Professional Documents

Culture Documents

Instructions: SCA/CHV 50-125

Uploaded by

PRASANNAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instructions: SCA/CHV 50-125

Uploaded by

PRASANNACopyright:

Available Formats

Instructions

SCA/CHV 50-125

Installation

148R9512

148R9512

SCA CHV

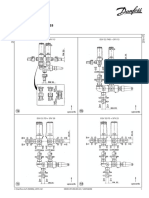

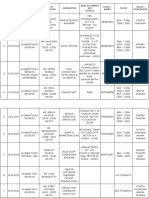

Fig. 1

Nm LB-feet

DN 50 44 32

DN 65 75 53

DN 80 44 32

DN 100 75 53

DN 125 183 135

Fig. 2 Fig. 3

RI7EB102 © Danfoss A/S (RC-CMS), 03-2005 1

Maintenance

Fig. 4 Fig. 5

Nm LB-feet

DN 50-65-80-100 60 45

DN 125 80 60

Fig. 6 Fig. 7

Fig. 8a Fig. 8b

2 RI7EB102 © Danfoss A/S (RC-CMS), 03-2005

ENGLISH Check that the cone has been fully screwed Assembly (fig. 8a)

back towards the bonnet before it is Remove dirt, if any, from pipes and housing

replaced in the valve body (fig. 3). before assembly. Important for the SCA

Installation valves: Full capacity is only obtained when

Important for the SCA valves: the spindle is screwed outward, “into the

Refrigerants Full capacity is only obtained when the bonnet”, i.e. counterclockwise (fig. 3).

Applicable to all common non-flammable spindle is screwed outward, “into bonnet”,

refrigerants, including R717 and non- i.e. counterclockwise (fig. 3). Rotate the V-port cylinder until placed as

corrosive gases/liquids dependent on shown in fig. 8b. The kv value is optimal in

sealing material compatability. Tightening this position.

Flammable hydrocarbons are not Tighten the bonnet with a torque wrench,

recommended. The valve is only to the values indicated in the table (fig. 3). Use a torque wrench to tighten the bonnet

recommended for use in closed circuits. For (fig. 3).

further information please contact Danfoss. Tightening of the bonnet should be

performed according to sound mechanical Tightening

Temperature range practice. Tighten the bonnet with a torque wrench,

SCA: –60/+150ºC (–76/+302ºF) to the values indicated in the table (fig. 3).

CHV: –60/+150ºC (–76/+302ºF) Colours and identification Tighten the packing gland with a torque

The SCA and CHV valves are painted with wrench, to the values indicated in the table

Pressure range a yellow primer in the factory. Precise (fig. 7).

The valves are designed for a max. working identification of the valve is made via the

pressure of 40 bar g (580 psi g). ID ring at the top of the bonnet, as well Tightening of the bonnet should be

as by the stamping on the valve body. performed according to sound mechanical

Installation The external surface of the valve housing practice.

The valve must be installed with the must be prevented against corrosion

spindle on top vertically upwards position with a suitable protective coating after Use only original Danfoss parts, including

(fig. 1). Stop check valves should be installation and assembly. packing glands, O-rings and gaskets for

opened by hand without the use of tools replacement. Materials of new parts are

or other devices. The valve is designed Protection of the name plate when certified for the relevant refrigerant.

to withstand a high internal pressure. repainting the valve is recommended.

However, the piping system should be In cases of doubt, please contact Danfoss.

designed to avoid liquid traps and reduce Danfoss accepts no responsibility for

the risk of hydraulic pressure caused by Maintenance errors and omissions. Danfoss Industrial

thermal expansion. It must be ensured Refrigeration reserves the right to make

that the valve is protected from pressure Packing gland (only SCA) changes to products and specifications

transients like “liquid hammer” in the When performing service and without prior notice.

system. maintenance, replace the complete

packing gland only, which is available as a

Flow direction spare part. As a general rule, the packing

Direct the flow towards the cone as gland must not be removed if there is

indicated by an arrow on the valve housing internal pressure in the valve. However, if

(fig. 1). the following precautionary measures are

taken, the packing gland can be removed

Welding with the valve still under pressure:

The bonnet should be removed before

welding (fig. 2) to prevent damage to Backseating (fig. 4)

the O-rings in the packing gland and To backseat the valve, turn the spindle

between the valve body and bonnet, as counterclockwise until the valve is fully

well as the teflon gasket in the valve seat. open.

Only materials and welding methods,

compatible with the valve housing Pressure equalization (fig. 5)

material, must be welded to the valve In some cases, pressure forms behind the

housing. The valve should be cleaned packing gland. Hence, a handwheel or a

internally to remove welding debris on large washer should be fastened on top of

completion of welding and before the the spindle while the pressure is equalized.

valve is reassembled. The pressure can be equalized by slowly

screwing out the gland.

Avoid welding debris and dirt in the

threads of the housing and the bonnet. Removal of packing gland (fig. 6)

Handwheel and packing gland can now be

Be careful not to damage the teflon cone removed.

ring.

Dismantling the valve (fig. 8a)

The valve housing must be free from Do not remove the bonnet while the valve

stresses (external loads) after installation. is still under pressure.

Check and stop/check valves must not

be mounted in systems where the outlet - Check that the spring (pos. A) is

side of the valve is open to atmosphere. intact.

The outlet side of the valve must always - Check that the O-ring (pos. B) has not

be connected to the system or properly been damaged.

capped off, for example with a welded-on - Check that the spindle (pos. C) is free of

end plate. scratches and impact marks.

- If the teflon cone ring (pos. D) has been

Assembly damaged, the whole cone assembly

Remove welding debris and any dirt from must be replaced.

pipes and valve body before assembly.

RI7EB102 © Danfoss A/S (RC-CMS), 03-2005 3

DECLARATION OF CONFORMITY

The Pressure Equipment Directive 97/23/EC

Name and Address of Manufacturer within the European Community

Danfoss Industrial Refrigeration A/S

Stormosevej 10

PO Box 60

DK-8361 Hasselager

Denmark

Description of Pressure Equipment

Refrigerant Check and Stop/Check valve, with straight or angled arrangement

Type CHV, SCA

Nominal bore DN 50-125 mm. (2-5 in.)

Fluid Group I (all refrigerants (toxic, nontoxic, flammable and nonflammable)).

Classified for

For further details / restrictions - see Installation Instruction.

Temperature range Standard application PS40 bar (580 psi) at –60°C/+150°C (–76°F/302°F)

maximum allowable PS50 bar (725 psi) at –90°C/+50°C (–130°F/122°F)

working pressure High pressure application

PS40 bar (580 psi) at +50°C/+150°C (+122°F/302°F)

Conformity and Assessment Procedure Followed

Category II III

Module D1 B1 + D

D1: 07 202 0511 Z 0009/1/H-0002 B1: 07 202 0511 Z 0058/1/H-0001

Certificate ID

D: 07 202 0511 Z 0009/1/H-0001

Standard

DN 50-80 mm. (2-3 in.) DN 100-125 mm. (4-5 in.)

applications

Nominal

bore High

pressure DN 50-65 mm. (2-2½ in.) DN 80-125 mm. (3-5 in.)

application

Name and Address of the Notified Body which carried out the Inspection

TÜV-Nord e.V.

Grosse Bahnstrasse 31

22525 Hamburg, Germany (0045)

Name and Address of the Notified Body monitoring the Manufacturer’s Quality Assurance System

TÜV-Nord e.V.

Grosse Bahnstrasse 31

22525 Hamburg, Germany

References of Harmonised Standards used

EN 10028-3 EN 10213-3 EN 10222-4

References of other Technical Standards and Specifications used

DIN 3840

AD-Merkblätter

Authorised Person for the Manufacturer within the European Community

Name: Morten Steen Hansen Title: Production Manager

Signature: Date: 03/07/2002

148B9728 - rev. 0

4 RI7EB102 © Danfoss A/S (RC-CMS), 03-2005

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- KDC InstallationDocument2 pagesKDC InstallationJIANG LUNo ratings yet

- Stop and Check ValvesDocument24 pagesStop and Check ValvesRahul PatilNo ratings yet

- Safety Valves and Double Stop ValvesDocument24 pagesSafety Valves and Double Stop ValvesRahul PatilNo ratings yet

- FlowCon EVS Instruction 04 2012Document8 pagesFlowCon EVS Instruction 04 2012Jeff Anderson CollinsNo ratings yet

- Flowcon ABM InstructionDocument4 pagesFlowcon ABM InstructionJeff Anderson CollinsNo ratings yet

- Válvula Globo Tipo Placa - Spirax SarcoDocument2 pagesVálvula Globo Tipo Placa - Spirax SarcodgarciabNo ratings yet

- Ball Valves and Rotary Actors GuideDocument12 pagesBall Valves and Rotary Actors GuideAdvokat HadziTonicNo ratings yet

- Manual Zetkama Fig.215 - 216Document8 pagesManual Zetkama Fig.215 - 216George_Wabag_2014No ratings yet

- Safety Relief Valves BSV 8: InstructionsDocument2 pagesSafety Relief Valves BSV 8: InstructionsPaweł HejmowskiNo ratings yet

- Model Da8: (Formerly DA8/9) Direct-Acting, Positive Bias Differential Back Pressure RegulatorDocument18 pagesModel Da8: (Formerly DA8/9) Direct-Acting, Positive Bias Differential Back Pressure RegulatorBoubekeur HamegNo ratings yet

- Apv Delta Sv1Document20 pagesApv Delta Sv1VLASTARNo ratings yet

- Iom WKM 310FDocument4 pagesIom WKM 310FNasir NaqviNo ratings yet

- Abovegroundhydrants Dropdownpillar 84-25-27 P7 PDFDocument4 pagesAbovegroundhydrants Dropdownpillar 84-25-27 P7 PDFLimhot SitanggangNo ratings yet

- Swing-Flex Check Valve: Operation, Maintenance and Installation ManualDocument8 pagesSwing-Flex Check Valve: Operation, Maintenance and Installation ManualAhmed ShawkyNo ratings yet

- VDLSE502 - VRB2-3 - Danfoss VentiliDocument8 pagesVDLSE502 - VRB2-3 - Danfoss VentilizigicsasaNo ratings yet

- p177 02 PDFDocument4 pagesp177 02 PDFJuan ZamoraNo ratings yet

- +GF+ Pressure Retaining Valve Type 586Document4 pages+GF+ Pressure Retaining Valve Type 586ROMNANo ratings yet

- Transformer Pressure Relief Valve For Power TransformersDocument4 pagesTransformer Pressure Relief Valve For Power TransformersKizito Emmanuel KyeyuneNo ratings yet

- 3 WayDocument18 pages3 WayLeonardNo ratings yet

- Piht0f402 Icmts Icad600tsDocument2 pagesPiht0f402 Icmts Icad600tsamruta21No ratings yet

- SV5 Safety Valve-Installation Maintenance ManualDocument12 pagesSV5 Safety Valve-Installation Maintenance ManualGOKUL PRASADNo ratings yet

- 12165-70 - 1 Sundry Instr.Document328 pages12165-70 - 1 Sundry Instr.kodrysNo ratings yet

- Betriebsanleitung Schieber CA EnglDocument9 pagesBetriebsanleitung Schieber CA EnglborodichNo ratings yet

- Chillersapikhubdocuments5wpq Iw7UC NV6ZJjGVizgcontentDocument18 pagesChillersapikhubdocuments5wpq Iw7UC NV6ZJjGVizgcontentsyhnhpc7qmNo ratings yet

- KTM Actuator CatalogueDocument12 pagesKTM Actuator CatalogueRahimNo ratings yet

- Sur-Flo Products Control Valve Liquid Turbine Meter RunDocument40 pagesSur-Flo Products Control Valve Liquid Turbine Meter RunCheng HuangNo ratings yet

- 8b Dados TecnicosDocument2 pages8b Dados TecnicosWeyvson SilvaNo ratings yet

- Control Valve Norriseal - Series2200 O&MDocument16 pagesControl Valve Norriseal - Series2200 O&MJairo AlonsoNo ratings yet

- Pre-Setting Manual Balancing Valves CIM 788: Technical InformationDocument7 pagesPre-Setting Manual Balancing Valves CIM 788: Technical InformationblindjaxxNo ratings yet

- I PM380-125 07 05 enDocument8 pagesI PM380-125 07 05 enOmprakash_janaNo ratings yet

- Quick closing oil drain valve guideDocument8 pagesQuick closing oil drain valve guideabdur rafayNo ratings yet

- SV 3 Safety ValveDocument7 pagesSV 3 Safety ValveWanderley FonsecaNo ratings yet

- Pressure Relief Valves Operating Instructions: Supplemental ProtectionDocument2 pagesPressure Relief Valves Operating Instructions: Supplemental ProtectionlorenzoNo ratings yet

- CSA Products For Waste Water: Combination Air ValveDocument9 pagesCSA Products For Waste Water: Combination Air ValvezaidNo ratings yet

- Install, Operate & Maintain Knife Gate ValvesDocument12 pagesInstall, Operate & Maintain Knife Gate ValvesSamet BabaNo ratings yet

- Install and service knife gate valvesDocument14 pagesInstall and service knife gate valvesCarlos SalazarNo ratings yet

- Operational Manualhcr-Fls Valve - 2 116 10K PDFDocument14 pagesOperational Manualhcr-Fls Valve - 2 116 10K PDFParag PadoleNo ratings yet

- CSA XLC 410-ND Automatic Control Valve ManualDocument26 pagesCSA XLC 410-ND Automatic Control Valve ManualnicolasgonzNo ratings yet

- Worcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance InstructionsDocument14 pagesWorcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance Instructionsافضح الكوارثNo ratings yet

- SFVL & DSVL Instructions RI7FE102 PDFDocument2 pagesSFVL & DSVL Instructions RI7FE102 PDFLuciano CaireNo ratings yet

- Sisto-C: 1. InstallationDocument1 pageSisto-C: 1. InstallationEric LarrondoNo ratings yet

- Valvetop D-Series With AS-interface: Installation, Operation & Maintenance ManualDocument16 pagesValvetop D-Series With AS-interface: Installation, Operation & Maintenance ManualAdeel RazaNo ratings yet

- NC No.10 New Niikura Hi-Vent Valve Instruction ManualDocument14 pagesNC No.10 New Niikura Hi-Vent Valve Instruction ManualSreejithNo ratings yet

- Installation and Maintenance Instructions for Naval Gas Ball ValveDocument5 pagesInstallation and Maintenance Instructions for Naval Gas Ball ValveMaria MarcanoNo ratings yet

- Instruction Manual Fisher 9500 Butterfly Control Valve en 127086Document20 pagesInstruction Manual Fisher 9500 Butterfly Control Valve en 127086Jan Richardo GultomNo ratings yet

- Sherwood Valves Cylinder ValvesDocument17 pagesSherwood Valves Cylinder Valvesklr_sean100% (1)

- 3890137e Tech Spec Data Sheets 1556604052Document14 pages3890137e Tech Spec Data Sheets 1556604052Prakash AnnamalaiNo ratings yet

- 52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFDocument7 pages52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFysr3eeNo ratings yet

- Spirax Sarco - Non Return Valve Type DCV3Document4 pagesSpirax Sarco - Non Return Valve Type DCV3jimmiilongNo ratings yet

- Venturi ManualDocument8 pagesVenturi ManualStavros DorisNo ratings yet

- Condensate Drain Valves CDV 32: DescriptionDocument4 pagesCondensate Drain Valves CDV 32: Descriptionconstantin.iacomi3837No ratings yet

- Series 767FR Specification SheetDocument4 pagesSeries 767FR Specification SheetFEBCONo ratings yet

- FA + Solenoid Valve ICF 15/20 EVRAT: Installation GuideDocument8 pagesFA + Solenoid Valve ICF 15/20 EVRAT: Installation GuideramonmartinezcatalaNo ratings yet

- k512 en MainDocument8 pagesk512 en MainSani PoulouNo ratings yet

- CVV N Manual de Instrucciones 1Document16 pagesCVV N Manual de Instrucciones 1LeonardNo ratings yet

- Yukenmodularvalves Yuken CatDocument140 pagesYukenmodularvalves Yuken Catchidambaram kasi100% (1)

- Check Valve Cmovalves Serie R Rev 03 Maintenance enDocument8 pagesCheck Valve Cmovalves Serie R Rev 03 Maintenance enKushen ScottNo ratings yet

- D 101550 X 012Document24 pagesD 101550 X 012Norberto SotoNo ratings yet

- Syllabuses ME 16 17 4YDocument17 pagesSyllabuses ME 16 17 4YPRASANNANo ratings yet

- EIC E 1001 0 DSG 01 Series Direction Control Valve PDFDocument12 pagesEIC E 1001 0 DSG 01 Series Direction Control Valve PDFmaherNo ratings yet

- General Combined Brochure RevisedDocument406 pagesGeneral Combined Brochure Revisedseeralan balakrishnanNo ratings yet

- Navigating the Psychrometric ChartDocument11 pagesNavigating the Psychrometric ChartmohdkamalhaziqNo ratings yet

- Material ComparisonDocument1 pageMaterial ComparisonSetiyo Bayu IndrayanaNo ratings yet

- Nano Fluid 2Document14 pagesNano Fluid 2PRASANNANo ratings yet

- EP19176429NWA1Document18 pagesEP19176429NWA1PRASANNANo ratings yet

- EMTDDocument9 pagesEMTDPRASANNANo ratings yet

- Osweiller 2000Document8 pagesOsweiller 2000PRASANNANo ratings yet

- Osweiller 1992Document8 pagesOsweiller 1992PRASANNANo ratings yet

- Sample Design Calculation - Vessel Supported On Legs (Beam)Document7 pagesSample Design Calculation - Vessel Supported On Legs (Beam)Eni Vino0% (2)

- Osweiller 2006Document8 pagesOsweiller 2006PRASANNANo ratings yet

- Cudok Etal 2021Document42 pagesCudok Etal 2021PRASANNANo ratings yet

- Alfa Laval U BendDocument23 pagesAlfa Laval U BendPRASANNANo ratings yet

- Scheme and Syllabus of BTech 1styr Automation RoboticsDocument37 pagesScheme and Syllabus of BTech 1styr Automation RoboticsPRASANNANo ratings yet

- SSCLiBr PDFDocument6 pagesSSCLiBr PDFLuis GarciaNo ratings yet

- 600TR VAPOR ABSORPTION CHILLER SPECDocument36 pages600TR VAPOR ABSORPTION CHILLER SPECaleemhakNo ratings yet

- ROD BAFFLE HEAT EXCHANGER TITLEDocument15 pagesROD BAFFLE HEAT EXCHANGER TITLEPRASANNANo ratings yet

- SSCLiBr PDFDocument6 pagesSSCLiBr PDFLuis GarciaNo ratings yet

- NH3&H2O Props EnglishDocument53 pagesNH3&H2O Props EnglishPRASANNANo ratings yet

- Analysis of Rectangular Water Tank by STADD ProDocument3 pagesAnalysis of Rectangular Water Tank by STADD ProPRASANNANo ratings yet

- Soluble & Insoluble Fiber Foods List: Fresh & Dried Fruits Serving Soluble Fiber (G) Insoluble Fiber (G) Total Fiber (G)Document2 pagesSoluble & Insoluble Fiber Foods List: Fresh & Dried Fruits Serving Soluble Fiber (G) Insoluble Fiber (G) Total Fiber (G)PRASANNANo ratings yet

- Water-Lithium Bromide Absorption Cooling AnalysisDocument132 pagesWater-Lithium Bromide Absorption Cooling AnalysisPRASANNANo ratings yet

- 600TR VAPOR ABSORPTION CHILLER SPECDocument36 pages600TR VAPOR ABSORPTION CHILLER SPECaleemhakNo ratings yet

- ABSIMDocument74 pagesABSIMchibinano0% (1)

- Java IntroductionDocument88 pagesJava Introductionpotharaju janaki deviNo ratings yet

- V382 - 20 (00205363) - DecryptDocument27 pagesV382 - 20 (00205363) - Decryptleodias.souzaNo ratings yet

- FM Approvals News Release 030117Document2 pagesFM Approvals News Release 030117Thuc PhanNo ratings yet

- Research Paper On Cyber Security & CryptographyDocument2 pagesResearch Paper On Cyber Security & CryptographyInternational Journal of Innovative Science and Research Technology100% (1)

- Flats and Apartments FINALDocument29 pagesFlats and Apartments FINALAditi SharmaNo ratings yet

- Package SsDocument2 pagesPackage SsNagaraj VjNo ratings yet

- Shell Scripting PreparationDocument23 pagesShell Scripting Preparationnjoy986No ratings yet

- Profile: Environmental OfficerDocument17 pagesProfile: Environmental OfficerAndi Tri Fardiyat SardiNo ratings yet

- Processor Design The Language of Bits: Computer Organisation and ArchitectureDocument71 pagesProcessor Design The Language of Bits: Computer Organisation and ArchitecturebinnyjNo ratings yet

- ASTRO 500: 10 Year LED Array WarrantyDocument2 pagesASTRO 500: 10 Year LED Array WarrantyJerome Cardenas TablacNo ratings yet

- Sample Problem Statement Project Hope RFP Geraci BrieDocument2 pagesSample Problem Statement Project Hope RFP Geraci Brieapi-195624308No ratings yet

- Low Pressure Switch Technical SpecsDocument10 pagesLow Pressure Switch Technical Specsdcf67myNo ratings yet

- LESSON PLAN FORMAT GUIDEDocument11 pagesLESSON PLAN FORMAT GUIDERjNo ratings yet

- JD730 Power Sensor JDPM Operating Guide R1.4Document44 pagesJD730 Power Sensor JDPM Operating Guide R1.4mborazNo ratings yet

- Acoplamentos de Lamela de Aço ROBA-DSDocument72 pagesAcoplamentos de Lamela de Aço ROBA-DSFernando KonitzNo ratings yet

- Gulf of Mexico Oil Gusher BPDocument308 pagesGulf of Mexico Oil Gusher BPVincent J. CataldiNo ratings yet

- Installation Instructions: BW Seals Q, QB SeriesDocument8 pagesInstallation Instructions: BW Seals Q, QB Seriesaliihsan3461No ratings yet

- Analyze and Design Sewer and Stormwater Systems with SewerGEMSDocument18 pagesAnalyze and Design Sewer and Stormwater Systems with SewerGEMSBoni ClydeNo ratings yet

- Social WeeblyDocument4 pagesSocial Weeblyapi-401560883No ratings yet

- Marketing Management: Marketing Audit Report: Sony CorporationDocument24 pagesMarketing Management: Marketing Audit Report: Sony CorporationJahanzaib ShahzadNo ratings yet

- Manual of Green Building MaterialsDocument153 pagesManual of Green Building MaterialsKawser HossainNo ratings yet

- Annexure - Aqar - 2019 - 2020Document92 pagesAnnexure - Aqar - 2019 - 2020Nishant KumarNo ratings yet

- 2az-Fe Engine Control System Sfi SystemDocument6 pages2az-Fe Engine Control System Sfi SystemMarcelo DecimaNo ratings yet

- JabongDocument18 pagesJabonghimanshusanga100% (1)

- Design of Sewerage SystemDocument51 pagesDesign of Sewerage SystemZac Francis Daymond91% (11)

- How To Filter Data by Multiple Colors in ExcelDocument3 pagesHow To Filter Data by Multiple Colors in ExceldarkwolfbrNo ratings yet

- High-Power LED Technical Data SheetDocument7 pagesHigh-Power LED Technical Data Sheetdyaza_1No ratings yet

- Machinery Inspection ChecklistDocument4 pagesMachinery Inspection ChecklistCynthia ChuaNo ratings yet

- Shortthree PDFDocument86 pagesShortthree PDFEnugukonda UshasreeNo ratings yet

- Assignment Sequential CircuitsDocument2 pagesAssignment Sequential CircuitsPavan SaiNo ratings yet