Professional Documents

Culture Documents

General Notes:: Fillet Weld Table

Uploaded by

francis sebastian lagamayoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Notes:: Fillet Weld Table

Uploaded by

francis sebastian lagamayoCopyright:

Available Formats

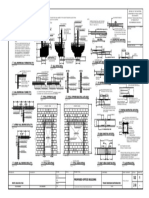

GENERAL NOTES: MINIMUM EMBEDMENT AND LAP SPLICE (mm)

1.0 GENERAL : fc' = 20.7 MPa to 41.4 MPa

1.1 ALL DIMENSIONS ARE SHOWN IN MILLIMETERS, ELEVATIONS ARE IN METERS, 3.2. REINFORCING BARS : BAR EMDEDMENT CLASS A CLASS B CLASS C TOP BARS (W/ MIN. 300 OF CONC. CAST BELOW)

5.0 FOUNDATIONS : STRAIGHT

UNLESS NOTED OTHERWISE. SIZE LENGTH 'E' TENSION SPLICE TENSION TENSION CLASS A CLASS B CLASS C

3.2.1 EMBEDMENT STRAIGHT

UNLESS OTHERWISE SPECIFIED ON PLANS, ALL REINFORCING BARS SHALL BE W/ STD. END ALSO FOR COM- SPLICE SPLICE TENSION TENSION TENSION

1.2 THE CONTRACTOR SHALL VERIFY ALL DIMENSIONS AND CONDITIONS AT THE 5.1 FOOTINGS WERE DESIGNED USING AN ALLOWABLE SOIL BEARING 'Ld' EMBEDMENT

DEFORMED WITH A MINIMUM YIELD STRENGTH, fy = 30000 PSI HOOK 'H' PRESSION SPLICE 1.3 * Ld 1.7 * Ld SPLICE SPLICE SPLICE

SITE, AND SHALL NOTIFY THE ENGINEER OF DISCREPANCIES BETWEEN ACTUAL CAPACITY OF 144 KPa (3000 PSF) AT DEPTHS INDICATED IN THE DRAWING. 1.4 * Ld 1.4 * Ld 1.82 * Ld 2.38 * Ld

CONDITIONS AND INFORMATION SHOWN ON THE DRAWINGS BEFORE PROCEEDING FOR Ø12 AND BELOW, AND fy = 40000 PSI FOR Ø16 AND ABOVE. CONFIRMATION OF ACTUAL SOIL BEARING CAPACITY SHALL BE DONE PRIOR TO

E = 25

WITH THE WORK. THIS SHALL INCLUDE THE LOCATION AND DIMENSIONS OF CONSTRUCTION OF FOUNDATION, INCREASE IN FOUNDATION SIZE SHALL BE DONE Ø10 250 300 400 500 350 350 450 600

3.2.2 ALL REINFORCING BARS SHALL BE CLEANED OF RUST, GREASE OR OTHER H = 150

GROOVES, REGLETS, SLEEVES, CURBS, OPENINGS, EMBEDDED OR ATTACHED WHEN ACTUAL SOIL BEARING CAPACITY, CONFIRMED DURING EXCAVATION, WARRANTS

MATERIALS WHICH TEND TO IMPAIR BOND. E = 150

ITEMS, ETC. REFER TO ARCHITECTURAL, MECHANICAL, ELECTRICAL AND PLUMBING REVISION OF FOUNDATION SIZES. Ø12 300 400 500 600 400 400 600 700

3.2.3 H = 200

ALL FIGURED DIMENSIONS SHALL TAKE PRECEDENCE OVER SCALE SHOWN ON PLANS, ALL REINFORCING BARS SHALL BE ACCURATELY AND SECURELY PLACED

DRAWINGS. BEFORE POURING CONCRETE OR APPLYING MORTAR OR GROUT. 5.2 WHERE LOOSE/SOFT MATERIAL IS ENCOUNTERED AT DEPTH OF FOOTING/FOUNDATION Ø16 400

E = 200

500 600 700 600 600 700 900

INDICATED, EXCAVATE TO FIRM LAYER AND REPLACE LOOSE/SOFT MATERIALS H = 250

1.3 SECTIONS OR DETAILS. SPECIFIC NOTES AND DETAILS ON DRAWINGS SHALL TAKE 3.2.4 LAPPED SPLICES SHALL BE STAGGERED WHERE POSSIBLE.

PRECEDENCE OVER GENERAL NOTES AND TYPICAL DETAILS. UNDERNEATH THE FOOTING WITHIN THE FOOTING AREA PLUS 1/2 DEPTH OF SOIL E = 250

3.2.5 UNLESS INDICATED OTHERWISE, SPLICING OF REINFORCEMENT SHALL BE IN Ø20 500 600 700 900 700 700 900 1200

MATERIAL ON ALL SIDES WITH SELECTED BACKFILL. COMPACT SELECTED BACKFILL H = 300

1.4 THE CONTRACT STRUCTURAL DRAWINGS AND SPECIFICATIONS REPRESENT THE ACCORDANCE WITH ACI- 318-95. TO 95% MAXIMUM DRY DENSITY ( ASTM D1557). E = 300

Ø25 800 800 1000 1400 1100 1100 1500 1900

FINISHED STRUCTURES. THEY DO NOT INDICATE THE METHOD OF CONSTRUCTION 3.2.6 UNLESS SHOWN OTHERWISE ON PLANS, SPLICES SHALL BE AS FOLLOWS : H = 400

5.3 ALL COLUMN FOOTINGS SHALL REST ON 50MM THK COMPACTED GRAVEL

UNLESS SO STATED. THE CONTRACTOR SHALL PROVIDE ALL NECESSARY E = 350

A. BEAMS AND FOOTING TIE BEAMS : TOP AND BOTTOM BARS SHALL NOT BASE COURSE, UNLESS OTHERWISE STATED. Ø28 900 900 1200 1500 1300 1300 1600 2100

MEASURES TO PROTECT THE STRUCTURES, ADJACENT PROPERTIES, WORKMEN H = 500

BE SPLICED WITHIN THE COLUMN OR WITHIN A DISTANCE OF TWICE THE

AND OTHER PERSONS DURING ALL PHASES OF CONSTRUCTION. 5.4 FILL/BACKFILL SHALL BE PLACED IN 200 MM LAYERS AND EACH LAYER SHALL BE E = 600

MEMBER DEPTH FROM THE FACE OF THE COLUMN ; AT LEAST TWO EXTRA Ø32 900 1100 1600 1860 1560 1560 2000 2600

COMPACTED TO 95% MAXIMUM DRY DENSITY BEFORE SUBSEQUENT LAYERS H = 750

1.5 THE CONTRACTOR SHALL IMMEDIATELY NOTIFY THE OWNER AND/OR THE STIRRUP - TIES SHALL BE PROVIDED AT ALL SPLICES. THE SPLICE LENGTH

ARE TO BE LAID. E = 750

THE ENGINEER OF ANY CONDITION WHICH IN HIS OPINION MIGHT ENDANGER SHALL NOT BE LESS THAN THE LENGTH IN ITEM 4.2.9 BELOW. Ø36 1200 1300 2000 2210 1820 1820 2400 2400

H = 600

THE STABILITY OF THE STRUCTURES OR CAUSE DISTRESS IN THE STRUCTURES. B. COLUMNS : SPLICES WHEN PERMITTED SHALL BE MADE WITHIN THE CENTER STRAIGHT STRAIGHT

HALF OF COLUMN HEIGHT, AND LAP SPLICE SHALL NOT BE LESS THAN S

1.6 CONSTRUCTION MATERIALS SHALL NOT BE STORED ON POURED FLOORS. IT

40 BAR DIAMETERS. THE USE OF APPROVED MECHANICAL DEVICES MAY BE

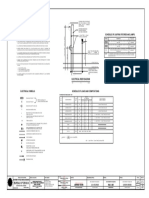

EMBEDMENT CLASS B CLASS C EMBEDMENT CLASS A CLASS B CLASS C

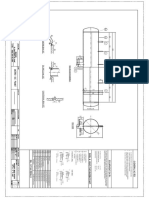

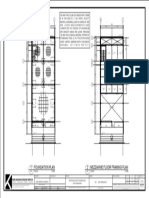

FILLET WELD TABLE K

CLASS A

IS THE GENERAL CONTRACTOR'S RESPONSIBILITY TO ENSURE THAT THE

E

E

SUB-CONTRACTORS ARE INFORMED AND DO NOT VIOLATE THIS IMPORTANT PERMITTED PROVIDED THAT NOT MORE THAN ALTERNATE BARS ARE

SPLICED AT ANY LEVEL AND THE MINIMUM VERTICAL DISTANCE T

REQUIREMENT. WELD SIZE, S SCALLOP NOTCH H

300

BETWEEN TWO ADJACENT BAR SPLICES SHALL BE 600MM. C

PLATE THICKNESS, t (MIN)

1.7 THE CONTRACTOR SHALL PROVIDE TEMPORARY ERECTION BRACINGS AND (MM) (MM) H STD. 90° OR

SHORINGS FOR ALL THE STRUCTURAL MEMBERS AS REQUIRED FOR STRUCTURE C. CMU WALLS : VERTICAL BARS SHALL BE SPLICED AT THE TOP OF WALL 180° HOOK

(MM) MIN. CONC.

STABILITY DURING ALL PHASES OF CONSTRUCTION. FOOTING OR TIE BEAM AND AT THE BOTTOM OF RC LINTEL T JOINTS LAP JOINTS R END AN- END AN- FOR FOR BEAM FOR FOR BEAM TOP BEAM TOP FOR

BEAM OR BEAMS. SPLICE LENGTHS SHALL BE 600MM MIN. CHORAGE CHORAGE COLUMN BOT. BARS CONC. BEAMS BARS BARS CONC.

1.8 THE CONTRACTOR SHALL TAKE ALL STEPS NECESSARY TO ENSURE THE R FOR BOT. FOR BOT. VERT. BARS, WHERE WALL VERT. INTO WHERE WHERE WALL VERT.

3.2.7 UNLESS INDICATED OTHERWISE ALL BEAMS TERMINATING AT THE COLUMN LESS THAN 6 S=t S=t 25

PROPER ALIGNMENT OF THE STRUCTURES DURING AND AFTER THE INSTALLATION SHALL HAVE TOP AND BOTTOM BARS EXTENDING TO THE FAR FACE OF E BARS OF BARS OF BEAM BOT. TENSILE BARS, SLAB WALLS TENSILE TENSILE BARS,

OF ALL STRUCTURAL AND FINISH MATERIALS. THE COLUMN, TERMINATING IN A STANDARD 90° HOOK LENGTH OF M SLAB & SLABS & BARS STRESS IN & BEAM STRESS IN STRESS IN BEAM TOP

6 TO 8 6 4 25 BEAMS BEAMS, WHERE BARS < BARS BARS < BARS < BARS

ANCHORAGE NOT LESS THAN 600MM. A

1.9 TYPICAL DETAILS AND GENERAL NOTES ON S-1 APPLY TO ALL PARTS OF THE WALL, COL. TENSILE 0.5* fy & % WHERE 0.5* fy & % 0.5* fy & % WHERE

WORKS UNLESS OTHERWISE SHOWN ON THE DRAWINGS. 9 TO 11 6 6 25 R DOWELS TO STRESS IN OF BAR TENSILE OF BAR OF BAR TENSILE

3.2.8 SHOP DRAWINGS FOR BENDING AND CUTTING OF REINFORCEMENT SHALL

BE SUBMITTED FOR APPROVAL TO THE ENGINEER PRIOR TO FABRICATION. K FOOTINGS BARS < 0.5* SPLICE > STRESS IN SPLICE > SPLICE > STRESS IN

S fy & % OF 75% BARS < 0.5* 75% 75% BARS < 0.5*

3.2.9 SPLICE LENGTH OF REINFORCING BARS SHALL BE AS SHOWN IN THE 12 TO 15 9 9 35

2.0 STANDARDS AND REFERENCES : BAR SPLICE fy & % OF fy & % OF

TABLE BELOW: > 75% BAR SPLICE BAR SPLICE

THE FOLLOWING SHALL GOVERN THE DESIGN, FABRICATION AND CONSTRUCTION 16 TO 18 9 9 35 > 75% > 50%

3.3 STRUCTURAL STEEL/ANCHOR BOLTS/BOLTS/WELDS & WELDMENTS

OF THE PROJECT :

3.3.1 ALL STRUCTURAL STEEL SHALL HAVE A MINIMUM YIELD STRENGTH, 19 OR OVER 12 12 35

2.1 AMERICAN CONCRETE INSTITUTE ( ACI PUBLICATIONS ) ; Fy = 248 MPa (36 KSI) AND SHALL CONFORM TO ASTM A 36

ACI 318-95 BUILDING CODE REQUIREMENTS FOR STRUCTURAL CONCRETE SPECIFICATIONS. STANDARD END HOOK DIMENSIONS

ACI 315-80 MANUAL OF STANDARD PRACTICE FOR DETAILS AND DETAILING 3.3.2 S

ALL STRUCTURAL STEEL SHALL BE FABRICATED AND ERECTED IN

OF CONCRETE REINFORCEMENT. ACCORDANCE WITH THE AISC SPECIFICATIONS (9TH EDITION) AND 180° HOOKS 90° HOOKS 135° HOOKS

2.2 AMERICAN INSTITUTE OF STEEL CONSTRUCTION (AISC) PUBLICATION: CODE OF STANDARD PRACTICE AS AMENDED TO DATE. BAR SIZE D(mm.)

WELD ALL AROUND

MANUAL OF STEEL CONSTRUCTION, NINTH EDITION. ALL COLD FORMED STEEL SHALL HAVE A MINIMUM STRENGTH, WELD ALL AROUND (mm)

3.3.3 A (mm.) J (mm.) A (mm.) A (mm.) H (mm.)

"ALLOWABLE STRESS DESIGN" (ASD) Fy = 230 MPa (33 KSI)

t1

3.3

t2

2.3 AMERICAN WELDING SOCIETY (AWS) PUBLICATION D.1.1-90. 3.3.4 NO STEEL SHALL BE FABRICATED OR ERECTED UNTIL SHOP DRAWINGS 8 50 105 65 130

t2

HAVE BEEN APPROVED BY THE STRUCTURAL ENGINEER.

2.4 AMERICAN SOCIETY FOR TESTING MATERIALS (ASTM) 10 60 125 80 155 110 65

3.3.5 ALL SHOP AND FIELD WELDING SHALL BE IN ACCORDANCE WITH AWS S

2.5 NATIONAL STRUCTURAL CODE OF THE PHILIPPINES (NSCP) VOL. 1, D.1.1-2000 AND PERFORMED BY QUALIFIED WELDERS. 12 80 155 100 200 115 80

FIFTH EDITION, 2001. 3.3.6 UNLESS INDICATED OTHERWISE, WELDING ELECTRODES SHALL BE E70XX, t=t1 OR t2, WHICHEVER IS THINNER

2.6 ASSOCIATION OF STRUCTURAL ENGINEERS OF THE PHILIPPINES (ASEP) MINIMUM THICKNESS OF WELD SHALL BE 3MM. 16 95 180 130 250 140 95

HANDBOOK OF STRUCTURAL STEEL SHAPES AND SECTIONS, 1987

3.3.7 UNLESS OTHERWISE INDICATED ALL ANCHOR NOTE: 20 120 220 165 325 205 115

2.7 UNIFORM BUILDING CODE (UBC), VOL. 2 1997 EDITION BOLTS SHALL CONFORM TO ASTM A307 SPECIFICATIONS. UNLESS OTHERWISE SPECIFIED, SIZE OF FILLET WELDS SHALL BE PROVIDED

3.3.8 BOLTS FOR MEMBER CONNECTIONS SHALL BE HIGH STRENGTH BOLTS, AS SHOWN ABOVE. THE WELD SIZE NEED NOT EXCEED THE THICKNESS OF 25 155 275 205 425 270 155

CONFORM TO ASTM A325 FRICTION TYPE WITH WASHERS. THE THINNER MATERIAL BEING JOINT.

3.0 MATERIALS 28 240 375 300 475

3.1. NORMAL WEIGHT CONCRETE : 3.4 CONCRETE MASONRY UNITS (CMU)

32 275 425 335 550

3.1.1 CONCRETE USED IN THIS WORK SHALL HAVE A MINIMUM COMPRESSIVE STRENGTH 3.4.1 CMU USED IN THESE WORKS SHALL HAVE A MINIMUM ULTIMATE

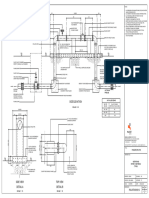

@ 28 DAYS AS FOLLOWS: COMPRESSIVE STRENGTH @ 28 DAYS AS FOLLOWS : W=1200 MAX W=1200 MAX STANDARD REINFORCEMENT DETAILS

100MM THICK NON-LOAD BEARING CMU, f'm = 6.9 MPa (350 PSI)

FOOTINGS, AND SLABS (3000 PSI) 100MM THICK NON-LOAD BEARING CMU, f'm = 6.9 MPa (350 PSI) (FOR W=1200 PLUS - CONSULT STRUC'L ENRG.) (FOR W=1200 PLUS - CONSULT STRUC'L ENRG.)

400 400 400 400 STANDARD HOOKS HOOK A

COLUMNS, PEDESTAL AND BEAMS (3000 PSI) 3.4.2 ALL CELLS SHALL BE SOLIDLY FILLED WITH GROUT. CONCRETE SHALL PROVIDE 12mmØ EXTRA

HAVE A MINIMUM COMPRESSIVE STRENGTH OF 13.80 MPa A TIES @ 100 MM O.C. A

d

d

3.1.2 ALL CONCRETE SHALL BE DEPOSITED, VIBRATED AND CURED IN ACCORDANCE

(2000 PSI) @ 28 DAYS. D

D

J

WITH ACI STANDARD 318-95

400

400

400

400

A

3.4.3 UNLESS INDICATED OTHERWISE, CMU REINFORCEMENT SHALL BE 10MMØ

12 d

3.1.3 MINIMUM CONCRETE COVER FOR REINFORCING BARS SHALL BE AS FOLLOWS: HOR. BARS @ 600 AND 10MMØ VERT. BARS @ 400. 4d

A LINTEL BEAM W/ 2-Ø12mm A

A. FOOTINGS = 75MM (CAST AGAINST EARTH)

3.4.4 ALL WALLS SHALL BE CONSTRUCTED IN CONVENTIONAL RUNNING BOND CONTINUOUS HORIZONTAL

B. BEAMS AND COLUMNS = 40MM (TO STIRUPS AND TIES) C 60mm min.

UNLESS NOTED OTHERWISE. REINFORCEMENTS WINDOW LINTEL END BLOCK

H

C. SLABS AND WALLS = 20MM (CAST AGAINST FORMS) OPENING 90° HOOKS 180° HOOKS

D. BOTTOM SLAB AND WALLS = 50MM (INSIDE SURFACE OF WATER RETAINING STRUCTURE) 3.4.5 GROUT MASONRY IN 2.4M MAXIMUM LIFTS. REINFORCING SHALL BE CHB WALL W/ 2-Ø12mm D=6d for d=8 mm. through d=25 mm. D=6d for d=8 mm. through d=25 mm.

DOOR

H

SECURED AGAINTS DISPLACEMENT PRIOR TO GROUTING BY WIRE OPENING VERTICAL REINF. D=8d for d=28 mm., d=32 mm. & d=36 mm. D=8d for d=28 mm., d=32 mm. & d=36 mm.

3.1.4 BEFORE CONCRETE IS POURED, CHECK WITH ALL TRADES TO ENSURE PROPER POSITIONERS AT INTERVALS NOT EXCEEDING 200 BAR DIAMETERS LINTEL END BLOCK B D=10d for d=42 mm., & d=47 mm. D=10d for d=42 mm., & d=47 mm.

W/ 2-Ø12mm 2-Ø12mm ADDITIONAL D=Finished bend diameters

SILL HEIGHT

PLACEMENT OF ALL OPENINGS, SLEEVES, CURBS, CONDUITS, ETC. RELATIVE TO NOR 3M.

VERTICAL REINF. VERTICAL BARS

THE WORK. 3.4.6 IF WORK IS STOPPED ONE (1) HOUR OR LONGER, PROVIDE HORIZONTAL B

3.1.5 WHEN CONCRETE WILL BE EXPOSED TO EXTERNAL SOURCES OF CHLORIDES IN FLR. LEV. FLR. LEV. 6d

(75

HOOK A

SERVICES, SUCH AS DEICING SALTS, BRACKISH WATER, SEAWATER OR SPRAY FROM 4.0 CONSTRUCTION JOINTS:

mm

135° HOOKS

DOOR OPENING ELEVATION WINDOW OPENING ELEVATION

mi

THESE SOURCES, CONCRETE MUST BE PROPORTIONED TO SATISFY THE SPECIAL 4.1 CONTRUCTION JOINTS NOT INDICATED ON PLANS SHALL BE MADE SO AS D=6d for d=8 mm. through d=25 mm.

n.)

EXPOSURE REQUIREMENTS OF ACI 318-95. TO LEAST IMPAIR THE STRENGTH OF THE STRUCTURE AND SHALL BE SUBJECT NOTE: OMIT EXTRA REINF. FOR OPENING LESS D=8d for d=28 mm., d=32 mm. & d=36 mm.

THAN 200MM VERT & 400MM HOR. D=10d for d=42 mm., & d=47 mm.

3.1.6 ALL CONCRETE SHALL BE KEPT MOIST FOR A MINIMUM OF 7 CONSECUTIVE DAYS TO APPROVAL OF THE ENGINEER.

H

IMMEDIATELY AFTER POURING BY THE USE OF WET BURLAP. 4.2 UNLESS SHOWN OTHERWISE, SLAB ON GRADE SHALL HAVE CONTROL JOINTS

@ 6.00M MAXIMUM CENTER TO CENTER.

d

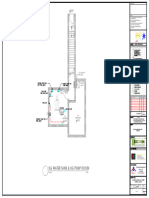

ARCHITECT CONSULTANT PROJECT OWNER SHEET CONTENTS DESIGNED JKMK 08-29-2023 SHEET NO.

DRAWN JKMK 08-29-2023

KABS BUILDING DESIGN SERVICE PROPOSED OFFICE WAREHOUSE

ARCHITECTS | INTERIOR DESIGN | ENGINEERS | DESIGN BUILD JOHN KRISTIAN KABILING MR. JOEL FERNANDO CHECKED JKMK 08-29-2023

ARCHITECT-OF-RECORD

WITH MEZZANINE (REPUBLIC ACT. 9266) DRAWINGS AND SPECIFICATIONS DULY SIGNED, STAMPED OR SEALED, AS INSTRUMENTS OF SERVICE,

30 LUCKY ST. SANTOLAN PASIG CITY, METRO MANILA, PHILIPPINES ARE THE INTELLECTUAL PROPERTIES AND DOCUMENTS OF THE ARCHITECT, WHETHER THE OBJECT FOR WHICH THEY ARE MADE IS EXECUTED

CP. NO.: +63 966 592 5770 | +63 966 235 1149 PRC: 24670 TIN: 264914365000 PRC: TIN: OR NOT. IT SHALL BE UNLAWFUL FOR ANY PERSON, WITHOUT THE CONSENT OF THE ARCHITECT OR AUTHOR OF SAID DOCUMENTS, TO

358 F. ORTIGAS, NEW ZANIGA, MANDALUYONG CITY, PHILIPPINES APPROVING OWNER DUPLICATE OR TO MAKE COPIES OF SAID DOCUMENTS FOR USE IN THE REPETITION OF AND FOR OTHER PROJECTS OR BUILDINGS, WHETHER

PTR: 0698729 DATE: 01-07-21 Q.C. PTR: DATE: EXECUTED PARTLY OR IN WHOLE.

You might also like

- General Construction NotesDocument1 pageGeneral Construction NotesCarlo M. FloresNo ratings yet

- General Notes:: Fillet Weld TableDocument1 pageGeneral Notes:: Fillet Weld Tablejohnkarl.bentingNo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- General Construction Notes: Typical Connection Detail of Masonry WallDocument1 pageGeneral Construction Notes: Typical Connection Detail of Masonry WallMItchNo ratings yet

- General Construction Notes: Bureau of DesignDocument1 pageGeneral Construction Notes: Bureau of DesignGarry WaveNo ratings yet

- General Construction Notes: Bureau of DesignDocument15 pagesGeneral Construction Notes: Bureau of DesignRicoyan YanNo ratings yet

- General NotesDocument1 pageGeneral NotesJohn Paul IldefonsoNo ratings yet

- F2 - Liquid ReceiverDocument1 pageF2 - Liquid ReceiverStan LeyNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NoteschrisNo ratings yet

- Structural 2storeyDocument11 pagesStructural 2storeyMark James Mateo100% (1)

- StructuralDocument15 pagesStructuralMark James MateoNo ratings yet

- Plan 20ld0130 - Part 3Document11 pagesPlan 20ld0130 - Part 3MarjanNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesLon OdiNo ratings yet

- Proposed Office Building: Thahz Buhisan Dapogracion Rufo Aga-On AyagDocument1 pageProposed Office Building: Thahz Buhisan Dapogracion Rufo Aga-On AyagJhon SabinoNo ratings yet

- Rfa Mep M 129Document2 pagesRfa Mep M 129kinidudissaNo ratings yet

- General Notes: Concrete Notes: Abbreviations: Reinforcement Clearance DetailDocument53 pagesGeneral Notes: Concrete Notes: Abbreviations: Reinforcement Clearance DetailbetojulioNo ratings yet

- 23kk0043 Set BDocument30 pages23kk0043 Set BcemirasmpcNo ratings yet

- Anchor BoltDocument2 pagesAnchor BoltWidya Prasetya100% (1)

- Roof Trellis Framing: Existing StructureDocument1 pageRoof Trellis Framing: Existing Structurejohnkarl.bentingNo ratings yet

- QAHD Office Building 30 M Structural Plans-S100.0Document1 pageQAHD Office Building 30 M Structural Plans-S100.0Adrian PachecoNo ratings yet

- Cottage WorkingDocument1 pageCottage WorkingSAL ARCHITECTURENo ratings yet

- Revised Structural PlansDocument46 pagesRevised Structural Plansangelandlucifergabriel009No ratings yet

- Meter - Stand - For - NRW - Monitoring Type BDocument1 pageMeter - Stand - For - NRW - Monitoring Type BMysarra HoneyNo ratings yet

- Structural Notes and Specifications for ConcreteDocument1 pageStructural Notes and Specifications for Concreteroger100% (2)

- U Wall 2 (25-01-2022) - Sheet1Document1 pageU Wall 2 (25-01-2022) - Sheet1Suneel BalaniNo ratings yet

- 1 Mps Building Dingras StructuralDocument6 pages1 Mps Building Dingras StructuralMekaela DiataNo ratings yet

- Overhead service entrance 230V 1Ø 2W 60Hz with weatherheadDocument1 pageOverhead service entrance 230V 1Ø 2W 60Hz with weatherheadrafael nazaretaNo ratings yet

- Plot - 1 - TERRACE ROOF BEAM LAYOUTDocument1 pagePlot - 1 - TERRACE ROOF BEAM LAYOUTMõhâmméd WassimNo ratings yet

- Wa0000.Document4 pagesWa0000.سلطان السواعيرNo ratings yet

- Genral NotesDocument1 pageGenral NotesArjay AletaNo ratings yet

- Standard Drawing 4071 Guard Fence Layouts For Bridge Approaches July 2020Document1 pageStandard Drawing 4071 Guard Fence Layouts For Bridge Approaches July 2020soumya1986No ratings yet

- Design: Construction NotesDocument1 pageDesign: Construction NotesLhea May Paz SarguetNo ratings yet

- Column Schedule Part-2Document1 pageColumn Schedule Part-2Sumit LathwalNo ratings yet

- Electrical Symbol Notes: Revised 15 DECEMBER 2015Document43 pagesElectrical Symbol Notes: Revised 15 DECEMBER 2015dawitgggNo ratings yet

- E:/1. Hai Phat/Nh19/1. Detail Design/99. Xuat Ho So/General Notes/General Notes - DWG - Date: Thu, 22 Oct 2020 - 1:58Pm Pc:LamntDocument2 pagesE:/1. Hai Phat/Nh19/1. Detail Design/99. Xuat Ho So/General Notes/General Notes - DWG - Date: Thu, 22 Oct 2020 - 1:58Pm Pc:LamntHoang Nguyen HuyNo ratings yet

- Abbreviations and Reinforcement Notes for Bridge DrawingDocument1 pageAbbreviations and Reinforcement Notes for Bridge DrawingphanikrishnabNo ratings yet

- Alta Prima Conv S-1Document1 pageAlta Prima Conv S-1Ronnel John CruzNo ratings yet

- Construction Notes: ElevationDocument1 pageConstruction Notes: ElevationJohn PaderangaNo ratings yet

- Typical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsDocument1 pageTypical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsRenel GarciaNo ratings yet

- Main Fire Station-1Document1 pageMain Fire Station-1Jhon CenaNo ratings yet

- General Notes Foundations: Two - Storey Residential Building With Roof DeckDocument1 pageGeneral Notes Foundations: Two - Storey Residential Building With Roof DeckKarlo CabanginNo ratings yet

- Prabh Design Architects & Associates: General Notes & SpecificationsDocument1 pagePrabh Design Architects & Associates: General Notes & SpecificationsKanhaiya PanwarNo ratings yet

- 32 Oakleigh Way - Drainage - Assessment-X9Document1 page32 Oakleigh Way - Drainage - Assessment-X9Juan Carlos Gaxiola ReinholdNo ratings yet

- SD-208 - Rev 2Document1 pageSD-208 - Rev 2sathishNo ratings yet

- General Notes:: LegendsDocument1 pageGeneral Notes:: LegendsajindesignjoshualopezNo ratings yet

- Rigid Pavement Details - 13.01.2022Document5 pagesRigid Pavement Details - 13.01.2022Sambit NayakNo ratings yet

- HVAC Symbols and Abbreviations Schedule for Steam Humidifier and Condensing UnitsDocument20 pagesHVAC Symbols and Abbreviations Schedule for Steam Humidifier and Condensing Unitsnfaa1986No ratings yet

- Otak International: Al Jurf Qasr Al Jurf 11Document1 pageOtak International: Al Jurf Qasr Al Jurf 11naveenNo ratings yet

- Crash Barrier With Friction SlabDocument1 pageCrash Barrier With Friction SlabSachin Dalal100% (1)

- Structurals 2Document1 pageStructurals 2seulipark2629No ratings yet

- Ns2-Vk02-P0ucb-171652 - CHS Electrical & Control Building - Beam & Girder Re-Bar Schedule - Fi-2Document3 pagesNs2-Vk02-P0ucb-171652 - CHS Electrical & Control Building - Beam & Girder Re-Bar Schedule - Fi-2Doan Ngoc DucNo ratings yet

- S029-STANDARD DETAILS-BLOCKWORKDocument1 pageS029-STANDARD DETAILS-BLOCKWORKWNo ratings yet

- Plinth Slab LVL (Rev.4) 10-08-2017 Sh.2Document1 pagePlinth Slab LVL (Rev.4) 10-08-2017 Sh.2Monali VarpeNo ratings yet

- Collector DrawingsDocument2 pagesCollector DrawingsMohammad ShayanNo ratings yet

- Electrical Power LayoutDocument5 pagesElectrical Power LayoutSaahil KhaanNo ratings yet

- QAHD Office Building 30 M Structural Plans-S102.0Document1 pageQAHD Office Building 30 M Structural Plans-S102.0Adrian PachecoNo ratings yet

- Setting up air conditioning ductsDocument1 pageSetting up air conditioning ductsNasrul FahmiNo ratings yet

- A Proposed Two Storey Residential Building Mr. Bonnie James Arcenal Justine D. BotillaDocument1 pageA Proposed Two Storey Residential Building Mr. Bonnie James Arcenal Justine D. BotillaNikki Marie A. CabahugNo ratings yet

- Suspended Track BarDocument1 pageSuspended Track Barfrancis sebastian lagamayoNo ratings yet

- Form - Transmittal SlipDocument1 pageForm - Transmittal Slipfrancis sebastian lagamayoNo ratings yet

- Materials Specification and General Notes Proposed 2 Storey Residence With BasementDocument8 pagesMaterials Specification and General Notes Proposed 2 Storey Residence With Basementfrancis sebastian lagamayoNo ratings yet

- Staad OutputDocument24 pagesStaad Outputfrancis sebastian lagamayoNo ratings yet

- Fence Foundation Plan Plan: Schedule of FootingsDocument1 pageFence Foundation Plan Plan: Schedule of Footingsfrancis sebastian lagamayoNo ratings yet

- Reinforced Concrete Beam: Location of D' & DTDocument14 pagesReinforced Concrete Beam: Location of D' & DTfrancis sebastian lagamayoNo ratings yet

- Construction Notes and Standard Details: Allyssa L. HiwatigDocument1 pageConstruction Notes and Standard Details: Allyssa L. Hiwatigfrancis sebastian lagamayoNo ratings yet

- Suspended Track BarDocument1 pageSuspended Track Barfrancis sebastian lagamayoNo ratings yet

- Reinforced Concrete Beam: Location of D' & DTDocument14 pagesReinforced Concrete Beam: Location of D' & DTfrancis sebastian lagamayoNo ratings yet

- Reinforced Concrete Beam: 3-16mmø 2-16mmøDocument14 pagesReinforced Concrete Beam: 3-16mmø 2-16mmøfrancis sebastian lagamayoNo ratings yet

- Reinforced Concrete Beam: Location of D' & DTDocument14 pagesReinforced Concrete Beam: Location of D' & DTfrancis sebastian lagamayoNo ratings yet

- Foundation Plan 1 Mezzanine Floor Framing Plan 2: Kabs Building Design ServiceDocument1 pageFoundation Plan 1 Mezzanine Floor Framing Plan 2: Kabs Building Design Servicefrancis sebastian lagamayoNo ratings yet

- PC 1Document9 pagesPC 1francis sebastian lagamayoNo ratings yet

- Materials Specification and General Notes Proposed 2 Storey Residence With BasementDocument8 pagesMaterials Specification and General Notes Proposed 2 Storey Residence With Basementfrancis sebastian lagamayoNo ratings yet

- Reinforced Concrete Column: Defining ConditionDocument9 pagesReinforced Concrete Column: Defining Conditionfrancis sebastian lagamayoNo ratings yet

- Reinforced Concrete Beam: Location of D' & DTDocument14 pagesReinforced Concrete Beam: Location of D' & DTfrancis sebastian lagamayoNo ratings yet

- Design Paramters: KN Mpa Mpa MM Kpa MM MM MM MM MM MMDocument4 pagesDesign Paramters: KN Mpa Mpa MM Kpa MM MM MM MM MM MMfrancis sebastian lagamayoNo ratings yet

- Reinforced Concrete Beam: Location of D' & DTDocument14 pagesReinforced Concrete Beam: Location of D' & DTfrancis sebastian lagamayoNo ratings yet

- Proposed 3-Storey Residence With Lower GroundDocument93 pagesProposed 3-Storey Residence With Lower Groundfrancis sebastian lagamayoNo ratings yet

- Reinforced Concrete Beam: Location of D' & DTDocument14 pagesReinforced Concrete Beam: Location of D' & DTfrancis sebastian lagamayoNo ratings yet

- Accessibility design for building entranceDocument1 pageAccessibility design for building entrancefrancis sebastian lagamayoNo ratings yet

- 09 19 2022 - Joey Cakderon 2 Storey Residential - PROJECT COST PROPOSALDocument5 pages09 19 2022 - Joey Cakderon 2 Storey Residential - PROJECT COST PROPOSALfrancis sebastian lagamayoNo ratings yet

- Design Paramters: KN Mpa Mpa MM Kpa MM MM MM MM MM MMDocument4 pagesDesign Paramters: KN Mpa Mpa MM Kpa MM MM MM MM MM MMfrancis sebastian lagamayoNo ratings yet

- Reinforced Concrete Beam: Location of D' & DTDocument14 pagesReinforced Concrete Beam: Location of D' & DTfrancis sebastian lagamayoNo ratings yet

- Structural AnalysisDocument17 pagesStructural Analysisfrancis sebastian lagamayo100% (1)

- Electrical panel circuit diagramDocument1 pageElectrical panel circuit diagramfrancis sebastian lagamayoNo ratings yet

- Plant Box Design DiagramDocument1 pagePlant Box Design Diagramfrancis sebastian lagamayoNo ratings yet

- E1 Short BondpaperDocument1 pageE1 Short Bondpaperfrancis sebastian lagamayoNo ratings yet

- Rebar Shape Codes: Slab Rebars: Column Strip Slab Rebars: Middle StripDocument1 pageRebar Shape Codes: Slab Rebars: Column Strip Slab Rebars: Middle Stripfrancis sebastian lagamayoNo ratings yet

- Schedule of Beams: Two-Way Slab DetailDocument1 pageSchedule of Beams: Two-Way Slab Detailfrancis sebastian lagamayoNo ratings yet

- 2016 CMCDocument536 pages2016 CMCStefan WeissNo ratings yet

- Espedosa Module3.5 AssignmentDocument2 pagesEspedosa Module3.5 AssignmentKhemgee EspedosaNo ratings yet

- Learning in Artificial IntelligenceDocument6 pagesLearning in Artificial IntelligenceAnikNo ratings yet

- 1-) 32 M Reactor Unit: Mr. Şahin Kaplan Polyester Polyol FacilityDocument14 pages1-) 32 M Reactor Unit: Mr. Şahin Kaplan Polyester Polyol FacilitySema TaranacıNo ratings yet

- MANAGEMENT CONTROL SYSTEMS IN NON-PROFITSDocument26 pagesMANAGEMENT CONTROL SYSTEMS IN NON-PROFITSPranita NarainNo ratings yet

- Statement of QualificationsDocument1 pageStatement of Qualificationsrf12345No ratings yet

- Photogrammetry and Remote SensingDocument14 pagesPhotogrammetry and Remote SensingJoseph Dincht83% (6)

- Of For of or Or: The Professional School of Psychology San Francisco, CaliforniaDocument9 pagesOf For of or Or: The Professional School of Psychology San Francisco, CaliforniaSamiMolinaNo ratings yet

- Nomothetic Vs IdiographicDocument9 pagesNomothetic Vs IdiographicBhupesh ManoharanNo ratings yet

- Modulus of FunctionsDocument14 pagesModulus of FunctionsVajan SelvaratnamNo ratings yet

- Cleaning Public Areas EfficientlyDocument231 pagesCleaning Public Areas EfficientlyDj-Ram Vicente Vida100% (6)

- Natural Lighting at The Kimbell Museum: Gifford Pierce of IdahoDocument5 pagesNatural Lighting at The Kimbell Museum: Gifford Pierce of IdahoPriscilia ElisabethNo ratings yet

- Measuring and managing intellectual capitalDocument6 pagesMeasuring and managing intellectual capitalAl-Farisi Ibnu EdyNo ratings yet

- Star Ii HoneywellDocument4 pagesStar Ii HoneywellAlejandro MagnoNo ratings yet

- Inside Earth's LayersDocument2 pagesInside Earth's Layersansh parasharNo ratings yet

- Kermann Led: Exproof Easylight Z1Document3 pagesKermann Led: Exproof Easylight Z1Abdulaziz AlrawiNo ratings yet

- Fly 10 Your Super FutureDocument3 pagesFly 10 Your Super FutureRichard Colón67% (3)

- GOLDEN DAWN 3 8 Highlights of The Fourth Knowledge LectureDocument7 pagesGOLDEN DAWN 3 8 Highlights of The Fourth Knowledge LectureF_RCNo ratings yet

- Fluxus F/G722: Non-Intrusive Ultrasonic Flow Meter For Highly Dynamic FlowsDocument2 pagesFluxus F/G722: Non-Intrusive Ultrasonic Flow Meter For Highly Dynamic FlowslossaladosNo ratings yet

- 2010 IMCO CatalogDocument170 pages2010 IMCO Cataloggeav25653855No ratings yet

- StrippingDocument17 pagesStrippingGhavban David0% (1)

- Acer LCD x193hq Sm080904v1 Model Id Ra19waanuDocument36 pagesAcer LCD x193hq Sm080904v1 Model Id Ra19waanuFrancis Gilbey Joson ArnaizNo ratings yet

- Commissioning FPFH SettingDocument6 pagesCommissioning FPFH SettingYulius IrawanNo ratings yet

- 4.3.c-Technology and IndustrializationDocument23 pages4.3.c-Technology and Industrializationjjamppong09No ratings yet

- Installation Manual Multi-Function PROTECTION RELAY GRE110, GRE120, GRE130Document22 pagesInstallation Manual Multi-Function PROTECTION RELAY GRE110, GRE120, GRE130Cecep Marfu100% (2)

- NoNuke Spec SheetDocument1 pageNoNuke Spec SheetEster TerneroNo ratings yet

- DAILY LESSON LOG in Grade 7 ScienceDocument2 pagesDAILY LESSON LOG in Grade 7 Sciencejanice alquizar100% (3)

- Sample Securitiser: Pressure Facility Re-InventedDocument4 pagesSample Securitiser: Pressure Facility Re-InventedMiguelNo ratings yet

- CB Certificate - CodeDocument668 pagesCB Certificate - CodeRosy SeafoodNo ratings yet