Professional Documents

Culture Documents

Track Adjustment - Adjust

Track Adjustment - Adjust

Uploaded by

asri novhandiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Track Adjustment - Adjust

Track Adjustment - Adjust

Uploaded by

asri novhandiCopyright:

Available Formats

SIS 2.0 https://sis2.cat.

com/#/print-preview/service/df17d968-e909-4634-98e5-be5140e7c703

Track Adjustment - Adjust (SEBU9247-10)

SMCS - 4170 i05647259

Personal injury or death can result from grease under pressure.

Grease coming out of the relief valve under pressure can

penetrate the body causing injury or death.

Do not watch the relief valve to see if grease is escaping. Watch

the track or track adjustment cylinder to see if the track is being

loosened.

Loosen the relief valve one turn only.

If track does not loosen, close the relief valve and contact your

Caterpillar dealer.

NOTICE

Keeping the track properly adjusted will increase the service life

of the track and drive components.

Note: The track tension must be adjusted according to the current operating conditions. Keep the track as slack as possible if the

soil is heavy.

1 dari 7 17/02/24 11.15

SIS 2.0 https://sis2.cat.com/#/print-preview/service/df17d968-e909-4634-98e5-be5140e7c703

Measuring Track Tension

1. Operate the machine in the direction of the idlers.

Illustration 1 g01103855

2. Stop with one track pin directly over the front carrier roller. Park the machine and turn off the engine.

2 dari 7 17/02/24 11.15

SIS 2.0 https://sis2.cat.com/#/print-preview/service/df17d968-e909-4634-98e5-be5140e7c703

Illustration 2 g03472827

3. Place a straight edge on top of the track grousers between the front carrier roller and the idler. The straight edge should be

long enough to reach from the front carrier roller to the idler.

Note: If your machine is equipped with three carrier rollers, place a straight edge on the tracks between the carrier rollers. The

straight edge should be long enough to reach from one carrier roller to another carrier roller.

4. Measure the maximum amount of sag in the track. The sag is measured from the highest point of the track grouser to the

bottom of the straight edge. A track that is properly adjusted will have a sag of 40.0 to 55.0 mm (1.57 to 2.17 inch).

5. If the track is too tight, or if the track is too loose, adjust the track tension according to the appropriate procedure below.

Adjusting Track Tension

3 dari 7 17/02/24 11.15

SIS 2.0 https://sis2.cat.com/#/print-preview/service/df17d968-e909-4634-98e5-be5140e7c703

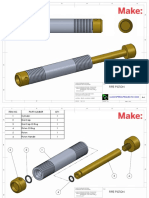

Illustration 3 g00270405

Typical example

The track adjuster is located on the track frame.

Tightening the Track

4 dari 7 17/02/24 11.15

SIS 2.0 https://sis2.cat.com/#/print-preview/service/df17d968-e909-4634-98e5-be5140e7c703

Illustration 4 g01091134

(1) Grease fitting

(2) Relief valve

Wipe the fitting before you add grease.

1. Add grease through grease fitting (1) until the correct track tension is reached.

2. Operate the machine back and forth in order to equalize the pressure.

3. Check the amount of sag. Adjust the track, as needed.

Loosening the Track

5 dari 7 17/02/24 11.15

SIS 2.0 https://sis2.cat.com/#/print-preview/service/df17d968-e909-4634-98e5-be5140e7c703

Illustration 5 g01091134

(1) Grease fitting

(2) Relief valve

1. Loosen relief valve (2) carefully until the track begins to loosen. One turn should be the maximum.

2. Tighten relief valve (2) to 34 ± 5 N·m (25 ± 4 lb ft) when the desired track tension is reached.

3. Operate the machine back and forth in order to equalize the pressure.

4. Check the amount of sag. Adjust the track, as needed.

6 dari 7 17/02/24 11.15

SIS 2.0 https://sis2.cat.com/#/print-preview/service/df17d968-e909-4634-98e5-be5140e7c703

PSP-00028581

2024/02/17

03:13:57+08:00

i01113097

© 2024 Caterpillar Inc.

7 dari 7 17/02/24 11.15

You might also like

- 3512C HD Fuel Injector AdjustmentDocument5 pages3512C HD Fuel Injector Adjustmentharikrishnanpd3327100% (2)

- 3516B Generator Set Engine - Fuel Injector Adjustment - SIS - CATERPILLARDocument5 pages3516B Generator Set Engine - Fuel Injector Adjustment - SIS - CATERPILLARpevare78% (9)

- Catalog Roxroth PDFDocument115 pagesCatalog Roxroth PDFSidnei SilvaNo ratings yet

- Omm DP50N CT28CDocument48 pagesOmm DP50N CT28Casri novhandi100% (2)

- Olympian Manual Parts - 404D-22G - CompressedDocument937 pagesOlympian Manual Parts - 404D-22G - Compressedasri novhandiNo ratings yet

- Tenzado de CadenaDocument5 pagesTenzado de CadenaCristian ZarricuetaNo ratings yet

- Engine Valve Lash - Inspect AdjustDocument4 pagesEngine Valve Lash - Inspect Adjustbenjir shuvoNo ratings yet

- 777D Service Brake Discs - CheckDocument13 pages777D Service Brake Discs - Checkhddsmsv7f2No ratings yet

- Valve Lash AdjustmentDocument9 pagesValve Lash AdjustmentsxturboNo ratings yet

- 3116 ValvulasDocument5 pages3116 ValvulasChristian Vinueza VillavicencioNo ratings yet

- Brake Wear 777Document7 pagesBrake Wear 777Kusuma JayaNo ratings yet

- Cylinder Head InstallDocument6 pagesCylinder Head Installboosterdaily16No ratings yet

- Camshaft Timing SIS 2.0Document7 pagesCamshaft Timing SIS 2.0isaac989No ratings yet

- Juego de Valvulas C27Document4 pagesJuego de Valvulas C27gerardoNo ratings yet

- KENR8738 - Service Brake Discs - Check - Extended LifeDocument13 pagesKENR8738 - Service Brake Discs - Check - Extended LifeAnderson Oliveira SilvaNo ratings yet

- Bomba de Aceite y Valvula RelifDocument4 pagesBomba de Aceite y Valvula RelifCRIATHIANNo ratings yet

- Adjustment of The Compression BrakeDocument2 pagesAdjustment of The Compression BrakeCarlos Juarez ChungaNo ratings yet

- Valve Lash and Valve Bridge AdjustmentDocument9 pagesValve Lash and Valve Bridge AdjustmentserarturNo ratings yet

- Valve Lash and Valve Bridge AdjustmentDocument9 pagesValve Lash and Valve Bridge AdjustmentRajan MullappillyNo ratings yet

- Top Center Position SIS 2.0Document4 pagesTop Center Position SIS 2.0isaac989No ratings yet

- Motor 3406Document115 pagesMotor 3406LuisJuniorNo ratings yet

- Final Drive, Steering Differential, and Brake (Left Side) - Remove and Install (M0076745-04)Document5 pagesFinal Drive, Steering Differential, and Brake (Left Side) - Remove and Install (M0076745-04)alejandro castañoNo ratings yet

- 735 ADT Parking Release Manual - 022828Document3 pages735 ADT Parking Release Manual - 022828Sohail AnaanNo ratings yet

- Engine Valve Lash - Inspect/Adjust: Shutdown SIS Previous ScreenDocument4 pagesEngine Valve Lash - Inspect/Adjust: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- Hartl Powercrusher PC1 Impact Crusher Service ManualDocument22 pagesHartl Powercrusher PC1 Impact Crusher Service ManualMax Perminov100% (1)

- Air Inlet ONstall Cat 3516Document4 pagesAir Inlet ONstall Cat 3516esa masivNo ratings yet

- Engine Valve LashDocument3 pagesEngine Valve LashYeremiaNo ratings yet

- Adjust Valve Lash PDFDocument7 pagesAdjust Valve Lash PDFX'mix ĐreamerNo ratings yet

- 3512 Techdoc - Print - PageDocument4 pages3512 Techdoc - Print - Pagefromgod83100% (1)

- Engine Valve LashDocument3 pagesEngine Valve LashImron Alif100% (3)

- REHS8790Document10 pagesREHS8790Daniel DonosoNo ratings yet

- Service Brake System Pressure - TestDocument3 pagesService Brake System Pressure - TestEver SaavedraNo ratings yet

- Xad41 U508735 Inst GB Rev2Document12 pagesXad41 U508735 Inst GB Rev2hesam asgariNo ratings yet

- 3412C Fuel System Pruebas y AjustesDocument13 pages3412C Fuel System Pruebas y AjustesJuan Carlos Inga VasquezNo ratings yet

- Valve Lash 1Document4 pagesValve Lash 1Daniel TekleNo ratings yet

- 3516 BlekDocument9 pages3516 BlekAna María AcostaNo ratings yet

- 3116 Cat Valvuklas Calibre PDFDocument4 pages3116 Cat Valvuklas Calibre PDFsergio blandon l100% (1)

- PDF Valve Adjustment PDF - CompressDocument9 pagesPDF Valve Adjustment PDF - Compressjavier gelvezNo ratings yet

- Pruebas y Ajustes C27 and C32 GeneratorDocument5 pagesPruebas y Ajustes C27 and C32 GeneratorMuhammad Ary safarta100% (1)

- Avance AutomaticoDocument3 pagesAvance AutomaticoCRIATHIANNo ratings yet

- MD6420 Test 4Document5 pagesMD6420 Test 4Miguel Angel Garrido CardenasNo ratings yet

- Adjust Valve Lash 777EDocument3 pagesAdjust Valve Lash 777EAgung WicaksonoNo ratings yet

- CAT C27 - C32 Ajuste La Luz de ValvulasDocument5 pagesCAT C27 - C32 Ajuste La Luz de ValvulasGdar KbzaNo ratings yet

- D10T Valve LAsh AdjustDocument3 pagesD10T Valve LAsh AdjustSyahdiNo ratings yet

- Engine Valve Lash - Inspect/Adjust: Shutdown SIS Previous ScreenDocument4 pagesEngine Valve Lash - Inspect/Adjust: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- Valve Lash G3408 2Document2 pagesValve Lash G3408 2Djebali MouradNo ratings yet

- Testing and AdjustingDocument10 pagesTesting and Adjustingale gamingNo ratings yet

- Fuel Injector AdjustmentDocument5 pagesFuel Injector AdjustmentserarturNo ratings yet

- Exhaust Bypass Valve: SpecificationsDocument3 pagesExhaust Bypass Valve: SpecificationsNimNo ratings yet

- SENR3130 - Torque General InformationDocument5 pagesSENR3130 - Torque General InformationAdolfo MarínNo ratings yet

- Aftercooler - Remove and Install - High Altitude Arrangement (SENR1126-36)Document9 pagesAftercooler - Remove and Install - High Altitude Arrangement (SENR1126-36)redminote12pro.5garNo ratings yet

- Engine Valve Lash - Inspect/Adjust: Shutdown SIS Previous ScreenDocument5 pagesEngine Valve Lash - Inspect/Adjust: Shutdown SIS Previous ScreenaliNo ratings yet

- Valve 950h PDFDocument5 pagesValve 950h PDFabdelrhmangbr86No ratings yet

- Valve Lash AdjusmentDocument9 pagesValve Lash AdjusmentmahmudiNo ratings yet

- Adjust Supensi 740Document9 pagesAdjust Supensi 740SyahdiNo ratings yet

- Fuel Transfer Pump - Assemble (SENR1126-36)Document5 pagesFuel Transfer Pump - Assemble (SENR1126-36)redminote12pro.5garNo ratings yet

- C4 4 CalibracionDocument5 pagesC4 4 CalibracionJaya Abadi100% (1)

- Bomba de AceiteDocument2 pagesBomba de AceiteCRIATHIANNo ratings yet

- Engine Valve Lash Testing and AdjustingDocument5 pagesEngine Valve Lash Testing and Adjustingsteven manuputty100% (6)

- MD6420 Test 3Document4 pagesMD6420 Test 3Miguel Angel Garrido CardenasNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- 99710-36130-12 - Service DataDocument11 pages99710-36130-12 - Service Dataasri novhandiNo ratings yet

- Omm 3512Document3 pagesOmm 3512asri novhandiNo ratings yet

- 1M210 11 - MaintenanceDocument43 pages1M210 11 - Maintenanceasri novhandiNo ratings yet

- Unbrako Catalog FastenerDocument26 pagesUnbrako Catalog Fastenerdesign_rajeev100% (2)

- APV Membrane Valve Delta M4 Operating Manual PDFDocument45 pagesAPV Membrane Valve Delta M4 Operating Manual PDFEmerson IpialesNo ratings yet

- Donghwa Tanabe H SeriesDocument95 pagesDonghwa Tanabe H Seriesjohn smith0% (1)

- FST and Ffs Gear CouplingDocument4 pagesFST and Ffs Gear Couplingadamnassir91No ratings yet

- Wassets - Downloads - Documents - Catalog - 07900 01073 A15.141 Accessories Manual XTN20 EN PDFDocument8 pagesWassets - Downloads - Documents - Catalog - 07900 01073 A15.141 Accessories Manual XTN20 EN PDFЯрослав СметанякNo ratings yet

- Belt Driven Ender 3: Bill of Materials (BOM)Document13 pagesBelt Driven Ender 3: Bill of Materials (BOM)Matthias RumpNo ratings yet

- Company Name MobileDocument1,690 pagesCompany Name MobilePALLAVI SHARMANo ratings yet

- Toughcarrier TCH10: Super High Load Capacity Single-Axis ActuatorDocument2 pagesToughcarrier TCH10: Super High Load Capacity Single-Axis ActuatornvkjayanthNo ratings yet

- Design and Fabrication of Horizontal and Vertical Tiles CleanerDocument8 pagesDesign and Fabrication of Horizontal and Vertical Tiles CleanerDANIEL DASNo ratings yet

- LimitDocument5 pagesLimitAllan Pradipta AndriantoNo ratings yet

- Bailey Bridge (Presentation) 31-10-11Document69 pagesBailey Bridge (Presentation) 31-10-11Zin Ko Linn100% (1)

- Automobile Engineering Experiment 8: ComponentsDocument5 pagesAutomobile Engineering Experiment 8: Componentssai ChaitanyaNo ratings yet

- Voron: 2.4 Assembly ManualDocument131 pagesVoron: 2.4 Assembly ManualNicolas DiasNo ratings yet

- LSDSS - TM & CM MCQSDocument26 pagesLSDSS - TM & CM MCQSravi maske100% (1)

- Features: Micropac® MC Compact Single Speed Hand PumpDocument3 pagesFeatures: Micropac® MC Compact Single Speed Hand PumpShankar BhardwajNo ratings yet

- Catalogue Saer Series NCBZDocument32 pagesCatalogue Saer Series NCBZBùi Xuân TạoNo ratings yet

- Fire Piston: Brass, Aluminum, Rubber 136.15 GDocument8 pagesFire Piston: Brass, Aluminum, Rubber 136.15 GannuunakiNo ratings yet

- Bom Cai910172Document19 pagesBom Cai910172Yuvraj BappiNo ratings yet

- Tables For Tap Dimensions: Table 302 - Standard Tap Dimensions - Ground Thread (Ref. Uscti Table 302)Document2 pagesTables For Tap Dimensions: Table 302 - Standard Tap Dimensions - Ground Thread (Ref. Uscti Table 302)kfctcoNo ratings yet

- An Overview of Geosynthetics KoernerDocument11 pagesAn Overview of Geosynthetics KoernerlollazzoNo ratings yet

- Presentation 1Document8 pagesPresentation 1JACKMAAAANo ratings yet

- Parts Catalog: StackerDocument46 pagesParts Catalog: StackerАлександр ОбозовNo ratings yet

- BS 3410-1961 PDFDocument20 pagesBS 3410-1961 PDF2601220150379No ratings yet

- Liftech-Le BeonDocument5 pagesLiftech-Le BeoncoutoNo ratings yet

- Brochure India Where To Buy For Copeland Brands en SG 7109610Document3 pagesBrochure India Where To Buy For Copeland Brands en SG 7109610bramhanand vermaNo ratings yet

- Clevis & Eye Turnbuckles: Product DescriptionDocument1 pageClevis & Eye Turnbuckles: Product DescriptionilyastohirNo ratings yet

- Values of C For Simply Supported Beams W-Shapes: Table 3-1 Table 3-2Document31 pagesValues of C For Simply Supported Beams W-Shapes: Table 3-1 Table 3-2MarkNo ratings yet

- DLH Packer: DescriptionDocument6 pagesDLH Packer: DescriptionDEATH ASSASSIN GAMERNo ratings yet

- Piping Drawings Basics: N.P.TodkarDocument37 pagesPiping Drawings Basics: N.P.Todkaredgar_glezav100% (2)