1Vandana BaburajNo ratings yet

- ELEV 1 MergedDocument4 pagesELEV 1 MergedVandana BaburajNo ratings yet

- D.I. Pipe Line Detail: Drawing ReferenceDocument1 pageD.I. Pipe Line Detail: Drawing ReferencehimajcpNo ratings yet

- Vertical Wall With No Slope2Document1 pageVertical Wall With No Slope2aldeto71No ratings yet

- Sarin CV Updates24Document3 pagesSarin CV Updates24arun sNo ratings yet

- BiswajitDocument3 pagesBiswajitarun sNo ratings yet

- Hse Credibility Score 25-09-2023Document1 pageHse Credibility Score 25-09-2023arun sNo ratings yet

- B224-EPCC07-LT-125-CN-QD-M-ITP-0001 Inspection and Test Plan For AG Piping Fab. & Erection Works.Document4 pagesB224-EPCC07-LT-125-CN-QD-M-ITP-0001 Inspection and Test Plan For AG Piping Fab. & Erection Works.arun sNo ratings yet

- Hydro 1Document1 pageHydro 1arun sNo ratings yet

- STPM 2021 Sem 3 Mock AnsDocument2 pagesSTPM 2021 Sem 3 Mock AnsNATASHA NADIA BINTI ABDULLAH MoeNo ratings yet

- Nce 8295 AkDocument7 pagesNce 8295 Akandre kressnerNo ratings yet

- Mahatma Gandhi University: Priyadarshini Hills, Kottayam-686560Document136 pagesMahatma Gandhi University: Priyadarshini Hills, Kottayam-686560Rashmee DwivediNo ratings yet

- Ref 5 Failure Analysisi of A Crude Oil PipelineDocument17 pagesRef 5 Failure Analysisi of A Crude Oil PipelineGumelar KalamalNo ratings yet

- Pump Series D-H-M-HD-PGH ParkerDocument13 pagesPump Series D-H-M-HD-PGH ParkerDaniel MarNo ratings yet

- Arches MCQDocument9 pagesArches MCQjampanivenkat8No ratings yet

- Alba SP LIST For D 32-36-42 LDocument24 pagesAlba SP LIST For D 32-36-42 Ldrmasster100% (1)

- Tutorial 5-1Document2 pagesTutorial 5-1chandan rajNo ratings yet

- Operation Manual: Portable Density/Specific Gravity MeterDocument53 pagesOperation Manual: Portable Density/Specific Gravity MeterEduard Florez EfresNo ratings yet

- 530BOD01 - 530BOD01 - DS - enDocument4 pages530BOD01 - 530BOD01 - DS - enBhageerathi SahuNo ratings yet

- Three Phase Induction MotorDocument29 pagesThree Phase Induction MotorAnirban SarkarNo ratings yet

- J Jfoodeng 2016 02 026Document57 pagesJ Jfoodeng 2016 02 026Kim SeokjinNo ratings yet

- Products-Brochure GB New SMOG HOGDocument5 pagesProducts-Brochure GB New SMOG HOGJinex KuangNo ratings yet

- De La Salle University Gokongwei College of Engineering Civil Engineering DepartmentDocument9 pagesDe La Salle University Gokongwei College of Engineering Civil Engineering DepartmentAdrian PerezNo ratings yet

- Principles of Analog Electronics 1st Saggio Solution ManualDocument10 pagesPrinciples of Analog Electronics 1st Saggio Solution Manualfrizz.archlyiwmhmn100% (43)

- Windsor Steampac WT Boiler Brochure 2019Document2 pagesWindsor Steampac WT Boiler Brochure 2019AnthonyNo ratings yet

- Temperature Controller Catalog - EngDocument9 pagesTemperature Controller Catalog - EngJuan Gervacio OrtegaNo ratings yet

- VFD LastDocument31 pagesVFD LastSujith KumarNo ratings yet

- 18-0022 Elliot JA22Document33 pages18-0022 Elliot JA22basemNo ratings yet

- Time in Quantum Mechanics (J. Gonzalo Muga, Rafael Sala Mayato Etc.) (Z-Library)Document461 pagesTime in Quantum Mechanics (J. Gonzalo Muga, Rafael Sala Mayato Etc.) (Z-Library)Samuel OliveiraNo ratings yet

- Unit 7 Radar: StructureDocument28 pagesUnit 7 Radar: StructureParminder singh parmarNo ratings yet

- Group Members: Suhaidah Binti Nazori UK21425 Mohd Faizuddin Bin Abu Hasan UK21455 Siti Fasihah Binti Rameli UK21478Document27 pagesGroup Members: Suhaidah Binti Nazori UK21425 Mohd Faizuddin Bin Abu Hasan UK21455 Siti Fasihah Binti Rameli UK21478ah_16036566No ratings yet

- GD TheoryGuide PHmeasurement en 30078149 Mar16 (001-102) Parte2Document54 pagesGD TheoryGuide PHmeasurement en 30078149 Mar16 (001-102) Parte2nelson valenciaNo ratings yet

- Mos2 PaperDocument16 pagesMos2 PaperJosé Adriano SilvaNo ratings yet